High Temperature Interconnect and Die Attach Technology: Au–Sn SLID Bonding

advertisement

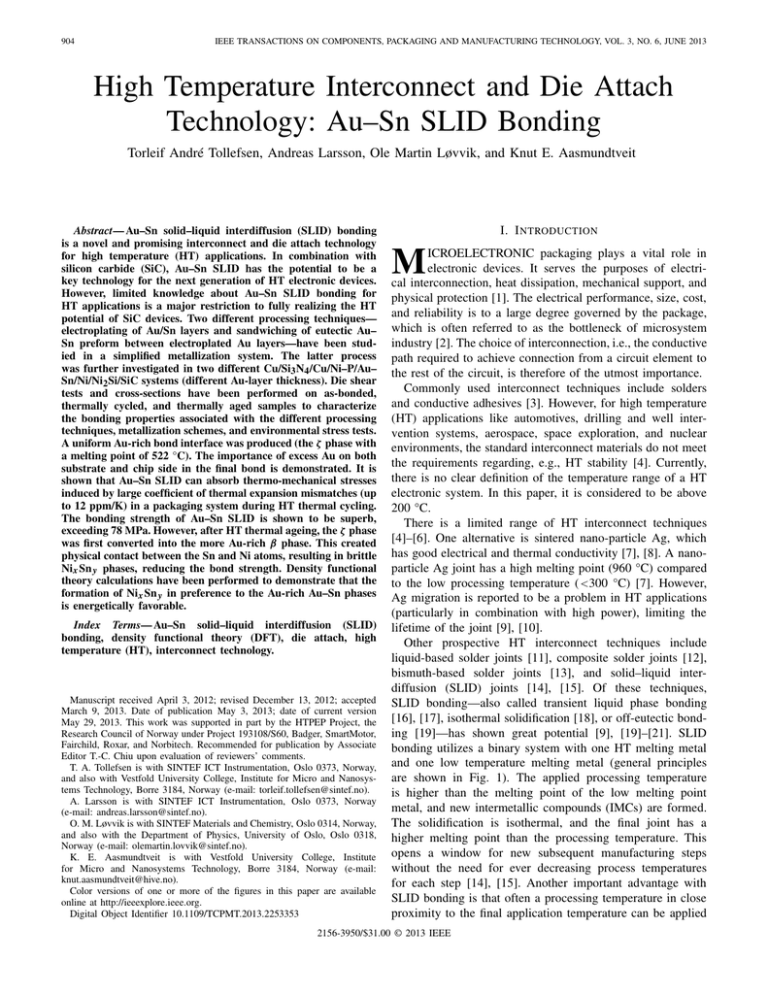

904 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 3, NO. 6, JUNE 2013 High Temperature Interconnect and Die Attach Technology: Au–Sn SLID Bonding Torleif André Tollefsen, Andreas Larsson, Ole Martin Løvvik, and Knut E. Aasmundtveit Abstract— Au–Sn solid–liquid interdiffusion (SLID) bonding is a novel and promising interconnect and die attach technology for high temperature (HT) applications. In combination with silicon carbide (SiC), Au–Sn SLID has the potential to be a key technology for the next generation of HT electronic devices. However, limited knowledge about Au–Sn SLID bonding for HT applications is a major restriction to fully realizing the HT potential of SiC devices. Two different processing techniques— electroplating of Au/Sn layers and sandwiching of eutectic Au– Sn preform between electroplated Au layers—have been studied in a simplified metallization system. The latter process was further investigated in two different Cu/Si3 N4 /Cu/Ni–P/Au– Sn/Ni/Ni2 Si/SiC systems (different Au-layer thickness). Die shear tests and cross-sections have been performed on as-bonded, thermally cycled, and thermally aged samples to characterize the bonding properties associated with the different processing techniques, metallization schemes, and environmental stress tests. A uniform Au-rich bond interface was produced (the ζ phase with a melting point of 522 °C). The importance of excess Au on both substrate and chip side in the final bond is demonstrated. It is shown that Au–Sn SLID can absorb thermo-mechanical stresses induced by large coefficient of thermal expansion mismatches (up to 12 ppm/K) in a packaging system during HT thermal cycling. The bonding strength of Au–Sn SLID is shown to be superb, exceeding 78 MPa. However, after HT thermal ageing, the ζ phase was first converted into the more Au-rich β phase. This created physical contact between the Sn and Ni atoms, resulting in brittle Ni x Sn y phases, reducing the bond strength. Density functional theory calculations have been performed to demonstrate that the formation of Ni x Sn y in preference to the Au-rich Au–Sn phases is energetically favorable. Index Terms— Au–Sn solid–liquid interdiffusion (SLID) bonding, density functional theory (DFT), die attach, high temperature (HT), interconnect technology. Manuscript received April 3, 2012; revised December 13, 2012; accepted March 9, 2013. Date of publication May 3, 2013; date of current version May 29, 2013. This work was supported in part by the HTPEP Project, the Research Council of Norway under Project 193108/S60, Badger, SmartMotor, Fairchild, Roxar, and Norbitech. Recommended for publication by Associate Editor T.-C. Chiu upon evaluation of reviewers’ comments. T. A. Tollefsen is with SINTEF ICT Instrumentation, Oslo 0373, Norway, and also with Vestfold University College, Institute for Micro and Nanosystems Technology, Borre 3184, Norway (e-mail: torleif.tollefsen@sintef.no). A. Larsson is with SINTEF ICT Instrumentation, Oslo 0373, Norway (e-mail: andreas.larsson@sintef.no). O. M. Løvvik is with SINTEF Materials and Chemistry, Oslo 0314, Norway, and also with the Department of Physics, University of Oslo, Oslo 0318, Norway (e-mail: olemartin.lovvik@sintef.no). K. E. Aasmundtveit is with Vestfold University College, Institute for Micro and Nanosystems Technology, Borre 3184, Norway (e-mail: knut.aasmundtveit@hive.no). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TCPMT.2013.2253353 I. I NTRODUCTION M ICROELECTRONIC packaging plays a vital role in electronic devices. It serves the purposes of electrical interconnection, heat dissipation, mechanical support, and physical protection [1]. The electrical performance, size, cost, and reliability is to a large degree governed by the package, which is often referred to as the bottleneck of microsystem industry [2]. The choice of interconnection, i.e., the conductive path required to achieve connection from a circuit element to the rest of the circuit, is therefore of the utmost importance. Commonly used interconnect techniques include solders and conductive adhesives [3]. However, for high temperature (HT) applications like automotives, drilling and well intervention systems, aerospace, space exploration, and nuclear environments, the standard interconnect materials do not meet the requirements regarding, e.g., HT stability [4]. Currently, there is no clear definition of the temperature range of a HT electronic system. In this paper, it is considered to be above 200 °C. There is a limited range of HT interconnect techniques [4]–[6]. One alternative is sintered nano-particle Ag, which has good electrical and thermal conductivity [7], [8]. A nanoparticle Ag joint has a high melting point (960 °C) compared to the low processing temperature (<300 °C) [7]. However, Ag migration is reported to be a problem in HT applications (particularly in combination with high power), limiting the lifetime of the joint [9], [10]. Other prospective HT interconnect techniques include liquid-based solder joints [11], composite solder joints [12], bismuth-based solder joints [13], and solid–liquid interdiffusion (SLID) joints [14], [15]. Of these techniques, SLID bonding—also called transient liquid phase bonding [16], [17], isothermal solidification [18], or off-eutectic bonding [19]—has shown great potential [9], [19]–[21]. SLID bonding utilizes a binary system with one HT melting metal and one low temperature melting metal (general principles are shown in Fig. 1). The applied processing temperature is higher than the melting point of the low melting point metal, and new intermetallic compounds (IMCs) are formed. The solidification is isothermal, and the final joint has a higher melting point than the processing temperature. This opens a window for new subsequent manufacturing steps without the need for ever decreasing process temperatures for each step [14], [15]. Another important advantage with SLID bonding is that often a processing temperature in close proximity to the final application temperature can be applied 2156-3950/$31.00 © 2013 IEEE TOLLEFSEN et al.: HIGH TEMPERATURE INTERCONNECT AND DIE ATTACH TECHNOLOGY Fig. 2. Fig. 1. Schematic illustration of SLID bonding (TB bonding temperature, Tm melting temperature, RT room