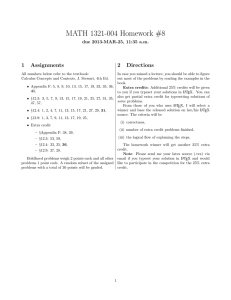

Notes Field INFORMATION SYSTEM

advertisement

ý f 3 ENGINEERING TECHNICAL FIELD NOTES TECHNICAL REPORTS DATA RETRIEVAL MANAGEMENT INFORMATION SYSTEM PROFESSIONAL DEVELOPMENT -q1 VOLUME NUMBER 2 Notes Field Figueroa Mountain I Rubberized Chipseal Bituminous Skyline Analysis Program Washington Office FOREST SERVICE ýpF51 News FEBRUARY SEgyk Era.c.E U.S. DEPARTMENT OF AGRICULTURE 1978 ERRATA TO JANUARY FIELD NOTES 10 1 Volume Correct page 4 5i of ai of ýI 5i ýI II 4I NI ýI ýI NI ýI Cs1 OI NI UI 4 to Number read the box labeled SANITARY ENGINEER Sanitary Engineer and Leon Lehr In Correct page Change Correct page 7 to add Bill Opfer between read William to Bill Opfer 11 to read Change William Cournay to William Gournay US ENGINEERING FIELD NOTES Volume Information contained in this publication 10 has Number 2 been developed for of employees respon-sibility of the United Federal cooperating for The the of any guidance its The Department of Agriculture agencies. by other than of this information contractors assumes its own and its no employees. firm or corporation names in this publication is for the information and Such use does not constitute an official endorsement or approval or service product may be text in the publication be or policy except engineers and engineering intended by the United construed by States Department of Agriculture to the exclusion suitable. must not not Service Agriculture-Forest of the reader. of others that The and State of interpretation or use use of trade convenience Department States as FSM exclusively the personal represents recommended Because references. technicians for opinions or approved should of the type read each issue however engineers. DEPARTMENT OF AGRICULTURE Washington D.C. author and of material in the publication FOREST SERVICE U.S. of the respective procedures mandatory instructions 20013 this publication all is MOUNTAIN FIGUEROA BITUMINOUS CHIPSEAL RUBBERIZED SURFACE TREATMENT Jim Penskoverr Civil Engineer Sheldon Perkins Chuck Sheen District Engineer Project Padres Los Inspector National Forest R-5 aggre-gate PROJECT DESCRIPTION A worn cracked asphalt pavement was successfully coated with an The seal is now over with a latex rubber additive. surface chipseal a year old and a 10-year life expectancy or greater is predicted. the 2-1/2 mile length of road little serious wide had with developed fig. 1. up of this the that most of the surface. It was consensus deformation consolidation due to either or expansion during subgrade cracking was not Basement Thereforeremoval and were wet periods. repair performed. The project had alligator cracks Cracks to 1/4 throughout inch be-tween soils consisted of mixed expansive shales and clays. using this road consisted of autos and light trucks with an one per month full HS-20 load. Daily traffic averaged with maximums 120 and 150 vehicles exceeding 500 vehicles during and early spring weekend. hunting season snow-play weekends The traffic occasional DESIGN CONSIDERATIONS located near Vandenburg Air A small test strip of rubberized chipseal Force Base was examined. Indications were that the rubber additive greatly improved low temperature flexibility of the mat and drastically increased the tackiness of the asphaltic emulsion. Aggregate that was 1 Jim Penzkover has been transferred to the Idaho Forest. 1 Panhandle National cracks in mile road. ad-hering Figure AZZigator 1. slightly imbedded in the one foot out it of the mat 2-1/2 rubberized emulsion could be pulled as much with a rubber band-like string of rubber as No stone back when released. After conferring with the Santa Barbara County Department of Public Works who placed the test strip a specification was developed for the Figueroa Mountain Project. to excess chips and the remained string the on the pulled surface. COST COMPARISONS The following table shows annual cost and present value when compared with latex rubber conventional aggregate aggregate chipseal against seal at 6-1/8 interest. slurry percent 2 and Alternatives 1. Conventional chip 2. 3. chip latex Expected2 Cost Value Life $2780 $31540 2160 24480 10 yrs. 2770 31480 4 6-2/3 yrs. seal rubber Slurry seal 1Present Present seal Aggregate with aggregate Annual value represents a 20-year need for this road yrs. surface. the aggregate seal with latex rubber is considered The city of Chula Vista California has chipseals native soils still in good condition with 15 years of service. over Expected life on alternatives 1 and 3 are maximums based on similar 2Expected life of conservative. roads. Alternative number one has a replacement calculated at 6-2/3 years and Alternative number two has a replacement calculated at 13-1/3 years. alternative number three has a replacement every 4 years. and year 10 PROJECT DESIGN brooming and washing cracked Project specifications called for complete the cracked with SS-1 at 0.08 gallon/ areas and dirty areas sealing and RS-2 inch 4 chips and a 3/8 x No. yard2 applying single chipseal Six of and 0.35 latex at the rate 22 pounds/yard2 gallon/yard2. with of emulsion about ton of latex rubber were added asphalt per gallons Added cost of the latex rubber shipping to Santa 