Document 11448415

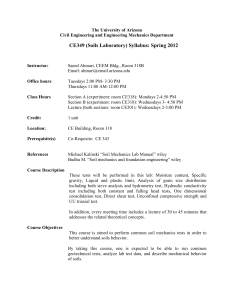

advertisement