This document outlines a proposed capability and mission to rendezvous... the Hubble Space Telescope (HST) and thereafter safely and cost... Project Overview - Hubble Telescope Autonomous Rescue Vehicle (HTARV) Introduction

advertisement

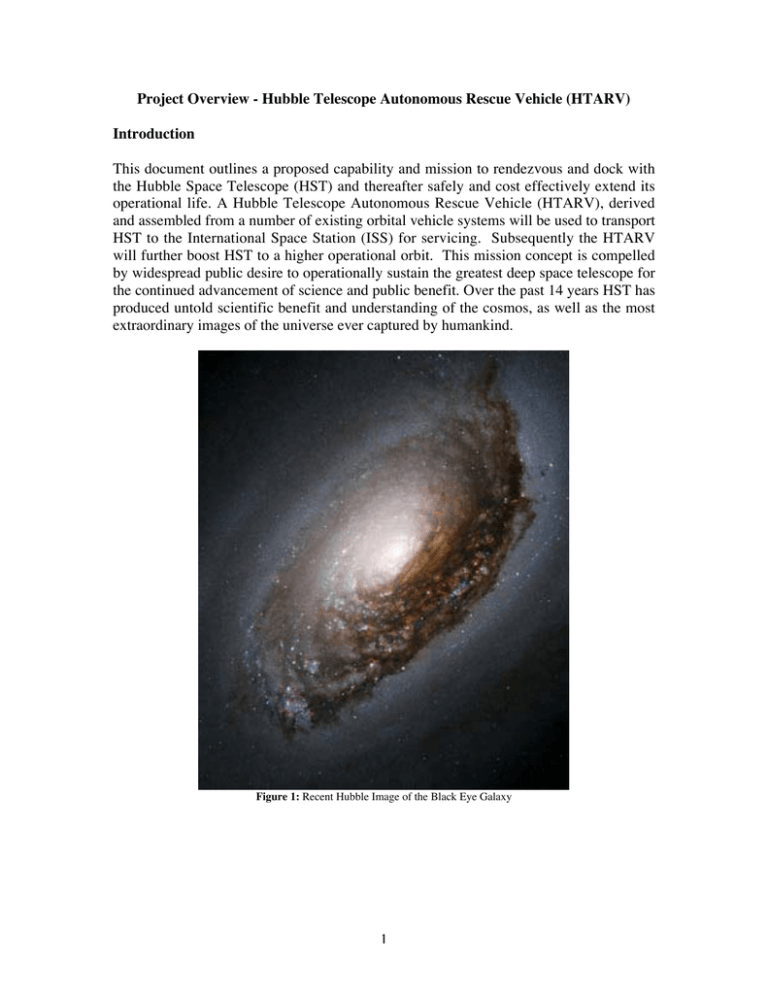

Project Overview - Hubble Telescope Autonomous Rescue Vehicle (HTARV) Introduction This document outlines a proposed capability and mission to rendezvous and dock with the Hubble Space Telescope (HST) and thereafter safely and cost effectively extend its operational life. A Hubble Telescope Autonomous Rescue Vehicle (HTARV), derived and assembled from a number of existing orbital vehicle systems will be used to transport HST to the International Space Station (ISS) for servicing. Subsequently the HTARV will further boost HST to a higher operational orbit. This mission concept is compelled by widespread public desire to operationally sustain the greatest deep space telescope for the continued advancement of science and public benefit. Over the past 14 years HST has produced untold scientific benefit and understanding of the cosmos, as well as the most extraordinary images of the universe ever captured by humankind. Figure 1: Recent Hubble Image of the Black Eye Galaxy 1 HTARV Project & Mission Team The following companies and government activities have formed a team to respond to NASA’s Hubble Space Telescope Rescue RFI. These entities and their prospective roles are: • • • • • • • • • SkyCorp, Incorporated (Huntsville, AL) o Program Team Leader o HTARV System Design o Hall Thruster System Optimization o Flight Computer and Navigation System Orbital Recovery Corporation (Washington, DC) o Commercial licensee for DLR Intellectual Property TRL level 7 for robotics, rendezvous and docking o Commercial link to ESA o Ariane V Contract NASA Langley Space Center (Langley, VA) o Systems Engineering o Space Truss Intellectual Property o On orbit construction expertise NASA Johnson Spaceflight Center (Houston, TX) o Robonauts o EVA Systems NASA Goddard Spaceflight Center (Greenbelt, MD) o Hubble Systems o Hubble Servicing Pratt & Whitney o Hall Thruster Propulsion System HawkEye Systems (Alexandria, VA) o EVA Experience o EVA Planning o On orbit construction architecture planning Alliance Space Systems (Pasadena, CA) o Space Robotics (built the Mars rover robotic arms) o System design, structures, thermal simulation Boeing Satellite Systems (El Segundo, CA) • Boeing 702 Solar arrays 2 SkyCorp will lead a study to: 1. Evaluate and critique the suitability of either an electric propulsive based rescue of HST while detailing contingency plans that move HST to a 100-year orbit. 2. Work with NASA to develop a credible scenario enabling HST refurbishment at or in the proximity of ISS 3. Develop a high fidelity cost and mission timeline leading which captures, refurbishes and releases the HST SkyCorp specifically proposes that NASA funds a six month long intensive design and development effort in cooperation with our other team members as well as partnership with Goddard Space Flight Center Hubble servicing team. This is a serious effort and requires serious commitment from NASA for this to be successful. Our team requests $3M from the agency to fund this effort. This would be a fixed price contract. SkyCorp has the financial wherewithal to fund this effort in a normal contract environment of payment on 30-day increments or less. SkyCorp is a member of the DoD Central Contractor Registry (CCR) database and has all export licenses needed to work with Orbital Recovery Corporation. Any additions can be handled through amendments to existing Technical Assistance Agreements. Request for Information Background As a result of recent budget announcements, NASA has come under significant public pressure and political interest in response to the decision to cease HST support. A senior NASA official recently remarked: “You know we cancelled the Space Shuttle, the Space Station, and Hubble programs- guess which one everyone is up in arms about?” In the past six months, two companies, SkyCorp Incorporated and Orbital Recovery Corporation, have met with NASA officials regarding Hubble. The purpose of these contacts has been to brief the Agency on viable options that may be available to continue Hubble operations, at considerably less expense to the federal budget. The principal reason for cancellation of the SM4 HST mission is due to the recommendation of the Columbia Accident Investigation Board (CAIB) to conduct Space Shuttle missions only when the capability exists to move the Orbiter to ISS “safe” haven, or after an on-orbit Orbiter Thermal Protection System (TPS) repair capability has been proven. This decision opens the door for creative ways to salvage Hubble from de-orbit and certain destruction. This document proposes a solution that does not depend on use of Shuttle Orbiters. When established in the same orbit as ISS, and moved to a position in close proximity to ISS, NASA HST could be readily serviced before subsequent relocation to a higher operating orbit. Proposed to accomplish the HST repositioning maneuvers is a multi-purpose, multi-use HTARV tug. The HTARV will be used to save HST, support ISS logistics, and contribute to the Administration’s new Space Initiative. 