Aspergillus Niger Lignocellulosic Biofuel Production Stephanie J Sibert

advertisement

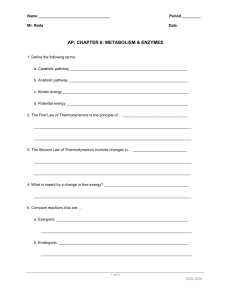

Production of Bacterial-Derived Enzymes in Aspergillus Niger with Applications in Lignocellulosic Biofuel Production Stephanie J Sibert Office of Science, Summer Undergraduate Laboratory Internship (SULI) Program University of California, Berkeley Lawrence Berkeley National Laboratory Berkeley, California August 10, 2013 Prepared in partial fulfillment of the requirements of the Office of Science, U.S. Department of Energy’s Summer Undergraduate Laboratory Internship under the direction of John Gladden in the Physical Biosciences Division at Lawrence Berkeley National Lab Abstract The development biofuels from Lignocellulosic (LC) biomass, which includes a variety of plant feedstocks such as agricultural and forestry residues and dedicated energy crops, is one route to clean and renewable alternatives to petroleum-base fuel. The first step in converting plant biomass to fuels is breaking down cellulose, the most abundant plant cell wall polymer, into fermentable sugars. Pretreament of LC biomass with ionic liquids (ILs) greatly reduces the difficulty in breaking down the plant cell wall, allowing more efficient enzymatic hydrolysis of cellulose to sugar. Unfortunately, currently available commercial cellulase cocktails are not active in the presence of ILs, an incompatibility that required the addition of expensive and wasteful washing steps. Due to the efficacy of IL pretreatment, finding IL-tolerant cellulolytic enzymes is necessary. An ideal place to look for such enzymes is high salt and high temperature environments that harbor halophilic and thermophilic bacteria, which tend to produce highly stable enzymes that may be IL-tolerant. Researchers at JBEI have identified 17 novel bacterialderived cellulase enzymes which have been isolated from enriched compost material. However, enzyme production at a scale large enough to be commercially viable is limited due to the inability of common laboratory heterologous expression systems (E. coli and Saccharomyces cerevisiae) to produce sufficient titers of these enzymes. A frequently used commercial host, Aspergillus niger (A. niger), which is known for large scale heterologous/endogenous protein production, is a promising solution to this limitation. The Fungal Biotechnology Group at JBEI is focused on understanding and engineering enzyme hyper production phenotypes into A. niger for use as a high-titer expression platform for cellulase enzymes discovered at JBEI. The Fungal Biotechnology group has created DNA constructs for expression of heterologous enzymes in A. niger and has begun screening these enzymes for expression. To determine how well these bacterial-derived enzymes express in A. niger, bacterial genes were transformed into A. niger and the enzymes were assayed for activity using the model cellulose substrates Azo-CM-cellulose (CMC), p-Nitrophenyl β-D-cellobioside (pNPC) or p-Nitrophenyl β-D-glucaopyranoside (pNPG) assays. Here we show that these enzymes can be functionally expressed in A. niger with varying degrees of success. Based on our initial results, we will perform further assays on these enzymes and apply forward and reverse genetic approaches to identify genetic features responsible for high protein secretion and engineer these features into a master high production strain. Introduction The use and depletion of fossil fuels has become a major environmental and energy security issue [1],[2]. Therefore, the development of renewable biofuels as an alternative to petroleum is critical for the safety and security of future generations [3],[4]. The most advanced biofuel technology currently available in the US is ethanol produced from corn grain; however the use of corn for fuel production has problematic effects on food markets [4]. Alternatively, Lignocellulosic (LC) biomass, which includes a variety of plant feedstocks such as agricultural and forestry residues and dedicated energy crops, is abundant and does not compete with other market demands [4]. The first step in converting biomass to fuels is breaking down cellulose into sugars [5]. Pretreament of LC with ionic liquids (ILs) greatly reduces the difficulty in breaking down cellulose locked inside the plant, allowing enzymes to more readily hydrolyze cellulose into sugar [6]. Unfortunately, currently available commercial