2-1/2% by volume. and associated expenses cost the Maria from La Mirada California This amounts to about a 7 of additive. about $9 per gallon cost above a conventional increase to project chipseal. con-tractor per-cent CONSTRUCTION Preparation work began by power brooming the old pavement surface. SS-l asphalt emulsion Cracked areas were hosed to remove imbedded dirt. The latex rubber TEXAPAVE tack coat was applied and allowed to cure. was added to the RS-2 by pouring it from 5-gallon factory containers The distributor truck agitated the into the loaded distributor truck. mixture by pumping it through its pressure pump for about 15 minutes. The mixture was spread and the aggregate was immediately placed and There was little appreciable difference rolled with a pneumatic roller. The first in appearance or workability from a conventional chipseal. the freshly noticeable difference appeared when traffic drove over 3 rolled aggregate with virtually no stone pickup. The mat was immediately for slow traffic and set for appeared normal traffic within ready enough 1 hour was 78 air temperature approximately degrees. All chips mat were attached to the with only a very small latex rubber/asphalt mixture remained during aggregate application for The asphalt mixture will not set up prematurely approximately 6 hours. providing the temperature remains within specification tolerances. amount of to even them. those The asphalt adhering in the distributor truck The chipsealed surface today still has its original elasticity and the old cracks have not reappeared fig. 2. Small but strong strands of rubber adhere to the stone when pulled from the surface however all stones are firmly imbedded into the mat. f Figure 2. ChipseaZed surface 1 year 4 Zater. Note the surface roughness. ADVANTAGES OF USING LATEX RUBBER durability and is greatly improved. 1. Mat 2. Skid resistance is much better than 3. Chip retention is almost 4. No 5. Life expectancy bleeding or strength 100 double a conventional occurs. or more. DISADVANTAGES OF USING LATEX RUBBER 1. 2. Some inconvenience is encountered ADDITIVE in adding latex rubber. mixture overrun must be disposed Excess asphalt will not allow it to be returned. supplier GENERAL chipseal. percent. summer softening is ADDITIVE of since COMMENTS have chipsealed 17 miles of native and gravel surfaced roads using both single and double seal coat applications with latex additives. On double seal coats we have required 7 days between applications from the emulsified so as to ensure that all moisture has evaporated recommends the latex within 48 hours The manufacturer using asphalt. We in-stalled re-duce after One local plant has not opening and mixing with asphalt. for latex additive bulk storage and blending facilities the costs of handling and purchasing 5-gallon cans. to construc-tion Our experiences have thus far indicated that normal design and practices for typical bituminous surface treatments also apply to A prime coat must be used surface treatments with the latex additive. because the asphalt-latex mixture provides little penetration into the The The mixture bonds very well to the prime coat. aggregate. in-creased flexibility and elasticity derived to frost subject very desirable in climates surface deformation roads where some speed the total design thickness of the pavement should make the use of latex con-structed In addition on low tolerated or where structure cannot be heave. can be in timber sales contracts to a lack of supplemental funds relatively with the latex additive may provide a sufficient a chipseal basic investment in the free surface that will the maintenance protect than and surface erosion much more economically road surface prevent associated dust and other methods i.e. multiple oiling watering due blading. latex manufacturer recommends adding latex to hot mix and all other to freeze-thaw conditions. concrete mixes and seals subject asphalt The 5 suc-cessfully Although we have no experience with asphalt-latex mixtures other than that described here it is our opinion that they may very well be used in other asphalt mixtures particularly when increased cohesion or flexibility is desired. flexi-biZity rubber manufacturer TEXA COTE claims their product modifies asphalts to improve low temperature and increases summer temperature viscosity cohesion Rubber in softening point and enhances aging properties. latex form amalgamates easily with emulsified asphalts to TEXAPAVE lattices form a reinforced rubber-bitumen lattice. are particles of unvulcanized synthetic rubber in a waste base emulsion. The rubber particles are extremely small and The latex TEXAPAVE ex-posed Thus a very large amount of surface area is bitumen during mixing which promotes rapid and blends The latex rubber easily thorough dispersion of rubber. into emulsified asphalts at temperatures between 140 and 150 degrees Fahrenheit. uniform. to the TEXAPA VE looks like and has the consistency of cream-colored The shelf latex paint but it is very sticky like glue. latex similar It is essential to use the is to life paint. TEXAPAVE 65k with cationic asphalt cationic latex rubber emulsions and anionic TEXAPAVE 70 with anionic asphalt emulsions. Information