3 Overview of Orbital Recovery’s On Orbit Servicing Business Orbital Recovery Corporation (ORC) is actively developing an on-orbit system that is designed for servicing of currently orbiting and planned GEO communications spacecraft. “ConeXpress” Orbital Recovery System (ORS) is a robotic system that is designed for either autonomous or tele-directed operations. Figure 2: ConeXpress Orbital Recovery System (ORS) ORC and its prime contractor, Dutch Space, are completing final design and proceeding into the production of the ConeXpress ORS. The European Space Agency (ESA) is participating in development of the ORS and is providing matching funds under the authority of its Public/Private Partnership program. ORC has recently signed a contract with the DLR (German Space Agency) to license the use of its robotics capabilities and Rendezvous-and-Capture software for use in the ConeXpress ORS. Other advanced rendezvous hardware (cameras and a communication system), to be provided by a Japanese firm, Astro Research Corporation, will be incorporated into the system. DLR, whose robotic experience began in 1983 with the Spacelab D2 mission, has substantial experience with on orbit servicing systems and tele-operation. DLR built a robot (that flew on the larger spacecraft and the GETEX experiment) which examined the dynamics of how a robotic arm influenced the overall stability of a coupled pair of spacecraft. DLR and its industrial partner Kayser Threde are currently working closely with ORC in development of the ConeXpress ORS. Figure 3 is a rendering of the joint DLR/NASDA ETSVII (GETEX) mission in 1998. 4 The current configuration of the ConeXpress ORS is not capable of performing the Hubble Rescue mission because of its limited size, power, and thruster performance. However, a significant portion of the technology that is incorporated into the system is directly applicable to an upgraded ORS that is designed to in response to the requirements for a Hubble rescue mission. In particular, a number of DLR’s advanced robotics capabilities, its onboard spacecraft navigation computer (proven on SMART-1), and its rendezvous and docking simulation system are directly usable for this application. Figure 3: ETS VII Joint DLR/NASDA Cooperative On Orbit System Also, DLR is in the midst of advanced development of a mission known as TECSAS that will be flown in a joint venture with the Russian Space Agency. DLR will launch and operate an advanced robot on the mission that is designed to grapple a companion spacecraft. Among other objectives, DLR will gain invaluable data and experience in understanding the dynamics of a coupled pair of orbiting spacecraft. Within the next 18 months, and preceding the TECSAS mission, a test version of this system will be delivered to ISS to prove out operation of the robotic joints. This system will be mounted on the outside of the Russian Zvezda module and undergo a set of activities that are planned to accurately characterize operation of DLR’s robotic arm joints in the actual mission operating environment. Successful achievement of the planned objectives will elevate maturity of this system from its current Technology Readiness Level (TRL) 5 to TRL 7. The subsequent TECSAS mission will further this maturing process and demonstrate system TRL 8. Figure 4 is a rendering of this system. 5 Figure 4: DLR’s TECSAS Mission Of key importance to the Hubble rescue mission, an Americanized “heavy” version of the original Spacecraft Life Extension System (SLES), developed by ORC, could be readily adapted for use in the HST rescue mission. SLES Heavy (HTARV) To the Rescue At the outset of the Orbital Recovery System development process, SkyCorp worked directly with ORC to develop the SLES for GEO ComSat lifetime extension missions. The SLES design can be readily scaled up in capability in order to perform rescue missions of stranded GEO ComSats. The design was baselined to be capable of “rescuing” ComSats of up to 5000-Kg mass. Conceptually, the SLES is designed to rendezvous with ComSats located in intermediate LEO orbits of any inclination or GTO orbits, and move them to GEO. Mission operations such as these would likely require addition of velocity increments (V’s) that are on the same order of magnitude as a Hubble rescue mission would require. Figure 5 is an illustration of the SLES as it is envisioned for the Hubble rescue mission. 