Strength reduction and delamination growth in thin and

advertisement

ComputationalMechanics16(1995)17o-1899 Springer-Verlag1995

Strength reduction and delamination growth in thin and

thick composite plates under compressive loading

B. P. Naganarayana, S. N. Atluri

17o

Abstract In this paper, the coupled local-global buckling

behavior in laminated composite plates with elliptic

delaminations and the associated mechanisms of delamination

growth under compressive loads are critically examined. The

J-integral technique is used for delamination growth prediction

in terms of pointwise energy release rate distribution along

the delamination edge. A Multi-plate model, in conjunction with

a 3-noded quasi-conforming shell element, is used to model

the delaminated plates. The incremental equilibrium equations

are set up based on total Lagrangian formulation. The solution

strategy incorporates Gauss elimination in a cycle of

Newton-Raphson iterations and is augmented with automated

arc-length controled load incrementation and equilibrium

iterations; and with automated post-buckling path tracing based

on a linearised asymptotic solution. The effects of structural

parameters such as delamination thickness, size and shape, on

the post-buckling behavior and on the delamination growth are

critically examined.

1

Introduction

It is known that delaminations are the most frequent causes

of failure of laminated structures, particularly under

compressive loads. The presence of delaminations leads to

a reduction in the overall buckling strength of the structure.

In addition, the delaminations tend to grow rapidly under

post-buckling loads, causing a further reduction in structural

strength, and finally, leading to fatal structural failure. In this

paper, in an effort towards gaining an understanding of the

possible strength reduction due to the presence of the

delaminations, and the mechanisms of their growth,

a parametric study of the influence of the thickness, shape and

size of elliptic delaminations in plates is undertaken.

The Reissner-Mindlin theory of plate flexure is used to model

the undelaminated plate and the delaminated sublaminates

Communicated by S. N. Atluri, 10 January 1995

B. P. Naganarayana, S. N. Afluri

Computational Modeling Center, Georgia Institute of Technology,

Atlanta GA 30332-0356, USA

This work was supported by the FAA to the Center of Excellence for

Computational Modeling of Aircraft Structures at Georgia Institute

of Technology, and in part by a grant from ONR. These supports

are gratefully acknowledged. The first author also acknowledges the

support by the INDO-US Science and Technology Fellowship under the

auspices of United States Agency for International Development and

Department of Science and Technology, India

Correspondence to: B. P. Naganarayana

independently; and the junction between the delaminated

sublaminates and the undelaminated plate is modelled by using

a two-dimensional generalisation of the so called Multi-Domain

Model, presented earlier for one-dimensional problems by Chai,

Babcock and Knauss (1981) [Naganarayana and Atluri (1994)].

A quasi-conforming 3-noded plate element [Huang, Shenoy

and Atluri (1994)] is used to model the delaminated structure.

An automated incremental post-buckling solution strategy,

incorporating an arc-length controlled load incrementation,

and branch switching based on a linearised asymptotic solution

[Huang and Atluri (1994)], is utilised while using the

displacement type finite element model. The stresses are

post-processed to obtain pointwise energy release rate

distribution along the delamination front, by using the adapted

J-integral approach [Naganarayana and Atluri (1994)] for each

load increment.

In this paper, the influence of the structural parameters such as the location of the delamination with reference to the

plate mid-surface, the shape and the size of the elliptic

&lamination, and the structural thickness, material orthotropy,

fiber orientation and lay-up sequence in general laminates - on

the coupled local-global buckling phenomena, reduction in

structural strength, and mechanisms of delamination growth

is critically examined as the delaminated plate is subjected to

compressive inplane loads.

2

Multi-Plate model

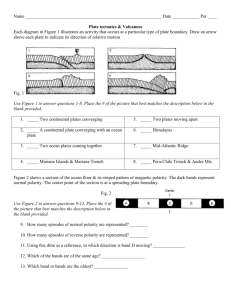

In this paper, we shall consider a general laminated composite

plate with a single delamination of an arbitrary shape and

location subjected to arbitrary buckling loads (Fig. 1). The

structure is modelled using the multi-plate model

[Naganarayana and Atluri (1994)] where the delaminated plate

is assumed to be assembled with three distinct plates-(1)

Laminate: the undelaminated zone 12~ (2) Delaminate: the

thinner side of the delaminated zone 12(2) and (3) Base: the

thicker side of the delaminated zone 12(3/. The three plates have

midsurface areas sr thicknesses t(~ boundaries 812{i);and

midsurface boundaries 8 d (~ for i = 1, 2, 3 respectively (Fig. 1).

The delamination edge is denoted by F. The Reissner-Mindlin

theory of plate bending is used for modeling each of the plates

and the interface between them. Thus, for each plate, the

3-dimensional displacement field (U {U1U2U3}) can be

expressed in terms of the corresponding midsurface

displacement (u - {u~u2u3}) and rotation (0 = {01020}) fields

=

as,

u (') (x~, x3) = u {') (x~) - x~i) 0 (~)(x~)

(1)

#

DeLaminote fl~2~

Delaminotion"~F

I

X2

L

;

Ondetominote f~m

Iw

N

Bose

Assumed deformotion at pLote-junction

(U I~l = UI~I= Ul~l)r

Xl

a,

IX

_

(2>~

L~ ~ •

.

T

/

3

171

I

/

"

- -

"1

iI

I

I

i

I

Iq)A t

-

X3 T/

XF, - - - x ,

I

(3)

h'

-l/._

Ft:l.0N/mm

t

t

t

/

,

Fig. la-r

.

.

.

I

r

I

e

},1

.

iI

!

L

I*[

I

I

I

XF~

b

- -

t!

//U:31

t"

_

/I

/ Um

I

Multi-plate model, a Delamination in an arbitrary plate, b Clamped square plate with central elliptic delamination, c Section x-x

where x~~ (~ = 1, 2) are the inplane coordinates and x~~ is the

thickness coordinate for the ?h (i = 1, 2, 3) plate. The structural

continuity at the delamination front F is maintained by

assuming the deformation to be unique at the junction of the

three plates i.e. U ~ = U (2) = U (3) on F.

For each plate, the inplane components (en, e=, q2) and the

transverse shear components (e~3, e23) of the 3-dimensional

Green-Lagrange strain tensor (including large deformations)

can be expressed in terms of the membrane, flexural and

transverse shear (engineering) strain c o m p o n e n t s - e , ~,

7 respectively - as,

where the material constitutive parameters E!!) are functions

of the thickness coordinate of each plate x~i/~JGenerally, for

a laminate with orthotropic layers, E!!

1 are assumed to be

U

piecewise constants over the laminate thickness.

Now, for each plate, the strain energy density (per unit

volume) can be calculated using Eqs. (2), (3) and (4) as,

1

,•(i)

~a=~[u

~+

~(u) =

Ufl,.

+ u~y~,e,

1(i)

W(~)=

[o-. ( e +

and the total strain energy stored in the i ~hplate is given by,

~(1

= l [ u .,fl -F uB,. -I- u3,=u3,fl] (i) - x(i) !2 tr~ o:,fl -I- O fl,~.](i)

~

_ ~ [u3,~

~[ 3,~+u~,3]~'~-~

- 0J0

(3)

respectively where, again, ~, fl = 1, 2 and i = 1, 2, 3.

Assuming orthotropic material behaviour for each lamina,

the inplane stresses ~r/~)= {G~ cr22cr12}l~/and the transverse shear

stresses r (~ = {z13z23}(~ are related to the corresponding strain

components as,

f:t

i) _~

"En

EI2

El6

0

0'(i)

El2

E22

E26

0

0

El6

E26

E66

0

0

0

0

0

E44

%

0

0

0

E45 Ess

/

(6)

i= 1 \~r

(2)

1 v(i)

= ~.~

-(2i

89 N - e + M - r + Q. r)U/d~r

=

~(i) __

_ _1 U

Q)

~ ~ W~Od

i=1 \

~_ ~(i) 4 - "v(i)~"(i)

(5)

x3x)](~) + [r. r] (i)

where N - {N u N= N12} are the inplane stress resultants; M -{M11M22M~2} are the bending moment resultants; and Q =

{Q13Q23}are the transverse shear stress resultants given, for each

plate, by,

(i)

.(i)

(i)

(7)

and

(4)

(Akl;Bkl;DkS I= f E~i)(x3)(1;x3;x2)dx3

and

G~

tl

as k,l= 1,2,3 correspond to

correspond to i, j = 4, 5.