temperature, IMC intermetallic compound). (since the melting point of the final joint is much higher than the processing temperature). This can help reduce the thermo-mechanical stresses induced by coefficient of thermal expansion (CTE) mismatches in the final package. SLID bonding was performed in various metal systems. Examples include Ag/In [14], [15], Ag/Sn [22], Au/In [14], [23], Au/Sn [6], [9], [19]– [21], [23]–[25], Cu/Sn [26]–[29], and Ni/Sn [28], [29]. Ag/In, which is among the first SLID systems [14], [15], was investigated for HT applications in several studies [9], [30]–[32]. Here, a HT stable joint can be achieved (stable up to 700 °C [30]) using a processing temperature of only 210 °C, followed by annealing at 150 °C [32]. However, the HT lifetime of the joint is reported to be limited (especially in combination with high power), due to Ag migration [9], [10]. Au/Sn is a promising SLID system for HT applications [9], [19]–[21], [33], [34]. Based on the Au–Sn phase (shown in Fig. 2), several Au–Sn phases can be appropriate for HT applications. However, when long time stability is taken into account, the ζ phase is the most promising. The final bond structure is reported to be layered [21]—Au/ζ /Au—where the ζ phase undergoes a phase transition to the ζ phase at 190 °C [35], [36]. The ζ phase has a melting point of 522 °C [35], [36], making it desirable for HT applications. Thorough investigations of the Au–Sn phase diagram suggest that the actual layered bond structure probably is Au/ζ /Au, since the ζ phase is stable down to −5 °C (depending on Au concentration). Another possible bond structure is Au/β/Au. The β phase has an even higher melting point than the ζ phase, i.e., 532 °C [35], [36]. However, the β phase is reported to be more brittle than the ζ phase [37], indicating that a Au/ζ /Au bond probably is more reliable than a Au/β/Au bond. Au/Sn SLID was already shown good HT stability and thermal cycling abilities in studies performed by Johnson et al. [9], [19]. 905 Au–Sn phase diagram [35], [36]. Silicon carbide (SiC), a wide bandgap semiconductor, is commonly considered as the best alternative for the next generation of innovative, high performance, cost-effective, and environmental-friendly drilling and well-intervention systems for the oil industry [38]. SiC has a high breakdown field strength, a high thermal conductivity, and offers excellent performance in HT (up to 600 °C) and high power applications [39]–[41]. However, lack of qualified HT packaging technology is a major limitation to fully realize the potential of SiC. This paper presents a study of Au–Sn SLID bonding in a package utilizing a bipolar junction transistor (BJT) SiC chip. First, two different processing techniques—electroplating of Au/Sn layers and sandwiching a eutectic Au–Sn preform between electroplated Au layers—are investigated in a simplified metallization system to find the best technique. The latter process is further investigated for metallized Si3 N4 substrates, in two different Cu/Si3 N4 /Cu/Ni–P/Au–Sn/Ni/Ni2 Si/SiC systems (different Au-layer thickness). Die shear tests and crosssections are performed on the different samples to characterize the bonding properties associated with the different processing techniques, metallization schemes, and environmental stress tests. Furthermore, density functional theory (DFT) calculations were performed to investigate the relative thermodynamic stability of different Au–Sn and Ni–Sn phases, to enhance the understanding of how Ni acts as a diffusion barrier between substrate/chip metallization and a AuSn SLID bond. II. M ETHODOLOGY A. Test Assemblies 1) SLID 1a & b Samples: Oxidized Si wafers with sputtered Ti-W (60 nm)/Au (100 nm) adhesion/seed layers were used as both substrate (diced in 4.3 × 6.6 mm2 after plating) and chip (diced in 2 × 2 mm2 after plating) in the simplified bonding samples, hereby referred to as SLID 1 samples. These were then electroplated with a uniform Au layer (5 μm). The Au electroplating was performed in a gold cyanide solution at a temperature range 60 °C–65 °C, with a current density of 5.4 mA/cm2 . Two different types of SLID 1 samples were manufactured. 906 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 3, NO. 6, JUNE 2013 (a) (b) Fig. 3. SLID 1a samples. (a) Layers as plated. (b) Expected structure after bonding. (a) (b) Fig. 5. SLID 2a & b samples. Sketch of expected layer structure after bonding. (a) SLID 2a. (b) SLID 2b. (a) (b) Fig. 4. SLID 1b samples. (a) Layers as plated. (b) Expected structure after bonding. a) SLID 1a: Sn (2 μm)/Au (0.1 μm) layers were electroplated on the chip side using a tin sulfate solution at room temperature, with a current density of 10 mA/cm2 . The thin Au layer was applied to minimize oxidation, making fluxless bonding possible [24]. A Sn/Au-plated chip was then bonded to a substrate (see Fig. 3 for illustration). b) SLID 1b: A eutectic Au 80 wt.% Sn 20 wt.% preform (7.5 μm) was sandwiched between a chip and substrate to make the joint. The preform was purchased from Micro Joining KB (see Fig. 4 for illustration). The bonding was performed in two steps; first, a flip chip bonder was used to pick and place at a moderate temperature (120 °C) applying a force of 35 N for 30 s. Secondly, the positioned samples were bonded using a hotplate in a vacuum chamber and a clamping force to ensure intimate contact. The applied force translated to a pressure 2.5 MPa on the surface to be bonded. First, the samples were heated to 250 °C and held there for 5 min (to bake out any residual moisture and to assure a uniform temperature distribution in the bonding layers). Then, the samples were heated to 350 °C, and kept there for 20 min to ensure that the desired phases were created. 2) SLID 2a & b Samples: Commercialy purchased Si3 N4 substrates (from Denka Chemicals) with active metal bonded Cu (150 μm) and plated Ni–P (7 wt% P) were used as substrates for both SLID 2a & b samples. The substrates had symmetrical metallization (Cu/Ni–P layers on both top and backside) to minimize warpage of the substrate due to CTE mismatches between Si3 N4 and Cu. An additional Au layer (3 or 5 μm) was electroplated on the substrates in a gold cyanide solution at a temperature range 60 °C–65 °C, with a current Fig. 6. Picture of manually aligned SLID 2a & b samples on a hot plate fastened with a clamping force. density 2.7 mA/cm2 . The substrate was diced in 6 × 6 mm2 samples after plating. The BJT SiC dummy chips, delivered from Fairchild, had sputtered Ni2 Si (140 nm)/Ni (300 nm)/Au (100 nm) metallization. The chips were electroplated with a uniform Au layer (5 μm), and diced in 1.855 × 3.4 mm2 samples. Two different types of SLID 2 samples were produced. a) SLID 2a: As for SLID 1b samples, an eutectic Au 80 wt.