E%ect of electric &elds on fracture behavior of ferroelectric ceramics H.G. Beom

advertisement

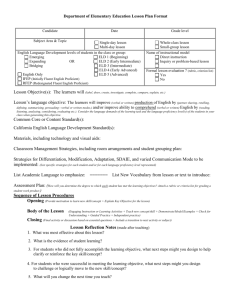

Journal of the Mechanics and Physics of Solids 51 (2003) 1107 – 1125 www.elsevier.com/locate/jmps E%ect of electric &elds on fracture behavior of ferroelectric ceramics H.G. Beoma;∗ , S.N. Atlurib a Department of Mechanical Engineering, College of Engineering, Chonnam National University, 300 Yongbong-dong, Kwangju 500-757, South Korea b Center for Aerospace Research & Education, School of Engineering and Applied Science, University of California at Los Angeles, 7704 Boelter Hall, Los Angeles, CA 90095-1600, USA Received 30 May 2002; received in revised form 25 October 2002; accepted 7 December 2002 Abstract The asymptotic problem of a semi-in&nite crack perpendicular to the poling direction in a ferroelectric ceramic subjected to combined electric and mechanical loading is analyzed to investigate e%ect of electric &elds on fracture behavior. Electromechanical coupling induced by the piezoelectric e%ect is neglected in this paper. The shape and size of the switching zone is shown to depend strongly on the relative magnitude between the applied electric &eld and stress &eld as well as on the ratio of the coercive electric &eld to the yield electric &eld. A universal relation between the crack tip stress intensity factor and the applied intensity factors of stress and electric &eld under small-scale conditions is obtained from the solution of the switching zone. It is found that the ratio of the coercive electric &eld to the yield electric &eld plays a signi&cant role in determining the enhancement or reduction of the crack tip stress intensity factor. The fracture toughness variation of ferroelectrics under combined electric and mechanical loading is also discussed. ? 2003 Elsevier Science Ltd. All rights reserved. Keywords: A. fracture; B. crack mechanics; ferroelectrics; C. asymptotic analysis; domain switching 1. Introduction Ferroelectric ceramics have been extensively investigated for applications as smart structures. Examples of widely used ferroelectric ceramics are barium titanate (BaTiO3 ), lead zirconate titanate (PZT) and lead lanthanum zirconate titanate (PLZT). The attractive use of ferroelectric ceramics has been in sensors, actuators and nonvolatile ∗ Corresponding author. Tel.: +82-62-530-1682; fax: +82-62-530-1689. E-mail address: hgbeom@chonnam.ac.kr (H.G. Beom). 0022-5096/03/$ - see front matter ? 2003 Elsevier Science Ltd. All rights reserved. doi:10.1016/S0022-5096(03)00004-8 1108 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 ∞ K IC 0 K IC Type I Type II Type III K E∞ Fig. 1. Typical types of fracture toughness variation for ferroelectric ceramics. memories. The subject of reliability of smart structures composed of ferroelectric ceramics has recently gained much attention. Crack growth in a ferroelectric material is a potential reliability concern. Considerable researches have been devoted to problems for the e%ects of an electrical &eld on the crack growth in a piezoelectric material. In the previous works, the fracture toughness of ferroelectric ceramics under combined mechanical and electrical loading has been analyzed as a function of applied electric &elds. Experimental studies for cracks perpendicular to the poling direction in various PZT ceramics have been carried out in order to explore the role of electric &eld on fracture behavior. Tobin and Pak (1993) performed indentation tests on PZT-8 specimens. They found that a positive electric &eld with the same direction of the polarization reduces the apparent fracture toughness, while a negative &eld with the direction opposite to the polarization enhances the apparent toughness. Subsequently, Park and Sun (1995) used conventional fracture tests to investigate electric &eld e%ects on crack growth in a PZT-4 ceramic under combined mechanical and electrical loading. They obtained the result consistent with that of Tobin and Pak (1993). However, Wang and Singh (1997) observed opposite phenomena in the crack growth in a PZT EC-65 ceramic under applied electric &elds from Vickers indentation tests. Their results showed that a positive electric &eld impedes crack propagation, whereas a negative electric &eld promotes crack propagation. Recently, Fu and Zhang (2000) also performed compact tension tests and indentation fracture tests on a PZT-841 ceramic. They observed the reduction in the fracture toughness for a positive electric &eld as well as for a negative electric &eld. As seen in the previous works, the inHuence of electric &eld on fracture toughness is di%erent for each piezoelectric material. The experimental results obtained in the previous works can be classi&ed into three types of fracture toughness variation for ∞ piezoelectric ceramics, which are shown in Fig. 1. Here KIC is the apparent fracture H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1109 0 toughness, KIC is the fracture toughness under purely mechanical loading, and KE∞ denotes the applied intensity factor of the electric &eld. It is seen easily from Fig. 1 that regardless of the direction of applied