Thermodynamics of stressed solids: Slow deformation and roughening of material interfaces T E

advertisement

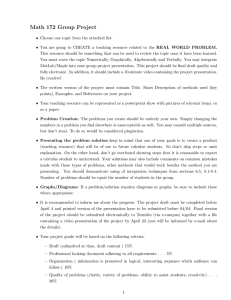

Eur. Phys. J. Special Topics 178, 123–132 (2009) c EDP Sciences, Springer-Verlag 2010 DOI: 10.1140/epjst/e2010-01185-3 THE EUROPEAN PHYSICAL JOURNAL SPECIAL TOPICS Regular Article Thermodynamics of stressed solids: Slow deformation and roughening of material interfaces L. Angheluta1 and J. Mathiesen1,2,a 1 2 Physics of Geological Processes, University of Oslo, Oslo, Norway Niels Bohr Institute, University of Copenhagen, Blegdamsvej 17, 2100 Copenhagen O, Denmark Abstract. At every turn in nature we are confronted with complex patterns. Patterns often formed in multiphase systems by an intricate dynamics of mass transport, e.g. diffusion and/or advection, and mass exchange between individual phases. Here we consider instabilities of phase boundaries in idealized stressed multiphase systems. Specifically, we study the growth of small perturbations of surfaces by considering mass transport from regions, where the stress and chemical potential is high, to surrounding regions where the stress and chemical potential is low. We present a linear stability analysis for various stress configurations and their corresponding stability diagrams. 1 Introduction Pattern formation in multiphase systems is a central subject in the research on nonlinear dynamics. The interest has been sparked by the ubiquitous appearance of spectacular patterns on all scales in nature. A common goal for research on pattern formation has been to illuminate the underlying fundamental mechanisms and the coupling between them. Here we shall demonstrate in few model systems how basic physical principles can explain complex morphologies formed in deformable and reactive materials. The evolution of solid surfaces is usually governed by stress or thermally activated physical processes. It involves mechanical deformation often coupled with chemical alteration e.g. surface growth by dissolution and precipitation. A classical example of surface instability is thermal grooving triggered by evaporation and condensation [11]. At surfaces of stressed solids, mass is typically transported by surface diffusion from regions of relatively high stress (high chemical potential) to regions of low stress (low chemical potential). This process corrodes the surface and gives rise to the Asaro-Tiller-Grinfeld instability [4,6]. Often the mass transport is mediated by an interstitial fluid via dissolution in stressed regions and the subsequent precipitation at free sites, a process also known as “pressure solution” [17]. Sutured grain boundaries in sandstone [14] is one example where undulating surfaces are believed to be generated by pressure solution. From a modeling perspective, we consider interfaces as transition regions over which material properties (densities, rheological properties, stress, velocity) undergo steep gradients. In the limit where the thickness of these regions is much smaller than any other relevant length scale of the system, one may consider the internal structure of a material to be represented by continuous regions connected at discontinuity surfaces or sharp interfaces. The term interface is used throughout this text to denote borders that separate different phases or individual but homogeneous regions. Below, we shall present in details the stability analysis of various sharp interfaces in two-phase systems. We show that the interfacial stability depends on the stresses in the system, its rheology (viscous, elastic) and other discontinuities in material properties. a e-mail: mathies@nbi.dk 124 The European Physical Journal Special Topics The change in field variables, as small undulations of size h(x) develop along an otherwise flat interface, is conveniently calculated using linear