% Sn 20 wt.% preform (7.5 μm) was sandwiched between the chip and the substrate to make the joint. For SLID 2a samples, the electroplated Au layer on the substrate was only 3 μm. This means that there would be no excess Au left on the substrate side of the joint [see Fig. 5(a) for illustration]. b) SLID 2b: Same as SLID 2a samples, but with 5 μm electroplated Au on both sides, resulting in excess Au on both the substrate and the chip side in the final joint [see Fig. 5(b) for illustration]. The bonding was performed in two steps: first, the substrate, the preform, and chip were aligned manually on a hot plate and fastened with a clamping force (see Fig. 6). Secondly, the samples were bonded using the hotplate in a vacuum chamber. The same bonding profile as for SLID 1 samples were used. However, the final bonding time was reduced from 20 to 10 min based on work published in [20]. TOLLEFSEN et al.: HIGH TEMPERATURE INTERCONNECT AND DIE ATTACH TECHNOLOGY 100 150 100 50 0 0 50 100 Time (min) Fig. 7. Cycling profile for thermal cycling. The temperature in the joint was measured by a k-type thermocouple and an Agilent 34970A data acquisition unit. B. Test Methods and Equipment Thermal cycling tests were peformed in a Heraeus HT 7012S2 thermal cycling chamber. Both SLID 1a & b and SLID 2a & b samples were cycled between 0 °C and 200 °C, with a gradient 10 °C/min, and a dwell time 15 min at the temperature extremes (see Fig. 7 for cycling profile—the temperature in the joint was measured by a k-type thermocouple and an Agilent 34970A data acquisition unit). Two levels of cycling were performed (500 and 1000 cycles). The cycled samples were shear tested in a Dage 2400A shear tester with a 50 kgf load cartridge, and the results were compared to measurements on as-bonded samples. SLID 1a & b and 2a & b samples were aged in air at 250 °C for 6 months in a Binder laboratory oven. The aged samples were shear tested in a Dage 2400A shear tester with a 50 kgf load cartridge, and compared to measurements on as-bonded samples. Cross-sectioning was performed on all groups of samples. The samples to be cross-sectioned were embedded in epoxy resin prior to grinding, and then ground (on SiC paper grade 320 through 4000, using water cooling) and polished (using 6 μm diamond particles and an alcohol-based lubricant prior to fine polishing using 3 and 1 μm diamond particles with a water- and oil-based lubricant). Note that SiC is a very hard material compared to the Au and the Au–Sn phases, making it difficult to prepare planar cross-sections. The cross-sectioned samples and the fracture surfaces of shear tested samples were investigated by optical microscopy (Neophot 32), scanning electron microscopy (SEM: JEOL JSM-5900LV) and energy-dispersive spectroscopy (EDS: Oxford X-MAX 50). C. Ab Initio Calculations Periodic DFT calculations were performed using the Vienna ab initio simulation package (VASP) [42], [43] within the generalized gradient approximation according to Perdew et al. [44]. The projector augmented wave (PAW) method was used to treat the core regions within an allelectron framework [45]. The plane wave basis set cut-off energy was 450 eV, and the density of the k-point grid was at least 0.25 Å−1 for all the structures. Standard PAW potentials were used, which implied that the following valence Die shear strength (MPa) Temperature (°C) 200 907 As bonded 500 cycles 1000 cycles 80 60 40 20 0 SLID 1a SLID 1b Sample group Fig. 8. Die shear strength of SLID 1a & b samples as a function of thermal cycles (0 °C–200 °C, 10 °C/min, dwell time of 15 min). The bars show the standard deviation for the different groups. Fig. 9. Optical microscopy image of a cross-section of an as-bonded SLID 1b sample showing the challenges associated with co-planarity during bonding. orbitals were used in: 5d10 6s1 (Au), 5s2 5p2 (Sn), and 3d8 4s2 (Ni). The criterion for self-consistency was that the energy difference between two consecutive iterations was <10−6 eV. All structures were relaxed with a quasi-Newton method (the residual minimization scheme with direct inversion in the iterative subspace) using a force convergence criterion of 0.05 eV/Å. The atomic positions as well as the unit cell size and shape were relaxed simultaneously. Structural relaxation was performed twice, before a final high-accuracy calculation of the total energy. Experimental structures from a database (Inorganic Crystal Structure Database) were used as input for the structural relaxations [46]. III. R ESULTS AND D ISCUSSION A. Thermal Cycling 1) SLID 1a & b Samples: After 500 and 1000 thermal cycles, the die shear strength was determined and compared to the as-bonded strength. Five samples from each group were tested. The results have some clear trends (shown in Fig. 8). a) Variations: There are large variations (standard deviation) in the shear strength. The reason for this most likely originate from the sample manufacturing. A clamp force was used to ensure sufficient contact between the bonding surfaces (see Fig. 6). The clamp force is only in contact with a restricted part of the surface area of the chip and the substrate. During the bonding process, 908 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 3, NO. 6, JUNE 2013 b) c) d) e) parts of the bonding materials will be liquified, meaning that if the clamp force is not symmetrically placed on the chip/substrate, problems with co-planarity will occur. This was confirmed by cross-section pictures (see Fig. 9). Die shear strength: The shear strength has a substantial increase after 500 cycles. The shear strength after 1000 cycles also increased compared to the as-bonded samples, but it had decreased compared to the strength after 500 cycles. The explanation for the relative increase in shear strength probably stems from the challenges associated with co-planarization. During thermal cycling, the samples are regulary heated and kept at 200 °C, increasing the diffusion rate between the bonding partners, i.e., making a stronger joint. The