Amir H. Torkaman Objective Education MS

advertisement

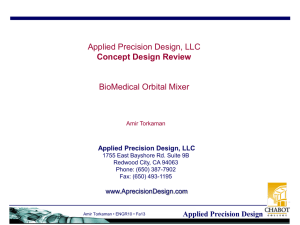

Amir H. Torkaman torkaman@Aprecisiondesign.com Objective Seeking contracting / consulting positions in design and analysis of precision electro-mechanical subassemblies. Education MS in Mechanical Engineering from MIT, Cambridge, MA: Jan 2000. Graduate research in Precision Machine Tool Design; graduate courses taken in Robotics and Mechatronics, Digital Control Systems, Advanced Dynamics, Kinematics and Dynamics of Manipulators, Manufacturing, math and statistics. GPA: 5.0/5.0 BS in ME from University of Florida, Gainesville, FL; Aug. 1998; concentration in design, kinematics/dynamics, and controls. Overall GPA 3.95/4.00. Earned a BS degree in ME in 2.5 years, graduating with Highest Honors. Ranked #1 in the ME department. Experience Consultant, Sr. Mechanical Engineer Applied Precision Design, Palo Alto, CA Provide consulting services for various companies in Semiconductor, Energy, and Defense industries. Primary areas of consulting include design of ultra-high precision mechanisms, electro-mechanical and optomechanical assemblies, thermal / vacuum systems, and basic machine / equipment design. March 2007 – Present. Mechanical Engineer, 5 KLA-Tencor, Wafer Inspection Division, Milpitas, CA Designed layout and critical subsystems of the first DUV Wafer Inspection machine—one the most successful products ever launched at KT. Design and fabrication of precision mechanisms for optical metrology equipment. Duties included system architecture design, opto-mechanical design, mechatronics, FEA, CFD, Thermal, and Vibration analysis of critical systems. Consulted Carl Zeiss to design next generation optics. Developed systemlevel optical alignment strategies. Assigned to highest level engineering problems of WIN division: lens photocontamination, system vibration, stability of optical mounts and nano-manipulators. Lead mechanical designer (level T-25) in development of next generation DUV platform from concept to full production. Jan 2004 – March 2007. Senior Design Engineer Advanced Semiconductor Materials Lithography (ASML) / Aviza Technology, Scotts Valley, CA Developed an advanced new semiconductor manufacturing tool as the company’s key strategic product line: a short cycle-time vertical furnace used in CVD and Oxidation processes. Lead engineer in complete design and fabrication of machine from concept to production. Reported to the division president in a small selected research group. Duties included design of elector–mechanical systems, precision actuators, sensors, and drivers. Designed mechanical parts from AL, SS, plastics, quartz, exotic metals, etc. Also debugged design problems of single wafer RTP, CVD and ALD machines. Worked in system engineering, operated the machines, ran demos and developed new films and processes. US Patent 6,874,770 and several others pending. Dec 1999 – Jan 2004. Research Assistant Massachusetts Institute of Technology, Manufacturing Institute, Cambridge, MA Designed and built a full-scale precision polishing CMP machine for silicon wafers from concept to a working prototype. Designed the entire upper-half of the machine, including micron-precision X and Z linear motions with 2m of travel, and the complete load-port mechanism. Duties included conceptual/detail design, drawings, selecting machine components (motors, ball screws, bearings); modeling system dynamics; developing control algorithms; assembly and testing. Machine shop experience. Sept. 1998 – Jan 2000. Mechanical Engineering Intern Reflectone Inc./ University of Florida, Gainesville, FL Designed and built a full-scale 4-Axis helicopter simulator platform from concept to prototype. Architecture of system layout. Designed electro-pneumatic actuators; kinematic / dynamic / FEA analysis, Aug. 97 – May 98. Computer Pro-Engineer, Solidworks, CF Design, Pro-Mechanica, Flowtherm, C/C++, Cosmos, MATLAB, Maple, Mathcad. Personal Diligent, responsible, and friendly. US Citizen. Enrolled in graduate school at MIT at the age of 18. Almost a perfect academic record. Hobbies include traveling, mountain biking, surfing, mixing records, and cars. References Available upon request. Amir Torkaman Professional Biography Amir holds an MS degree from MIT in Mechanical Engineering. His primary area of graduate research focused on Precision Machine Design and Robotics, studying under the Head of Dept. Prof. Nam P Suh. After graduating, Amir worked as a Research Faculty at MIT, developing a full-scale ultra precise Chemical Mechanical Polishing machine for the Semiconductor Equipment Manufacturing industry. As a Sr. Mechanical Engineering at Silicon Valley Group / ASML, Amir developed an advanced new semiconductor manufacturing tool as the company’s key strategic product line: a short cycle-time vertical furnace used in CVD and Oxidation processes. He was the lead engineer in complete design and fabrication of machine from concept to production, and reported to the division president in a small selected research group. He worked at ASML from Jan 2000 to Jan 2004 and was awarded several US Patents. Later at KLA-Tencor, Amir designed the layout and critical subsystems of the first DUV Wafer Inspection machine—one the most successful products ever launched at KT. During his four years there, Amir was typically assigned to highest level engineering problems of WIN division, such as lens photo- contamination, system vibration, stability of optical mounts and nano-manipulators. He later became the lead mechanical designer (level T-25) in development of next generation DUV platform from concept to full production. In early 2007, Amir co-founded Applied Precision Design, a Mechanical Engineering consulting firm that specialized in automation, robotics, and electro-mechanical systems. He has since helped several start-up companies grow significantly including Optisolar, a leading Silicon Valley photovoltaic solar energy company.