electric &eld, the electric &eld may enhance or reduce the apparent fracture toughness, depending on each PZT material. This result gives a suggestion that the fracture toughness variation may be controlled by material properties characterizing each piezoelectric ceramic. On the other hand, several theoretical models have been proposed to evaluate the e%ect of electric &eld on fracture toughness of ferroelectric ceramics. Analysis based on linear theory yields the symmetric variation of fracture toughness as a function of the applied electric &eld, which disagrees with the experimental observations. Ferroelectric ceramics show electrically nonlinear behavior at high electric &eld. The electric displacement in a ferroelectric ceramic attains a saturation value at large electric values. An electrical nonlinear zone typically forms at distances close to the crack tip since the linear theory predicts the singular behavior of the electric displacement near the crack tip. Gao and Barnett (1996) and Gao et al. (1997) employed the model of strip saturation near the crack tip to examine the e%ect of the electrical nonlinearity on fracture behavior. Their result shows that the fracture toughness of a piezoelectric material depends linearly on the applied electric &eld. Fulton and Gao (2001) also proposed recently a model for electrical nonlinearity to investigate e%ect of local polarization switching on piezoelectric fracture. Yang and Zhu (1998) studied switch toughening in ferroelectrics subjected to combined electrical and mechanical loading. They estimated the toughness variation from the change of crack tip stress intensity induced by the domain switching near the crack tip. Their result shows the asymmetric variation of fracture toughness of ferroelectrics as a function of the applied electric &eld. Subsequently, Zeng and Rajapakse (2001) evaluated rigorously fracture toughness variation in anisotropic ferroelectrics with electromechanical coupling based on the domain switching model. Zhu and Yang (1997) studied the inHuence of the crack surface boundary condition on toughness variation of ferroelectrics by domain switching. Their model based on linear theory shows that the change of the crack tip stress intensity factor due to the domain switching is sensitive to the modeling of the boundary condition on the crack surface. Thus, their model requires knowledge of accurate crack surface boundary condition. Each model mentioned above is successful in giving a theoretical explanation for the experimental observation on fracture behavior of a speci&c piezoelectric material. However, a uni&ed model consistent with various experimental observations of fracture behavior in ferroelectric ceramics has not been developed as yet. The purpose of this study is to investigate the e%ect of electric &elds on fracture behavior of ferroelectric ceramics subjected to combined electric and mechanical loading. In order to derive the form of a universal relation between the crack tip stress intensity factor and the applied intensity factors of stress and electric &eld under small-scale conditions, the asymptotic problem of a semi-in&nite crack in a ferroelectric ceramic is analyzed. The material shows the electrical nonlinearity at distances close to the crack tip, whereas the material is still linear mechanically. When the sizes of the electric nonlinear zone and the switching zone around the crack tip are comparable with each other, the nonlinear electric &eld state inHuences the domain switching of the material. 1110 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 The nonlinear solution of the electric &eld is used to estimate the shape of the domain switching zone. It is shown that the shapes of the switching zone boundaries depend strongly on the relative magnitude between the applied electric &eld and stress &eld as well as on the ratio of the coercive electric &eld to the yield electric &eld. The change of the crack tip stress intensity factor due to the switching is evaluated from the solution of the switching zone. The fracture toughness variation of ferroelectrics is also discussed. 2. Ferroelectric ceramics A summary of ferroelectric properties such as a spontaneous polarization and a ferroelectric domain can be found in Ja%e et al. (1971), Lines and Glass (1977) and Xu (1991). A detail of a constitutive law for ferroelectric ceramics has been given in Hwang et al. (1995), Huber et al. (1999), Kamlah and Tsakmakis (1999) and Sze and Pan (2001). Much attention has been still devoted to constitutive models of ferroelectric ceramics for domain switching and electric saturation. Ferroelectric materials have strong electric nonlinearities at large &eld strengths. As an applied electric &eld is increased, the electric displacement of a ferroelectric material approaches &nite limit, referred to as electric saturation. Some ferroelectric materials exhibit piezoelectric behavior. The piezoelectric e%ect causes a coupling between electric and mechanical &elds. In order to investigate the role of electric &eld in fracture behavior, we introduce a simple constitutive model for the ferroelectric ceramics. For