reduction in the shear strength after 1000 cycles compared to 500 cycles indicates that there is a reduction in fatigue lifetime during thermal cycling. However, due to the limited amount of samples, and the large standard deviation, this should be further investigated. SLID 1a versus 1b: The SLID 1b samples has higher die shear strength than the SLID 1a samples after thermal cycling. There are no obvious reason for this trend, but careful investigations of the cross-sections of 1a and 1b samples revealed that there was a through crack in all SLID 1a samples (Fig. 10). There were no cracks in the SLID 1b samples, so the through crack in the 1a samples probably explains the lower strength. The cracks, located at the interface between the electroplated Au and Sn layers on the chip side, probably originated from contaminatons during Sn plating (e.g. on the Au surface, not pure enough Sn, etc.). Hieber et al. [47] experienced problems regarding the pureness of the electroplated Sn in a CuSn SLID joint. They reported that only e-beam evaporated Sn is pure enough for CuSn SLID bonding. This shows the importance of the Sn quality. However, strong and uniform CuSn SLID joints have been produced using electroplated Sn [26]. Bond configuration: The bond interface of the the good samples (without co-planarity problems) was uniform with regard to IMC formation. Fig. 11 shows a optical microscopy and a SEM image of the cross-section of a SLID 1b sample. EDS was used to identify the bonding phase as most probably the ζ phase. This supports our assumption that a AuSn SLID bond most probably has a Au/ζ /Au structure when the overall Au:Sn ratio in the bondline is designed appropriately. Fracture surfaces: The fracture surfaces of samples with high-bond strength were located at the interfaces between the substrate/chip and Ti-W. The fracture surfaces of samples with low-bond strength were located in the actual bond layer. This indicates that the samples with low die shear strength fail because of coplanarization issues. However, the samples with high die shear strength fail in the chip/substrate metallization, indicating that a good AuSn SLID bond has higher bond strength than 80 MPa (the highest measured bond strength). This is also supported by previous work by Fig. 10. Optical microscopy image of a cross-section of a SLID 1a sample showing the through crack in the electroplated Au/Sn interface. TABLE I D IE S HEAR S TRENGTH OF SLID 2a S AMPLES AS A F UNCTION OF N O OF T HERMAL C YCLES (0 °C–200 °C, 10 °C/min, D WELL T IME OF 15 min) As Bonded (MPa) 500 Cycles (MPa) 1000 Cycles (MPa) >78 >78 >78 71.8 64.3 >78 >78 69.0 66.9 50.3 >78 >78 43.8 36.4 35.5 TABLE II D IE S HEAR S TRENGTH OF SLID 2b S AMPLES AS A F UNCTION OF N O OF T HERMAL C YCLES (0 °C–200 °C, 10 °C/min, D WELL T IME OF 15 min) As Bonded (MPa) 500 Cycles (MPa) 1000 Cycles (MPa) >78 >78 >78 >78 >78 >78 >78 >78 >78 50.9 >78 >78 >78 >78 >78 >78 >78 >78 >78 52.9 >78 >78 >78 >78 >78 >78 69.9 68.4 66.3 65.5 Johnson et al. [19], who reported a die shear strength above 90 MPa for AuSn SLID joints. EDS analysis indicates that a AuSn SLID bond is constructed of a layered Au/ζ /Au structure. When the joining is well performed, high-bond strengths are achieved. Importantly, a AuSn SLID joint can withstand thermal cycling between 0 °C and 200 °C in a package with small CTE mismatches (Si chip and substrate). 2) SLID 2a & b Samples: After 500 and 1000 thermal cycles, the die shear strength was determined and compared to the as-bonded strength. Ten SLID 2b samples and five 2a samples were tested. The results have some clear trends (shown in Fig. 12, Tables I and II). a) Variations: The standard deviation in the shear strength was greatly reduced compared to SLID 1a & b samples. The assembly was performed as for SLID 1a & b samples, but experience assured a higher yield. Note that the majority of the samples had a bond strength above the equipment limit (50 kgf), indicating that there could be a considerable variation not measureable with the applied equipment. TOLLEFSEN et al.: HIGH TEMPERATURE INTERCONNECT AND DIE ATTACH TECHNOLOGY (a) 909 (b) Fig. 11. Optical microscopy image of (a) a SLID 1a sample with (b) a magnified SEM image of a representative region. The rectangles show regions where EDS was performed. The atomic percent for the regions is included. Note that the features on the left side of the SEM image most probably stems from cross-section preparations. Die shear strength (MPa) 100 As bonded 500 cycles 1000 cycles 80 60 40 20 0 SLID 2a SLID 2b Sample group Fig. 12. Die shear strength of SLID 2a & b samples as a function of the number of thermal cycles (0 °C–200 °C, 10 °C/min, dwell time 15 min). Note that this figure is only included to visualize the main trends. Since many of the tested samples did not fracture during testing, due to the equipment limit (50 kgf), a proper average cannot be made. b) Shear strength: The bond strength of SLID 2b samples remained relatively unchanged and superb (>78 MPa) during thermal cycling (note that the majority of the samples had a bond strength above the equipment limit, indicating that there could be a degradation in the bond strength not measureable with the applied equipment). For SLID 2a samples, there was a decrease in the bond strength as a function of the number of thermal cycles. In SLID 2b samples, there was excess Au on both the substrate and the chip side (Fig. 13). In SLID 2a samples, there was no excess Au left on the substrate side (Fig. 14), causing formation of brittle Au–Ni–Sn IMCs during thermal cycling. These brittle IMCs are believed to be the primary cause of the degradation of the bond strength. Fig. 13. Optical microscopy image of a cross-section of a SLID 2b sample showing a uniform bondlayer, with excess Au on both substrate and chip side. The different phases were identified by SEM and EDS. Fig. 14. Optical microscopy image of a cross-section of a SLID 2a sample showing a uniform bondlayer, but with excess Au on only the chip side. On the substrate side brittle Au–Ni–Sn phases have been created, weakening the die shear strength. The different phases were identified by SEM and EDS. c) Bond configuration: As for SLID 1a & b samples, the bond interface was uniform with regard to IMC formation, EDS was used to identify the bonding phase as most probably the ζ phase. 