perturbation theory. When the amplitude is small enough, the new fields may be written perturbatively as an expansion around the values of the flat interface. Formally, this is written as U (x, y) = U (0) (x, y) + U (1) (x, y) + O(2 ), (1) where U (0) (x, y) is the solution to a planar interface and U (1) (x, y) is a first order correction accounting for small undulations. Evaluated at a point on the interface y = h(x), the expansion becomes U (x, h(x)) = U (0) (x, 0) + h(x)∂y U (1) (x, y)|y=0 + U (1) (x, 0) + O(2 ). (2) In Section 2 we summarize essential parts of interfacial perturbation schemes using as an example the classical problem of viscous fingering. This instability has important similarities to instabilities of liquid-solid (Section 3) and solid-solid stressed interfaces presented in Section 4. 2 Viscous fingering Viscous fingering is realized when a less viscous fluid displaces a more viscous fluid contained in the narrow gap between two glass plates (a Hele-Shaw cell). When the less viscous fluid is inserted through a gap at one side of the glass plates, a finger-like pattern is formed at the interface separating the two immiscible fluids. The fluid velocity v of the displaced fluid in a Hele-Shaw cell satisfies Darcy’c law, where p is the pressure. Namely, a less viscous fluid (e.g. water) migrates into a more viscous fluid (e.g. oil) by developing fingers which move ahead of the interface at various speeds. Contrarily, the interface remains planar when the water is displaced by the oil. This instability is known as SaffmanTaylor instability [15] or viscous fingering. The governing equations for an incompressible viscous flow are given by Stokes equations combined with the continuity equation, µ∇2 v − ∇(p + ρgz) = 0 ∇2 p = 0, (3) (4) where v = (vx , vy , vz ) is the velocity vector field which is a solenoidal field when the fluid density ρ is constant. µ is the kinematic fluid viscosity. The gravitational field g is pointing downwards opposite with respect to the vertical z-axis. The pressure field is denoted by p(x, y, z, t). When the flow is confined between two parallel plates in the (x, z)-plane, the velocity in the y-direction vanishes (see Fig. 1). For a single phase flow, we can assume a homogeneous flow in the xdirection and therefore obtain essentially an uniaxial flow in the z-direction with vz (y, t). For small perturbations, it is enough to study the stability of an arbitrary mode hk (t) exp(ikx), where hk (t) ∼ exp(ωt), i.e. a mode with a growth rate ω. If ω > 0 the mode will be unstable and have an initial exponential growth rate. Inserting this perturbation in the governing equation we obtain the usual dispersion relation for Saffman-Taylor fingering gH 2 ρ1 − ρ2 µ1 − µ2 ω = + V (0) . k 12 µ1 + µ2 µ1 + µ2 (5) From the above relation, we see that the stability of the interface depends on the direction of the flow (by the sign of V (0) ) and the relative density ρ1 − ρ2 and viscosity µ1 − µ2 . The interface becomes unstable when the flow is under gravity with the denser fluid on the top of a lighter fluid or when the flow is upwards with a positive V (0) and the less viscous fluid at the bottom migrating into the more viscous fluid above it. The growth rate is linearly proportional to the wavenumber, and therefore there is no mode selection, e.g. the interface is either stable Order, Robustness and Instabilities in Complex Systems 125 Fluid 1 g H Fluid 2 z x y Fig. 1. Basic setup used to study the Saffman-Taylor instability. or unstable at all length scales. In the presence of surface tension, there will be an additional term in the growth rate related to the curvature and surface tension and one can show that this term√is stabilizing the interface perturbations with wavelengths smaller than a critical value 2πH σ[12V (0) (µ1 − µ2 ) + (ρ1 − ρ2 )gH 2 ]−1/2 , with σ being the surface tension [15]. Some of the features of the Saffman-Taylor instability are recovered when two stressed linear elastic solids are in contact and when the solids are allowed to exchange mass along the contact interface. That is, the solids cannot flow and deform like the viscous fluids, however if mass can be transferred across contacts, the contact interface evolves and in certain cases becomes unstable. 