Steven T Rose/Billy Allen ‐ Upstream Harish Santhanam‐

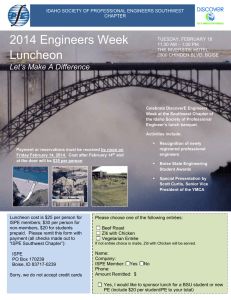

advertisement

BioProcess Engineering “Role of a Chemical Engineer in the Biotech Industry” Steven T Rose/Billy Allen ‐ Upstream Harish Santhanam‐ Downstream ISPE Biotech Presentation October 3 2010 1 Manufacture of Drug Product Drug Product Excipients ISPE Biotech Presentation October 3 2010 API Fill/Finish 2 Biotech API Processes Upstream Downstream API ISPE Biotech Presentation October 3 2010 Produce aqueous process stream containing the bioproduct Concentrate and purify the bioproduct Active Pharmaceutical Ingredient for Formulation and Packaging 3 Upstream Process Objectives • Provide a robust manufacturing cell culture / fermentation process that has the following performance capabilities – Consistent product quality – Consistent process yield – Consistent level of process impurities • Host cell protein • DNA • Product variants – Consistent broth conditions for predictable downstream unit operations performance • Clarification • Primary capture column ISPE Biotech Presentation October 3 2010 4 Upstream Process Unit Operations Master Cell Bank Thaw Expansion Working Cell Bank Antifoam Feed Glucose er2 arg Thaw Expansion Flask Expansion ISPE Biotech Presentation October 3 2010 15L NaOH 50L 250L Seed Reactor Expansion 1000L 5000L Production Reactor 5 Key Steps in Upstream Process Development • Construct Cell Line – Genetically engineer host organism (mammalian cell line, E. coli, etc.) to produce desired bioproduct. • Clone Selection – Select from many hundreds of clones (genetically different cells) the most appropriate production cell line based on product quality and productivity. • Process Development – Optimize production process parameters to maximize productivity, obtain acceptable product quality and scale up process to production. • Process Transfer – Enable information transfer (process and equipment) between Process Development and Production groups to minimize process issues and speed commercialization. ISPE Biotech Presentation October 3 2010 6 Cell Culture Process General Requirements • Phenotypic Stability – The cells grow, metabolize, and produce with a predictable profile from batch to batch. • Genetic Stability – The cells retain the genetic code for the protein of interest over the population generations from the cell vial to the production vessel harvest. • Axenic Processing – The process is free of foreign growth. ISPE Biotech Presentation October 3 2010 7 Construct Cell Line • Genetically engineer cells to produce monoclonal antibody of interest. – Construct DNA for monoclonal antibody. – Transfect Host Cell with DNA Construct. – Select cells with desired performance capabilities. – Create a bank of the cells with the desired performance. ISPE Biotech Presentation October 3 2010 8 Plasmid Construct For MAbs • Plasmid Contains – DNA of interest LC • Antibody light chain • Antibody heavy chain Promoter Promoter Poly A – Promoters SV40 Intron • Enhance DNA transcription Selector HC – Selector DNA • Glutamine Synthetase • Without Glutamine Synthetase cells are not as likely to survive. Promoter ISPE Biotech Presentation October 3 2010 AmpR ColE1 Ori 9 DNA Incorporation into the Host Cells (Transfection) Plasmid (Engineered DNA) Host DNA Insertion Sites • Inserting Engineered DNA into the host DNA • Have the host cell make something it normally would not make. • Same method that viruses use to infect us. ISPE Biotech Presentation October 3 2010 10 DNA Transfection • Plasmid DNA inserts at specific sites in the host DNA • The insertion site is based on the codon sequence of the host DNA ISPE Biotech Presentation October 3 2010 11 DNA Transfection ISPE Biotech Presentation October 3 2010 12 DNA Transfection • Plasmid DNA is now part of the Host DNA • The host system will read and process the engineered plasmid DNA as if it were its own. ISPE Biotech Presentation October 3 2010 13 DNA Transfection • DNA insertion is in all practicality a random event • 1000s of insertion sites. • Potential for multiple copy numbers. • Outcome is not predictable. ISPE Biotech Presentation October 3 2010 14 Outcome of Transfection • Random Insertions can impact the cells. – Inactivate Genes • Affect the reaction network of the cells – Negative or positive affects – Location near Active Genes • Production associated with cell growth • Production associated with maintenance. – Location in Inactive DNA • Tends to be low productivity. www.tulane.edu/~wiser/malaria/Summary.html ISPE Biotech Presentation October 3 2010 15 Protein Synthesis stemcells.nih.gov/info/scireport/appendixA.asp