910 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 3, NO. 6, JUNE 2013 Die shear strength (MPa) 100 As bonded 80 Aged 60 40 20 0 SLID 1a SLID 1b Sample group Fig. 16. Die shear strength of SLID 1a & b samples as a function of thermal ageing (250 °C, 6 months). The bars show the standard deviation for the different groups. TABLE III D IE S HEAR S TRENGTH OF AS B ONDED AND T HERMALLY A GED (250 °C, 6 M ONTHS ) SLID 2a S AMPLES As Bonded (MPa) Aged (MPa) >78 >78 >78 >78 >78 43.8 71.8 36.4 64.3 35.5 Fig. 15. SEM images of the fracture surface of SLID 2a & b samples. The fracture surfaces were identified with optical microscopy, scanning electron microscopy (SEM), and energy dispersive X-ray spectroscopy (EDS). d) Fracture surfaces: In Fig. 15, SEM images of the fracture surfaces of thermally cycled (1000 cycles) SLID 2a & b samples are shown. The fracture surface of 2b samples was located at the chip/Ni2 Si/Ni interface, again indicating that a good AuSn SLID bond has higher bond strength than 78 MPa. The fracture surface of 2a samples was located at the ζ phase/Au–Ni–Sn IMCs interface, confirming that these brittle IMCs are the primary cause of the degradation of the bond strength for 2a samples. Notably, the AuSn SLID joints withstand thermal cycling between 0 °C and 200 °C for a package with large CTE mismatches (12 ppm/K difference between SiC and the thick Cu film). The importance of excess Au on both substrate and chip side in the final bond is also demonstrated. The soft Au layer is important since it absorbs thermo-mechanical stresses in the package, induced by, e.g., CTE mismatches between the chip and the conducting layer. Excess Au on both sides of the final joint is also important since it acts as a diffusion barrier between the Au–Sn phases and the chip/substrate metallization, which tends to develop brittle IMCs like Ni3 Sn4 [48], greatly reducing the lifetime and the reliability of the package. Furthermore, excess Au is central for the prediction of the properties of the joint, since it assures stable material phases with predictable/known properties. The superb die shear strength of a AuSn SLID joint shows that this is one of the most promising SLID bonding material schemes for HT applications. In addition, the ability of AuSn SLID joints to absorb stress makes them very attractive. However, for applications with temperatures above ∼0.5× Tm , creep is considered to be important for the long time reliability [2]. (Tm is the melting point given in absolute temperature.) For a ζ phase bond, 0.5 × Tm = 125 °C, making it vulnerable for creep during long time HT applications with constant stresses in the system (e.g., from CTE mismatches). But, by, e.g., applying a process temperature in close range to the operation temperature (which often is possible for SLID bonds, since the melting point of the final joint is well above the processing temperature), stresses induced by the CTE mismatches in the system can be minimized. The effect of creep in a Au–Sn SLID joint should be more carefully investigated. B. Thermal Ageing 1) SLID 1a & b Samples: After six months of thermal ageing, the die shear strength was determined and compared to the as-bonded strength. Five samples from each group were tested, and the results are shown in Fig. 16. The results had the same tendency as the thermally cycled SLID 1a & b samples. There was a large standard deviation, the shear strength increased after ageing, the bond strength of 1b samples was higher than that of 1a samples, and the fracture surface of samples with high-bond strength was located at the interfaces between the subsrate/chip and Ti-W, while the fracture surface of samples with low bond strength was located in the actual bond layer. For a more thorough discussion about these results, see the thermal cycling test section. TOLLEFSEN et al.: HIGH TEMPERATURE INTERCONNECT AND DIE ATTACH TECHNOLOGY 911 TABLE IV D IE S HEAR S TRENGTH OF AS B ONDED AND T HERMALLY A GED (250 °C, 6 M ONTHS ) SLID 2b S AMPLES As Bonded (MPa) Aged (MPa) >78 >78 >78 >78 >78 >78 >78 >78 >78 50.9 >78 >78 >78 >78 >78 72.9 66.9 58.5 55.9 54.1 Die shear strength (MPa) 100 As bonded Aged 80 60 40 20 Fig. 18. SEM image of a SLID 2a sample. The composition shown was found by EDS analyses. Notably, these results demonstrate that the Au/ζ /Au bond is not stable at 250 °C. Sn continues to diffuse into the pure Au layers/Au continues to diffuse into the ζ layer, creating a β/ζ layer with no excess Au between the diffusion barrier, Ni, and the bond layer. When there is a physical contact between Sn and Ni, interdiffusion results in the formation of the brittle Ni3 Sn2 and Ni3 Sn4 IMCs, leaving only pure Au in the original bond (probably with some Sn). In Fig. 19, a schematic overview over the AuSn SLID bond structure at different stages is shown. C. DFT Calculations 0 SLID 2a SLID 2b Sample group Fig. 17. Die shear strength of SLID 2a & b samples as a function of thermal ageing (250 °C, 6 months). Note that this figure is only included to visualize the main trends. Since many of the tested samples did not fracture during testing, due to the equipment limit (50 kgf), a proper average cannot be made. 2) SLID 2a & b Samples: After six months of thermal aging, the die shear strength was determined and compared to the as-bonded strength. Five SLID 2a samples and 10 SLID 2b samples were tested. The results are shown in Fig. 17, Tables III, and IV. The results can be compared to the thermally cycled SLID 2a & b samples. However, the bond stength of the aged SLID 2a samples was reduced more than that of the thermally cycled samples. Furthermore, the bond strength of the SLID 2b samples wasalso reduced (the bond strength of SLID 2b samples was not reduced during thermal cycling). Cross-sections of the thermally aged samples revealed large alterations in the bond structure compared to the as-bonded structure. In Fig. 18, a SEM image of a cross section of an aged SLID 2a sample is shown. It reveals that all the Sn in the AuSn SLID bond has diffused into the diffusion barrier, Ni, creating Ni3 Sn2 and Ni3 Sn4 , leaving only pure Au in the original bond. Notice that the composition analysis was performed with EDS. Due to the uncertainty in EDS analyses, and the thickenss of the Ni–Sn IMC layers, there probably is some remaining Sn in the bond layer. As seen from the Au–Sn phase diagram in Fig. 2, the Au phase can contain up to 2–3 at.