may be obtained from TEXACOTE INC. Textile Rubber and Chemical Company 14241 East AZondra Boulevard La Mirada The Special California 90638. Project Specifications used for this project were as follows SPECIAL PROJECT SPECIFICATIONS FIGUEROA CHIP SEAL Forest Service Standard Specifications for Construction of Roads and and Section 100 General Specifications 11/13/73 Bridges 1972 Editions is modified as follows incorporated by reference SECTION 407 407.04 - TACK COAT Preparation of Surface to be Treated. and substitute the following 6 Delete entire paragraph The Forest pavement 407.05 Service will patch and clean prior to applying tack coat. Application of Bituminous the existing asphalt Add Material. Emulsified Asphalt Grade SS-l shall be spread the rate of 0.08 gallon per square yard. SECTION 410 410.02 - BITUMINOUS SURFACE TREATMENT Add the Bituminous Materials. uniformly at following anionic rubber additive TEXAPAVE 70 or equivalent shall of additive for each ton be added at the rate of six gallons The additive shall be added prior to of emulsified asphalt. and agitated thoroughly according to manufacturers application An published 410.04 specifications. Construction Requirements - General. Add the following concrete placed on all Portland cement and to surfaces as sidewalks driveways curbing prevent to areas to from coating concrete surfaces adjacent asphalt is to be removed After of be sealed. application chips paper materials on concrete Excess edge. asphalt leaving a straight be disposed of by and shall shall be cleaned building paper Building paper shall be such the 410.08 Contractor. deter-mined The first sentence is deleted and the following is substituted The accepted quantities of bituminous surface treatment price as provided above will be paid for at the contract and per ton for bituminous material and rubber additive per in place which price and payment ton for aggregates complete will be full compensation for the work in this Section. SECTION 702.05 702 MATERIALS - BITUMINOUS Application Temperatures. the following substituted Temperature be not less of asphalt than 150 The first sentence is deleted and emulsion at the time of application than 180 degrees F. nor more degrees 7 shall F. SECTION 714 714.1 Rubberized - RUBBER ADDITIVE additive ASPHALT EMULSION FOR for emulsion shall asphalt conform to the following requirements Monomer Ratio Butadiene/Styrene Solids Content min. % Solids Content min. lbs./gal. Coagulum on 80 mesh screen max. Mooney viscosity of Polymer ML4 Ph of Latex Surface Tension dynes/cm Brookfield For and 714.2 67 5.3 % @ 0.1 212F. min 100 9.4-10.5 28-42 1000-2000 cps formulation purposes 5.4 Rubber Viscosity 70/30 average solids content runs 68% lbs./gal. additive specified rate shall in the be asphalt emulsion at the Supplemental Construction Specifications. added to the i 714.3 Rubber additive shall be blended recommendations. 714.4 The rubber be opened additive just shall be prior to in according to manufacturers sealed adding into 8 the containers and emulsion. shall SKYLINE ANALYSIS PROGRAM J. Robert McRae Six Rivers National Forests R-5 A new programs have been developed for live standing running multiple span skyline analysis and are on file for your use at the Fort Collins Computer Center FCCC. The topographic data for and calculations of the net payloads for either flying or load analysis dragging loads are prepared from these programs. set of skyline and The multiple span skyline analysis program has been revised from the Carson formulation outlined in PNW Research Note 31 1975 and expanded The live standing and by John Sessions to include mainline effects. also John Sessions using the running skyline programs were developed by link formulation proposed by Carson in PNW Research Note 205 rigid The do 1976. not require the use of a plotter however for programs minimum cost it is advantageous to have the critical points. The programs are interactive in that they can be run in the demand mode rather than batch. This allows the operator to examine the output and changing input information to adjust the geometry for recalculation of the loads. the most efficient use and of running the live standing and running skyline analysis The cost of running the programs is approximately $0.06 per profile. multiple span skyline analysis program is approximately $1 per profile. Note that the above costs are approximate only and are dependent upon exercised. the number of options The cost interpre-tation For further information documentation input instructions or please write John Sessions output of these programs Service Advanced Logging Systems Training Program Department Forest School of Forestry Forest Oregon State University Engineering 97331 FTS 8-420-4420. Corvallis Oregon of 1FormerZy the Advanced Logging Systems Training Program Oregon University. 