=

~E(o

mk(x3)dx3

ti

i,j=

1,2,6 and

re, n=1,2

172

If f(0= {f~ f2 f3} (~ are reference body forces acting on D(~

F = {F~ F2 F3}/~>are the traction forces acting on ~d(~ and 2 is the

current load factor, the potential of the current external forces

is given by,

(hAW(U) - A2bB (U) - (62W(U) -- A2c3B(U)) = 0).t(u,~)

(14)

2 B ( U ) = 2 ~ =( ~1 f .

3q- [ K t ] . A q - A23q.F = 0

i)

UdD@

~.Q(i)

F.Ud~)

where, assuming that f and F3 do not vary over the plate

thickness,

"f(i)= ~ f(Odx3; ~(i) = ~ F(i)dx3; ~(i) = ~ F(i)x3dx3.

ti

ti

For a typical finite element application, incremental

equilibrium Eq. (14) can be written as,

(15)

where Aq are the incremental nodal displacements; F are the

discretised reference nodal forces (typically as specified in the

input for the problem); and [Kt] is the tangent stiffness of the

system. The incremental equilibrium equations thus become,

[Kt]-Aq - A2F = 0

(16)

On the other hand, the total equilibrium for the system

(Eq. (12)) can be written, in finite element context, as,

ti

Applying the minimum total potential energy principle

(cSYi = c~( W (U) - )3 (U)) = 0), we obtain internal equilibrium

equations:

[Ks] .q + 2F = 0

(17)

where [Ks] is the secant stiffness (or simply stiffness) matrix

for the system.

{N~/~,~+ j ~ = 0 ; M~,~+T~=O; T~,~+f3=0}~(~/

(9)

For each incremented external load vector, the incremental

equilibrium equations (Eq. (16)) are solved in a cycle of Newton

the boundary conditions on the external boundary:

type iterations and using the total equilibrium condition

(Eq. (17)) for computing the residual load vector which in turn

{ G = 0 or N~.n~=F~; 0 ~ = 0 or M~.n~=lfI~;

is used for convergence check. The load increment is optimised

for each iteration using the constant arc-length criterion to

u3=O or T..n.=F3}o:g(~,

(10)

assure faster and definite convergence of the solution even while

and the equilibrium condition on the delamination front:

traversing limit points on the solution path. The presence and

location of an instability point is determined by the singular

{ : ~ ( N ) = 0 ; : ~ ( M ' ) = O; : ~ ( T ) = 0}r

(11)

nature of the tangent stiffness matrix at the instability point;

and the nature of the instability point - whether limit point or

where T~ = O~3 + N~u3 ~; (M')(~) = M(i) + h(~)N(~ ~ n (*) = (,)(1) __ bifurcation p o i n t - is determined in a heuristic sense by

(,)(2) _ (,)(3) with (,)(~)'corresponding to the value of (,) at the comparing the load increment and increment in the generalised

specified point on the delamination boundary of the i~hplate;

deflection across the instability point. If the instability point

and n is the unit vector normal to delamination front.

identified is a bifurcation point, a cost-effective branch

However, it should be noted here that the equilibrium Eq. (11) switching technique is used to follow the desired postbuckling

may be violated when the delamination edge intersects the

branch - the nonlinear fundamental state between two points

structural boundary and when the delaminated plies come into in the neighborhood of the bifurcation point is linearised to

contact after global buckling.

obtain an asymptotic solution on the desired postbuckling

solution branch. Refer to Huang and Atluri (1994) and

3

Naganarayana (1994) for the automated post-buckling solution

Incremental solution

algorithms.

Here, we shall derive the incremental equilibrium equations

for an elastic conservative system D under linear loading. The 4

generalised deflection B (U) is assumed to be a linear function J-integral adaptation for pointwise energy release rate along

in U; and the load factor 2 is assumed to be an arbitrary constant. a planar delamination front

In an incremental solution strategy, the solution is known at

In the case of a delamination, the growth is assumed to be along

the initial point (U, 2) of the current increment. Then by the

the interlaminar zone parallel to the midsurface of the plate (i.e.

principle of minimum total potential energy, we have,

the crack cannot shear into the neighboring laminae). In other

words, the crack is assumed to grow in a self-similar sense

(3W(U) -- 2c3B (U) = 0

(12)

[Naganarayana and Atluri (1994) ].

The pointwise energy release rate for self-similar

Now, the equilibrium at the unknown point (U + AU, 2 + A2)

3-dimensional crack growth (~(_F)) is defined as [Atluri

requires,

(1986)1,

3W(U + AU)

- (2 + A2) cSB(U + AU) = 0

(13)

Expanding the incremented functions W and B and neglecting

the higher order incremental terms; and by using the

equilibrium conditions at the initial point (U, 2) (Eq. (12)) we

get,

N ( r ) A F = L i m i t ~ L[ W e l - G ,_ n p OU~q

~JdA

e~O

Ae

A1

-- ~ 6,2~

A2

~0~ dA

+ i G2 ff~x~

891

(18)

x2

r

aX3

7

73

,n

/ ~ - ~ ~ 1

~

xl

,n

F

A2

where A i (j = 1-9) are the segments forming the surface area

A e of the rectangular tube (Fig. 2c). Since the Reissner-Mindlin

assumptions (#13,#23 are constant over plate thickness; and

#33 = 0) are used for the element formulations as well as to

achieve displacement continuity at the delamination edge; and

since fi= {00 +_1} on the segments Aj, j = 4 - 9 (see Fig. 2c),

the integral in Eq. (19) vanishes over the segments Aj, j -- 4-9.

Now, since fi= { + 1 0 0} on the segment A~ and fi = { - 1 0 0}

on the segments A2 and Ar Eq. (19) becomes,

(20)

AF-~0

Now, carrying out the integration through the thickness for each

plate, we get,

b

As

§ ....

A~

6~(F)AF'= j" ffg[lk7,r- (]k[s:fi. 1+MI~O~, 1 q-(7)13U3,1)1dr' (21)

AF

,._.2k_.a:

x~l

11

{1)L.~. . . . *'-"

. ._3.

X ~,

A~

Therefore, as A F ~ 0, the pointwise energy release rate at any

p o i n t on the delamination front Ng' computed from the

Gauss-point variables, in a finite element model using constant

strain elements, is given by,

i ....

. _ .9.t-

. -t

xL!'A.I

Xg'A31

. -

Aa

13

Ng(F) = fig [ ~/-- (/q, d2~,~+ M~O~,l +

Av

Fig. 2a-c. J-Integral for delamination growth in a plate model

where, c~, fi=1,2,3; A e is the area of the tube of radius

e enclosing the crack front; A1and A2 are the areas covering the

ends of the tube (Fig. 2a); and ri, #, 0 and o7are defined in the

crack tip coordinate system 2 (Fig. 2b).

For the present problem of delamination progression, it is

assumed that the material is homogeneous along the :~1, such

that (8W/8,~)e~p~, = 0, in other words,

8W

0XI

8G~

[~W~

O-aft~1AV ~ 1

(22)

where, Yg (,) = ( * )g(1) - - ( * )g(2) - - ( * )g(3)and (*)g(,)corresponds

to the quantities (,) evaluated at specified points on the annular

surface. For example, in a finite dement analysis, these specified

points would be preferably the optimal stress recovery

points - normally the Gauss points corresponding to reduced

integration [Barlow (1976); Naganarayana (1991)] - i n the

adjoining element of the i'h plate nearest to the delamination

front F. The local stress resultants (N, M, Q) and displacement

gradients (~.~) can be obtained from their global Cartesian

counterparts (N, M, Q; Urn), by applying the regular tensorial

transformations between the reference coordinate system x and

the crack tip coordinate system ~.

5

Numerical experiments

8G~

explicit

which case, the path-independence of the ]-integral

is maintained [Atluri (1986)] for opening mode of crack

growth and hence the tube can have a cross section of any

shape.

Consider a rectangular tube enclosing the delamination front

and passing through the nearest stress recovery points (S(~ of

the adjoining elements. Note that, the integrals over the areas

A1 and A2 nearly cancel each other in a constant strain/stress

element model, since the quantities like 6"and 80~/0~ do not

vary in the neighbourhood of a point in an element domain.

