Technology Transfer gy Herwig Kapeller, Novartis Pharmaceuticals Corp. September 10, 2009

advertisement

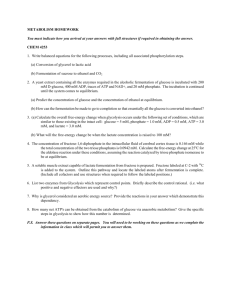

Technology gy Transfer Herwig Kapeller, Novartis Pharmaceuticals Corp. September 10, 2009 Page 1/29 Agenda g • What is a Technology Transfer • Structures for Success – Transfer Plan • Case study 1: Transfer of an improved process from Development into Production • Case study 2: Transfer of a recombinant protein from 3rd party production into Novartis production • Lessons learned September 10, 2009 Page 2/29 Technology gy Transfer • Transfer all the knowledge g needed to perform a given biotech process from a Transferring Site to a Receiving Site ¾ Transfer processes from Development into Production ¾ Transfer processes from one No Novartis artis site to another Novartis site ¾ Transfer of processes from other Biotech/Pharma companies into Novartis ¾ Transfer processes from Novartis to 3rd parties September 10, 2009 Page 3/29 Novartis Biopharmaceutical O Operations ti - BPO September 10, 2009 Page 4/29 BPO - Transfer Plan • • • • • • • • • Transfer strategy gy Timelines and key milestones Transfer costs Organization and responsibilities Transfer acceptance criteria P Process d description i ti Status evaluation and gap analysis Process adaptations at the receiving site Equipment adaptations at the receiving site September 10, 2009 Page 5/29 Transfer Strategy gy • Description of the process being transferred and whether a change in scale is involved with the site transfer • Risk Assessment whether the process transferred fits into the facility of the receiving site • Possible process adaptations or equipment adaptations of the receiving site • On site Training of RS people at TS before transfer and at RS during engineering runs • How many technical transfer batches in small-scale pilot-scale bioreactors/fermenters and lab-scale or p DSP equipment September 10, 2009 Page 6/29 Transfer Strategy gy • Number of engineering g g and GMP batches at largeg scale • Need for a pre-comparability study with material f from the th pilot-scale il t l technical t h i l transfer t f batches b t h prior to the start of the large-scale campaign • Which batches manufactured at the transferring site will be included in the comparability study • Need for validation studies, what needs to be repeated t d September 10, 2009 Page 7/29 Phases of Technology gy Transfer Information Transfer Analytical Phase Pilot Phase Scale Up M Manufacturing f t i September 10, 2009 Page 8/29 Organization g and Responsibilities p • Define who is responsible for what • Leave no interpretation room • Responsibility list (e.g. RACI chart) • Full responsibility for the manufacture of the batches and the process itself is transferred to the receiving site or some activities remain with the transferring site? • Discuss responsibilities in case process adaptations have to be made. September 10, 2009 Page 9/29 Transfer Acceptance p Criteria • These criteria will depend on the phase of development – obviously the more advanced the project, the more detail will be required. • The Th transfer f acceptance criteria must be agreed by the transferring g and receiving g sites prior to the start of the transfer. • Involve In ol e QA and RegCMC Title of test Specification Properties Appearance of lyophilizate 1) Color of solution Solubility White or almost white powder Report result Freely soluble in water Identity Identity b y N-terminal amino acid sequence Identity b y HPLC Identity b y Trypsin digest (Peptide Mapping) Positive identity Positive identity Positive identity Purity Purityy b y HPLC Related substances by HPLC ≥ 95.0 % ((area)) ≤ 3.0 % (area) for any single peak ≤ 5.0 % (area) for all peaks ≥ 95.0 % (area) ≤ 3.0 % (area) for any single peak ≤ 5.0 % (area) for all peaks ≤ 3.0 % (area) for N-acetyl-Cys1-CT (impurity A) Purity b y CEX Related Substances by CEX ≤ 0.6 % (area) for Gly-CT (impurity E) ≤ 0.2 % (area) for SO3-CT (impurity F) ≤ 0.2 % (area) for SO3-Gly-CT (impurity G) Related Substance (Dimer) of sCT by SE-HPLC 1) Bacterial endotoxin (LAL) Bioburden Ethanol Report main peak % (area) Report dimer peak % (area) ≤ 25 EU/mg sCT ≤ 100 cfu/100 mg sCT ≤ 0.5 % Assay September 10, 2009 Assay by HPLC Water content Acetic Acid content ≥ 80.0 % (w/w) ≤ 10.0 % 4.0 – 15.0 % Sum of contents of Acetic Acid + Water ≤ 20 % Potency Potency determination by cAMP ELISA with T47D cells ≥ 5000 IU/mg of peptide Page 10/29 Process & Equipment q p Adaptations p • Based on status evaluation and g gap p analysis y • Goal is to fit the process into the facility at the receiving site • Aim is to keep process and resulting product quality the same • Depending on phase of product possibilities for changes may be limited September 10, 2009 Page 11/29 Need for Adaptations p • Amount of available vessels vs. disposable t h l technology • Volumes of vessel (e.g. volume of seed vessel too small, small change process or change equipment, equipment change transfer criterion, additional studies) • Corrosion (e.g. (e g trace element solution in HCl - in glass flasks at lab scale, steel tanks at manufacturing scale) • Accuracy of feed rates (e.g. glucose feeding at start required lowest pump rate, could not be realized with mass flow at manufacturing scale) September 10, 2009 Page 12/29 Process & Equipment