9 State of I WASHINGTON OFFICE NEWS CONSULTATION AND Walter BILLING Furen Director E. Assistant MONTHLY FOR ELECTRIC The monthly billing for electric service and government customers usually consists for of SERVICE large two industrial Demand commercial parts This varies directly with the amount Energy Cost. the during billing period measured in kilowatt hours 1. used STANDARDS of energy kWh. based on the maximum power demand during The reason for this cost kW. billing period can be illustrated by comparing two customers with equal energy use but demands. different Customer A has a load of 5 kW which he operates 200 hours per month making his monthly energy use 1000 kilowatt hours. Customer B has a load of 10 kW which he operates 100 hours per month his use also kilowatt-hours month. making 1000 However the power per i.e. generators company must have more or larger equipment and transmission lines to supply customer B compared to that for customer A. 2. Cost. This is measured in kilowatts the transform-ers re-quired Another way of illustrating the relative cost of electric demand is by For example if you want to haul 10 analogy with other kinds of power. of material in will need a 10-ton truck but if you tons one trip you make The are willing to two trips you can get by with a 5-ton truck. amount in of work equipment accomplished in each case is the same but the investment is less when the work is spread out over a longer period of time. Billing demand can often be reduced by rescheduling operations to spread the use of energy over a longer period of time or by using equipment with a lower horsepower or kW rating. Time clocks interlock controls and other devices can also be used to prevent simultaneous operation of equipment. 10 TECHNOLOGICAL IMPROVEMENTS Heyward T. Tay Zor Assistant Director LEVELS IN MONITORING OF TURBIDITY SURFACE-SOURCE DRINKING-WATER SYSTEMS drinking-water Regula-tions 93-523 was enacted to ensure directed The Act public drinking to establish national Environmental Protection EPA the Agency The National Interim Primary Drinking Water regulations. These regulations 40 CFR Pt. 141 were promulgated in 1975. contained in FSM 7420 require the Forest Service to monitor and control In 1974 that the Safe Drinking Water Act is provided the with P.L. safe water. A recent turbidity levels in surface-source drinking-water systems. that about 787 Forest Service revealed potable water supply inventory that fall under the utilize surface-source facilities supplies regulations. A water sample must be taken each day a water system is in use and tested for turbidity within Additionally any single water sample level of tested exceeds a maximum one nephelometric turbidity unit NTU In view of must be taken preferably within 1 hour. a repeat sample to have time limitations it is often impossible or very costly these of water certified independent laboratories measure the turbidity 24 hours. samples obtained from remote if field locations. 1NepheZometric turbidity units correspond to the method of turbidity measurement when using a nephelometric turbidimeter--an instrument for or particle size of suspensions by means determining the concentration transmitted or reflected of Light. 11 i II con-tact Managers of Forest Service facilities should review their electric bills to monitor and wherever possible to reduce energy use and see if the If so efforts should be bills include any significant demand charges. the maximum demand. The best to this is to made to reduce approach their assistance. The the electric utility company and request have staff who will be knowledgeable people utility companies generally is also available from the Office. Assistance Washington glad to help. FY 1977 turbidimeters were investigated and tested by San Dimas to determine if they Equipment Development Center SDEDC engineers could be adopted for field use in remote locations. Parameters examined included accuracy cost portability and reliability. In turbidimeters were tested at two independent laboratories and at to determine if the meters met EPA design criteria and to determine their overall operating characteristics. The MonitekPortable Model 21 Turbidimeter Monitor Technology Inc. Redwood City CA since it was found to be the most practical for remote field locations Seven San Dimas port-able that was battery operated and portable. one found However now being conducted on two additional battery-operated Lomb turbidimeters one made by Bausch Rochester N.Y. and the HF Other turbidimeters other Instruments Bolton by Ontario Canada. tested can be used wherever turbidity of water is to be measured and there is a source of power. was the tests only are labora-tories measur-ing variations in data obtained from the two occurred because of different methods of Differences were also encountered in turbidity readings turbidity. between the turbidimeters because of differences in the spectral response During the and test at program San Dimas turbidi-meter re-corded in each turbidimeter. Thus it is expected that optics systems different results. To minimize turbidimeters will different produce for in a methodology turbidity readings specific discrepancies and should be adopted calibration sample taking operation of turbidities. A suggested and included with any report Record to be issued upon in San Dimas will be provided a Project of the method-ology con-sisting project completion. read-ing In general of all a of light the turbidimeters tested source for operate the same each water sample and one or illuminating