cellulase cocktails are not active in the presence of ILs, an incompatibility that required the addition of expensive and wasteful washing steps. [7]. Due to the efficacy of IL pretreatment, IL-tolerant cocktails will be necessary to create efficient and cheap IL-based biofuel technologies [6]. In the search for enzymes that are tolerant to ILs, researchers at JBEI investigated enzymes tolerant to high salt and high temperature derived from halophilic and thermophilic bacteria and found that some of these enzymes could also tolerate high concentrations of ILs. They then used those enzymes to generate cellulase cocktails. One such cocktail is composed of a cellobiohydrolase from Caldicellulosiruptor saccharolyticus (C. sac) and a β-glucosidase from Thermotoga petrophila (A5IL97) and has been show to function at both high temperatures and in the presence of ILs [8]. However, development of larger scale production systems for these enzymes has not been possible using heterologous expression systems such as E. coli and Saccharomyces cerevisiae due to the inability of these organisms to produce high titers of these enzymes [8]. A frequently used commercial host, Aspergillus niger (A. niger), known for large scale heterologous/endogenous protein production and is a promising solution to this limitation [9]. The Fungal Biotechnology Group at JBEI is focused on understanding and engineering enzyme hyper production in A. niger for use as a high-titer expression platform for IL-tolerant cellulases targeted for use in lignocellulosic biofuel production. Initial results show A. niger can functionally express IL-tolerant enzymes (A5IL97 and C. sac); based on those results, forward and reverse genetic approaches are being employed to develop a synthetic biology tool set to enable efficient engineering of a master hyper-production strain of A. niger [9]. Researchers at JBEI have identified 17 novel bacterial cellulases derived from compost microbial communities using metagenomic sequencing techniques. DNA constructs have been created for expression of these enzymes in bacteria but the enzymes could only be produced in small quantities in standard bacterial lab strains. To determine how well these bacterial-derived enzymes express in A. niger, the DNA constructs were transformed into A. niger and the resultant enzymes assayed for activity using Azo-CM-cellulose (CMC), 4-nitrophenyl-β-Dcellobioside (pNPC) or 4-nitrophenyl-β-D-glucopyranoside (pNPG). Materials and Methods DNA preparation: Extant DNA constructs (circular) were removed from -80˚C storage and placed on ice. Each construct was then used to inoculate a mixture of 5 ml LB broth and 5µl chloramphenicol (Cam; 30 μg/ml). The mixture was shaken at 37˚C for 14-16 hours. Each culture was divided into two centrifuge tubes. The bacterial cells were harvested by centrifugation (6800 g, 3 min) and the supernatant discarded. Some samples were frozen (-20˚C) to be thawed and purified later, others were immediately subjected to isolation. The DNA was isolated through the use of QIAprep® Miniprep (Qiagen) using manufacturer’s protocol [10]. The pellet was re-suspended in P1 buffer (250 µl) with a gentle pipette up and down. Lysis was accomplished with P2 (250 µl), followed by neutralization with N3 (350 µl). The tubes were then centrifuged (18,000 g, 10 min) and the supernatant decanted into QIAprep spin column. The samples were spun through (18,000 g, 1 min) and washed with 0.75 ml Buffer PE. (18,000 g, 30 sec, discard flow through, 1 min). The DNA was then eluted with 50 µl purified water (50˚C) and concentrated (Vacufuge® vacuum concentrator) to 500 ng/µl or greater. Protoplast preparation [11]: Spores from A. niger (ATCC® 11414™) were collected in purified water. Spores were counted and 106 (~1ml H20) added to 100 ml YEPD broth in salinized (5% Dichloromethylsaline in hexane rinse followed by UV exposure for 1.5 hrs) flask. Culture was grown overnight (150 rpm, 30˚C). Mycelia were harvested by vacuum filtration through Miracloth and rinsed with sterile water. The collected biomass was added to 40 ml of Vino Taste Pro (30 mg/ml) in protoplasting buffer (0.5 M Ammonium Sulphate, 50 mM Maleic Acid, pH 5.5). Protocol was modified to 0.5 M from 0.6 M Ammonium Sulphate to reduce lysis in ATCC® 11414™. Mycelia digested at 30˚C, 70 rpm for 3-4 hours; with progression checked intermittently. When the mycelia was sufficiently (all or