6 Figure 5: SLES Docked to Hubble at the ISS Orbital Plane The SLES version shown in Figure 4 is the baseline “lightweight” version. The V required to move Hubble from its present orbit at 28.5 degrees to the ISS orbit of 51.6 degrees is approximately 3.4 km/sec (at 90% thrust efficiency). Theoretically, a 10 kilowatt SLES (0.5 Newtons thrust) could accomplish this task, but it would require a very long time, measured in multiple years, to complete the transfer. Therefore a more powerful version of the SLES, henceforth referred to as the HTARV, is needed to perform and complete the mission within an acceptable time period, generally envisioned as one year or sooner. Preliminary calculations indicate that to move the system within a year long mission, a system that delivers at least 2 Newtons and possibly as much as 5.6 Newtons of thrust is required. This is currently achievable, but the power required to do so is between 44 and 88 kilowatts. Current solar array technology would require over 250 m2 of solar array for the 88 KW worst case power demand. This is a very sizeable solar array, which would quite likely be difficult to fabricate and assemble, verify, and launch, if confined to a Delta IV class vehicle. Proposes is the use of two to four pairs of solar arrays adapted from Boeing’s “702 Series” GEO ComSat. A single Boeing 702 solar array delivers peak performance of 22KW, thus two to four sets would provide the 44 to 88 KW BOL power requirement. The 702 solar arrays are currently operating successfully on orbit in ComSat applications, and therefore are at TRL 9. It is planned to scale up these flight elements by a factor of 4 worst case to meet the projected mission requirements. Planned deorbit of the HST bounds the timeframe that is available to complete system scaleup and any proof of concept requirements. Success of this approach will depend on the ability to minimize new development. For this proposed mission to be successful, it is anticipated that Hubble would need to be retrieved before it descends below an altitude of ~ 250Km, wherein after increased atmospheric drag would begin to severely hamper effective control of the HTARV system. Retrieval above this altitude could be 7 accomplished with the proposed HTARV system even if Hubble were to lose effective benefit of its gyros due to gravity gradient induced spacecraft orientation. SkyCorp and its team have a proposed design solution for a Hubble rescue tug (HTARV). While obligating a very innovative system design approach, all technologies required to accomplish this mission are well within c what is commonly recognized as the current state of the art and meet or exceed NASA’s HST Rescue Mission RFI requirements of TRL 5 or greater. A companion file to this RFI response, (HLESweights.xls) provides a preliminary weight budget for the system, including provision for the required Xenon wet mass. The referenced file also catalogs the assessed TRL levels of each of the HTARV subsystem elements. A second included file (HSTrescue.ppt) d provides detailed mission implementation data associated with the performance of the propulsion system and mission flight profile timelines. Proposed Spacecraft and Mission Architecture Design Options for HTARV Tug To relocate HST from its current orbit of 593-Km altitude at 28.5 degrees to an orbit of 340 Km at 51.6 degrees requires a propulsion system of considerable capability and capacity. Hubble weighs in excess of 11,000 Kg, which requires system performance that lies well outside the capability of any currently available propulsion system. To underscore this point, Centaur, the most energetic upper stage currently available for transfer of ComSats to GEO is able to transport a 5,000 + / - Kg spacecraft. This requires only 1.5 Km/sec of V. Application of an equivalent amount of energy would result in only 0.7+ / - Km/Sec of V, or only about 15% to 20% of the total energy required to move HST to the orbital plane of ISS. Inasmuch as Centaur also performs a plane change from 28.5 degrees to 0 degrees (albeit at a GEO altitude where energy demands are much reduced), there is comparatively even more performance contained in Centaur. It should be possible, then, to increase the scale of a Centaur Tug to perform most, if not all of the required transfer mission. This HST Centaur Tug would be a stretched version whose substantially increased fuel volume would consume the entirety of a Delta IV-H payload bay. However, HST’s deployed solar arrays impose