Then, Eq. (18) for the opening mode of delamination growth

becomes,

in

(19)

AFj=I Aj

(~)13/~3,1)]

In this section, we shall analyse a number of delaminated

structures for their post-buckling behavior and the associated

delamination growth.

5.1

Problem description

An isotropic square plate of edge length L with a central elliptic

delamination (Fig. lb), is considered for the following

numerical experiments. The plate is subjected to biaxial

compressive loads and its boundary is assumed to be clamped

against out-of-plane deformations. One quarter of the plate is

modelled by imposing appropriate symmetry conditions. 264

shell elements are used for the undelaminate plate and 192

elements each are used for the delaminate and base plates

respectively. The reference applied biaxial compressive loads

are assumed to be of unit intensity (Fs = 1.0) and the equilibrium

equations are solved at each load step for an applied load

F = 2Fs, where 2 is the corresponding load factor (Fig. lb).

173

200"

strength of the delaminate plate (G(

[] 'AnaLytical' solution /

-

"~l~rFx/t,))is given by

(23)

IOO

The local buckling strength of the delaminate plate obtained

from the finite element analysis compares very accurately with

the analytical estimate (Eq. (23)) as shown in Fig. (3a).

Further, assuming that the post-buckling deformation is

axisymmetric and nearly linear in the neighbourhood of local

buckling point, the pointwise energy release rate is given by

[Evans and Hutchinson (1984)],

.i.r

0"

0

174

0.1

0.2

0.3

t2/tl

0.~

0.5

2-'o1

(ffrb(V)

A,*: 3./.55

-

-

( 1 - v2) t 2

(1.8-28-5~v)E (r _ 0-2)

(24)

where rr0( = 2FJq) is the actual stress level at which the energy

release is being computed.

The ratio, ffFe/~qrb, is plotted along the delamination

1.60

periphery, in Fig. (3b) for a case of very thin delaminate

1./.0

~

1.084

configuration (tE/t~ = 0.01). It can be observed that, fife is close

,%*= 2.105

to Nrb when the post-buckling loads are in the close vicinity of

1.20'

x*= x/;%

local buckling point (i.e. 2* = M2tcr-- 1.0). However, ffrb is

1.00

under-estimated when compared to ffF~ even when 2 -~ )]cr"This

0o

3bo

6'0~

9'00

8

is because, in the present problem, though the &laminate plate

is very thin when compared to the total laminate thickness

(t2/t 1 = 0.01), the base plate is flexible as opposed to the rigid

base as considered in Evans and Hutchinson (1984).

Laminate is also thin when compared to its edge length,

L

(tJL

= 0.05). Hence, the finite element model represents

[ ] Represents'analyticaL'

a reasonably flexible laminate and base plates. The deviation

Energy Release

increases as the buckling load increases beyond its critical value

[ Evans and

Hutchinson (198l,) ]

for local buckling of the delaminate plate. This is because, the

analytical solution (Eq. (24)) is based on the assumption of

[ ] Represents 'actual'

E

o

Energy Release

a quasi-linear post-buckling behavior for the delaminate plate.

Z

But, in practice, particularly when the laminate is thin,

post-buckling behavior of the delaminate plate is highly

'Normalised' displacement (A~)

nonlinear. Accordingly, much higher energy-release-rates are

Fig. 3a-c. Clamped square plate with central circular delamination

expected when compared to Nrb as shown in Fig. (3c). Note that,

(Validation of the model) a Criticallocal buckling strength. Comparison in Fig. (3c), actual stress ((r) and displacement (A) are

of F. E. solution with 'analytical' solution, b Pointwise energy release

'normalised' by the critical stress G and the associated critical

rate distribution Comparison of F. E. solution with 'analytical'

inward radial displacement A c respectively.

solution (t21t1=0.01; 2/r=0.125). C Effect of 'quasi-linear'

post-buckling behavior for delaminate on energy-release-rate

5.3

[] Represents 'analytical' energy release [Evans and Hutchinson

Effects of delaminate-plate-thickness

(1984)] [] Represents 'actual' energy release

The numerical experiment is repeated for varying delaminate

thicknesses, for a fixed laminate thickness (tJg = 0.05),

delamination size (a/L = 0.3), and aspect ratio of delamination

(a/b = 1.5). The mechanisms are examined for both

supplementary and complementary modes of post-buckling

5.2

deformations of the delaminated plate.

Validation of the model

The structure is assumed to be isotropic with Young's modulus

5.3.1

E = 6500 and Poisson's ratio v = 0.3. The laminate thickness

is chosen as tl = 0.05 L. The numerical experiment is conducted Supplementary modes of post-buckling deformation

For very thin delamination (t2/tl = 0.02), the delaminate plate

for a near-surface circular delamination with tJtl = 0.01,

undergoes a second mode of buckling before reaching the global

a/b = 1.0 and all = 0.3. Assuming that the base plate and the

undelaminated plates are infinitely stiff when compared to the buckling load level. Typical post-local-buckling modes of

deformation are presented in Fig. (4a) and (b) for first and

delaminated plate, the delaminate plate can be considered as

second mode respectively. The deflection at the centroids of

a clamped circular plate under the same radial compressive

the delaminate and base plates are traced in Fig. (5). For very

stress [Evans and Hutchinson (1984)]. Then, the buckling

= 1.80

X * : 2.793

0

-0.5

-1.0

5O

lo

2o

~u

30

~

a,

10

u

50

0

0

-0.2

-0.4

-0.6

-0.8

0

b

~

50

z,O

1.5

1.0

0.5

0

50

0

'-~

30

,

~

~

10

Fig. 4a-c. Post-local and post-global buckling deformation a/b = 1.50;

a/L = 0.30; tJL = 0.05. a Typical post-local-buckling deformation

(First Mode) t2/t1 = 0.02; )~= 58.5. b Typical-local-buckling deformation

(Second Mode) tE/t~= 0.02; )o= -48.8. c Typical post-global-buckling

deformation tE/t~ =0.20; )0 = 218.0

thin delaminate (t2/t ~ = 0.02), there exists a load l i m i t p o i n t at

2 = 92.3 as the delaminate plate undergoes second mode of

buckling (see Fig. (4b) and Fig. (5a)). However, for larger

delaminate thickness, the delaminate plate does not undergo

a second mode of buckling. On the other hand, the locally

buckled delaminate plate acts as a geometric imperfection for

the base plate and leads to premature global buckling of the

structure. As expected, the local buckling strength of the

delaminate plate increases as its thickness increases (see Fig. (5)

and Fig. (6)). However, the global buckling strength of the

structure decreases as the delaminate thickness increases (see

Fig. (5) and Fig. (6)). The reduction in the global buckling

strength due to the presence of delamination is nearly 50% (see

Table 1). In fact, for t 2 =< 0.2t~, the global buckling strength of

the structure is less than that of the plate with the delaminate

plate completely removed. This is understandable since the

locally buckled delaminate plate acts as a geometric imperfection

and can lead to a highly premature structural failure.

The energy release rate distribution is nearly uniform along

the delamination edge for very thin elliptic delaminate plate

in the vicinity of the local buckling point (Fig. (7)). However,

the energy release distribution pattern changes as the load factor

increases, and as the thickness increases. The maximum energy

release rate is observed to be in the vicinity of the direction

of maximum local-buckling-stiffness. In this case, the

delaminat e plate exhibits maximum stiffness against buckling

in the minor axis direction and hence the point of maximum

pointwise energy release rate is found to be at an angle of 75 ~

with reference to the major axis. As the delaminate plate

thickness increases the energy release rate becomes negative at

certain zones. This indicates, in a qualitative sense, that the

delaminate and base plates are in contact. This happens because,

for higher delaminate thickness, the local buckling point is very

close to the global buckling point (see Fig. (5f)).

For very thin delaminates, the energy release rate increases

upto the load limit point ()~ = 92.3); then decreases as the

delaminate enters the second buckling mode whence the

delamination starts closing; and takes a non-zero positive value

for )~ = 0.0. Then as the traction forces become tensile in nature,

the buckled delaminate plate starts unfolding from its second

mode of deformation, and tends to open the delamination

at its edge and hence the energy release rate increases from that

point onward. The variation of the maximum and the average

pointwise energy release rates with reference to the load factor

are presented in Fig. (8). Since, for very thin delaminates, the

energy release rate distribution is nearly even, the average

energy release rate is very close to the maximum energy release

rate.