mostly) digested, culture was filtered through sterile miracloth, filtrate pelleted (800 g, 10 min) and supernatant discarded. Pellet was fully re- suspended in 25 ml ST solution (1.0 M sorbitol; 50 mM Tris, pH 8.0) then spun down. (800 g, 10 min). ST wash was repeated, and then pellet re-suspended in 10 ml STC (1.0 M sorbitol; 50 mM Tris, pH 8.0, 50 mM CaCl2) and spun down again. (800 g, 10 min). Pellet re-suspended in 1 mL STC and protoplasts counted. STC added to final concentration of 1.2x107 spores/ml. PEG solution (40%) added to 20% volume and mixed gently. DMSO added to 7% volume of protoplast+PEG solution. Transformation: To 100 µl protoplast solution, 10 µl DNA added by pipetting gently to the center of the protoplast solution and very gently pipetting 4-6 times. Samples were incubated on ice for 15 min, followed by the addition of 1 ml 40% PEG. (pipette to center, gently pipette 4-6 times). Samples incubated at room temperature for 15 min. Minimal medium (50 ml/L 20x nitrate, 1 ml/L 1000x vitamin soln, 1 ml/L trace soln, 1% glucose) plus 1 M sorbital, 10 ml, added to samples. Samples then subjected to shaking (~65 rmp) at 30˚C for 1 hour. Cells spun down (800 g, 5 min) and re-suspended in 12 ml minimal medium with 1 M sorbitol, 0.8% agar and 100 µg/ml hygromycin then poured onto a plate. After the agar solidified, 12ml overlay applied. (with hygromycin). Plates were grown at 30˚C until visible colonies formed (usually 3-4 days). Enzyme Preparation: Individual colonies were cut from the agar using sterile needle and placed on 2-3ml slant of minimal media plus sorbitol with 1.6% agar and grown at 30˚C until black spores cover all or most of the surface. (~1 week) Spores removed with 1 ml sterile H2O. For each sample, a mixture of 150 µl spores and 5 ml Hmm-140p (70 g/L sodium citrate, 15 g/L of (NH4)2SO4, 1 g/L NaH2PO4.H2O, 1 g/L MgSO4, 1 ml/L Tween 80, 0.05 ml/L Antifoam 204 to sub for 2 ml of Mazu DF60-P, 45 g/L Peptone 140, 120 g/L of maltose, pH 6.2) was shaken (150 rpm) at 30 ˚C for 3 days. The biomass and supernatant were then transferred to centrifuge filter tube by pipette with ~0.5 cm of the pipette tip cut off at a slant with sterile scissors and spun at ~14600 g for one minute. The filter and biomass were discarded. Enzyme Assay: Samples were tested by one of three assays, depending on the type of enzyme activity seen when enzymes were expressed previously in E. coli. Thirteen samples were assayed using 4-nitrophenyl-β-D-cellobioside (pNPC), thirteen samples were assayed using 4-nitrophenyl-β-Dglucopyranoside (pNPG) and three were assayed using a modified version of Megazyme’s assay of endo-1,4- β-Glucanase using Azo-CM-cellulose [12]. The pNPG and pNPC assays are nearly the same except the uses of different stock solution; 4-nitrophenyl-β-D-glucopyranoside or 4-nitrophenyl-β-D-cellobioside. A mixture was prepared of 80 µl (125mM) buffer solution, 10 µl Substrate Solution (50mM, pNPG or pNPC) and 10µ of the filtered supernatant and incubated for 30 minutes at an optimal temperature determined by assays of the enzyme when expressed in E. coli. Mixture was quenched with 100 µl filtered 2% Na2CO3 and absorbance read at 410nm. The modified Azo-CMC [12] assays were performed by mixing 27 µl Azo-CMC substrate solution [12] with 27 µl culture supernatant and 5 µl 1M buffer and incubating for 30 minutes at an optimal temperature and pH determined using assays of the enzyme when expressed in E. coli. The reaction was stopped by mixing in 144 µl precipitation solution (40g sodium acetate trihydrate, 4g zinc acetate, H2O to 200 ml, pH 5.0 with 5M HCL; added to 800 ml ethanol 95%). Precipitate was spun out at 1000 g for 10 minutes and absorbance of supernatant read at 590 nm. Results Of the genes used for transformation, sixteen resulted in viable colonies when grown on plates containing hygromycin. The transformation of gene J31 was attempted twice with no growth in either trial. The other genes resulted in a range of activity. The maximum values for the assays using 4-nitrophenyl-β-D-cellobioside (pNPC) and 4-nitrophenyl-β-D-glucopyranoside (pNPG) are shown in Figure 1. The activity values were calculated using the formulas in Table 1. The maximum activity in M p-nitrophenol released/L enzyme supernatant/min values per gene range from 0.00451 (J19, pNPC) which shows minimal activity to 7.22 (J07, pNPG). The maximum values for each gene assayed using