mathematical simplicity, it is assumed that the ferroelectric material has perfect polarization saturation. A nonhardening material leads to simple analysis of fracture behavior. An idealized behavior of typical ferroelectric ceramics is shown for the electric displacement versus electric &eld in Fig. 2. Such a curve is of fundamental importance for describing the properties of ferroelectric materials. The ferroelectric material has the magnitude of the spontaneous polarization Ps , the coercive electric &eld Ec and the yield electric &eld E0 . First, D Ps Ec E0 E Fig. 2. Idealized electric displacement–electric &eld curve for a typical ferroelectric material. H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1111 consider the ferroelectric material with negative remnant polarization −Ps . A positive electric &eld is applied, which has the direction opposite to the current polarization. Under the small value of electric &eld, the electric displacement obeys a linear law and the slope is equal to the dielectric permittivity. When the applied electric &eld reaches the coercive &eld, the ferroelectric domain switching is induced. The polarization switches to the same direction of the applied electric &eld. Upon further increase of the electric &eld, the electric displacement reaches a perfect saturation value. The onset of polarization saturation occurs at E = E0 . Next, we consider the ferroelectric material with positive remnant polarization Ps . A positive electric &eld has the same direction to the current polarization. The direction of polarization vector is not changed even though an applied positive electric &eld exceeds the coercive &eld since the domain is oriented in the direction of the applied electric &eld. For the applied electric &eld exceeding the yield electric &eld, the electric displacement is perfectly saturated. Ferroelectric ceramics possess domains with uniform polarization. SuNciently large external loads such as electric &eld and stress can induce 90◦ or 180◦ domain switchings. Polarization switch characterizes a feature of ferroelectrics. A switching criterion governs the polarization switch. The domain switching criterion proposed by Hwang et al. (1995) is employed here for the analysis. Their switching criterion has the following form: ij Oij + Ei OPi ¿ 2Ps Ec : (1) Here, ij and Ei are the stress tensor and the electric &eld vector, respectively. Oij and OPi denote the changes in the spontaneous strain and spontaneous polarization, respectively. In developing the above energy-based criterion, the same energy barrier is assumed to be of 90◦ and 180◦ domain switchings. Consider a ferroelectric material with a uniformly poled domain. The initial polarization vector forms an angle with x1 -axis. We are concerned only with the simple case of mono-domain ferroelectrics in this paper. When the switching criterion (1) is satis&ed under combined mechanical and electrical load, polarization switching occurs. There are strain changes associated with the domain switching. The changes in spontaneous strain and polarization due to 90◦ domain switching can be expressed as (Yang and Zhu, 1998) 3 cos ± 4 √ OPi = 2Ps ; sin ± 3 4 −cos 2 −sin 2 ; (2) Oij = s −sin 2 cos 2 where s is the spontaneous strain associated with 90◦ domain switching, and the values of − 34 and + 34 in (2) indicate the quantities for clockwise and counterclockwise 90◦ switchings, respectively. For 180◦ domain switching, the changes of the polarization 1112 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 switch vector and switching strain tensor are given, respectively, as cos OPi = −2Ps ; sin Oij = 0: (3) It is noted that the 90◦ domain switching generates strains whereas no strains are induced due to the 180◦ switching. Thus, the mechanical load satisfying the switching criterion (1) induces only 90◦ domain switching, while the electrical loading can generate 90◦ or 180◦ domain switchings. 3. Asymptotic problem 3.1. Crack tip ;elds for a nonlinear dielectric Consider a crack in a ferroelectric ceramic under combined electric and mechanical loading. Tractions and charge vanish on the crack surfaces. Here we are only concerned with the case in which the crack surfaces are electrically impermeable. Studies on crack surface boundary conditions have been widely performed. Examples of contributions to the subject can be found in Zhang et al. (2002). Small-scale conditions are assumed in this study. Under the small-scale conditions, the sizes of the nonlinear zone and the switching zone around the crack tip are suNciently small compared with the length of the crack. In order to investigate the e%ect of the electric &eld on fracture behavior under the small-scale conditions, we consider the asymptotic problem of a semi-in&nite crack in a ferroelectric ceramic under combined electric and mechanical loading as shown in Fig. 3. The material is assumed to be isotropic in this paper. Neglecting the material anisotropy, there is no electromechanical coupling induced by the piezoelectric x2 r θ R0 R Θ x1 Fig. 3. Asymptotic problem of a crack in a ferroelectric material. H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1113 