3 Morphological evolution of a liquid-solid interface The dissolution and precipitation of a solid surface in contact with a surrounding fluid at rest may induce a net transport of mass along the surface and in certain cases even lead to morphological instabilities. Diffusion-controlled growth by material deposition or heat flow give rise to the Mullins-Sekerka instability [12] which has been studied e.g. in systems of growing ice crystals in contact with undercooled water [8]. In the nonlinear regime, the same instability may give rise to side-branching and tip-splittings [9]. Like the thermal fluxes, stress can bring the solid out of chemical equilibrium with the surrounding fluid and thus induce local changes in the interface morphology. Surface corrosion controlled by stress variations at a liquid-solid interface has been studied in [4]. The linear instability caused by stress corrosion was discovered independently by Asaro and Tiller in [4], Grinfeld in [6] and is known as the ATG-instability. Nonlinear stability analysis combined with numerical simulations reveal that the interfacial shape evolves into cusp-like singularities when higher order terms in the amplitude expansion are retained [18,19]. The ATG instability has been studied extensively using diffuse interface models, e.g. [7,20]. Hereby, we shall present its equivalent formalism for sharp interfaces. When a stressed solid is in contact with a saturated fluid, the chemical potential at the solid surface becomes a function of stress on the form [16] µ(s) = F(s)V − σnn (s)V, (6) where s is a parameterization of the surface, V is the molar volume of the solid component, F is the Helmholtz free energy density, σnn is the normal component of the stress vector. For a free 126 The European Physical Journal Special Topics Fig. 2. Basic setup of two stressed linear elastic solids in contact. The solids are allowed to exchange mass across the interface such that the interface evolves in time. We show that depending on the elastic parameters of the solids the interface may be either morphologically stable or unstable. surface σnn = 0, while if the surface is in contact with the fluid then σnn = −p with p being the hydrostatic pressure in the fluid. Unless the normal stress is small or vanishes, the Helmholtz free energy is in general small compared to the last term and therefore, to the leading order approximation, can be neglected. The surface gradients in the chemical potential produce a drift of surface atoms with a flux given by [11] Ds a ∂µ(s) , (7) J =− kT ∂s where a is the surface density of atoms, Ds is the surface diffusion coefficient and kT is the Boltzmann’s constant times temperature. Note that depending on the system, Ds could represent diffusion along the solid surface or along a thin fluid film in contact with the interface. If we take the divergence of the mass flux, we achieve an expression for the local change in number of atoms per unit area per unit time which is directly related to the normal velocity of the interface via Ds aV ∂ 2 µ(s) ∂J = V = −V . (8) ∂s kT ∂s2 For small undulations on a planar interface, the above equation can be approximated by ∂h(x, t) ∂2 = M 2 µ(h(x, t)), ∂t ∂x (9) s aV where M = DkT is a positive-defined mobility coefficient. The above equation describes the morphological evolution due to mass transport by diffusion. This is an alternative mass transport mechanism to the Mullins-Sekerka instability