ISPE Biotech Presentation October 3 2010 http://scienceblogs.com/transcript/2008/03/whats_encoded_in_your_genome.php 16 Protein Production metabolism • The amount of proteins produced is dependent on – Availability and Use of Nutrients – Accumulated Number of Cells – Specific Rate of Protein Production per Cell ISPE Biotech Presentation October 3 2010 17 Protein Production metabolism • Ideal Process – – – – Product Quality Profile Consistent with Prior Proteins High Specific Rate of Protein Production High Cell Density Low Metabolic Waste ISPE Biotech Presentation October 3 2010 18 Clone Selection • Clone Selection is the process of identifying the clones with the desired product quality, yield and phenotype. Transfection Grow Out Photomultiplier Tube Laser • Uses relatively rapid methods to quickly reduce the number of clones examined – – – – – • ------ FACS (Specific productivity) Grow out (Growth Phenotype) Titer (Yield) 1mL wells / 125mL flasks / 4L bioreactors Full product quality package is reserved for final top four clone candidates. Once clone is selected, the master cell bank is prepared. ISPE Biotech Presentation October 3 2010 FACS ++ ++ Electrical ++ Wire ++ ++ Grow Out High Throughput Titer Screening Titer and Growth Screening Limited PQ Clone Selection Titer, Growth, PQ Process Screening 19 Clone Selection • Challenges with Clone Selection – Screening is performed in systems that are not entirely representative of the manufacturing process. • Microwell Plates (1mL) • Shake Flasks (20mL) • Production Bioreactor (5,000L) – Screening is performed on relatively young cells. • Phenotype of cells may change with increased number of generations from the transfection. • Nutrient and process requirements may change with cell age. ISPE Biotech Presentation October 3 2010 20 Process Development Roles for Engineers • Process definition and optimization – Final clone selection – Empirical lab‐scale experiments to define process parameters using DOE approach • Process scale up – Translation of process from lab to production scale equipment for clinical trial production – Equipment performance characterization • Commercialization – Development of increased process understanding through further DOE experimentation and process models – Design of manufacturing facility and process equipment – Translation of process to manufacturing facility ISPE Biotech Presentation October 3 2010 21 Process Development • Upstream process development is predominately empirical – Complex reaction mechanisms not fully understood. – The DNA integration modifies the reaction mechanisms. • Number of studies is manageable with platform processes – Use a systematic DOE approach to gain understanding – Parameters to explore process performance to be similar across projects • Priority tends to be conserved. • Similar studies to examine appropriate set points. – Platform approach to cell culture process. • Limits the need to revisit characterizing equipment, logistics, control or facility capabilities. www.tulane.edu/~wiser/malaria/Summary.html ISPE Biotech Presentation October 3 2010 22 Process Development Approach Y Response Surface Acceptable Limits σx Manufacturing Capabilities μx Process Limits X Set point ISPE Biotech Presentation October 3 2010 23 Process Development Approach Y Response Surface Acceptable Limits σx Manufacturing Capabilities Process will not meet required outcomes μx Process Limits X Set point ISPE Biotech Presentation October 3 2010 24 Process Development Approach Y Response Surface Acceptable Limits σx Manufacturing Capabilities μx Set point ISPE Biotech Presentation October 3 2010 Process Limits X Process will have unnecessary deviations 25 Process Development Approach Y μx(1) μx(2) X For nonlinear responses, changing the process set point changes the process robustness. ISPE Biotech Presentation October 3 2010 26 Example of Process Development Data Prediction Profiler Titer 2.97035 1.698718 ±0.2969 Trp(25) Oxi 0.51532 13 4.673895 ±0.3968 3.7496 Ser(46) Phosph 16.0132 13.28696 ±0.6068 1.8 1.090141 ±0.1659 0.57188 10 2.473784 ±0.4437 DO (%) ISPE Biotech Presentation October 3 2010 Initial Temp (C) T Shift (C) N-1 Temp (C) 18 14 8 11 36 36 1 0 1 34 34 36 34 70 90 1.3738 50 % des H/HG % Pyruvylated 6.24031 Day 27 Stirred Tank Bioreactors • Closed systems operations • Better control than shake flasks • Mass and energy transfers more complex • Engineering role – Designing – Controlling – Scaling bioreactor to conserve the operating space across scale, sites, and runs. ISPE Biotech Presentation October 3 2010 28 Scale Up / Scale Down • Scale and Vessel Configuration