the located 90 degrees to the incident light more photoelectric detectors detectors to the A meter connected photoelectric provides a path. in the water sample. of scattered of the intensity light by particles turbidimeter is supplied with one or more-reference standards that of a A reference standard consists are used for calibration purposes-. inside. of known tube with a liquid suspension turbidity sealed glass The glass tube is designed to fit in an enclosure called a cell that is After the turbidimeter is turned on and part of the turbidimeter. A is placed in the cell. allowed to warm up the reference standard and the the standard that keeps out stray light cover is placed over turbidimeter is then adjusted to read the same as the known standard. The standard is then taken out of the cell and replaced by a sample The cover is replaced over the water to be measured. tube that contains and turbidity of the water sample is read from the meter the sample tube Each in NTUs. 12 OPERATIONS Harold L. Strickland Assistant Director ORGANIZATIONAL STUDY Currently a consultant is studying the Washington Office organization to In conjunction with this determine the effectiveness of the organization. study Engineering was asked to provide a discussion on the effects of recent legislation and/or administrative decisions on the WO Engineering Staff. We think our response which follows may be of interest to you. follow-ing. re-lationship of recent achieve a good understanding of the effects legislation and/ administrative decisions on our staff it is important to the discussion that we have a common understanding of the mission and role of the Engineering Staff Unit. The following is intended to show the of legislative matters and administrative decisions to the To or job we are total required to accomplish. the role of Engineering in the Forest Service is to provide the technical and professional leadership in all fields of engineering which Service programs in Research are needed to accomplish Forest State and Private Forestry and the protection and development of lands management This leadership involves in the National Forest the setting of System. First perfor-mance policies objectives providing systems standards of programs and performing review evaluation and accountability. Included in this mission is specific responsibility for Providing timely and competent engineering consultation to line for as new solution of engineering managers required programs in or more effective methods for problems on-going programs developing the of Forest Service handling engineering aspects operations. 1. and staff Providing the required engineering capacity by use of In-Service through technically supervised consultants to accomplish the planning design construction operation and maintenance of all physical facilities built by the Forest Service regardless of purpose to be served used. This includes basic responsibility for providing or source of funds technical standards design criteria review and technical acceptance of designs and specifications for facilities whether developed by a or by In-Service forces. 2. forces or consul-tant 13 Providing engineering direction and management of engineering activities support including management of the transportation system fleet and maps cadastral surveying and technical equipment surveys solid waste and waste water treatment and disposal dam drafting safety engineering applications computer systems and technical and economic input to administrative and recreation facility management and 3. operations. 4. Providing professional engineering consultation and review for under construction or engineering aspects of improvements proposed being operated on lands in the National Forest System by others whether under easement or special use permit. This includes review of means of accomplishing the proposed installation which would better meet National Forest management objectives and review of designs specifications operating procedures and maintenance requirements. This also includes consultation on determining land management objectives that will best meet public needs where engineering considerations are alterna-tive the engi-neering soci-eties profession-ally fur-therance neces-sary con-ferences involved. Keeping abreast of current technological advances in the and association with professional through contacts engineering research groups universities and other oriented organizations. Where it appears that these materials 5. field processes of equipment or systems may make the objectives of the Forest investigations or 6. Forest studies to provide major contributions to institute the Service the basis for the implementation. Providing professional engineering liaison and representing the as assigned for staff studies and work Service meetings with other Government and private organizations. exper-tise Interwoven into all of these responsibilities are the engineering-related aspects of legislation and administrative decisions. Engineering and experience are continually called upon to contribute to the formulation of legislative material as well as certain administrative direction. This is generally only the