where the mass exchange takes place across the interface and thus is driven by the jumps in the chemical potential, ∂h(x, t) = M µ(h(x, t)) . ∂t (10) Previous studies of the ATG instability treat the limit where the fluid is at rest and thus possible shear stresses at the interface are neglected. However, many natural interfaces are able to sustain shear stresses. In a recent work, shear stresses induced by a flowing fluid are shown to have a stabilizing effect [3] on the surface growth. In the next section, we discuss the morphological evolution of stressed solid-solid interface. Order, Robustness and Instabilities in Complex Systems 127 4 Morphological stability of two contacting solids 4.1 Phase transformation kinetics in one dimension It is illustrative to consider the dynamics in a one-dimensional system of two linear elastic solids separated by a single interface. The solids are allowed to exchange mass at a rate determined by their chemical potential. Assume that a force σ is applied at one boundary of the system and that the other boundary is kept fixed. Each solid phase, i, is characterized by Young’s modulus Ei (i = 1, 2), undeformed density ρ0i and length L0i . When the external force is applied, the system deforms to a length Li = L0i (1+σ/Ei ). Similarly, the density is changed to ρi = ρ0i L0i /Li . We shall now follow the analysis presented in [2]. For the solid i, the total specific free energy is given by 1 σ2 . (11) fi = 2 ρi (Ei + σ) In this simple setup we do not allow new phases to nucleate within the solids and we only consider the propagation of a single interface separating the two solids. Moreover, we assume that the system is isothermal and that there is no bulk diffusion of mass. The interface moves as one phase, slowly transforms into the other and an amount ρ1 dL1 , of solid 1 is replaced by an amount ρ2 dL2 of solid 2 such that the total mass is conserved. The phase transformation is assumed to be irreversible and to occur on time scales that are much larger than the time it takes for the system to relax mechanically under the deformational stresses. The local mass exchange rate Q is proportional to the jump in the Gibbs potential across the interface, i.e. Q ∼ f − σ/ρ, where 1/ρ is the mass specific volume and the jump condition, a = a1 − a2 , is defined as the difference in the quantity a when approaching the interface from each material phase. In that way, we can write the change in mass of e.g. solid 1 as 2 2 σ σ σ σ − + 0 , (12) ṁ1 = −K =K 2ρ0 E ρ 2ρ0 E ρ with K > 0 being some dimensional constant of proportionality. In most cases, the contribution from the jump in the elastic energy density will be small compared to the contribution from the work term σ/ρ (because σ/E 1, within the linear elasticity regime). The change in the total length will in general follow the sign of the stress 1 ρ1 L̇ = L̇1 1 − = ṁ1 ρ2 ρ 2 1 σ σ σ + + . =K 2Eρ0 ρ0 ρ0 Eρ0 If the densities in the undeformed states are identical, ρ01 = ρ02 , the change in the total length is given by 2 σ3 1 L̇ = K 0 , (13) 2ρ E whereas a jump in the referential densities (ρ01 = ρ02 ) will result in a work term given by L̇ ≈ Kσ 1 ρ0 2 . (14) In summary, a compressional load will favor growth of the dense phase at the expense of the less dense phase (if the two phases have the same Young’s modulus). If the two phases have the same density, the soft phase grows at the expense of the hard phase, such that overall the system responds to the external force by shrinking. The one-dimensional model cannot predict the morphological stability of the propagating phase boundary in two dimensions. 