Best Practices in Design-Build Contracting for Projects in Texas

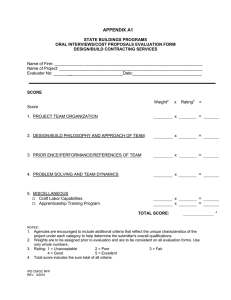

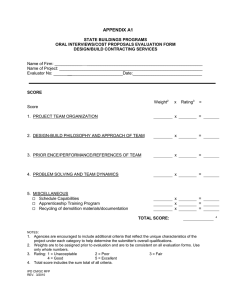

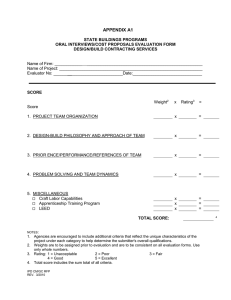

advertisement