e%ect. Under the small-scale conditions, the remote &elds in the asymptotic problem are given by the near-tip &elds for the crack in the linear material. Introducing cylindrical coordinates r and centered at the tip of the crack as shown in Fig. 3, the stress &eld and electric &eld at in&nity are written as K∞ ij = √ I ˜ij (); 2r K∞ Ei = √ E Ẽ i (): 2r (4) Here KI∞ and KE∞ denote the applied stress intensity factor of the Mode I and the applied intensity factor of the electric &eld, respectively. ˜ij () and Ẽ i () are the universal distribution functions of stress and electric &eld, respectively. At distances close to the crack tip, the material is still linear mechanically whereas the material shows the electrical nonlinearity. The stress &eld near the crack tip is thus expressed as K tip ij = √ I ˜ij () 2r as r → 0; (5) where KItip represents the crack tip stress intensity factor of the Mode I. KItip is di%erent from KI∞ due to domain switching, and will be determined exactly later. The solution of the electric &eld for the asymptotic problem can be obtained from a well-known solution for a mode III crack in a perfect plastic material (Rice, 1967; Beom, 1999). In order to express the solution of the electric &eld in a compact form, we introduce another set of cylindrical coordinates (R; ) with the origin located at the point (R0 ; 0) as shown in Fig. 3. Here R0 is the radius of the saturation zone with the circular shape, given by 2 1 KE∞ R0 = : (6) 2 E0 The material outside the cylinder with radius R0 is linear dielectric, whereas inside the cylinder the ceramic is the perfect saturation material. The solution of the electric &elds outside the electrical nonlinear zone (R ¿ R0 ) is given as 1 K∞ ER = √ E sin ; 2 2R 1 K∞ E = √ E cos : 2 2R (7) The electric &elds inside the electrical nonlinear zone (R ¡ R0 ) can be written as Er = 0; E = 2E0 R0 cos : r (8) 1114 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 3.2. Domain switching zone A domain switching zone typically forms around the tip of a crack in ceramics. We &rst estimate the shape of the domain switching zone in order to evaluate the crack tip stress intensity factor due to the domain switching. Exact determination of the shape of the domain switching zone is diNcult since the form of the switching zone boundary depends on the redistribution of the stress and electric &eld due to the domain switching. A &rst approximation to the shape of the switching zone can be obtained by using the stress &eld (4), and the electric &elds (7) and (8). In this calculation, the zone shape changes due to the redistribution of the stress and electric &eld are neglected. The stress &eld (4) together with (7) and (8) can be substituted into the switching criterion (1) to derive the shape of the switching zone. This leads to the following dimensionless form of an expression for the switching zone boundary: r=Rc = r̃(; ; Ec =E0 ); (9) where Rc and are given, respectively, as 2 1 s KI∞ Rc = ; 2 Ps Ec = Ps KE∞ : s KI∞ (10) In obtaining (9), a dimensional analysis has been performed. The length parameter Rc and dimensionless parameter have been originally proposed by Zhu and Yang (1997). On the physical ground, the domain switching occurs in the direction with larger value of r when the criterion (1) is satis&ed for 90◦ switching and 180◦ switching. The range of the angle for the switching zone is determined so as to satisfy the condition r ¿ 0. 3.3. The stress intensity factor Under the small-scale conditions, we derive the form of a universal relation between the local crack tip stress intensity factor and the applied intensity factors of stress and electric &eld. The switching strains cause deformation mismatch across the boundary of the switching zone under the constraint of the unswitched material. The material both outside and inside switching zone undergoes an additional deformation to match the displacements and surface tractions along the boundary of the switching zone. Consequently, the strains induced by the domain switching around the crack tip generate additional stresses. Thus, the crack tip stress intensity factor is di%erent from the applied stress intensity factor due to the additional stress intensity factor induced by domain switching. The local crack tip stress intensity factor KItip is related to KI∞ by KItip = KI∞ + OKItip : (11) H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1115 Here OKItip is the change of the crack tip stress intensity factor induced by the switching strains, which can be evaluated by an Eshelby technique or the Duhamel analogy for thermal stress analysis. The explicit form of OKItip can be found in Rice (1985) and Gao (1989) for an elastic material with transformation strains, which is expressed as Y Uij Oij dA: (12) OKItip = 1+ A Here Y and denote the Young’s modulus and the Poisson’s ratio, respectively. A is the switching region. Uij (r; ) is the near-tip weight function given by cos 32 + 3 cos 72 −3 sin 32 + 3 sin 72 1 √ U(r; ) = : 16(1 − ) 2r 3=2 −3 sin 32 + 3 sin 72 7 cos 32 − 3 cos 72 (13) Once the boundary of the domain switching zone is found from (9), the change in crack tip stress intensity can be calculated by (12). 