128 The European Physical Journal Special Topics 4.2 Stability analysis in 2D Under the assumption that the system is instantaneously relaxing to its equilibrium configuration, we consider the steady state of the momentum equations for both elastic solids. The stress of an elasto-static two-dimensional configuration is conveniently calculated using the Airy stress function, U (x, y) [13], which satisfies the biharmonic equation ∆2 U = 0. Here, we have ∂2 ∂2 introduced the Laplace operator ∆ = ∂x 2 + ∂y 2 . Once the stress function has been found, the stress tensor components readily follow from the relations σxx = ∂2U , ∂y 2 σyy = ∂2U , ∂x2 σxy = − ∂2U . ∂x∂y (15) Here we solve the elasto-static equations with the boundary conditions of a normal load applied in the y direction at infinity, i.e. σyy → −|σ∞ | < 0 and σxy = 0 for y → ±∞. The continuity of the stress vector across the interface follows from force balance. In addition we require that the displacement in the x-direction vanish for ux (±∞, y) = 0. For a flat interface, the stress field is homogeneous in space. This implies that the Airy stress function is quadratic in x and y, with coefficients determined by the boundary conditions. With the boundary conditions specified above, the stress function for the i-th phase can be written in the form |σ∞ | 2 (x + νi y 2 ), Ui (x, y) = (16) 2 where νi is the Poisson’s ratio of phase i. From this stress function we can calculate the Gibbs potential which in the case of dissimilar phases is discontinuous across the interface. The velocity of the phase transformation readily follows from the potential 1 1 1 − 3ν2 |σ∞ |2 1 − 3ν1 (0) (0) 0 (0) = M |σ∞ | V = M F /ρ + W − 0 − − 0 . ρ01 ρ2 4 ρ01 G1 ρ2 G2 (17) The superscript of the free energy density and the work term refers to an unperturbed interface. From the above equation, we see that the direction of propagation depends on the jump in the material properties in a similar way to Saffman-Taylor instability. When the referential densities are different, the above expression is dominated by the first term and predicts that the phase transformation is directed from the denser phase into the lighter phase. In the case where the referential densities are the same, the second term becomes the leading order and, for ν < 1/3, gives a reverse propagation from the softer phase (higher shear modulus) into the harder phase (lower shear modulus). In the case of an arbitrarily shaped interface separating the two phases, the analytical solution to the stress field is in general far from trivial. In-plane problems can in some cases be solved using conformal mappings or perturbation schemes [5,10,13]. Here, we solve the stress field around a small undulation of flat interface employing the linear perturbation scheme introduced above. Using the linear stability analysis, we now study the growth of an arbitrary harmonic perturbation with wavelength k, i.e. h(x, t) = Aeωt cos(kx) with A 1. The Airy stress function can be written as a superposition of the solution to the flat interface and a small correction due to undulation, U (x, y) = U (0) (x, y) + U (1) (x, y), where U (1) (x, y) is determined from the interfacial constraints of continuous stress vector and displacement field. When the wave number k is much smaller than the cutoff introduced by the surface tension, we obtain the following expressions for the Airy stress functions (1) U1 (x, y) = (1) U2 (x, y) = −|σ∞ |h(x) exp(−ky)(α1 y + β) k(G2 κ1 + G1 )(G1 κ2 + G2 ) |σ∞ |h(x) exp(ky)(α2 y − β) k(G2 κ1 + G1 )(G1 κ2 + G2 ) (18) Order, Robustness and Instabilities in Complex Systems 129 i where κi = 3−ν 1+νi , Gi is the shear modulus of phase i and we have introduced the material specific constants, α1 = −k(1 − ν1 )(G2 − G1 )(G1 κ2 + G2 ) α2 = k(1 − ν2 )(G1 − G2 )(G2 κ1 + G1 ) and 1 − ν2 1 − ν1 ν1 − ν2 . − 2G22 + 4G1 G2 1 + ν2 1 + ν1 (1 + ν2 )(1 + ν1 ) In order to evaluate the jump in Gibbs energy density, i.e. F/ρ0 + W , we need to determine the stress field around the interface by solving the elastostatic equations. We have that under plane stress conditions, the local strain energy density can be written on the form 1 ν 2 2 2 (σxx + σyy )2 + 2σxy F= + σyy − (19) σxx 4G 1+ν β = 2G21 and the work term is defined as = −σnn ρ−1 W = −σnn ρ−1 i i,0 (1 + Tr()). (20) The trace of strain is given in terms of stress by Tr() = 1 − 2ν (σxx + σyy ). 