The variation of the maximum and the average pointwise

energy release rates with reference to the load factor

are presented for varying thicknesses in Fig. (9) and

Fig. (10) respectively. It can be observed from Fig. (9) that,

for thin delaminates, the energy release rate is predominantly

due to the local flexural deformation of the delaminate plate

after the load level crosses its buckling strength. In fact the

energy release rate is very much negligible for 5[ < Z~crfor thin

delaminates (see Fig. (9a)). However, for thick delaminates, the

maximum energy release rate is positive - and comparable with

that with thin delaminate in post-local-buckling

conditions- even when the load level is lower than

corresponding local buckling strengths. In this case, the growth

mechanisms are predominantly due to the membrane action.

However, the maximum pointwise energy release rate increases

steeply as the global buckling of the structure approaches

(see Fig. (gb)), irrespective of the delaminate thickness; and

delamination growth is relatively more rapid for thinner

delaminate configurations.

For thin delaminates, the variation of the average pointwise

energy release rate with the load factor is similar to that of the

maximum pointwise energy release rate (see Fig. (9)). However,

for a very thick delaminate, the delaminate and base plates are

in contact for lower load factor on the average (i.e. the

average energy release rate is negative) as depicted in the

corresponding energy release rate distributions (see Fig. (7)).

This is because, the local buckling strength becomes very close

to the global buckling strength as delaminate thickness

increases (see Fig. (5)). In fact, for t J t 1 = 0.40, local and global

buckling occur almost simultaneously (see Fig. (50).

Accordingly, the pointwise energy release rate increases steeply

175

1.5

a~ t2/t ~: 0.02

'.C

u

7.5

I

~.o

!

/

b t2/t 1=0.05

w3 /

e

t2/t 1=0.10

/ /

6.0

5.0

://

-~ o.s

8.084

/

//

VO

W2

2.5

g

2.0

W3

(..2

- 100

176

- 50

0

50

100

5.0 84

d t2/tl:0.20

?

I

2.0

200

30O

6.0-

/

54.0

o=

3.0

100

e t2/tl=0.30

/

,

Z,.O-

/

5.0 84

260

300

f t2/tl= 0.40

4.0 84

2.0

[...

100

20

~.o

0

0

100

200

Load footer ,L

300

0 I ----~0

16o

260

Load factor L

360

Ok

10o

260

Load factor X

360

Fig. 5. Effect of delaminate thickness on load-deflection response a/b = 1.50; a/L = 0.30; tt/L = 0.05

as the load factor crosses beyond the corresponding local critical

value.

It is observed that, the thicker delaminates reduce the overall

global buckling strength of the structure (Fig. (6)), while the

thinner delaminations are more critical from the energy release

rate point of view (Fig. (9) and Fig. (10)).

5.3.2

Complementary modes of post-buckling deformation

Normally the locally buckled delaminate plate acts as

a geometric imperfection and causes a premature global

buckling in a supplementary (signifying that the deflections of

the delaminate and the base plates are in the same transverse

direction) sense (Fig. (4c)). However, when the delaminate plate

is thick, the eccentricity of the geometric imperfection is small;

and, as a result, the delaminate and the base plates may

snap into complementary (signifying that the delaminate and

the base plates deflect in opposite directions) modes of

post-global-buckling deformations (Fig. ( 11 ) and Fig. (12) ). The

load-deflection curves are plotted for the centroids of the

delaminate and the base plates in Fig. (12). The centroid of the

delaminate plate undergoes a displacement limit point as the

plate enters global buckling mode. Then both the base and the

delaminate plates, with comparable thicknesses, enter higher

order buckling modes. As they enter second buckling mode, the

centroids of both the sublaminates pass a load limitpoint as

shown in Fig. 12. It is also interesting to note that the critical

load factors, triggering local and global buckling, remain the

same whether the two modes are complementary or

supplementary to each other.

It is also interesting to study the energy release patterns in

the complementarymodes. For thick delaminate configurations,

the delaminate and base plates close the crack at many parts

of the delamination periphery, in supplementary modes

(Fig. (7)). However, they tend to open the crack at all points

in the complementary modes. All-positive energy release rate

distribution shown in Fig. (13) signify this observation. As

a result, though the maximum energy release rate is slightly

lower in case of the complementary mode (Fig. (14)), the crack

tends to open at all points on the average (Fig. (15)). Note that,

the crack tends to close on the average in case of supplementary

modes for higher delaminate thicknesses in post-globalbuckling range of loads (Fig. (10) and Fig. (15)). Thus, in case

of thicker delaminate plate configurations, the complementary

modes of buckling pose a serious threat of rapid delamination

growth and fatal failure. In case of thin delaminate plate

configurations, the residual strength of the base plate is still

comparable with the original strength; while both the base and

the delaminate plates may face failure almost simultaneously

(in case of complementary local and global buckling modes)

leading to catastrophic failure of the whole structure.

5.4

Effects of aspect ratio of delamination

The experiment is repeated for varying aspect ratios (a/b) of

the elliptic delamination with specified thickness (t2/t ~= 0.1)

and major axis length (a/L = 0.3) and fixed total plate thickness

(tl/L = 0.05).

A typical solution path for the transverse deflections at center

of delaminate (w2) and base (w3) is shown in Fig. (5c) for an

aspect ratio a/b = 1.5, depicting local and global buckling. It

is observed that the local buckling load increases as aspect ratio

increases (Fig. (16)). The global buckling strength also increases

as the aspect ratio increases. However, global buckling strength

Table 1. Reduction in global buckling strength of plate with elliptic

delamination: Effects of the delaminate thickness

200

(;~~ (t = t~))o~- (;~)~.

.... * 100

(;.~T(t = tl))oo~,

%lc~

'< 100

Rb -

,100

(,t~

= t3))ooo~

(2~r(t = t))~aIF~= 5.30n2Et3/12 (1 --v 2) (Timoshenko (1940)]

0.1

0.2

t2/tl

0'.3

177

0.4

Fig. 6. Effect of delaminate thickness on local and global buckling

strengths

becomes saturated asymptotically as aspect ratio increases

beyond 2.0 as seen in Fig. (16). The global buckling strength

of the delaminated plate is compared with that of the

undelaminated plate of full thickness and of base thickness in

Table 2. It can be noted here, again, that the delaminate buckles

locally prior to the global buckling; acts as a geometric

eccentricity to the global behavior of the plate; and hence leads

to premature failure of the plate. For the structure considered,

the global buckling strength reduces to nearly half its original

strength. In fact, the delaminated structure is nearly 30% weaker

than the structure with the delaminate plate being completely

peeled off. Thus, the reduction in the buckling strength of

the delaminated plate is very high due to the presence of the

delamination irrespective of its shape.

The variations of the maximum and the average point-wise

energy release rates with reference to the applied load are

presented in Fig. (17) and Fig. (18) for different aspect ratios.

As the aspect ratio increases, local buckling strength increases

and hence the energy release rate is lower at lower load factors.

But, as the external load increases, the energy release rate

increases sharply for higher aspect ratios. Thus, for

a delamination with higher aspect ratio, the onset of

delamination growth may be delayed, but the delamination

growth rate is much higher once the growth is set-in.

The location of the point on the delamination edge where

the point-wise energy release rate is maximum is traced

in Fig. (19). It is observed that the point of maximum

energy release rate occurs at an angle of 0m = 45 ~ with

reference to the major axis when a/b = 1.0. It is observed that

as the aspect ratio increases, maximum energy release rate is

experienced at 0~ = 75 ~ This is, again, due to the larger

crack opening at minor-axis-tips than at major-axis-tips for

a given locally buckled configuration.

5.5

Effects of size of delamination

Now, the numerical experiment is repeated for varying sizes

of the elliptic delamination with specified delaminate thickness

(tJt 1 = 0.1), aspect ratio of the delamination (a/b = 1.5) and

plate thickness (q/L = 0.05). The major axis length of the elliptic

delamination, a, is varied. As the delamination size increases,

both the local and global buckling strengths decrease as

t2/t 1

0.02

0.05

0.10

0.20

0.30

0.40

Rb

34.39

25.72

1.39

-37.08

- 108.16

Rf

43.75

45.48

49.50

52.98

55.04

presented in Fig. (20). The percentage reduction in the

global buckling strength of the structure is given in Table 3

for varying delamination size. Again the delaminated structure

is weaker in buckling when compared to undelaminated

laminates.