Azo-CM-cellulose are shown in Figure 2 in Activity Units/mL enzyme solution/min where Activity Units are determined by reference to Trichoderma sp. endo-cellulase standard curve on Azo-CM-Cellulose [12]. The variability within the different transformations of each gene can be seen in Figure 3 and Figure 4. Figure 3 shows the pNPG results for each of the ten transformations assayed for both J08 and J09. There are two noticeably more active transformations for J08, one for J08 that is much less active and the remaining for both J08 and J09 have essentially no activity. Figure 4 shows the pNPC results for each of the ten colonies assayed for both J08 and J09. There are three noticeably more active transformations for J08, a few for J08 and J09 that are much less active and some for both J08 and J09 have essentially no activity. Discussion/Conclusion Initial results show that A. niger can functionally express most of the IL-tolerant bacterial enzymes tested.. It is not known whether more enzymes were produced by the strains showing more activity or the enzymes are present in the same number, but are more active in some strains. As these are bacterial genes expressed in a eukaryote, potential post translational modifications may affect activity. Both quantity and activity need to be better understood; protein purification of the expressed enzymes would aid in making necessary quantitative distinctions. The large variability within transformations of the same and related genes suggests that >10 transformants need to be screened for each gene of interest. The genes identified as J08 and J09 only differ by one amino acid. Yet as shown in Figure 3 and Figure 4 there are several high activity transformants from J08 and none from J09, additionally many of the other J08 transformation also had no activity. This may suggest that the one amino acid is a critical mutation leading to enzyme incompatibility, cellular toxicity, folding or secondary structure problems; however the only way to verify the importance of the amino acid shift would be to screen enough transformations to be sure that the lack of activity in J09 is not due to variations in copy number, insertion location, or transcript stability. Additional screens are also recommended to further isolate the best strains for future work. Next steps will include the best transformations resulting from this screening being tested for optimal temperature and pH be ensure their optimal activity conditions are unaltered compared to expression in E. coli. They will also be screened for ionic liquid and thermal tolerance as these features are critical for their use in Lignocellulosic biofuels. The expression and characterization of novel bacterial enzymes in A. niger gives researchers a larger synthetic biology tool set, provides more enzymes and strains for use in forward and reverse genetic approaches and aids to identify features responsible for high protein secretion and efficient Lignocellulosic breakdown; all of which contribute to the creation of a master hyper-production strain of A. niger. ACKNOWLEDGMENTS This work was supported in part by the U.S. Department of Energy, Office of Science, Office of Workforce Development for Teachers and Scientists (WDTS) under the Science Undergraduate Laboratory Internship (SULI) program. Work done under the mentorship of John Gladden, Deputy Director, with direction and assistance from Jed Lynn, Guest Postdoctoral Fellow; Fungal Biotechnology Group at the Joint BioEnergy Institute at Lawrence Berkeley National Lab. REFERENCES [1] M.T. Klare, “The Dependency Dilemma: Imported Oil and National Security,” in Blood and Oil: The Dangers and Consequences of America’s Growing Dependency on Imported Petrolium, 1st ed. New York: Owl Books, 2004, ch. x, pp. 1–25. [2] J. Barnett, "Security and climate change," Global Environmental Change, vol. 13, no. 1, pp. 7-17, Apr. 2003. [Online]. Available: http://dx.doi.org/10.1016/s0959-3780(02)00080-8 [3] L. Wright, "Worldwide commercial development of bioenergy with a focus on energy cropbased projects," Biomass and Bioenergy, vol. 30, no. 8-9, pp. 706-714, Aug. 2006. [Online]. Available: http://dx.doi.org/10.1016/j.biombioe.2005.08.008 [4] C. Schubert, "Can biofuels finally take center stage?" Nature Biotechnology, vol. 24, no. 7, pp. 777-784, Jul. 2006. [Online]. Available: http://dx.doi.org/10.1038/nbt0706-777 [5] S. Merino and J. Cherry, "Progress and