4. Numerical results and discussion In order to seek the form of a universal relation between the crack tip stress intensity factor and the applied intensity factors of stress and electric &eld, we consider the asymptotic problem of a semi-in&nite stationary crack lying along the negative x1 -axis. The remote &eld in the asymptotic problem is prescribed to be the near-tip &eld of the crack problem (4). Here we are only concerned with the case of = 90◦ in which the crack surface is perpendicular to the poling direction. When a positive electric &eld is applied, which has the same direction of the polarization, the electric intensity factor KE∞ has a positive value. The electric intensity factor is negative for a negative applied electric &eld with the direction opposite to the polarization. Due to the symmetry of the problem, any nonzero stress intensity factor of the Mode II for the crack with a switching zone near the crack tip is not induced. For convenience, we consider separately the problem under the combined loading and purely electric loading since the dimensionless parameter tends to in&nity when a purely electric loading is applied. 4.1. Combined mechanical and electrical loading We consider a stationary crack in a ferroelectric ceramic subjected to combined electrical and mechanical loading. It is convenient to consider separately the problem under the positive electric &eld or the negative electric &eld. We consider &rst the case under the positive electric &eld. Inserting (2)–(4), (7) and (8) into (1), the expression of the switching zone shape for the case in which KE∞ ¿ 0 can be obtained. Making use of the condition of r ¿ 0, it can be shown that a 180◦ switching does not occur under a positive electric &eld, and the domain may switch 90◦ clockwise or counterclockwise. On the physical ground, the actual domain switching occurs in the direction with larger value of r. The forms of the boundaries of the 90◦ switching zone inside the saturation 1116 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 0.3 0.3 o 90 switching R=R0 90o switching zone 0.2 0.2 0.1 x2/Rc x2/Rc 0.1 0.0 (a) 0.0 -0.1 -0.1 -0.2 -0.2 -0.3 -0.3 -0.2 -0.1 0.0 x1/Rc 0.1 0.2 -0.3 -0.3 0.3 (b) 90o switching R=R0 90o switching zone -0.2 -0.1 0.0 0.1 0.2 0.3 x1/Rc Fig. 4. Domain switching zones for = 1 with (a) Ec =E0 = 1=3 and (b) Ec =E0 = 1. zone (R ¡ R0 ) and outside the saturation zone (R ¿ R0 ) can be expressed for ¿ 0, respectively, as 1=2 √ Ec 2 3 1 r 1 3 2 2 3 sin sin + 2 cos cos ||− = − sin sin + ; Rc 4 2 16 2 E0 4 ; for R ¡ R0 ; ¡ || ¡ 4 2 r sin 1 3 1 3 1 = − sin sin + √ cos − || for R ¿ R0 : (14) Rc 2 2 sin 4 2 2 Here it is noted that the 90◦ switching zones in upper half plane (x2 ¿ 0) and lower half plane (x2 ¡ 0) have clockwise and counterclockwise 90◦ switchings, respectively. The clockwise and counterclockwise 90◦ domain switchings, however, generate same strains. Thus, we make no distinction between them in this paper since they have the same inHuence on the change of the crack tip stress intensity factor. It can be seen easily from (14) that the switching zones are symmetric about the crack plane. In the limiting case as E0 → ∞, (14) reduces to the following closed form: 3 r 1 3 1 1 = − sin sin + √ cos (15) − || : Rc 2 2 4 2 2 This is identical to the well-known result for a linear dielectric (Zhu and Yang, 1997). For the special case of = 0 in which no external electrical loading is applied, (14) reduces to 3 r 1 (16) = − sin sin : Rc 2 2 The shapes of the switching zone boundaries predicted from (14) are shown in Fig. 4 for = 1 with two speci&c values of Ec =E0 , respectively. In calculating H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1117 0.2 K E∞ > 0 K Itip K I∞β 0.1 β= 0.1 β= 1 β= 10 0.0 -0.1 -0.2 0.0 0.2 0.4 0.6 0.8 1.0 Ec E0 Fig. 5. Change of the crack tip stress intensity factor as a function of Ec =E0 with various positive . numerically the switching zone boundary outside the saturation zone, the relation r R0 = (17) sin sin( − ) has been used. Here the length parameter Rc is used in normalizing the coordinates. It is seen from the numerical calculation that the switching zone size becomes larger as increases. It is found that the shape and size of the switching zone for small is insensitive to Ec =E0 , whereas the inHuence of Ec =E0 on the switching zone becomes stronger as gets larger. Using (2) and (12), the explicit expression of OKItip for the case of = 90◦ is obtained as r 3 5 OKItip = − KI∞ sin sin d; (18) 2 R 2 c 0 where r is the boundary of the 90◦ switching zone as a function of , and is the dimensionless parameter given by Y2s = : (19) (1 − 2 )Ps Ec According to Yang and Zhu (1998), the range of for typical ferroelectric ceramics is 5 ¡ ¡ 20. It is worth mentioning that a 90◦ switching zone in the region tip 2 4 5 ¡ ¡ 5 makes a positive contribution to OKI , while the contribution of a 90◦ switching zone in the region 0 ¡ ¡ 25 and 45 ¡ ¡ to OKItip is negative. Once the integral in (18) is performed numerically, OKItip can be obtained directly. In Fig. 5, the numerical results of the change of the crack tip stress intensity factor