For a smaller delamination, the local buckling begins at

a higher load level; and hence, the energy release rate becomes

significant at higher load levels. However, the energy release

rate increases steeply once the local buckling sets in. In the

pre-global-buckling stages, both the average energy release rate

(Fig. (21)) and the maximum energy release rate (Fig. (22)) are

lower for smaller delaminations since the local buckling

strength is higher. However, in post-global buckling stages, the

smaller delaminations tend to grow more rapidly. Thus the

smaller the delamination, the later the delamination growth

sets-in; but once it sets in, the delamination growth will be much

more rapid than with the larger delaminations.

5.6

Effects of total plate thickness

Here, the numerical experiment is repeated for varying

thicknesses ratio of the plate (tl/L), for a fixed delamination

thickness ratio (t2/t 1 =0.1), delamination aspect ratio

(a/b = 1.5), and delamination size (a/L = 0.3). The critical

buckling load increases as the cube of the plate thickness

(Fig. 23). Both local and global buckling strengths increase as

the plate thickness increases. However, the increase in the

critical load factors is slightly lower than that expected from the

expected variation proportional to cubic variation of the

thickness (Fig. (23)). This is because, the actual delaminate

thickness also increases as the plate thickness increases for

a fixed delaminate thickness ratio. Hence, the eccentricity of

the delaminate plate with reference to the plate midsurface

increases as the plate thickness ratio increases with fixed

delaminate thickness ratio. Accordingly, the rate of reduction

in the global buckling strength of the structure increases as the

plate thickness increases. In case of delaminated plate, 30-60%

strength reduction is observed with reference to undelaminated

0.3(

2.0

t2/t 1 : 0,02

0.2!

,?:o;o

1.8

. . . . .

1.6

0.20

1.4

0.15

1.0

1.2

0.8

0.10

0.6

0.4

0.2

0.05

t78

0

1;

20

3'o ~'o 5o

6o

io

8o 9o

0.25

0 ,

%

25

t2/t 1: 0.20

0.20

15

0.10

10

0.05

5

0

0

-0.05

-5

i

0

1;~ 2o

='297.2

2O

0.15

-0.10

%

3o

i

~o

5'0

i

~o

~o 8o

~o

-10

t 2/tl : 0.40

xQg.9

0

~

10

'

20'

30

'

~0

60

'

5'0

70

'

80

'

90

Fig. 7. Pointwise energy release rate distribution along delamination edge a/b = 1.50; a/L = 0.30; t,/L = 0.05

o,o6.

0.050.3"

0.04

i 0.03"

"

0.2

0.02

1

2

3

4

t2/t~=O.02

tJt~:O.05

tJt~:O.lO

t2/tl=0.20

5 t2/t1:0.30

5 t2/tl:0.40

i

1;/7

//

//

0.01

0

0.1

0

a

10

20

30 z,O 50 60

Load factor X

70

80

30

J

- 100

- 50

i

i

0

50

100

;k

Fig. 8. Average and maximum pointwise energy release rate for very

thin delamination a/b = 1.50; a/L = 0.30; tilL = 0.05; tJtl = 0.02

20

t2/tl=O.05

tjfl=0.10

t2/t1:0.20

2"///

3////

&//4//L

t2/tl: 0.30

IIII l

tJtl:O.L

10

plate of thickness tl, while 1 0 - 4 5 % strength reduction is

observed with reference to u n d e l a m i n a t e d plate of thickness

t l - t2 (see Table 4).

The n o r m a l i s e d average and m a x i m u m pointwise energy

release rates - ~q~J)/cr and ~max/)Jcr -- are plotted in Fig. (24) and

Fig. (25) respectively with reference to n o r m a l i s e d load factor

2/)/cr. As the plate thickness increases, even though the

d e l a m i n a t i o n growth m a y start at m u c h higher load factors, the

0

0

16o

260

360

Load factor ~,

Fig. 9a, b. Influence of delamination thickness on maximum energy

release rate a/b = 1.50; a/L = 0.30; tall = 0.05. a Pre-global-buckling

regime, b Post-global-buckling regime

0.1

300

0

/t21q:

O.~'~~.3-

g

-0.1 '

200

100

t79

-0.2

10

20

30

40

50

Load factor k

60

70

80

0

-6

-i

0

2

w

/*

,.

Fig. 12. Load-deflection paths at the centroids of delaminate and

base plates. (In complementary mode), t2/t~ = 0.20, q/L = 0.05,

a/b = 1.50, a/L = 0.30

9

0.6

0.5

0.4

90.3

0.2

-2

2;o

o

b

3oo

Load factor: ;L

9

0.1

Fig. lOa, b. Influence of delaminate thickness on average energy

release rate a/b = 1.50; a/L = 0.30; tilL = 0.05. a Pre-global-buckling

regime, b Post-global-buckling regime

10

20

30

40

50

60

70

80

90

8

Fig. 13. Pointwise energy release rate distribution. (In complementary

mode) t2/q = 0.20, till = 0.05, a/b = 1.50, a/L = 0.30

6.0

1.0

(1) In complementary mode

(2) ]n supptementary mode

/..5

/

50

3.0

Lu

30 ~

/

/ ~

10

1.5

Fig. 11. A typical complementary post-buckling deformation mode.

fi = 205.8, tz/t ~ = 0.20, tJL = 0.05, a/b = 1.50, a/L = 0.30

-1.5

e n e r g y release rate i n c r e a s e s v e r y steeply. Thus, t h e t h i c k e r the

l a m i n a t e plate, the later t h e d e l a m i n a t i o n g r o w t h begins; a n d

the m o r e d a n g e r o u s the d e l a m i n a t i o n g r o w t h will be.

5.7

Effects of the material orthotropy

A n o r t h o t r o p i c s q u a r e plate of edge l e n g t h L a n d t h i c k n e s s

q = 0.05L, w i t h a c e n t r a l elliptic d e l a m i n a t i o n (Fig. l b ) , is

c o n s i d e r e d for the following n u m e r i c a l e x p e r i m e n t s . The

0

. . . . . .

100

9

, 9

200

,

X

Fig. 14. Average pointwise energy release rate distribution. (In

complementary mode) t2/t ~= 0.20, t~/L = 0.05, a/b = 1.50, all = 0.30

d e l a m i n a t i o n c o n f i g u r a t i o n is fixed as: a/L = 0.3; a/b = 1.5; a n d

t2/t 1 = 0.1. The l o a d i n g a n d b o u n d a r y c o n d i t i o n s , a n d t h e finite

e l e m e n t m o d e l i n g are t h e s a m e as in the p r e v i o u s p r o b l e m s .

The m a t e r i a l p r o p e r t i e s are t a k e n as: E 2 = 26000; vi2 = v~3 =

/

15

(1)

10'

In

comptementarymode

supplementary mode

(2) In

0.03

[

(2 t/

1

2

3

t,

0.02

•

u

E

5

j ~ ( 1 ]

a/b:1.00

a/b=1:50

a/b=2.00

a/b =3.00

0.01

180

0

o

1;o

x

200

so

Fig. 15-. Maximum pointwise energy release rate distribution. (In

complementary mode) tg/t~ = 0.20, t~/L = 0.05, a/b = 1.50, a/L = 0.30

80

220

16o

1so

2so

L

Fig. 17. Influence of aspect ratio on maximum energy release rate

a/L = 0.30; tJL = 0.05; t2/t 1 = 0.10

i:iill lab100

III

III

2 o/b:150

3 a/b~2100

60

I

/

2t0

x? 40

200

20

0

1.0

,

1.5

,

2.0

a/b

2.5

190

3.0

Fig. 16. Effect of aspect ratio of delamination on local and global

buckling strengths a/L = 0.30; tJL = 0.05; t2/t ~= 0.10

Olo

50

100

2,.

150

200"

250

Fig. 18. Influence of aspect ratio on average energy release rate

a/L = 0.30; tJL = 0.05; t2/t 1 ~ 0.10

900

Table 2. Reduction in

global buckling strength

of plate with elliptic

delamination: Effects of

the aspect ratio

a/b

R~

Rf

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.75

3.00

31.86

27.40

25.70

23.52

22.81

22.46

22.25

22.14

22.11

50.33

47.07

45.49

44.24

43.73

43.47

43.32

43.24

43.22

800

70 o

600

500

o/b =1.0

z,0o

v23 = 0.16; G12 = G13 = G 2 3 = 7500. T h e n u m e r i c a l e x p e r i m e n t s

are c o n d u c t e d for v a r y i n g r a t i o o f Y o u n g ' s m o d u l i i , E1/E 2 =

1.0-10.0; while fiber o r i e n t a t i o n is fixed a l o n g t h e m a j o r axis

o f t h e elliptic d e l a m i n a t i o n .