a mission operating constraint that precludes use of a larger scale Centaur. Acceleration loads imposed on HST would require retraction and redeployment of its solar arrays, considered to be an untenable risk factor, and moreover, Hubble housekeeping functions require that power must be continuously applied to the spacecraft. Even if capable of retraction and redeployment, HST would founder. A corollary challenge would be excessive boiloff losses of cryo propellant that would severely limit the time available to rendezvous, dock, and move HST to the ISS inclination. An unrelated (to HST rescue), but long-term disadvantage of a Centaur based system would be that it has no capability for reuse for Lunar transfer missions without a companion capability to replenish both LOX and liquid Hydrogen while on orbit. This capability is strongly needed in support of the Administration’s Space / Lunar Exploration Initiative but would require considerable additional near term development. 8 A Xenon ion propulsion system would require only the replacement of the Xenon tanks, a far less hazardous and cost effective refueling capability with more long term potential for heavy payloads of a non time critical nature. Electric Propulsion System Option In first order terms, Electric Propulsion (EP) appears, to offer a solution that is achievable and presents the least degree of consequential risk to the telescope itself. One detriment associated with EP is the significantly increased transit time between the two orbits. In discussing electric thrusters a differentiation must be made between a grided ion system such as was used for the Deep Space 1 mission and Hall Effect thrusters that were originally developed in the former Soviet Union. Response to NASA’s RFI does not warrant an extensive discourse on the relative merits of Hall thrusters versus Grided Ion thrusters. However, it is plainly evident that the Hall thrusters provide significantly greater thrust, albeit at a lower Isp than grided ion thrusters. Hall thrusters deliver Isp that is 4 to 6 times greater than that of chemical propulsion systems therefore requiring much less propellant than for a chemical system for the Hubble rescue mission. However, it has been the combined experiences of both SkyCorp and ORC experience in prior design circumstances that grided ion thrusters with high Isp and very low thrust simply do not provide sufficient performance to move spacecraft around in LEO orbits within any reasonable time period. Figure 6: Pratt & Whitney Electric Propulsion Systems The specific thruster that will enable this mission possible Pratt & Whitney’s T-220HT, which is in currently in advanced development today at a demonstrated TRL of 5 shown in figure 6. This thruster delivers Isp of 1875 seconds at a thrust of approximately 1.42 Newtons while consuming 22 KW of input power at an output from the power processor of 300 volts. For each solar array, two T-220HT thrusters would be clustered for 9 redundant operation. This configuration would easily provide the thrust that is necessary to move a HST class spacecraft to its new orbit. The voltage applied to the Hall thruster could be reduced in order to minimize fuel consumption, at the expense of increased transit timelines. Optimization of this tradeoff is to be further studied as part of the proposed effort. Power System The propulsion system is not the critical path system for this development. The most challenging aspect to the spacecraft is the power system, including the solar arrays, array pointing, and power interface to the T-220HT thrusters. An important starting point that would simplify the system would be to adopt the Boeing 702 22 KW BOL solar arrays, array pointing system, rotary joints, and power preprocessor. It would take 2 to 4 full sets of solar arrays, which is within Boeing’s (SpectraLab) production capabilities, especially in the current market for commercial ComSats. Since the HTARV would not be leaving LEO in order to perform the Hubble mission there is little concern relative to solar array degradation with the use of the proposed solar panels. A very robust and failure tolerant system could be accomplished through implementation of an electric propulsion system design that is analogous to NASA’s Saturn 1 launch vehicle. In this adaptation, each pair of EP engines would be paired with discrete and independent solar array and power processing systems connected to the clustered pair of T-220HT thrusters. This would avoid reliability problems associated with the aggregation of 44-88 kilowatts of power into a single power system and subsequent switching and distribution of power into separate thrusters. A byproduct of this would be that each solar array-power