2G(1 + ν) (21) Note that we could as well have formulated the problem under plane strain conditions; however, the generic behavior in both plane stress and strain is the same although the detailed dependence on the material parameters is altered. From the Airy stress functions, we then calculate the stress components using Eq. (15) and find the jumps in the Gibbs energy density from Eqs. (19) and (20). The evolution of the shape perturbation relative to a uniform translation of the flat interface is a dispersion relation given as M F + W − V (0) ω= . (22) h Below follows an evaluation of the growth rate for a small harmonic perturbation to a flat interface. For this perturbation, the general expression for the growth rate follows directly upon insertion of the Airy functions in Eq. (18) and then in Eq. (22), however, the growth rate is not easily expressed in a short and readable form and we have therefore limited our presentation to a few special cases. The growth rate is a function of the six material parameters (νi , µi , ρi ) and the external stress. Naturally, the stability of the growing interface is invariant under the interchange of the solid phases and correspondingly the region of the stability diagram that we have to study is reduced. 4.3 First and second order phase transitions Whenever the system is stressed, only one of the two phases will be stable, i.e. the two phase system will evolve to a global equilibrium state consisting of a single phase. In the absence of stress it is possible for two phases to coexist without any phase transformation taking place at their interface. In the aforementioned 1D model system, the specific Gibbs energy is given by the stress applied to the system σ, g(σ) = σ σ2 − . 2Eρ0 ρ (23) 0 −0. 03 −0.01 ρ2, (ρ1 = 1) 0.5 ρ2, (ρ1 = 1) 0.5 2 0.10 1.5 ρ2, (ρ1 = 1) 0.15 µ2, 1 (µ1 = 1) 05 −0 . 7 1.5 0 1 µ2, (µ1 = 1) 1.5 2 −0.10 0 10 −0.15 −0.20 0.15 0.10 0.05 0 0.0 −0.05 −0.10 2 0 0. 6 1 0.5 0.5 0.00 −0.02 .06 −0 .1 −0 0.02 0.5 4 0.5 1 −0.05 6 −0.0 1 −0. .14 −0 −0 .04 0 −0.02 .02 −0 0. 0 0.00 −0.02 0. 04 0.00 0 0.08 0.1 2 0.0 2 −0.0 2 ρ2, (ρ1 = 1) ρ2, (ρ1 = 1) ρ2, (ρ1 = 1) ρ2, (ρ1 = 1) ρ2, (ρ1 = 1) −0 .06 −0.0 4 .0 4 −0 0.01 5 −0.0 3 −0.01 08 −0. −0.0 −0 0.10 10 2 1 −0.15 2 1 0.05 0.0 (µ1 = 1) 1.5 0.15 6 0.0 −0. 11 1.5 0.01 µ2, 1 4 0.0 0.5 0.02 0.09 0.5 2 4 0.0 .14 1 −0.10 0.0 6 1.5 0 05 0.05 −0.05 −0.15 −0.2 0.10 0.02 (µ1 = 1) 0.04 2 µ2, 1.5 −0.05 1 (µ1 = 1) 08 0.5 0.05 1 2 .06 −0 .1 −0 0.02 0.03 −0 0.0 4 2 0.10 µ2, 0.10 −0.01 03 −0. 0.01 −0.10 0.00 0.5 06 0. 1 −0.05 0.5 1.5 2 14 −0.1 .2 −0 0.5 0. 1.5 −0. −0.20 0.00 3 1 8 −0.0 0 05 0.05 0 (µ1 = 1) −0.15 0.0 −0.04 1.5 07 0. µ2, −0.10 1.5 0.0 3 0.0 0.5 0.01 0.5 0.0 5 1.5 0.1 0 1 4 0.0 1 1 (µ1 = 1) −0.05 0.02 0.00 µ2, .16 5 0.0 2 0.05 1 .0 −0 ρ2, (ρ1 = 1) 0.5 3 0.0 0 2 1.5 −0 0.5 0.01 −0.02 −0.15 0. 0 4 0.02 −0. 1 −0. 08 −0. 06 −0.0 4 1 −0 .08 1.5 06 −0. .1 −0 −0 .05 1 (µ1 = 1) µ2, −0.02 0.08 . −0 −0.10 0.0 2 6 0.0 3 0.0 0.5 0 .0 1 0. 0 5 0.5 −0.05 0.00 1 0.0 6 15 1.5 4 0.0 1 −0.0 .03 −0 6 .0 −0 2 0 05 0.05 04 .06 0. 0 1 0.0 4 2 0.10 15 1.5 0.00 2 0 −0.01 0.05 15 1.5 0. 04 2 0.0 −0.0 2 3 0.0 0.01 2 3 The European Physical Journal Special Topics −0. 