% Sn in solid solution at room temperature. DFT calculations utilizing VASP were performed to enhance the understanding of interdiffusion at the Au–Sn/Ni interface. The enthalpy of formation for hypothetical reactions taking place at the interface was calculated by comparing the ground state electronic total energy of the various compounds. Only combinations in the relevant part of the phase diagram (Au/Ni > 0.75) were included. The results are shown in Table V and Fig. 20, and confirm that a combination of pure Au and intermetallic Ni–Sn is thermodynamically more stable than a combination of Au–Sn and pure Ni. This is valid for all combinations of Au–Sn phases (the ζ -phase Au31 Sn5 , the β-phase Au11Sn, or Au5 Sn) and Ni–Sn phases (Ni3 Sn2 or Ni3 Sn4 ). It is furthermore instructive to see how the enthalpy of reaction defines a convex hull of the final combination of Au and Ni–Sn when plotted as a function of the Au/Ni ratio in Fig. 20. That is, depending on the effective Au/Ni ratio, both Ni3 Sn2 and Ni3 Sn4 will be thermodynamically accessible in the relevant part of the phase diagram. The local, effective Au/Ni ratio will depend on a number of parameters like the global Au/Ni ratio, the temperature profile, the morphology, other phases present, as well as the kinetic barriers of solidstate diffusion. The calculations above were performed at the ground state, i.e., with no contributions from temperature, entropy, or zeropoint motion. This means that we have in reality only probed the phase diagram at 0 K. We have also neglected the possibility of other phases in this part of the phase diagram, including amorphous ones. Finally, the factors governing the effective Au/Ni ratio, mentioned above, have also been disregarded. Nevertheless, the results are consistent and conclusive enough to rationalize the tendency of Sn to diffuse from the Au–Sn phases into Ni when they are in physical contact. As long as 912 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 3, NO. 6, JUNE 2013 Fig. 19. Schematic overview of the AuSn SLID bond structure at different stages in a SLID 2b sample. Note that the As bonded and After HT ageing structures are based on experimental observations, whereas the after TC structure is deduced as an intermediate state between the two aforementioned, based on the phase diagram (Fig. 2). TABLE V G ROUND S TATE E NTHALPY OF R EACTION Hr OF P OTENTIAL C HEMICAL R EACTIONS AT THE Au–Sn/Ni I NTERFACE C ALCULATED BY DFT. A N EGATIVE E NTHALPY OF R EACTION I NDICATES T HAT THE R EACTION I S E NERGETICALLY FAVORABLE . Hr I S G IVEN IN kJ/mol P ER Au ATOM Potential Reaction 4Au11 Sn + 3Ni → 44Au + Ni3 Sn4 4Au31 Sn5 + 15Ni → 124Au + 5Ni3 Sn4 2Au11 Sn + 3Ni → 22Au + Ni3 Sn2 4Au5 Sn + 3Ni → 20Au + Ni3 Sn4 2Au31 Sn5 + 15Ni → 62Au + 5Ni3 Sn2 2Au5 Sn + 3Ni → 10Au + Ni3 Sn2 Au/Ni 0.94 0.89 0.88 0.87 0.81 0.77 Hr (kJ/mol) −2.47 −3.19 −4.14 −3.02 −6.15 −6.70 0 -1 ΔHr (kJ/mol) -2 -3 -4 -5 -6 -7 -8 0,75 0,80 0,85 0,90 Au/Ni 0,95 D. Some Final Remarks When the DFT results are seen together with the experimental results from the ageing of SLID 2a & b samples, we can understand how Ni–P acts as a diffusion barrier between Cu and Au; Sn from intermetallic Au–Sn will diffuse into Ni and form intermetallic Ni–Sn. This furthermore stresses the importance of having a residual pure Au layer acting as a diffusion barrier between substrate and chip metallization as well as on both sides of the final Au–Sn SLID bond. One then needs to take into account that the final Au–Sn SLID bond may be a Au/ζ /Au bond. For a Au–Sn SLID bond to withstand long-time HT exposure, the bondline should be designed with a Sn:Au ratio corresponding to max. 8 at.% Sn, to ensure surplus Au also after transformation to a ζ phase. It should be mentioned here that Ti seems to act as a better diffusion barrier than Ni for interdiffusion of Sn. The SLID 1b samples had exactly the same bonding metallization as the SLID 2b samples. However, the SLID 1b samples used Ti-W as a diffusion barrier instead of Ni. After six months of thermal ageing at 250 °C, there was no trace of Sn in the Ti-W layer. This is consistent with the work performed by Anhock et al. [49], where Ti was found to be a better diffusion barrier than Cr, Ni, Pd, and Pt. 1,00 Fig. 20. Enthalpy of reaction Hr of the tentative reactions listed in Table V, as a function of the Au/Ni ratio. The enthalpy is given in kJ/mol per Au atom. The dotted line designates the convex hull of the reaction products (Ni–Sn intermetallic phases and Au) in this part of the ternary Au–Ni–Sn phase diagram at 0 K. the solid-state diffusivity is high enough for such transport to take place, there is a strong thermodynamic driving force for the formation of intermetallic Ni–Sn. IV. C ONCLUSION Two different AuSn SLID processing techniques were investigated, where sandwiching of a eutectic Au–Sn preform between electroplated Au layers was found to be the preferred scheme. Initial processing issues regarding co-planarization and through cracks in the Au/Sn interface were solved, and strong uniform Au/ζ /Au joints were produced. The bond strength of a Au–Sn SLID bond is shown to be superb, >78 MPa. However, for joints without excess Au on TOLLEFSEN et al.: HIGH TEMPERATURE INTERCONNECT AND DIE ATTACH TECHNOLOGY both substrate and chip side, the shear strength is reduced by thermal cycles. Importantly, it is demonstrated that a Au–Sn SLID joint can absorb thermo-mechanical stresses induced by large CTE mismatches (12 ppm/K) in a package during HT thermal cycling. However, after long-time HT exposure, the joint is transformed from Ni/Au/ζ /Au/Ni to Nix Sn y /Au/Nix Sn y , apparently through a Ni/β/Ni stage. The primary cause of the formation of the Nix Sn y IMCs has been investigated by DFT calculations. The results indicate that the combination of pure Au and intermetallic Ni–Sn is energetically more favorable than pure Ni and intermetallic Au–Sn. The Sn:Au ratio should thus be below 8 at.