Chabot College Fall 2006 Course Outline for Automotive Technology 62

advertisement

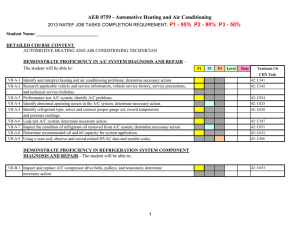

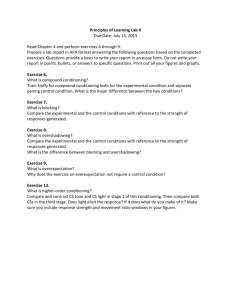

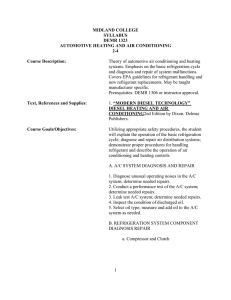

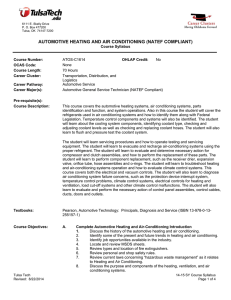

Chabot College Fall 2006 Course Outline for Automotive Technology 62 AUTOMOTIVE AIR CONDITIONING, COOLING AND HEATING SYSTEMS Catalog Description: 62 - Automotive Air Conditioning, Cooling and Heating Systems (May be repeated three times) 2.5 units Diagnosis, testing, adjustment, and repair of air conditioning, cooling and heating systems. Includes heat and energy, psychometrics, air flow, refrigerant recycling, equipment and controls. Strongly recommended: Automotive Technology 60A or equivalent (may be taken concurrently). 1.5 hours lecture, 4.0 hours laboratory. [Typical contact hours: lecture 26.25, laboratory 70] Prerequisite Skills: None Expected Outcomes for Students: Upon completion of the course, the student should be able to: 1. complete work orders to meet industry and Bureau of Automotive Repair standards; 2. identify and interpret heating and air conditioning concerns; 3. research vehicle and service information and technical service bulletins; 4. performance test A/C systems and diagnose A/C system malfunctions using appropriate gauges and test equipment; evacuate and recharge A/C system; 5. identify refrigerant systems for sealers and refrigerant type; 6. leak test A/C system; 7. inspect condition of discharged oil and determine correct oil type for application; 8. diagnose A/C system protection devices; 9. inspect and replace drive belts; 10. inspect, test, and/or replace compressors, clutch, or complete assembly and determine need for additional filters; 11. remove and inspect hoses, lines, fittings, O-rings, seals, and service valves; 12. inspect condenser for airflow restrictions; 13. remove and install receiver/drier or accumulator/drier; 14. remove and install expansion valve or orifice tube; 15. diagnose temperature control problems; 16. perform cooling system tests; check/inspect coolant, radiator, pressure cap, hoses, and drive belts; 17. inspect, test, and replace thermostat; 18. determine coolant condition and coolant type; drain and recover coolant; 19. inspect and test cooling system fan operation, both electrical and mechanical; 20. inspect and test heater control valves; 21. diagnose electrical malfunctions of heating, ventilation, and A/C systems; 22. perform correct use of refrigerant recovery, recycling, charging, and handling equipment. 23. Optional: participate in an air conditioning refrigerant handling certification program. Course Content: 1. Fundamentals of air conditioning, cooling and heating systems 2. Introduction to refrigeration 3. Heat, temperature and transfer of heat 4. Safety and shop procedures and practices 5. Refrigerant identification, recovery, and recycling 6. Air conditioning components and control devices 7. Laboratory practice in inspection, diagnosis, service, adjustment and repair of air conditioning, cooling and heating systems Chabot College Course Outline for Automotive Technology 62, Page 2 Fall 2006 8. Hazardous material handling 9. Air conditioning refrigerant handling certification (optional with an additional fee) Assignments and Methods of Evaluating Student Progress: 1. Typical Assignments a. Read assigned chapters 1 through 4 b. Perform assigned lab tasks and complete assignments sheets c. Identify air conditioning system problems and perform repairs 2. Methods of Evaluating Student Progress a. Final exam and quizzes b. Lab performance Textbook(s) (Typical): Automotive Heating, Ventilation, and Air Conditioning Systems, Chek Chart, 2005 Special Student Materials: Safety glasses and shop/safety clothing Sas atec62 10/5/05