q p Adaptations p • Exactly the same raw materials might not be available • Quality may vary despite the same specification • A hi higher h quality lit material t i l is i nott always l better b tt September 10, 2009 Page 13/29 Case Study 1 – Development V Vacaville ill to t Production P d ti Vacaville V ill Extracellular recombinant protein in yeast Simple p process: p • Fermentation • Centrifugation • Filtration • Capture Chromatography • Concentration C t ti September 10, 2009 Page 14/29 Case Study y 1 – Fermentation • Process developed early 1990 • Successfully running at 12k production scale • Process improvements identified • • • • Small scale model in 20L lab scale developed 36 experiments to establish Design Space Fermentation with an exponential feed profile Abbreviated transfer plan due to existing process knowledge September 10, 2009 Page 15/29 Case Study y 1 – Fermentation • • • • • • • • • Transfer strategy Timelines and key milestones Transfer costs Organization and responsibilities Transfer acceptance criteria Process description Status evaluation and gap analysis Process adaptations at the receiving site Equipment adaptations at the receiving site September 10, 2009 Page 16/29 Case Study y 1 – Fermentation • First test rruns ns at scale “failed” • Altered growth behavior • Altered ethanol metabolism & productivity Main Culture - Cell Growth 30 OD failing f ili run 100 25 OD good run 80 20 [Ethanol] good run 60 15 ` 40 10 20 5 0 [[Ethanol] (g/L) Optical Density O [Ethanol] failing run] 0 0 10 September 10, 2009 20 30 40 runtime (h) 50 60 70 Page 17/29 Case Study y 1 – Fermentation • Structured Str ct red Root Ca Cause se Anal Analysis sis • Glucose Feed changed • ADH promotor in cells is highly glucose sensitive • Local g glucose concentration gradients g • Experimental mixing time 7 - 9 minutes • Cells are “switching on and off” ¾ Improve mixing at scale September 10, 2009 Page 18/29 Case Study y 1 – Fermentation ¾ Process & Equipment adaptations at the receiving site • Agitation g rate increased • Glucose feed line submerged Did we succeed? September 10, 2009 Page 19/29 Case Study y 1 – Fermentation • More Root Ca Cause se Anal Analysis sis • Signs of limiting nutrient •O One off the th complex l raw materials t i l had h d slightly changed in respect to its composition p ¾Addition of a larger amount of trace elements September 10, 2009 Page 20/29 Case Study 2 – Production 3rd party t Production to P d ti Novartis N ti Extracellular recombinant protein in yeast More complex p process: p • Fermentation • Centrifugation • Multiple Chromatography Steps • Concentration September 10, 2009 Page 21/29 Case Study y2 • Process successfully running at 3rd party 20k production scale for years • Fermentation employs a sophisticated dissolved oxygen/pH depending glucose feed control • Transfer to 40k scale via pilot phase at Sandoz Kundl • Excellent process description available • 3rd party supports transfer with experienced on site it personnell • Successful transfer into pilot phase September 10, 2009 Page 22/29 Case Study y2 • First test rruns ns at scale “failed” • Growth behavior comparable • Productivity only 20% September 10, 2009 Page 23/29 Case Study y2 • Structured Str ct red Root Ca Cause se Anal Analysis sis • Calibration of DO probes is different • 2nd Agitator blade hits the surface just at the time of induction September 10, 2009 Page 24/29 Case Study y2 • Adaptations ¾ Change criteria for DO to accommodate for different calibration of probes ¾ Change starting volume ¾ Change position of agitator blades on shaft September 10, 2009 Page 25/29 Lessons Learned • People & Communication • Face-to-face kick-off meeting • Visit transferring site and watch process • Physical presence of experts from the transferring site during first runs • Understand process complexity • Equipment / Facilities • Detailed knowledge of the technical set set-up up of the receiving site needed • Availability of Lab and pilot plant resources September 10, 2009 Page 26/29 Lessons Learned • Materials & Methods • Analytical transfer phase often underestimated • Include information about what can go wrong, which points should be carefully watched in tech transfer documents • Information about the origin of limits and parameters • Processes • A structured structured, well defined approach saves time and money • Anticipate p changes g from outside your y control area September 10, 2009 Page 27/29 Lessons Learned • Questionnaire to gather information • Group meetings to finalize the output Background (Issue(s) faced within the project or the team) Chosen Management (What did you chose to do about the issue and why?) What was done well/not done well? Why do you think things went well/did not go well? What should be done similarly next time? What could be improved next time? Are there any generalizable LLs to be gained from this experience? (List actionable LLs) Key words: ((for archiving gp purposes) p ) September 10, 2009 Page 28/29 Acknowledgements g • Novartis Vacaville Manufacturing Technology & Engineering Gabriel Batey, Matt Colemann, Ross Cox, Ji-eun Lee, Viki Levi, Julie McKnight, Michael Plesha, Peter Tan, Diana Tierra, Kent Xu, Xiaoyue Zhu, Korchang Hsu • Sandoz Kundl Development Klaus Graumann, Bettina Knorr, Norbert Palma, Gerhard Schneider September 10, 2009 Page 29/29