Document 11492431

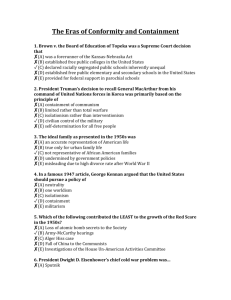

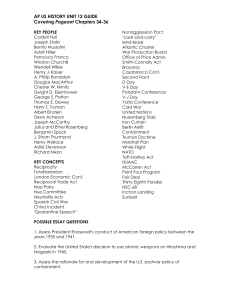

advertisement