processor-thruster pair has its own built in redundancy. This treatment would introduce approximately 200-Kg weight penalty, but would appreciably increase system reliability. The mass penalty is minimal in a total system (including HST) whose projected mass is on the order of 17,000 Kg. Some cross strapping would be required so that a failure of a thruster group would not eliminate the ability to use the fuel tanks from that thruster group on the remaining thrusters. System Architecture Using On Orbit Assembly Another factor for a solar electric tug is the difficulty to assemble it as a single entity that can be integrated on a launch vehicle, deployed, and operate reliably. This is not impossible and should be studied with equal consideration to any other approach. However, such a system lends itself to an on-orbit assembly approach whereby the system is assembled at ISS by crew and robots, solar arrays deployed, sent to Hubble, wherein it rendezvous, retrieves and returns to ISS. While the total V is increased, the much lower mass on the trip to Hubble dramatically reduces total impulse needed (18,706,000 N-sec there vs. 47,741,000 N-sec on the return). On orbit assembly of this system would enable a much lighter weight structure, a more reliable deployment of the solar arrays and thruster booms, and an opportunity to pretest before release. It also lends itself to a modular system implementation, robust 10 redundancy, and designed in later reuse capabilities. Also, an on orbit assembled system would not have to qualify for the full dynamic environment or the volumetric limitations of existing launch systems due to the use of SkyCorp’s patented vibration reduction packaging for protecting subsystem components for launch. With the total cost of this system is constrained by choice to no greater than that budgeted for de-orbit of Hubble, HTARV system requirements, costs and resultant schedules could be very tightly controlled while also producing a system that has multiple uses beyond the Hubble mission. Because the Administration’s policy is to reserve use of the remaining Space Shuttle orbiter fleet as much as possible for ISS completion, reliance on it should be held to a minimum for this mission. A preliminary concept would be that the HTARV components be sent up in a European ATV or Russian Progress vehicle specifically purchased for this mission. An alternative system such as the Kistler K1 or the future SpaceX Falcon V could be used as well for this purpose, however, viability of both would need to be vigorously assessed. It may be that as a minimum, the solar arrays could be flown on a logistics mission where the Shuttle carries the MPLM. In this case the Lightweight MPESS Carrier (LMC) that flies in the rear bay of the Shuttle would be used. It normally does not count fully against payload weight due to its role replacing ballast mass for Shuttle CG optimization. These alternatives would have to be seriously addressed in the context of the Shuttle’s role in completing the construction of ISS before its retirement. The crew for the assembly process would be transported to ISS in a Soyuz vehicle that is commercially purchased for this specific purpose. Discussions with Energia indicate that with an 18-month lead-time, this is very achievable. Both American and Russian robotics assets on ISS would be used to support the mission. All three Soyuz crew persons would be tasked to work on this project, with two of them being American and one Russian. The crew would stay for up to two weeks and execute EVA’s to assemble the HTARV. Extra resources to support this crew would be taken up in the cargo carrier. This assembly process would involve the human participants to set up the worksite, and thereafter robots such as the NASA Robonauts used to assemble truss elements for the spacecraft, deploy the solar arrays, and test the system. The worksite would be set up with at least one NASA Langley Space Crane, the existing ISS robotics systems, as well as any other robotic assistants needed. The crew persons would either assist the Robonauts or be there in case of some difficulty. This would help to maximize crew safety and help to further develop these techniques for the assembly of future lunar mission components. This would be further developed during the study phase. NASA Langley has extensive experience in this area and has agreed to be a team member. NASA JSC would be a team member to bring their experience with the Robonauts into the process. Figure 6 shows two of the Robonauts assembling Langley truss elements. A very valuable aspect to this system architecture is that at operational validation can be accomplished before the mission deployment. Multiple large solar