Guide to Using Existing Pavement in Place and Achieving Long Life

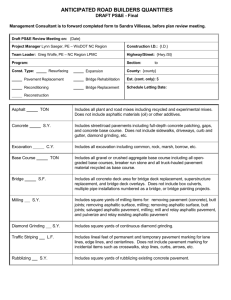

advertisement