beginning of our involvement. Depart-ment the Engineering Staff was required to contribute a great example effort to the preparation of the National Trails System Act of October 1968. Our initial effort was to identify and furnish the of Agricultures data concerning existing and needed trails to the Bureau of Outdoor Recreation in conjunction with their responsibility for conducting the nationwide trails study. Their assessment was in response to President Johnsons Natural Beauty Message of February 8 1965. The preliminary effort related to the need for legislation and extended from February 1965 until the passage of the legislation on October 2 1968. As an deal of 14 work-ing was just the beginning. Following passage of the legislation of Agriculture and Interior and between the Departments agreements between agencies Forest Service Park Service and BLM had to be were established. Advisory councils required by the legislation and for them was required. In October of 1972 the Congress staff support the Federal Committee Act which created additional Advisory passed the activities of the trail councils. needs to continued staffing support This identifica-tion in the governing use of those trails included of the The requirement legislation. and acquirement of rights-of-way for the trails in addition to and management were all requirements location design construction the associated with the legislation. It is accurate to state that of associated with the National Trails Act a minimum effort required staffman in this office the of one full-time during period February 1965 when the for trails until April 1975 was management responsibility This manpower requirement was to the Recreation Staff Unit. detailers to this office by met by requesting the Regions to furnish farming out individual work assignments to various Regions and by staff support located here within Engineering. Secretarys regulations Trails Act were another re-assigned indi-vidual be-fore man-power diversified method for acquiring sufficient manpower determine with accuracy the actual man-years of work associated specifically with legislative and administrative requirements. It becomes evident however that there can be a tremendous impact during and after the passage of laws which govern management of Sometimes the impact is clearly defined and the National Forests. is devoted to the effort on a full-time basis. Generally the effort prior to enactment is not as great as it was for the Trails Act however it is quite common that after passage a similar effort is generally required in formulating work agreements with other Federal agencies and preparing Secretarys regulations along with Forest Service policy and direction for implementing the requirements of the enacted As a it is difficult result of this to legislation. APPROVAL TO ATTEND MEETINGS Administrative Management has advised us that more attention should be paid to the justification statement when we fill out a form AD-179 we frequently do not clearly Request to Attend Meeting. Apparently state why the attendees needs to go to the meeting. In addition FSM 1360 specifies some time requirements for requests that have to be cleared by the Washington Office. Most of our trouble has been with National meeting attendance requests which must be received 30 days in advance of the travel date. If you are late with a request be sure to explain why. 15 TO READERS OF FIELD NOTES INVITATION reader Every is author potential a of an article for Field Notes. If you have a news item or accu-rate you would short article publication Material in Field submitted to share with like Service we engineers you invite Notes. to the Washington Office for should publication be send to it for by the reviewed Washing-ton respective Office Regional and of informative may material submitted however short articles Office Field and white Notes is the list ask number Each from or news information is timely technically FSM 7113. The length current Service-wide engineers short sentences several items are preferred. double-spaced all to several typewritten material submitted All should illustrations be to original of pages the drawings or photos. and Forest your Office Manager sent to your Office directly Service retirees. or the office. Regional to Regional Station all you If Information are not currently Coordinator Copies of back issues are also to and on the increase from the available Office. Region questions to Forests of copies Washington interest vary the distributed from the Washington Area Headquarters mailing that be typed should black glossy to see has an Information and material for Dittmer R-1 Melvin R-2 Royal M. Ryser R-3 Bill Coordinators Coordinator Strohschein should direct The publication. Ted R-5 Jim McCoy R-6 Kjell R-8 Bob Bowers questions Telephone submit both R-9 Fred Hintsala R-10 F. WO W. Baxandall Al Colley format editing publishing dates and other Service Staff Attn Gordon P.O. Box 2417 Washington should personnel are Bakke concerning Forest Engineering field Wood R-4 problems to USDA whom to Coordinators L. D.C. Rm. 1108 RP-E Rome or Rita E. Wright 20013 Area Code 703-235-8198 16 U.S. GOVERNMENT PRINTING OFFICE 1978 0-261-474/FS-31