30 o

200

10 ~

0o

1

50

100

150

200

250

X

Fig. 19. Location of point of maximum pointwise energy release rate

a/L = 0.30; tJL = 0.05; tg/tt = 0.10

B o t h the local a n d global b u c k l i n g s t r e n g t h s i n c r e a s e as E1/E 2

increases (Fig. (26)). The local b u c k l i n g s t r e n g t h (2~c,) o f the

d e l a m i n a t e plate, as expected, increases linearly as E1 increases.

However, the global b u c k l i n g s t r e n g t h (2~r) of the d e l a m i n a t e d

50

230

0.035

III

2 o:30

0.030

220

40

0.025

g

>

210

-xu30

s,~ 0.020

0.015

20O

0.010

20

4~ ~

19o

0.O05

0

10

20

2;

3o

35

~0

0

180

a

Fig. 20. Effect of delaminate size on local and global buckling strengths

a/b = 1.50; tJL = 0.05; t i t 1 = 0.10

50

100

450

x

200

250

Fig. 22. Effect of delamination size on maximum energy release rate

a/b = 1.50; tJL = 0.05; t2/t 1 = 0.10

100000

Table 3. Reduction in

global buckling strength

of plate with elliptic

delamination: Effects of

the delamination size

10 000

1 000

100

a/L

Rb

Rf

0.40

0.50

0.60

0.70

0.80

22.26

23.32

25.69

31.86

31.86

43.45

44.22

45.51

48.07

52.70

10

g o

(~,gcr)FE

1

(2~)FE

0.1

0101

.

.

.

0.01

0.010

0.008

.

.

.

.

.

.

.

.

.

.

.

.

.

.

0.1

L/L

Fig. 23. Influence of the plate thickness (t~) on buckling strengths

of the delaminated plate a/b = 1.50; a/L = 0.30; t2/t I = 0.10

II I

I/I

1 Q--2o

2~

Table 4. Reduction in

global buckling strength

of plate with elliptic

delamination: Effects of

the laminate thickness

0.006

>

a

0.00~,

0.002

50

100

150

200

250

k

Fig. 21. Effect of delamination size on average energy release rate

a/b = 1.50; tl/L = 0.05; t2/t ~ = 0.10

structure increases initially a n d reaches a saturation point as

E 1 increases. Finite element solutions are obtained for the

critical buckling strength of equivalent u n d e l a m i n a t e d plates

of original laminate thickness tl a n d of base plate thickness t3:

~ r (t = tl) and 2~r(t = t3) respectively. As it can be observed from

Fig. (26), the critical buckling strength of the actual delaminated

plate is m u c h lower t h a n that of the original u n d e l a m i n a t e d

tJL

Rb

Rf

0.01

0.05

0.10

0.15

0.20

0.25

7.05

25.71

33.85

45.12

42.11

37.91

31.93

45.50

51.77

59.99

57.80

54.73

plate. It can be observed that, the delaminated plate is actually

weaker than the plate with the delaminated layers completely

peeled off.

Typical energy release rate distributions along the

d e l a m i n a t i o n front are shown in Fig. (27) for E~/E 2 = 8.0. Again,

the m a x i m u m energy release rate is observed to be in the vicinity

of the direction of m a x i m u m local-buckling-stiffness. For the

109

40

t2/t 1=0.10

o/b =1.50

a/L:0.30

8

7

7<./

/

~82

1

t~/L:O.05

0

0

10

20

30

40

tl/L =0.01

;

1;

50

60

70

~0

90

X

15

Fig. 27. Typical p o i n t w i s e e n e r g y release rate d i s t r i b u t i o n for

d e l a m i n a t e d o r t h o t r o p i c plate E1/E 2 = 8 (a/b = 1.50; a/L = 0.30;

tl/L = 0,05; tE/t ~ = 0.10)

Fig. 24. Influence of laminate t h i c k n e s s o n average energy release

rate a/b = 1.50; a/L = 0.30; t2/t ~ = 0.10

//

50

,oi

/

t2/t1=0.10

o/,:o.3o

8

/

~/

/

/

~-/

5

E

/

..;

~X-

~x //

40

/

?/~

~o 30

El/E2:

10

60

s~

~/

~.-I

,,'/.~ /

4

20

o

2

0

.

0

5

10

15

,~,~

1250

1000

~< 750, ~ . ~ 500 1

250 1

]

1

•Lcr

"

i

2

9

i

3

,

i

4

9

J

5

600

800

t i t I = 0.i0

aspect ratio of the delamination (a/b = 1.5) and the material

orthotropy (EllE 2 = 8.0) considered, the delaminate plate

exhibits maximum stiffness against buckling in the fiber

direction and hence the point of maximum pointwise energy

release rate is found to be at an angle of 0 ~ with reference to

the major axis. As E1 increases, the local buckling strength

increases and hence the energy release rate become significant

at higher compressive loads. However, the average and

maximum pointwise energy release rates are higher for higher

material orthotropy at local-post-buckling range of loads

(Fig. (28-29)).

1750

0

,

400

X

Fig. 28. Effect of orthotropic material properties on maximum

pointwise energy release rate a/b = 1.50; a/L = 0.30; tl/L = 0.05;

Fig. 25. Influence of l a m i n a t e thickness o n m a x i m u m e n e r g y release

rate a/b = 1.50; a/L = 0.30; talt ~ = 0.10

1500

200

9

i

9

i

6

7

El/E2

9

i

8

9

i

9

,

10

Fig. 26. Influence of material o r t h o t r o p y o n b u c k l i n g s t r e n g t h s

a/b = 1.50; a/L = 0.30; tJL = 0.05; ta/t ~ = 0.10

5.8

Effects of fiber orientation

Now the numerical experiments are repeated for the problem

considered in the previous section for varying fiber orientation

(~b = O, 15, 30, 45, 60, 75, 90); and the material orthotropyis fixed

at EllE 2 = 8.0.

The post-buckling deformation is plotted in Fig. (30) for

typical fiber orientations. When the fiber is along the major axis

of the delamination, the delaminate plate stiffness against

buckling along major axis is comparable with that along the

El/E2:

10

12.5

S

10.0

B

6

2

4

7.5

-1.0

. . . .

40

5.0

0

zu

a

2.5

n

200

400

>,

600

30 ~

0

50

0

10

183

S00

Fig. 29. Effect of orthotropic material properties on average pointwise

energy release rate a/b = 1.50; a/L = 0.30; tt/L= 0.05; t2/t ~= 0.10

-0.2

5-0.4

--0

0..8

6~

C

minor axis for the aspect ratio of delamination (a/b = 1.50) and

5O

LO

material orthotropy (E~/E 2 = 8.0) considered. Hence, the

0

lO 2o

20

postbuckling deformation conforms with the fundamental

Lu 30 540~ ~ 0 0 10

b

buckling mode in both x 1- and x2-directions. However, the

delaminate plate becomes much weaker in the major axis

direction against compressive loads as the fiber orientation

deviates from the major axis direction. Accordingly, the

delaminate plate deforms at a higher mode in the x~-direction

0

while it is undergoing postbuckling deformation in the

-0.2

f u n d a m e n t a l mode in the x2-direction. Initially, the local

buckling strength (21cr)slightly decreases as the fiber orientation ):-0.4

-0.6

(qb) increases; however, 2~crincreases for q5 > 30 ~ (Fig. (31)). The

finite element solutions for the critical buckling strengths of

50

4C

the equivalent undelaminated plates of thicknesses t~ and

0

t 3 -A~r(t = ti) and 2~ = t3) respectively- are found to be

~u 30 5L0~ ~ 0 0 10

maximum for fiber orientation ~b = 45 ~ The global buckling

o

strength of the actual delaminated plate (2gr) is, again, highly

underestimated when compared to both the undelaminated

configurations as shown in Fig. (31).