Impacts – Mixing • Blend time increases with scale • Heterogeneity of the culture increases with scale – Gas Exchange • Dissolved oxygen control and carbon dioxide accumulation scale by different parameters – Time required to deliver or transfer materials • Hold times will be longer with scale – Controller response time • Increased capacitance slows controllers at larger scale – Interaction of process parameters • Process parameters can fight each other. Need to balance control with scalability. ISPE Biotech Presentation October 3 2010 29 Bioreactor Characterization ISPE Biotech Presentation October 3 2010 30 Oxygen Transfer Rate Data Process Model 120 100 Oxygen Transfer Rate = Kla x C*(1‐ DO) ) (% 80 n e gy x O 60 d e lv o ss i 40 D 20 0 0 20 40 60 80 100 Time (s) ISPE Biotech Presentation October 3 2010 120 140 Downstream Operations Considerations • The bioreactor is the source of many of the impurities that downstream removes. – Lower culture viabilities release host cell proteins, DNA, and proteases that can impact regulatory requirements or product quality. – Lower culture viabilities challenge the capability of clarification to remove the cells and cellular debris prior to the first chromatography column. – The downstream platform may not always be capable to efficiently remove product variants. • The development and operation of the cell culture process needs to take into account the impact to downstream processing. ISPE Biotech Presentation October 3 2010 32 Product Quality Attributes and Impact to Downstream Processing • High Priority – Product quality variants that impact potency and cannot be removed downstream • Medium Priority – Product quality variants that can be removed downstream and impact yield. – Process yields. – Harvest conditions; viability, cellular debris • Low Priority – Variability in cell densities or metabolites. ISPE Biotech Presentation October 3 2010 33 Downstream Operations‐ EColi Process A FERMENTATION Chromatography ISOLATION Ultrafiltration A Crystallization FILTRATION Ultrafiltration Chromatography ISPE Biotech Presentation October 3 2010 34 DRYER Downstream Operations‐Cell Culture Process ISPE Biotech Presentation October 3 2010 35 Process Chromatography Chromatographic Process‐ Block Diagram Adsorption Chromatography (IEX, HIC, RØ, Affinity) Equilibration Load Post wash Elution Regeneration ISPE Biotech Presentation October 3 2010 Size Exclusion Chromatography Column preparation Equilibration Sample application Load Residual sample removal Sample separation Elution Column clean‐up Regeneration 36 Role of a Bioprocess Engineer Manufacturing Environment Pressure profile of column 45 Pressure(psi) 40 35 30 25 20 15 10 ISPE Biotech Presentation October 3 2010 37 Lot… Lot… Lot… Lot… Lot… Lot… Lot… Lot… Lot 9 Lot 8 Lot 7 Lot 6 Lot 5 Lot 4 Lot 3 Lot 2 Lot 1 0 Lot… 5 Column Hydraulics‐Continued ⎛ 150μu L ⎛ 1− ε ⎞2 106 1.75ρ (u )2 L 1− ε 1 ⎞ 14.7 0 b 0 b ⎟ ⎟ ⎜ (psi) + ΔP = ⎜ 2 5 ⎟ ⎜ ⎜ dp ⎝ ε b ⎠ 6 dp ε b 3.6 ⎟ 1.013×10 ⎠ ⎝ Voidage trend at different steps 0.31 0.29 Voidage 0.27 0.25 0.23 0.21 0.19 Column repacked 0.17 0.15 Lot number ISPE Biotech Presentation October 3 2010 38 Tangential Flow Filtration RETENTATE FEED REVERSE TFF OSMOSIS UNIT Operation PERMEATE In general, Tangential Flow Filtration (TFF) operations are used for clarifying, concentrating, diafiltering, and purifying proteins ISPE Biotech Presentation October 3 2010 39 Difference between TFF and NFF Normal Flow Filtration Tangential Flow Filtration Reference: Millipore Technical Brief “Protein Concentration and Diafiltration by Tangential Flow Filtration”. ISPE Biotech Presentation October 3 2010 40 TFF Systems ISPE Biotech Presentation October 3 2010 41 Role of a BioProcess Engineer Manufacturing Environment Flux (GFD/psi Flow(L/min), Permeate Flow/Flux in during CIP 9 0.35 8 0.3 7 0.25 6 5 0.2 4 0.15 3 0.1 2 1 0.05 0 0 0 5 10 15 Data from CIP's ISPE Biotech Presentation October 3 2010 20 42 Permeate Flow (L/min) NWP (GFD/psi) Role of a BioProcess Engineer Continued Flux (J) = TMP /(Rm+Rf+Rg) Rm=Membrane Resistance Rf‐ Fouling Resistance Rg‐ Gel layer Resistance Monoclonal Antibody TFF Process ISPE Biotech Presentation October 3 2010 43 Disposable System ‐ Mixing ISPE Biotech Presentation October 3 2010 44 Conclusions • The objective of the bioprocess process is to reproducibly produce bioproteins that are consistent in product quality, yield, purity and provides a predictable feed stream for downstream unit operations. • This is accomplished with a team of scientists, engineers, statisticians, and other specialists. ISPE Biotech Presentation October 3 2010 45