%. When the insight above is implemented, Au–Sn SLID bonding is an excellent candidate for HT die attach and interconnect technology. ACKNOWLEDGMENT The authors would like to thank T. T. Luu and Dr. K. Wang for manufacturing the SLID 1a&b samples and to Dr. M. M. V. Taklo for proofreading. R EFERENCES [1] R. R. Tummala and E. J. Rymaszewski, Microelectronics Packaging Handbook. New York, NY, USA: Van Nostrand, 1989. [2] R. R. Tummala, Fundamentals of Microsystems Packaging. New York, NY, USA: McGraw-Hill, 2000. [3] H. Oppermann, “The role of Au/Sn solder in packaging,” in Material for Informations Technology, E. Zschech, Ed. New York, NY, USA: Springer-Verlag, 2005. [4] H. S. Chin, K. Y. Cheong, and A. B. Ismail, “A review on die attach materials for SiC-based high-temperature power devices,” Metall. Mater. Trans. B, vol. 41, no. 4, pp. 824–832, Aug. 2010. [5] L. Coppola, D. Huff, F. Wang, P. R. Burgos, and D. Boroyevich, “Survey on high-temperature packaging materials for SiC-based power electronics modules,” in Proc. IEEE Power Electron. Specialists Conf., vols. 1–6. Jun. 2007, pp. 2234–2240. [6] P. Zheng, “High temperature electronics packaging processes and materials development,” Ph.D. dissertation, Dept. Technol. Eng., Auburn Univ., Auburn, AL, USA, 2010. [7] J. G. Bai, Z. Z. Zhang, J. Calata, N. Lu, and Q. Guo-Quan, “Low-temperature sintered nanoscale silver as a novel semiconductor device-metallized substrate interconnect material,” IEEE Trans. Compon. Packag. Technol., vol. 29, no. 3, pp. 589–593, Sep. 2006. [8] C. R. Chang and J. H. Jean, “Effects of silver-paste formulation on camber development during the cofiring of a silver-based, lowtemperature-cofired ceramic package,” J. Amer. Ceramic Soc., vol. 81, no. 11, pp. 2805–2814, Nov. 1998. [9] P. Zheng, P. Zheng, P. Henson, and L. Chen, “Metallurgy for SiC Die attach for operation at 500 °C,” in Proc. Int. Conf. Exhibit. High Temp. Electron., 2010, pp. 8–17. [10] S. A. Yang and A. Christou, “Failure model for silver electrochemical migration,” Ieee Trans. Device Mater. Rel., vol. 7, no. 1, pp. 188–196, Mar. 2007. [11] S. H. Mannan and M. P. Clode, “Materials and processes for implementing high-temperature liquid interconnects,” IEEE Trans. Adv. Packag., vol. 27, no. 3, pp. 508–514, Aug. 2004. [12] G. Muralidharan, “Composite die-attach materials for high-temperature packaging applications,” in Proc. High Temp. Electron. Conf., 2006, pp. 593–601. [13] Y. Takaku, I. Ohnuma, R. Kainuma, Y. Yamada, Y. Yagi, Y. Nishibe, and K. Ishida, “Development of Bi-base high-temperature Pb-free solders with second-phase dispersion: Thermodynamic calculation, microstructure, and interfacial reaction,” J. Electron. Mater., vol. 35, no. 11, pp. 1926–1932, Nov. 2006. [14] L. Bernstein, “Semiconductor joining by solid-liquid-interdiffusion (SLID) process,” J. Electrochem. Soc., vol. 113, no. 12, pp. 1282–1288, Dec. 1966. 913 [15] L. Bernstein and H. Bartholomew, “Applications of solid-liquid interdiffusion (SLID) bonding in integrated-circuit fabricatoin,” Trans. Metall. Soc. AIME, vol. 236, no. 3, pp. 405–411, 1966. [16] D. S. Duvall, W. A. Owczarshi, and D. F. Paulonis, “TLP bonding: A new method for joining heat resisant alloys,” IEEE J., vol. 53, no. 4, pp. 203–214, Apr. 1974. [17] W. D. Macdonald and T. W. Eagar, “Transient liquid-phase bonding,” Ann. Rev. Mater. Sci., vol. 22, no. 1, pp. 23–46, Aug. 1992. [18] R. Schmid-Fetzer, Design Fundamentals of High-Temperature Composites, Intermetallics and Metal-Ceramic Systems, R. Y. Lin, Ed. Warrendale, PA, USA: TMS, 1995, pp. 75–97. [19] W. R. Johnson, C. Wang, Y. Liu, and D. J. Scifield, “Power device packaging technologies for extreme environments,” IEEE Trans. Electron. Packag. Manuf., vol. 30, no. 3, pp. 182–193, Jul. 2007. [20] K. E. Aasmundtveit, K. Y. Wang, N. D. Høivik, J. M. Graff, and A. Elfving, “Au-sn SLID bonding: Fluxless bonding with high temperature stability to above 350 °C,” in Proc. Eur. Microelectron. Packag. Conf., Jun. 2009, pp. 723–728. [21] K. Aasmundtveit, T. T. Luu, H.-V. Nguyen, R. Johannessen, N. D. Høivik, K. Y. Wang, “Au-Sn fluxless SLID bonding: Effect of bonding temperature for stability at high temperature, above 400 °C,” in Proc. Electron. Syst. Integr. Technol. Conf., Sep. 2010, pp. 1–6. [22] J. F. Li, P. A. Agyakwa, and C. M. Johnson, “Kinetics of Ag3 Sn growth in Ag-Sn-Ag system during transient liquid phase soldering process,” Acta Mater., vol. 58, no. 9, pp. 3429–3443, May 2010. [23] C. L. Lee, Y. W. Chen, and M. Goran, “Advances in bonding technology for electronic packaging,” J. Electron. Packag., vol. 115, no. 2, pp. 201–207, Jun. 1993. [24] K. Y. Wang, K. E. Aasmundtveit, and H. Jakobsen, “Surface evolution and bonding properties of electroplated Au/Sn/Au,” in Proc. 2nd Electron. Syst., Integr. Technol. Conf., vols. 1–2. Sep. 2008, pp. 1131-1134. [25] G. S. Matijasevic, C. C. Lee, and C. Y. Wang, “Au-Sn alloy phasediagram and properties related to its use as a bonding medium,” Thin Solid Films, vol. 223, no. 2, pp. 276–287, Feb. 1993. [26] N. D. Høivik, K. E. Aasmundtveit, G. Salomonsen, A. Lapadatu, G. Kittilsland, and B. Stark, “Fluxless wafer-level Cu-Sn bonding for micro-and nanosystems packaging,” in Proc. Present. Electron. Syst. Integr. Technol. Conf., Sep. 2010, pp. 1–5. [27] H. Huebner, S. Penka, B. Barchmann, M. Eigner, W. Gruber, M. Nobis, S. Janka, G. Kristen, and M. Schneegans, “Microcontacts with sub30 mu m pitch for 3D chip-on-chip integration,” Microelectron. Eng., vol. 83, nos. 11–12, pp. 2155–2162, Nov.-Dec. 2006. [28] S. Bader, W. Gust, and H. Hieber, “Rapid formation of intermetallic compounds by interdiffusion in the Cu-Sn and Ni-Sn systems,” Acta Metall. Et Mater., vol. 43, no. 1, pp. 329–337, Jan. 1995. [29] P. F. Yang, Y.-S. Lai, S.-R. Jian, J. Chen, and R.-S. Chen, “Nanoindentation identifications of mechanical properties Of Cu6 Sn5 , Cu3Sn, and Ni3 Sn4 intermetallic compounds derived by diffusion couples,” Mater. Sci. Eng. A, Struct. Mater. Properties Microstruct. Process., vol. 485, nos. 1–2, pp. 305–310, Jun. 2008. [30] W. W. So and C. C. Lee, “High temperature joints manufactured at low temperature,” in Proc. IEEE 48th Electron. Compon. Technol. Conf., May 1998, pp. 284–291. [31] R. W. Chuang and C. C. Lee, “Silver-indium joints produced at low temperature for high temperature devices,” IEEE Trans. Compon. Packag. Technol., vol. 25, no. 9, pp. 453–458, Sep. 2002. [32] P. Quintero, “Development of a shifting melting point ag-in paste via transient liquid phase sintering for high temperature environments,” Ph.D. dissertation, Dept. Mech. Eng., Univ. Maryland, College Park, Md, USA, 2008. [33] T. A. Tollefsen, A. Larsson, O. M. Løvvik, and K. Aasmundtveit, “Au-Sn SLID Bonding—Properties and possibilities,” Metall. Mater. Trans. B, vol. 43, no. 2, pp. 397–405, Apr. 2012. [34] T. A. Tollefsen, A. Larsson, O. M. Løvvik, and K. Aasmundtveit, “Au-Sn SLID bonding for high temperature applications,” in Proc. IMAPS High Temp. Electron. Network Conf., 2011, pp. 58–67. [35] H. Okamoto, “Au-Sn (Gold-Tin),” J. Phase Equilibria Diffusion, vol. 28, p. 490, Oct. 2007. [36] H. S. Liu, C. L. Liu, K. Ishida, and Z. P. Jin, “Thermodynamic modeling of the Au-In-Sn system,” J. Electron. Mater., vol. 32, no. 11, pp. 1290–1296, Nov. 2003. [37] R. R. Chromik, D.