arrays have their own 11 risk factors as well and the deployment of these items by crew and or tele-presence robotics can reduce risk and maximize mission success. We propose as a critical component of our study that we look to the relative value and safety of a crew assembled system versus a crew-assisted assembly utilizing something akin to the NASA Robonauts or similar tele-presence systems developed by DLR. Figure 6: JSC Robonauts at Work with Langely Space Crane Elements Figure 7 shows the configuration of the Langley Space Crane GENERIC SPACE CRANE CONCEPT BOOM 2 BOO M1 BO JOINT 2 OM 3 JOINT 3 TIP MANIPULATOR SYSTEM ELBOW JOINT 1 ROTARY JOINT MOBILE BASE TIP MANIPULATOR SYSTEM Figure 7: Langley Space Crane with Tip Manipulator 12 SkyCorp, along with the engineers at Langley, feel that it is very possible to couple the Robonauts with the Space Crane, and the ISS mobile robotics system to make a system that will allow the HTARV to be built with a minimum of time and a maximum of safety to the crew by limiting EVA’s and using tele-operation (software provided by DLR) to accomplish the task. The worksite, the production planning, and the production sequence Figure 8: Langley Space Truss Hardware and Packaging would be worked out during the proposed study. Figure 8 shows the Langley Space Truss hardware that is at an advanced state of development at Langley today. Langley has an extensive experience base on the use of this hardware, including considerable worksite preparation, timeline planning, as well as packaging for hardware to be used on orbit. While this is an ambitious undertaking, it specifically compliments the President’s recent announcement concerning return to the Moon. This system would be made reusable by replacing Xenon tanks and could be used to boost payloads similar in size to Hubble all the way to Earth/Moon L1 or even into Lunar orbit, thereby adding a very key component to a cis-lunar transportation architecture. Mission Requirements and Analysis The mission to save Hubble is different from missions to and from higher altitudes. The mission is almost a pure plane change between two orbits at different inclinations and 13 altitudes. An extensive analysis effort will be required to optimize the mission in order to minimize V and trip time. Below are some of the requirements and analysis required. • • • • • • • Plane change required is 23.16 degrees. Ascending nodes must also be aligned. Current nodal regression rates are 6.487 degree/day (Hubble) and 5.083 degree/day (ISS) At these rates, Hubble node will lap ISS node about 6 times in 4 years. Plane change delta V is about 3060 m/s. At 90% effectiveness, delivered delta V is about 3400 m/s. Thrusting 30% of the time (considers ideal thrusting half time plus effects of shadowing ~ 30% plus contingency) gives return time (Hubble orbit to ISS orbit) ~ 1 year. Node rate can be modified by altitude change plus strategic wait times, to enable nodal alignment at the conclusion of the return. This must be coordinated with ISS reboosts, which alter ISS nodal regression rate. Return trajectory can be optimized for minimum delta V in specified time. SkyCorp has access to a trajectory and electric propulsion system six-degree of freedom optimization tool that would be used in concert with Satellite Tool Kit to do the detailed mission planning to execute this mission. We have started with a conservative straw man mission that would be optimized throughout the process to deliver the desired result of minimum trip time and V. First Cut Mission Scenario The HTARV would depart ISS, climb to an altitude of 900-1000 km in order to maximize daylight time and remove any possibility of crashing into station if a catastrophic system failure occurred. Note that the ballistic coefficient is so low that the system would deorbit quickly in the event of a total system failure. The probability of this is low due to the fact that the system could be tested at full power while still attached to ISS. The HTARV would then execute the plane change to move between 51.6 degrees and the HST orbit plane. During the transfer orbit the thrusters would only be fired during the sunlit portions of the orbit. Care in picking the time of departure could result in a best case beta angle that would give a full sun condition during at least part of the orbit transfer. After reaching the HST orbital plane the altitude would be reduced to that of HST with great care to make sure and phase the planes properly in order to reduce total system transit time and V. The mission design is a very interesting intellectual exercise that lends itself to a whole group of trades. Some of the trades are: 14 • • • • Optimum departure/return time to minimize eclipse