In the supplementary modes of buckling (shown in Fig. (30)),

the base plate comes in contact with the delaminate plate and

-0.1

accordingly the energy release rate becomes partially negative

-0.2

-0.3

along the delamination front. However, when the local and

global post-buckling deformations are complementary, the

50

pointwise energy release rate is positive all along the

30

delamination front (Fig. (32)). Accordingly, the location of

,v 30 ~

10

maximum energy release rate changes from 0 = 0 ~ to 0 = 75 ~

as the fiber direction changes from ~b = 0 ~to 0 = 90 ~ as shown in d

Fig. (33). The average and the maximum energy release rates

E1/E2:8.0; t2/t 1:0.10; a/b:1.50; tl/L=0.05; o/L:0.60

are plotted in Fig. (33) and Fig. (34) for typical fiber orientations

Fig. 30a-d. Influenceoifiber orientation on postbuckling deformation

and for varying load levels. For a typical post-buckling load

EI/E 2 = 8.0; a/b = 1.50; a/L = 0.30; tJL = 0.05; t21t~= 0.10. a ~b=0~

level (Z = 740.0), the average and the maximum energy release

2 = 465.3. b ~b= 30~ ). = 259.8. c ~b= 60~ 2 = 287.5. d ~b= 90~

rates vary as fiber orientation varies as shown in Fig. (35). The ~. = 299.6

energy release rate is again found to be maximum in the vicinity

of the direction of maximum-stiffness against compressive

loads (Fig. (36)).

an antisymmetric sense. The plate thickness is assumed as

5.9

t 1 = 0.05 L. The delamination configuration is fixed as: a/L = 0.3;

Antisymmetric laminate with central elliptic delamination

a / b = 1.50; and t2/t1 =0.10. The loading and boundary

In the following numerical experiments, the plate is assumed

conditions, and the finite element modeling are the same as in

to be a laminated composite with orthotropic layers stacked in the previous numerical experiments. The material properties

-

-

3o'~

70

X2

60

50

40

30

20

1 800

10

1 600

0

1 400

184

-10

25

1 200

,4

b ~ = 30 ~

1 000

20

800

15

600

400

0

10

x~r

200

o

/s

6'o

r

9o

E~/E2:8.0, t 2 / t ~ = 0 . 1 0 , { a / b : l . 5 0 : t J L - - 0 . 0 5 : a / L : 0 . 6 0

0

25

Fig. 31. Influence of fiber orientation on local and global buckling

strengths E~/E 2 = 8.0; a/b = 1.50; alL = 0.30; t J L = 0.05; t2/t ~ = 0.10

20

15

10

for each layer are taken as: E~ = 208000; E z = 26000; v12 = v~3 =

v23 = 0.16; Ga2 = G13 = Gz3 = 7500. All layers are assumed to be

of equal thickness. The following three lay-up sequences are

considered: (i) the laminate is composed of 20 laminae stacked

0

in the recursive sequence 0~176 (ii) the laminate is composed

14

of 100 laminae stacked in the recursive sequence 0~176 and

(iii) the laminate is composed of 20 laminae stacked in the

12

d 0:90 ~

recursive sequence - 450/45 ~ The numerical experiments are

10

conducted for symmetric and antisymmetric configurations for

8

the delaminate plate.

The local and global buckling strengths of the delaminated

6

plates are plotted for varying delaminate thicknesses in

4

Fig. (37). It can be noted that local buckling strength increases as

2

the delaminate thickness increases and becomes nearly equal

to or greater than the global buckling. The finite element

0

solution for the equivalent undelaminated plate with

-2

base-plate-thickness is also plotted for comparison. The global

10' 20' 30' 4o" 5'o 60' 7b 8'0 90

@

strength of the actual structure is less than the equivalent

undelaminated-base-plate-strength. The behavior is nearly

E l / E 2 = 8.0: t2/t 1 =0.10; o / b =1.50, t l / L = 0 . 0 5 r a / L = 0.60

identical for case-i and case-ii. The threshold delaminate

thickness for case-i and case-ii is found to be t2/t ~ = .175 while Fig. 32. Influence of fiber orientation on pointwise energy release

rate distribution E1/E 2 = 8.0; t2/t 1 = 0.10; a/b = 1.50; tt/L = 0.05;

that for case-iii is t2/tt = .08 below which critical buckling

a/L = 0.30

strength of the actual structure is less than that of the base-plate.

The residual drop of buckling strength is found to be

considerably less in case-iii when compared to the other two

cases.

Even though, case-i and case-ii show identical results with

symmetric delaminate configuration (tE/t 1 -- 0.15). It is found

reference to their buckling strengths, the energy release rate

that the energy release rate drops considerably when the number

distribution is found to be quite different. The energy release

of layers (for the same total laminate thickness) increases

rates are plotted along the delamination front for the three cases (compare case-i and case-ii). Since the angle-ply configuration

with antisymmetric delaminate configuration (t2/t ~ = 0.10) and (case-iii) makes the plate stiffer (note the rise in buckling

90

~=0 ~

10

60o

30~

75'

---.60

j

6

45-

90 o

4

3015-

2 84

0

'

0

i

01

0o

,

100

200

300

400

X

500

600

700

800

.

,"

. . . .

150

300

9

450

. . . .

600

75 ~

90~

*

Fig. 33. Influence of fiber orientation on average pointwise energy

release rate E J E 2 = 8.0; t21q = 0.10; a/b = 1.50; tJL = 0.05; a/L = 0.30

Fig. 36. Angle of m a x i m u m energy release rate for different fiber

orientations E J E 2 = 8.0; t2/t ~ = 0.10; a/b = 1.50; tJL = 0.05; a/L = 0.30

0=0 ~

20

18 5

1600 J ' N

o

60"

30~

12001

90~

~ 1 5 84

600

o

S

o11

a

i

1

i

200

400

600

BOO

Fig. 34. Influence of fiber orientation o n m a x i m u m pointwise energy

release rate E1/E2 = 8.0; t2/t ~ = 0.10; a/b = 1.50; tJL = 0.05; a/L = 0.30

~.0

L

X~cr

0'.2

ola

o.a

tJtl

2 000

.1200! ~

8001

///

"".

4oo

~%=740.0

30

0

0'.1

b

012

t2/tl

0.3

0.4

~'~20

j

$

Fig. 37a, b. A n t i s y m m e t r i c laminate with central elliptic delamination.

Influence of delaminate thickness on local a n d global buckling

strengths, tJL = 0.05; a/L = 0.30; a/b = 1.50; a n d E1/E2 = 8 . 0 for each

lamina, a 10 x (0o/90 ~ b 10 x ( - 45~ ~

-----...

10

9

0o

i

150

.

'

i

300

,

i

45 ~

,

J

60 ~

9

i

75~

90 ~

Fig. 35. Variation of average a n d m a x i m u m pointwise energy release

rates with fiber orientation E1/E 2 = 8.0; t2/t 1 = 0.10; a/b = 1.50;

tJL = 0.05; a/L = 0.30

s t r e n g t h s , Fig. (37b) w h e n c o m p a r e d to Fig. (37a), t h e e n e r g y

r e l e a s e r a t e is c o n s i d e r a b l y l o w e r w h e n c o m p a r e d to c a s e - i f o r

t h e s a m e l o a d level. T h e a v e r a g e a n d t h e m a x i m u m e n e r g y

release rates are plotted for different cases considered here in

Fig. (39).

16

18/

,

~"o/,~

1/-.

14[

12

,>'i,

10

8

6

6

qqS.'~

4

2

0

]86

I

-20o

I

10~

I

20 ~

I

I

30 o

40 ~

a,

50 o

I

600

I

I

70 o 50 ~

-2

e

0.010 /

.

.

.

i

90 ~

0~

i

100

i

i

20 ~

i

300

I

/*0~

d

i

50 o

i

600

i

70 ~ 500 90"

e

2.5

.

0.009 k

0.008 t ~ =87/..2

0.007 ~ "

2.0

0.006 Ix. 787.1

1.5

~ 0.005 k~69~. 8

0.00/,1 \

~\

0.003 612./,

1.0

0.5

o

o. ooi

0

~ 0 ~O01

I

0~

--

10 0

I

20"

I

I ~

30 ~

50 ~ 60 ~ 70 ~ 50 ~ 90 ~ -0.5 0 o

4"0~

b

e

10 ~

I

I

A

20 ~ 30 ~

I

400

,('~

10

30

I

60 ~ 70 o

I

500 900

@

e

35

I

500

.

.

.

.

.

.

.

