Introduction to Production and Manufacturing Systems Gary M. Gaukler 5/29/2016

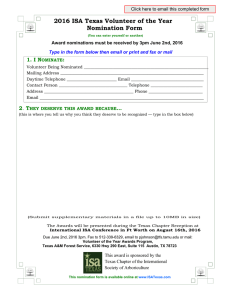

advertisement

Introduction to Production and Manufacturing Systems Gary M. Gaukler 5/29/2016 Texas A&M Industrial Engineering 1 What Is Manufacturing? • Varying definitions of scope – Our focus is on manufacturing systems • Technically complex manufacturing processes • Machining characteristics, assembly instructions... – Necessary to make the product • Technically complex manufacturing system operations and coordination • Facility layout, capacity planning, production control... – Necessary to make money making the product 5/29/2016 Texas A&M Industrial Engineering 2 Why Is Manufacturing Hard? • Customer demands have increased – Traditional: “The customer can have any color as long as it’s black.” - Henry Ford – Modern: Customers expect large product variety, reasonable price, superior quality, comprehensive service, and responsive delivery • Competition has increased – Low labor cost countries like China, Taiwan, Eastern European states 5/29/2016 Texas A&M Industrial Engineering 3 Evolution of Manufacturing • Completely custom - craftsman (pre 1800) • English system (1800s) – Introduction of general purpose machines that could be used for a variety of products. • American system (1850s) – Emphasized precision and interchangeability. Changed from a "best fit" to a "greatest clearance without loss of functionality" focus. • Scientific management (1900s) – Prespecified worker motions - Moved the control totally into the hands of management. 5/29/2016 Texas A&M Industrial Engineering 4 Evolution of Manufacturing • Process improvement (SPC) (1950s) – The identical procedure will produce different results on the same machine at different times. It emphasized outliers rather that mean performance. • Numerical control (1970s) – Combining the versatility of general purpose machines with the precision and control of specialpurpose machines. • Computer integrated manufacturing (1980s) • Logistics/Supply-chain management (1990s) 5/29/2016 Texas A&M Industrial Engineering 5 Eli Whitney Born 1765; died 1825 In 1798, received government contract to make 10,000 muskets Showed that machine tools could make standardized parts to exact specifications Musket parts could be used in any musket Frederick W. Taylor Born 1856; died 1915 Known as ‘father of scientific management’ In 1881, as chief engineer for Midvale Steel, studied how tasks were done Began first motion and time studies Created efficiency principles Taylor’s Principles Management Should Take More Responsibility for: Matching employees to right job Providing the proper training Providing proper work methods and tools Establishing legitimate incentives for work to be accomplished Henry Ford Born 1863; died 1947 In 1903, created Ford Motor Company In 1913, first used moving assembly line to make Model T Unfinished product moved by conveyor past work station Paid workers very well for 1911 ($5/day!)