challenges in enzyme development for biomass utilization," in Biofuels, ser. Advances in Biochemical Engineering/Biotechnology, L. Olsson, Ed. Springer Berlin Heidelberg, 2007, vol. 108, pp. 95-120. [Online]. Available: http://dx.doi.org/10.1007/10_2007_066 [6] H. Tadesse and R. Luque, "Advances on biomass pretreatment using ionic liquids: An overview," Energy Environ. Sci., vol. 4, no. 10, pp. 3913-3929, 2011. [Online]. Available: http://dx.doi.org/10.1039/c0ee00667j [7] M. B. Turner, S. K. Spear, J. G. Huddleston, J. D. Holbrey, and R. D. Rogers, "Ionic liquid salt-induced inactivation and unfolding of cellulase from trichoderma reesei," Green Chem., vol. 5, no. 4, pp. 443-447, 2003. [Online]. Available: http://dx.doi.org/10.1039/b302570e [8] J. I. Park, E. J. Steen, H. Burd, S. S. Evans, A. M. Redding-Johnson, T. Batth, P. I. Benke, P. D'haeseleer, N. Sun, K. L. Sale, J. D. Keasling, T. S. Lee, C. J. Petzold, A. Mukhopadhyay, S. W. Singer, B. A. Simmons, and J. M. Gladden, "A thermophilic ionic Liquid-Tolerant cellulase cocktail for the production of cellulosic biofuels," PLoS ONE, vol. 7, no. 5, pp. e37 010+, May 2012. [Online]. Available: http://dx.doi.org/10.1371/journal.pone.0037010 [9] D. Lubertozzi and J. D. Keasling, "Developing aspergillus as a host for heterologous expression," Biotechnology Advances, vol. 27, no. 1, pp. 53-75, Jan. 2009. [Online]. Available: http://dx.doi.org/10.1016/j.biotechadv.2008.09.001 [10] QIAprep Miniprep Handbook. Qiagen, 2006, pp. 14-15,22-23. [11] K.S. Bruno, “Aspergillus niger Transformation Protocol,” unpublished [12] Megazyme’s assay of endo-1,4- β-Glucanase using Azo-CM-cellulose. Megazyme, 2012, pp. 1-7 Figures Figure 1 8 Assay for β-glucosidase activity and cellobiohydrolase activity substrate: p-nitrophenyl glucopyranoside (pNPG) and p-nitrophenyl β-D-cellobioside (pNPC) M p-nitrophenol released/ L enzyme solution/min 7 pNPC 6 pNPG 5 4 3 2 1 0 Max value for gene tranformed into A. niger Figure 1. A graph showing the results for the transformation of each gene with the maximum value of M p-nitrophenol released/L enzyme supernatant/min. Table 1. Quantity Absorbance (abs) of p-nitrophenolate anion at 410 nm Extinction Coefficient (E) for p-nitrophenolate anion at 410 nm Path length (L) for 100μL assay Concentration (C) in mM p-nitrophenol released Value or Calculation Direct measurement of ABS at 410 nm minus measurement of enzyme blank 18.5 mL/μmol/cm 0.2 cm M p-nitrophenol released/L enzyme solution/min Table 1. The calculations used to convert the absorbance readings from pNPC and pNPG assays into units of M p-nitrophenol released/L enzyme solution/min Figure 2 Activity Units*/mL ezyme solution/min Assay for endo 1,4-β-glucanase activity substrate: Azo-CM-cellulose 0.3 0.25 0.2 0.15 0.1 0.05 0 J26 J28 J30 Max value for gene tranformed into A. niger *Activity Units determined by reference to Trichoderma sp. endo-cellulase standard curve on Azo-CM-Cellulose [12] Figure 2. A graph showing the results for the transformation of each gene with the maximum value Activity Units/mL enzyme solution/min. Table 2. Quantity Absorbance (abs) at 590 nm milliUnits (per assay) Value or Calculation Direct measurement of ABS at 590 nm minus measurement of enzyme blank (412.5 * abs) – 6.0 (determined by reference to Trichoderma sp. endo-cellulase standard curve on Azo-CM-Cellulose [12]) Activity Units/mL enzyme solution/min Table 2. The calculations used to convert the absormance readings from Azo-CM-cellulose assays into units of Activity Units/mL enzyme solution/min Figure 3 3.5 Comparison of β-glucosidase activity: J08 and J09, 10 transformants each substrate: p-nitrophenyl glucopyranoside (pNPG) M p-nitrophenol released/ L enzyme solution/min J08 3 J09 2.5 2 1.5 1 0.5 0 1 2 3 4 5 6 7 8 9 10 Tranformation number of gene tranformed into A. niger Figure 3. A graph showing the β-glucosidase activity results for all transformations of J08 and J09 in M p-nitrophenol released/L enzyme supernatant/min. Figure 4 3.5 Comparison of cellobiohydrolase activity: J08 and J09, 10 transformants each substrate: p-Nitrophenyl β-D-cellobioside (pNPC) M p-nitrophenol released/ L enzyme solution/min J08 3 J09 2.5 2 1.5 1 0.5 0 1 2 3 4 5 6 7 8 9 10 Transformation number of gene tranformed into A. niger Figure 4. A graph showing the cellobiohydrolase activity results for all transformations of J08 and J09 in M p-nitrophenol released/L enzyme supernatant/min.