-N. Wanga, A. Shugara, L. Limataa, M. R. Notisa, and R. P. Vincia, “Mechanical properties of intermetallic compounds in the Au-Sn system,” J. Mater. Res., vol. 20, no. 8, pp. 2161–2172, Aug. 2005. 914 IEEE TRANSACTIONS ON COMPONENTS, PACKAGING AND MANUFACTURING TECHNOLOGY, VOL. 3, NO. 6, JUNE 2013 [38] R. Johannessen, “High Temperature Power Electronic Packaging for Oil Well Applications,” in Proc. IMAPS High Temp. Electron. Network Conf., Sep. 2009, pp. 1–9. [39] Z. J. Shen, “High temperature, high power module design for wide bandgap semiconducters: Packaging architecture and materials considerations,” in Proc. High Impact Technol. Exchange Conf., May 2008, pp. 1–6. [40] M. N. Yoder, “Wide bandgap semiconductor materials and devices,” IEEE Trans. Electron Devices, vol. 43, no. 10, pp. 1633–1636, Oct. 1996. [41] N. G. Wright, B. H. Alton, and K. Vassilevski, “Prospects for SiC electronics and sensors,” Mater. Today, vol. 11, nos. 1–2, pp. 16–21, Jan.–Feb. 2008. [42] G. Kresse and J. Hafner, “Abinitio molecular-dynamics for liquidmetals,” Phys. Rev. B, vol. 47, no. 1, pp. 558–561, Jan. 1993. [43] G. Kresse and J. Furthmuller, “Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set,” Phys. Rev. B, vol. 54, no. 10, pp. 11169–11186, Oct. 1996. [44] J. P. Perdew, J. A. Chevary, and S. H. Vosko, “Atoms, molecules, solids, and surfaces: Applications of the generalized gradient approximation for exchange and correlation,” Phys. Rev. B, vol. 46, no. 11, pp. 6671–6687, Sep. 1992. [45] G. Kresse and D. Joubert, “From ultrasoft pseudopotentials to the projector augmented-wave method,” Phys. Rev. B, vol. 59, no. 3, pp. 1758–1775, Jan. 1999. [46] FIZ Karlsruhe Inorganic Crystal Structure Database (ICSD). (2010, Aug. 26) [Online]. Available: http://www.fiz-karlsruhe.de/icsd.html [47] H. Hieber, “Heat-resistant contacts with use of liquid phase transition,” in Proc. 7th Eur. Hybrid Microelectron. Conf., 1993, pp. 7–13. [48] D. R. Frear, Mechanical-Behavior Of Solder Joint Interfacial Intermetallics. Materials Park, OH, USA: ASM International, 1991. [49] S. Anhock, H. H. Oppermann, C. Kallmayer, R. Aschenbrenner, L. K. Thomas, and C. H. Reichl, “Investigations of Au/Sn alloys on different end-metallizations for high temperature applications,” in Proc. IEEE Int. Electron. Manuf. Technol. Symp., Apr. 1998, pp. 156–165. Torleif André Tollefsen was born in Kristiansand, Norway, in 1978. He received the M.Sc. degree in material physics from the University of Oslo, Oslo, Norway, in 2008. He is currently pursuing the Ph.D. degree in applied micro- and nanosystems with Vestfold University College, Borre, Norway. He was a System Engineer at FMC Technologies, Bergen, Norway, from 2008 to 2010, working with systems for the subsea production of oil and gas. In 2010, he joined the Research Institute SINTEF and Vestfold University College to pursue a Ph.D. degree. From 2013, he has been a Research Scientist at SINTEF. He has authored more than 25 journal and conference papers. His current interests include packaging for micro and nanosystems, with a special focus on materials for harsh environments. Andreas Larsson was born in Eskilstuna, Sweden, in 1980. He received the M.Sc. degree in engineering physics–applied physics from Uppsala University, Uppsala, Sweden, in 2006. He has been a Structural Engineer with the Norwegian Oil and Gas industry since 2006, where he performed finite element analysis and concept development. Since 2008, he has been with the Research Institute SINTEF, currently as a Senior Scientist responsible for harsh environment packaging. He has authored more than 40 publications and holds patents. His current research interests include packaging and interconnect technology for harsh environments, with the important topics being multiphysics simulations and concept development. Ole Martin Løvvik was born in Norway in 1968. He received the M.Sc. degree in theoretical physics and the dr.scient. degree in energy physics from the University of Oslo (UiO), Oslo, Norway, in 1993 and 1998, respectively. He was a Post-Doctoral Researcher at UiO from 1999 to 2006 and the Institute for Energy Technology, Kjeller, Norway. He was an Associate Professor with the Norwegian University of Life Sciences, As, Norway, in 2001, a Consultant with the Research Council of Norway, Oslo, in 2006, a Research Fellow with the Institute for Energy Technology, Kjeller, from 2006 to 2008, a Visiting Scientist with the University of Hiroshima, Hiroshima, Japan, in 2008, and a Visiting Professor with Osaka University, Osaka, Japan, in 2012. He is currently a Senior Researcher with the research institute SINTEF and an Adjunct Professor with the University of Oslo. He has authored around 65 papers in international journals with referee, and has given more than 90 invited and contributed talks at international conferences. His current research interests include atomic-scale modeling of materials for energy technologies, with the important topics being electronic materials, materials for hydrogen technology, and light weight metals. Knut E. Aasmundtveit received the M.S. degree in technical physics from the Norwegian Institute of Technology, Trondheim, Norway, in 1994, and the Ph.D. degree in materials physics from the Norwegian University of Science and Technology, Trondheim, in 1999. He was with Alcatel Space Norway/Ame Space (now Kongsberg Norspace), Horten, Norway, as a Radio Frequency System Design Engineer, until 2004, when he joined the Department of Micro and Nano Systems Technology, Vestfold University College, Borre, Norway, as an Associate Professor. He has authored or coauthored four book chapters and more than 60 journal and conference papers. His current research interests and teaching activities include packaging and integration technology for micro and nano systems, such as intermetallic bonding, polymer-based bonding, nanomaterials integration in microsystems, and biomedical packaging.