05 130 µ2, 1 (µ1 = 1) 1.5 −0.05 −0.10 2 Fig. 3. The rows from top to bottom are stability diagrams with Poisson’s ratio ν2 = 0.25,0.33,0.40, for solid 2. Note that µ in the figure represents the shear modulus G. From the left to the right, the columns show stability diagrams computed using for solid 1 Poisson’s ratio ν1 = 0.25,0.33,0.40. Note that the symmetry is broken since ρ1 = 1 and G1 = 1. We define a first order phase transformation process when the first derivative of the specific Gibbs energy with respect to σ is discontinuous at the critical point σ = 0. From the above relation, we see that this happens when the two phases have different referential mass densities. By a second order phase transition, we mean that there is a finite jump in the second order derivative which is related to the discontinuity of the Young modulus, E. We adopt the same terminology for the interfacial phase transformation in 2D. In the two dimensional system, we have that for the second order phase transition where both solids have the same referential densities ρ01 = ρ02 = ρ0 and when the Poisson’s ratios ν1 = ν2 = ν are identical, the dispersion relation assumes a simple form given by ω (3ν − 1)(1 − ν)(G1 + G2 )(G2 − G1 )2 = 0 k ρ G1 G2 (G1 + G2 κ)(G2 + G1 κ)(1 + ν) (24) where κ is the fraction introduced right below Eq. (18) and k the wave number of the perturbation. The expression reveals an interesting behavior where the interface is stable for Poisson’s ratio less than 1/3 and is unstable for Poisson’s ratio larger than 1/3. Fig. 3 shows stability diagrams for the specific case where G1 = 1 and ρ01 = 1 (in arbitrary units). The diagonal panels are calculated for two solids that have the same Poisson’s ratio, i.e. values ν = 0.25, 0.33, 0.40. The second order phase transition occurs along the horizontal cut ρ02 = 1 and is marked by a dashed gray line. We observe that ω/k is negative along this line and the interface is therefore stable. For ν larger than 1/3 (not shown in the figure) the horizontal zero level curve will flip around and the gray dashed line will then be covered with unstable regions. In order to see this flip, we expand Eq. (22) around the point (1,1), i.e. in terms of ρ02 − 1 and G2 − 1, and achieve the following expression for the zero curve ρ02 ≈ 1 + (1 − 2ν − 3ν 2 )(G2 − 1) . ν(7 + ν) (25) Order, Robustness and Instabilities in Complex Systems 0.75 131 (A) 0.5 0.25 0.0 0.75 (B) 0.5 0.25 0.0 -1.0 -0.75 -0.5 -0.25 0.0 0.25 0.5 0.75 1.0 Fig. 4. Simulations taken from [1] of the temporal evolution of solid-solid interfaces for first order transitions. Panel (A) shows a simulation using ρ1 = 1.0, G1 = 1.0 and ρ2 = 1.05, G2 = 2.0. Both phases have identical Poisson’s ratio, ν1 = ν2 = 0.45. Panel (B) is a simulation run with densities and shear modules similar to panel (A) but with a different Poisson’s ratios, ν1 = ν2 = 0.25. Note that the right hand side is in units of ρ1 . We directly observe that the horizontal zero curve flips around at the critical point ν = 1/3, which is also observed by following the diagonal in Fig. 3. In the case when the two solids are identical, i.e. at the point (1,1) in the stability diagram, all modes will as expected remain unchanged and the interface therefore remains unaltered. The other parts of the zero levels lead to marginal stability but will in general induce a motion of the interface with a constant velocity. We now consider a cut in the stability diagram where the two solids have the same shear modules, G1 = G2 = G, but different densities (first order phase transition) and Poisson’s ratios. For different Poisson’s ratios the dispersion relation Eq. (22) becomes (ν2 − ν1 )(ν1 ρ02 − ν2 ρ01 + 2(ρ02 − ρ01 )G) ω = . k 4ρ01 ρ02 G (26) From this expression we see that the vertical zero line observed in Eq. (24) and in Fig. 3 only exists for identical Poisson’s ratios. When the solids have different Poisson’s ratios, the separatrix or intersection of the two zero curves located at (1,1) in the diagonal panels of Fig. 3 will split into two non-intersecting zero curves. The off-diagonal panels show stability diagrams for solids with different Poisson’s ratios. In general the stability diagram is characterized by four quadrants, two stable and two unstable, delimited by neutral zero curves. The physical regions would typically correspond to the quadrants I and III under the assumption that higher density implies higher shear modulus. In these quadrants the growth rate is typically positive (i.e. the interface is unstable) except for a thin region at the borderline between a first and second order phase transition, i.e. when ρ2 ρ1 . 