8

25

6

20

~

~.~15

10

4

2

5

0

0

-5

i

0~

100

i

i

i

I

20 ~ 30 o 40"

500

I

i

-2

i

600 70 ~ 80 ~ 900

8

i

O"

f

10 ~

I

20"

i

300

i

i

40 ~ 500

e

i

~

i

600 70 ~ 50 ~ 90"

Fig. 38a-f. Antisymmetric laminate with central elliptic delamination. Influence of delaminate thickness on pointwise energy release rate

distribution a/b = 1.50; tl/L = 0.05; a l l = 0.30; E J E z = 8.0 for each lamina, a 10 x (00/90~ laminate tJt~ = 0.10. b 50 x (0o/90~ laminate

t2/t I =0.10. r 10 x ( - 450/45 ~ laminate tz/t ~ = 0.10. d 10 • (0o/90~ laminate t2/t ~ = 0.15. e 50 x (00/90~ laminate t2/t ~ = 0.15. f 10 x

( - 45o/45 ~ laminate t2/t ~ = 0.15.

5.10

Symmetric laminate with central elliptic delamination

In this section, the l a m i n a t e d plate considered in the previous

example is assumed to be symmetrically constituted with 32

orthotropic laminae in the following fashion: (i) ( 0 1 9 0 / 4 5 1 - 45),

a n d (ii) ( 4 5 / 9 0 / - 4 5 / 0 ) , . Material properties, laminate a n d

delaminate configurations, loading a n d b o u n d a r y conditions,

a n d finite element m o d e l i n g r e m a i n the same as in the previous

example. The d e l a m i n a t i o n is assumed to be between the n th

a n d the (n + 1) th layer from the top surface where n takes values

from 1 to 15.

The characteristic buckling strengths for the delaminated

structure are plotted in Fig. (40) for both case-i a n d case-ii. It

is found that the local buckling strength becomes nearly equal

for n = 8 or t J t l = 0.25. The threshold delaminate thickness for

which equivalent u n d e l a m i n a t e d base plate is stronger than the

actual structure in buckling is found to be 0.125 and 0.15 for

case-i a n d case-ii respectively. It is interesting to note that the

global buckling strength does not vary m u c h with the

delaminate thickness for case-ii.

The average a n d the m a x i m u m energy release rates are

plotted for case-i and case-ii for typical delaminate thickness

(n < 8) in Fig. (41) and Fig. (42). It should be noted that local

buckling does not occur when n > 8 a n d hence no delamination

growth is expected because of buckling action. Since the

delaminate alternates between symmetric a n d antisymmetric

2 000

1 800

1 600

1 4O0

200

/

x~

1 000

800

2a

6O0

4O0

~--...~,~ .

187

200

,

i

9

,

,

,

9

500

,

,

,

,

,

1000

1500

a

0

,

,

,

,

k

2 000

1 800

15

t 600

1400

1 200

~10

~

'~ I 000

E

J

800

6O0

5

400

2000

,

i

,

i

,

i

,

500

b

i

1000

,

i

,

i

1 10,(0~ ~ [erninote

2 50,(0~

~ tominute

3 lO,,(-/-,5~176

E~./E::8.0

(o)

(o)

(o)

for

Fig. 39a, b. Antisymmetric laminate with central elliptic delamination

a/b = 1.50; tJL = 0.05; a/L = 0.30. a Average pointwise energy release

rate. b Maximum pointwise energy release rate

configurations as n increases, the energy release rate variation

also changes for different delaminate thicknesses as shown

in the figures. Variation of the average and the maximum

energy release rates with the delaminate thickness is plotted

for typical load levels in Fig. (41c-d) and Fig. (42c-d)

respectively. It is observed that the average energy release rate

is lower for case-i while the maximum energy release rate is

lower for case-ii.

6

Concluding

0.05

b

t 2 / t l : 0 . 1 0 (b) t2/tl=0.15

t2/tl=0.10 (b) t2/t~=0.15

t2/t~=0.10 (b) t2/tl=O.15

each Lomino

remarks

In this paper, the reduction in buckling strength of a plate with

an elliptic delamination and the mechanisms of delamination

growth under post-buckling conditions, were critically

examined using a finite element method. A quasi-conforming

3-noded plate element based on Reissner-Mindlin plate theory

and the multi-plate modelling technique are used to model the

delaminated plate. Gauss elimination solution algorithm is used

to solve the incremental equations in a cycle of NewtonRaphson iterations. Arc-length controled load incrementation

and a linearised asymptotic solution for branch switching

are used for effectively traversing both limit and bifurcation

points.

,.

0

,

1500

X

Xt

0.10

0.15

0.20

0.25

t2/tl

Fig. 40a, b. Symmetric laminate plate with central elliptic delamination

Buckling strength reduction for different delaminate thickness, a Case-i.

b Case-ii a/b = 1.50; tt/L = 0.05; all = 0.30

The post-buckling solution and the energy release rate

models are validated using a simple classical p r o b l e m isotropic square plate with central near-surface delamination.

Influence of the following structural parameters on the local and

global buckling strengths of the structure, and on the pointwise

energy release rates along the delamination front, are critically

studied:

delaminate plate thickness (tJtl),

aspect ratio of the delamination (a/b),

size of delamination (a/L),

total laminate thickness (tJL),

material orthotropy (EJE2),

fiber orientation (~b),

antisymmetric laminate with

symmetric/antisymmetric delaminate plates

(viii) symmetric laminate with symmetric/asymmetric

delaminate plates

(i)

(ii)

(iii)

(iv)

(v)

(vi)

(vii)

The influence of these parameters are in particular examined

regarding the reduction of the structural strength against

buckling, coupling of local and global post-buckling solutions,

and pointwise energy release rate at the delamination front.

Several observations are made regarding the post-buckling

failure mechanisms.

15

!5

I

.

"1

aC

4

bC

10

15"

>

TO "

5

54

~88

O]

400

800

1200

.,

. . . . . . . . . . .

0

400

~00

X

1200

x

0.4

25

e-]l

Case -11

20

0.3

15

02

~10

0.1

Fig. 41a-d. Symmetric

composite plate with central

elliptic delamination Average

pointwise energy release rate

a/b = 1.50; tJL = 0.05;

a/L = 0.30

5

0

0

0

c At X- z,00

0.1

0.2

0

t2/tl

0.1

d At ;L =1300

Z,0

0.2

t2/tl

40

a Case-I

[/ 5

30

/

b Case-]I

30'

20

~-~ 20'

10

10.

0

0

0

400

800

5

1200

9

i

0

9

i

,

r

9

i

/,00

'

i

9

800

i

'

1200

x

4O

0.6

30

~

-

I

0.4

~ 20

0.2

10

0.1

c At,L : 400

0.2

t~/tl

00.1

d At ;~ =1300

0.2

t,~/tl

Fig. 42a-d. Symmetric

composite plate with central

elliptic delamination Maximum

pointwise energy release rate

a/b = 1.50; tl/L = 0.05;

a/L = 0.30

of Excellence of Computational Modelling of Aircraft Structures,

References

Atluri, S. N. 1986: Energetic approaches and path independent integrals Georgia Tech., Atlanta

Naganarayana, B. P. 1991: Consistency and correctness principles in

in fracture mechanics. In: Atluri, S. N. (ed): Computational methods

quadratic displacement type finite elements. Ph.D. Dissertation, Indian

in mechanics of fracture, Amsterdam: North-Holland

Barlow, ]. 1976: Optimal stress locations in finite element models. Int. Institute of Science, India

Naganarayana, B. P.; Atluri, S. N. 1994: Energy release rate evaluation

J. Numer. Meths. Engg. 10:243-251

for delamination growth prediction in a multi-plate model of a laminate

Chai, H.; Babcock, C. D.; Knauss, W. G. 1981: One-dimensional

modelling of failure in laminated plates by delamination buckling. Int. composite. Comput. Mech. (to appear)

Naganarayana, B. P. 1994: Incremental iterative strategies for

J. Solids and Struct. 17(11): 1069-1083

automated post-buckling analysis. (To be published)

Huang, B-Z.; Shenoy, V. B.; Atluri, S. N. 1994: A quasi-conforming

triangular laminated composite shell element based on a refined first Timoshenko, S. P. 1940: Theory of plates and shells. 1st Ed., McGraw

Hill, New York, 1940

order theory. Comput. Mech. 13:295-314

Huang, B.-Z.; Atluri, S. N. 1994: A simple method to follow postbuckling paths in finite element analysis. Internal Report, FAA Center

189