due to the switching are plotted as a function of Ec =E0 , for speci&c values of . It is seen 1118 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 from Fig. 5 that OKItip for the case of KE∞ ¿ 0 depends on and Ec =E0 strongly. Ec =E0 plays a signi&cant role in determining the sign of OKItip . OKItip has a positive value for Ec =E0 ¡ 0:4 and a negative value for Ec =E0 ¿ 0:6, respectively. This result implies that fracture toughness of the ferroelectric material under a positive electric &eld may be increased or decreased depending on Ec =E0 . Before proceeding, it is noted that the domain switching makes no contribution to OKItip for the case of = 0, which has been showed for elastic ceramics with dilatant transformation by McMeeking and Evans (1982) and Budiansky et al. (1983). Next, we consider the case of KE∞ ¡ 0 in which a negative electric &eld is applied. The solution procedure is similar to the case of KE∞ ¿ 0, which is brieHy described as follows. The expressions for the switching zone boundaries as a function of inside the saturation zone (R ¡ R0 ) are given for ¡ 0, respectively, as 1=2 √ Ec 2 r 1 3 3 1 2 2 3 =− sin sin + cos cos ||+ sin sin − 2 Rc 4 2 16 2 E0 4 for 90◦ switching; Ec 2 r =2 cos2 Rc E0 for 180◦ switching: (20) The geometry of the switching zones outside the saturation zone (R ¿ R0 ) can be expressed for ¡ 0, respectively, as 3 r sin 1 3 1 1 cos = − sin sin − √ + || for 90◦ switching; Rc 2 2 sin 4 2 2 R 1 = 2 cos2 Rc 2 for 180◦ switching: (21) It is noted that a 180◦ switching may occur under a negative electric &eld, in contrast to the case in which a positive electric &eld is applied. The shapes of the 90◦ switching zones obtained from (20) and (21) are shown in Fig. 6 for = −1 with two speci&c values of Ec =E0 , respectively. It is seen from the numerical result that the shape and size of the switching zone depend on and Ec =E0 strongly. A 180◦ switching makes no contribution to OKItip since a 180◦ switching produces no strain. Thus, performing the integral in (18) for the 90◦ switching zone, we obtain OKItip . Fig. 7 illustrates the e%ect of Ec =E0 and on OKItip for the case of KE∞ ¡ 0. It is seen from Fig. 7 that the values of OKItip are positive for Ec =E0 ¡ 0:4 and negative for Ec =E0 ¿ 0:6, respectively. This result implies that the fracture toughness of the ferroelectric material under a negative electric &eld may also be increased or decreased depending on Ec =E0 . 4.2. Electrical loading Consider a stationary crack perpendicular to the poling direction under purely electrical loading. For the case in which no external mechanical loading is applied, Rc is taken to be zero and goes to in&nity. The length parameter R0 is thus employed as a reference length scale to normalize the coordinates. Substituting (4), (7) and (8) into H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1.5 1.5 o 90 switching 180o switching 1.0 0.5 x2/Rc x2/Rc 90o switching 180o switching 1.0 0.5 0.0 0.0 -0.5 -0.5 R=R0 90o switching zone -1.0 -1.5 -1.0 (a) 1119 -0.5 0.0 0.5 x1/Rc 1.0 -1.0 1.5 -1.5 -0.5 2.0 R=R0 90o switching zone 0.0 0.5 1.0 1.5 2.0 2.5 x1/Rc (b) Fig. 6. Domain switching zones for = −1 with (a) Ec =E0 = 1=3 and (b) Ec =E0 = 1. 0.2 KE∞ < 0 β= -0.1 β= -1 β= -10 KItip K I∞ β 0.1 0.0 -0.1 -0.2 0.0 0.2 0.4 Ec E0 0.6 0.8 1.0 Fig. 7. Change of the crack tip stress intensity factor as a function of Ec =E0 with various negative . (1), the shape of the 90◦ switching zone for KE∞ ¿ 0 can be determined, which results in √ E0 3 r = 2 cos cos || − ; ¡ || ¡ ; for R ¡ R0 ; R0 Ec 4 4 2 2 1 R 3 1 E0 − || ; ¡ || ¡ ; for R ¿ R0 : = cos2 (22) R0 2 Ec 4 2 2 1120 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 2 0.4 90o switching R/R0=1 90o switching zone o 90 switching R/R0=1 90o switching zone 0.2 x2 /R0 x2/R0 1 0 -1 -2 0.0 -0.2 -2 -1 (a) 0 x1/R 0 1 -0.4 2 (b) -0.4 -0.2 0.0 0.2 0.4 x1/R0 Fig. 8. Domain switching zones induced by a positive electric &eld for (a) Ec =E0 = 1=3 and (b) Ec =E0 = 1. In a similar manner, it can be shown that the expressions for the switching zone boundaries are given for KE∞ ¡ 0 as inside the saturation zone: √ E0 r 3 = 2 cos cos || + ; || ¡ ; for 90◦ switching; R0 Ec 4 2 r E0 =2 cos2 R0 Ec for 180◦ switching; outside the saturation zone: 2 R 3 1 E0 1 = cos2 + || ; || ¡ ; for 90◦ switching; R0 2 Ec 4 2 2 1 R E0 = cos2 || for 180◦ switching: R0 Ec 2 (23) It is noted that any 180◦ switching does not occur under a positive electric &eld, in contrast to the case under a negative electric &eld. The shapes of the switching zone boundaries can be obtained from (23), which are shown in Figs. 8 and 9 for two speci&c values of Ec =E0 , respectively. Introducing integral I de&ned by 3 Ec r 5 I =− sin sin d; (24) 2 E0 0 R0 2 the expression of OKItip in (18) is rewritten as OKItip = |KE∞ |I (Ec =E0 ; sgn(KE∞ )); (25) H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 2 10 o 90 switching 180 o switching x 2 /R0 x2/R 0 90o switching 180o switching 1 5 0 0 -1 -5 R/R0=1 90o swicthing zone R/R0=1 90o swicthing zone -10 1121 -5 0 (a) 5 10 x1/R0 -2 15 -1 0 (b) x1/R0 1 2 Fig. 9. Domain switching zones induced by a negative electric &eld for (a) Ec =E0 = 1=3 and (b) Ec =E0 = 1. 