periods and phase with ISS orbit at 51.6 degrees. Optimum orbital altitude to minimize eclipse periods, residual atmospheric drag, and assist in minimizing trip time by timing the orbital phasing with ISS. Optimize cost of system by trading HTARV power/thrust Vs orbital transit time. Optimize system design for maximum reuse for ISS re-boost and lunar missions. The HTARV would then rendezvous and dock with HST using the EVA handholds on the rear of the bird with grappling accomplished by using the DLR grappling hands or other similar devices. DLR has in development a servicing system that uses multiple “hands” to grapple spacecraft. After a hard dock has been achieved the system would then begin the transit back to ISS. HST would be made dormant as much as possible and the telescope light door would be closed. Using electric propulsion there would be no need to furl the solar arrays, therefore the telescope would be able to remain powered during the flight. HST could be monitored by the Space Telescope Institute to insure proper operation of the telescope during the transit period. The combined system would be first boosted back up to 900-1000 km or another optimum altitude and then the plane change executed over a period of less than one year. Simulations carried out to date by Pratt & Whitney indicate that with the most powerful system that that transit time would be less than 250 days. The telescope would not have to come all the way back to ISS. It could be brought nearby and then serviced by a Shuttle crew. Nothing in this scenario should be construed to suggest that HST be serviced by the HTARV. We feel that this is still pretty much beyond the state of the art in the needed mission timeframe. During the servicing by the Shuttle or at ISS the tug would be refueled with Xenon. After the servicing is completed the HTARV would boost HST to an orbit to be defined by the science community. The Hubble telescope would then be cut loose and would run on its own systems again. The tug does not have the pointing capability that Hubble does so it would not be appropriate for that use. Other Missions for the HTARV The tug could then return to ISS where it could used for ISS re-boost. The amount of power that the system has is entirely adequate for orbital maintenance of the station, which would reduce logistics requirements for wet mass delivered by the Progress or European ATV by a fair margin. Provision could also be made to provide tens of kilowatts of additional power to ISS. Also, the system could be used as a tug to move heavy payloads to higher orbits, including an L1 space station. It could also be used to move fuel and other payloads to the L1 station or to move heavy landers all the way to lunar orbit. The NASA NeXT team has identified a Solar Electric Tug as part of its transportation infrastructure. For example this tug could take a full up manned Lunar lander to Lunar orbit without a crew and then have a chemical tug take the CEV to lunar 15 orbit. Such a tug, along with its siblings could become a vital part of a cis-lunar transportation architecture. This could move up the President’s timetable by years! Proposed Study to Develop HTARV and Mission The HTARV team led by SkyCorp Incorporated has already expended significant effort on this mission as well as funded efforts by DARPA and commercial interests in other on orbit assembly and Hall thruster powered systems. Orbital Recovery is in the serious design phase of the sister ConeXpress ORS and other team members not yet officially on board are interested in joining a funded effort. Orbital Recovery would lead any commercial participation by ESA in the engineering of the system by the provision of licensed technology under contract to ORC at this time. ORC also has the contracts and relationship with Arianespace and ESA for the acquisition of the ATV and the crewed Soyuz. Conclusion This mission is achievable. It is ambitious, but there is no part of this system that has not been used in at least component form in space or in at least advanced (TRL level 5) development. We feel that it can be built for no greater sum of money than is to be allocated for the de-orbit of Hubble. This system can be built in no more than four years and be ready for reliable flight in such a time as to save HST before the failure of all of its gyros. We urge NASA to budget and allocate funds for performance of a thoroughly detailed study that would establish the feasibility of our proposed solution. This is a bold plan is fully in keeping with NASA’s charter and directly applicable to mission to return to the Moon and to go beyond to Mars. Dennis Wingo CEO SkyCorp Incorporated 256-533-9967 202-321-1087 cell wingod@skycorpinc.com 16