5 Concluding remarks The linear stability analysis of an interface separating two reactive solids reveals an intricate stability diagram where the stability strongly depends on the material properties and densities of the two solids. In Fig 4, we show a figure where we have explored this stability beyond the linear regime using numerical methods. The numerics is based on solving the bulk elastostatic equations using the Galerkin finite element method. The discontinuous jumps appearing in the normal interfacial velocity are computed at the outer border of the interface. In addition, we have imposed periodic boundary conditions to minimize the possible influence of the finite system size in the x-direction (parallel to the interface). 132 The European Physical Journal Special Topics In Fig. 4 we present numerical simulations of the phase transformation kinetics using parameter regions where the interface is either stable or unstable. The simulations represent interface snap shots of a first order phase transition dynamics. In panel (A), the values of the parameters were chosen in a region of the stability diagram where the interface is predicted to be unstable and in panel (B) we have used parameters corresponding to a stable evolution of the interface. Note that the interface in both cases is moving from the denser phase into the lighter phase independent of its stability. For Poisson’s ratio smaller than 1/3, the kinetics is stable and the phase of small shear modulus grows into the phase of higher shear modulus while for higher values of Poisson’s ratio the behavior is reversed and the interface roughens with time. In general, it turns out that contrasts in the referential densities of the two solids often lead to the formation of finger-like structures aligned with the principal direction of the far field stress. In cases where the referential densities are identical the stability depends on the “compressibility” of the material and it turns out that Poisson’s ratio plays a central role in the stability of the interface. References 1. L. Angheluta, E. Jettestuen, J. Mathiesen, Phys. Rev. E 79, 031601 (2009) 2. L. Angheluta, E. Jettestuen, J. Mathiesen, F. Renard, B. Jamtveit, Phys. Rev. Lett. 100, 096105 (2008) 3. L. Angheluta, J. Mathiesen, C. Misbah, F. Renard, Morphological instabilities of stressed and reactive geological interfaces (2009) (preprint) 4. R. Asaro, W. Tiller, Met. Trans. 3, 1789 (1972) 5. H. Gao, Int. J. Solids Struct. 28, 703 (1991) 6. M.A. Grinfeld, Dokl. Akad. Nauk SSSR 290, 1358 (1986) 7. K. Kassner, C. Misbah, J. Muller, J. Kappey, P. Kohlert, Phys. Rev. E 63 (2001) 8. J.S. Langer, Rev. Mod. Phys. 52, 1 (1980) 9. O. Martin, N. Goldenfeld, Phys. Rev. A 35, 3 (1987) 10. J. Mathiesen, I. Procaccia, I. Regev, Phys. Rev. E 77 (2008) 11. W.W. Mullins, J. Appl. Phys. 28, 3 (1957) 12. W.W. Mullins, R.F. Sekerka, J. Appl. Phys. 35, 2 (1964) 13. N.I. Muskhelishvili, Some basics preblems of the mathematical theory of elasticity (P. Noordhoff Ltd., Groningen-Holland, 1953) 14. F. Renard, P. Ortoleva, J.-P. Gratier, Techtoniphysics 280, 257 (1995) 15. P.G. Saffman, G. Taylor, Proc. Royal Soc. London. Ser. A, Math. Phys. Sci. 245, 312 (1958) 16. R.F. Sekerka, J.W. Cahn, Acta Mater. 52, 1663 (2004) 17. P.K. Weyl, J. Geophys. Res. 64, 11 (1959) 18. Y. Xiang and W.E., J. Appl. Phys. 91, 11 (2002) 19. W.H. Yang, D.J. Srolovitz, Phys. Rev. Lett. 71, 10 (1993) 20. D.-H. Yeon, P.-R. Cha, M. Grant, Acta Mater. 54 (2006)