0.2 KE∞ > 0 KE∞ < 0 KItip KE∞ 0.1 0.0 -0.1 -0.2 0.0 0.2 0.4 Ec E0 0.6 0.8 1.0 Fig. 10. Change of the crack tip stress intensity factor due to an electric &eld as a function of Ec =E0 . where is given by Ys = : (1 − 2 )Ec (26) It is noted that OKItip depends linearly on KE∞ since the integral I is a function of Ec =E0 and the sign of KE∞ only. Performing the integral in (24) numerically, OKItip can be obtained from (25). Fig. 10 illustrates the e%ect of Ec =E0 on OKItip for KE∞ ¿ 0 and ¡ 0. It is noted that Ec =E0 plays a signi&cant role in determining the sign of OKItip . 1122 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 10 8 Ec/E0= 1 Ec/E0= 2/3 Ec/E0=0.525 Ec/E0= 1/3 Ec/E0= 0 K Itip K I∞ 6 4 2 0 -2 -4 -40 -20 0 β 20 40 Fig. 11. Change of the crack tip stress intensity factor as a function of . The stress intensity factor due to the strains induced by the switching under the electric &eld has a positive value for Ec =E0 ¡ 0:4 and negative for Ec =E0 ¿ 0:6, respectively. The absolute value of KItip under a negative electric &eld is larger than that under a positive electric &eld. The negative stress intensity factor leads to overlapping of the crack surfaces. The surfaces of the crack cannot be thus open completely and the surfaces of the crack contact near the crack tip. This result implies that under purely electrical loading, fracture may occur for a ferroelectric material with Ec =E0 ¡ 0:4, while fracture of a ferroelectric material with Ec =E0 ¿ 0:6 cannot be caused. 4.3. Fracture toughness variation The additional stress intensity factor induced by domain switching is obtained numerically for the crack under combined mechanical and electrical loading as shown in the previous section. The change of the crack tip stress intensity factor due to the domain switching is plotted in Fig. 11 for various values of Ec =E0 as varies. It is seen from Fig. 11 that regardless of the direction of an applied electric &eld, the value of Ec =E0 plays a signi&cant role in determining the enhancement or reduction of the crack tip stress intensity factor. KItip may be used as a fracture parameter governing the fracture processes near the crack tip. The onset of crack growth occurs when KItip reaches the intrinsic fracture toughness of the material. The apparent fracture toughness is the critical value of KI∞ when fracture occurs. The solution of the crack tip stress intensity factor for the crack can be used to predict fracture toughness variation. The numerical results of the normalized stress intensity factor KI∞ =KItip are shown in Fig. 12 as a function of Ps KE∞ =s KItip . Here = 10 has been used. This result shows H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1123 10 8 Ec/E0= 1 Ec/E0= 2/3 Ec/E0=0.525 Ec/E0= 1/3 Ec/E0= 0 K I∞ KItip 6 4 2 0 -10 -5 0 Ps KE∞ γs KItip 5 10 Fig. 12. Normalized crack tip stress intensity factor. that the value of Ec =E0 a%ects strongly the variation of fracture toughness regardless of the direction of an applied electric &eld. The results predicted here, however, do not give a theoretical interpretation for the experimental observation in Park and Sun (1995), even though the results give a theoretical explanation for the experimental result observed by Fu and Zhang (2000). It is noted that electromechanical coupling and material anisotropy are neglected in obtaining the change of the crack tip stress intensity factor due to domain switching in this paper. Due to electromechanical coupling induced by the piezoelectric e%ect, the electrical nonlinearity a%ects the crack tip stress intensity factor for a crack in a piezoelectric material. According to Gao and Barnett (1996) and Gao et al. (1997), the local crack tip stress intensity factor obtained based on the strip saturation model is given by KItip = KI∞ − cKE∞ ; (27) where c is a constant depending only on the linear material properties, and has a negative value for typical piezoelectric ceramics. When the piezoelectric coupling e%ect is ignored, c vanishes. In deriving (27), the domain switching e%ect on the change of the crack tip stress intensity is neglected. It is noted that the change of the crack tip stress intensity factor induced by the electrical nonlinearity due to the electromechanical coupling does not depend on electric yielding parameters. This result implies that the electromechanical coupling due to the piezoelectric e%ect reduces the apparent fracture toughness under the positive electric &eld, while the coupling e%ect enhances the apparent fracture toughness under the negative electric &eld. Taking the piezoelectric coupling e%ect into consideration, the nonlinear ferroelectric crack model 1124 H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 proposed in this paper may give a theoretical explanation for the experimental observation on various fracture behaviors of ferroelectric materials. 5. Concluding remarks The asymptotic problem of a semi-in&nite crack perpendicular to the poling direction in a ferroelectric ceramic subjected to combined electric and mechanical loading is analyzed to investigate e%ect of electric &elds on fracture behavior. Our attention is restricted to the case in which the material anisotropy is negligible. Electromechanical coupling due to piezoelectricity is thus neglected in this paper. The boundary of the domain switching zone near the crack tip is estimated based on the electrical nonlinear theory in order to evaluate the change of the crack tip stress intensity factor due to the domain switching. It is shown that the shape and size of the domain switching zone depend strongly on the relative magnitude between the applied electric &eld and stress &eld as well as on the ratio of the coercive electric &eld to the yield electric &eld. A universal relation between the crack tip stress intensity factor and the applied intensity factors of stress and electric &eld under small-scale conditions is obtained by employing the model of nonlinear domain switching. It is found that regardless of the direction of an applied electric &eld, the ratio of the coercive electric &eld to the yield electric &eld plays a signi&cant role in determining the enhancement or reduction of the crack tip stress intensity factor. The fracture toughness variation of ferroelectrics under combined electric and mechanical loading is also discussed. The fracture toughness of the ferroelectric material may be increased or decreased depending on the nonlinear material properties. The nonlinear ferroelectric crack model proposed in this paper gives a theoretical explanation for the experimental observation on various fracture behaviors of ferroelectric materials. Acknowledgements This work was supported by a grant from the ONce of Naval Research, with Dr. Y.D.S. Rajapakse as the cognizant program oNcial. The &rst author performed a part of this work at Center for Aerospace Research and Education, University of California at Los Angeles. References Beom, H.G., 1999. Small scale nonlinear analysis of electrostrictive crack problems. J. Mech. Phys. Solids 47, 1379–1395. Budiansky, B., Hutchinson, J.W., Lambropoulos, J.C., 1983. Continuum theory of dilatant transformation toughening ceramics. Int. J. Solids Struct. 19, 337–355. Fu, R., Zhang, T.-Y., 2000. E%ects of an electric &eld on the fracture toughness of poled lead zirconate titanate ceramics. J. Am. Ceram. Soc. 83, 1215–1218. Fulton, C.C., Gao, H., 2001. E%ect of local polarization switching on piezoelectric fracture. J. Mech. Phys. Solids 49, 927–952. H.G. Beom, S.N. Atluri / J. Mech. Phys. Solids 51 (2003) 1107 – 1125 1125 Gao, H., 1989. Application of 3-D weight functions—I. Formulations of crack interfaces with transformation strains and dislocations. J. Mech. Phys. Solids 37, 133–153. Gao, H., Barnett, D.M., 1996. An invariance property of local energy release rates in a strip saturation model of piezoelectric fracture. Int. J. Fract. 79, R25–R29. Gao, H., Zhang, T.-Y., Tong, P., 1997. Local and global energy release rates for an electrically yielded crack in a piezoelectric ceramic. J. Mech. Phys. Solids 45, 491–510. Huber, J.E., Fleck, N.A., Landis, C.M., McMeeking, R.M., 1999. A constitutive model for ferroelectric polycrystals. J. Mech. Phys. Solids 47, 1663–1697. Hwang, S.C., Lynch, C.S., McMeeking, R.M., 1995. Ferroelectric/ferroelastic interactions and a polarization switching model. Acta Metall. Mater. 43, 2073–2084. Ja%e, B., Cook, W.R., Ja%e, H., 1971. Piezoelectric Ceramics. Academic Press, New York. Kamlah, M., Tsakmakis, C., 1999. Phenomenological modeling of the non-linear electro-mechanical coupling in ferroelectrics. Int. J. Solids Struct. 36, 669–695. Lines, M.E., Glass, A.M., 1977. Principles and Applications of Ferroelectric and Related Materials. Clarendon Press, Oxford. McMeeking, R.M., Evans, A.G., 1982. Mechanics of transformation-toughening in brittle materials. J. Am. Ceram. Soc. 65, 242–246. Park, S., Sun, C.-T., 1995. Fracture criteria for piezoelectric ceramics. J. Am. Ceram. Soc. 78, 1475–1480. Rice, J.R., 1967. Stresses due to a sharp notch in a work-hardening elastic–plastic material loaded by longitudinal shear. J. Appl. Mech. 34, 287–298. Rice, J.R., 1985. Three-dimensional elastic crack tip interactions with transformation strains and dislocations. Int. J. Solid Struct. 21, 781–791. Sze, K.Y., Pan, Y.-S., 2001. Nonlinear fracture analysis of piezoelectric ceramics by &nite element method. Eng. Fract. Mech. 68, 1335–1351. Tobin, A.G., Pak, Y.E., 1993. E%ect of electric &elds on fracture behavior of PZT ceramics. Proc. SPIE, Smart Struct. Mater. 1916, 78–86. Wang, H., Singh, R.N., 1997. Crack propagation in piezoelectric ceramics: e%ects of applied electric &elds. J. Appl. Phys. 81, 7471–7479. Xu, Y., 1991. Ferroelectric Materials and Their Applications. North-Holland, Amsterdam. Yang, W., Zhu, T., 1998. Switch-toughening of ferroelectrics under electric &eld. J. Mech. Phys. Solids 46, 291–311. Zeng, X., Rajapakse, R.K.N.D., 2001. Domain switching induced fracture toughness variation in ferroelectrics. Smart Mater. Struct. 10, 203–211. Zhang, T.-Y., Zhao, M.H., Tong, P., 2002. Fracture of piezoelectric ceramics. Adv. Appl. Mech. 38, 147–289. Zhu, T., Yang, W., 1997. Toughness variation of ferroelectrics by polarization switch under non-uniform electric &eld. Acta Mater. 45, 4695–4702.