Notes Field INFORMATION SYSTEM

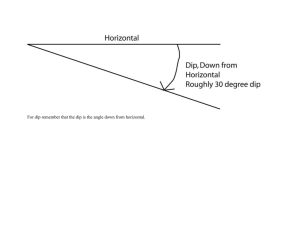

advertisement

ENGINEERING TECHNICAL FIELD INFORMATION SYSTEM DATA Volume i Field I Number 5 TECHNICAL NOTES RETRIEVAL REPORTS CURRENT TEXTS AWARENESS Notes 0 October 1973 Dip Design New E n g n ee Regional i ri Orientation ng Division WashingtonOffice Program of Engineering Division of News Engineering ýNews UtS FOREST SERVICE U.S. DEPARTMENT OF AGRICULTURE ENGINEERING newsletter is a monthly publication ideas of a technical or administrative This and text in this must not be or policy This publication as should This read each and one ask back issues is to distributed If Headquarters. Office Manager or are be from Area your of copies number among Forest personal opinions of approved procedures Service the The personnel. respective and author mandatory instructions for engineers. However because and engineering technicians exclusively publication the in engineering information exchange to published nature references. intended not NOTES of engineers all issue. publication Station recommended or FSM by is publication type of material the represents construed except the FIELD sent to the your the from to directly all and receiving copy Information Coordinator to you Regional office. Use Form also available Office Washington are not now for 7100-60 Regional like would the increase Copies of purpose. can be ordered on Form this Office and Washington the a 7100-60. Material submitted respective accurate of length to the Office Regional has Region and should Coordinators to Fran illustrations for is sentences R-I Bob R-2 Allen R-3 Dan several R-6 Hinshaw R-8 Groven R-IO Ron Pokrandt Bill Vischer R-5 Jim WO Al questions Division of concerning Engineering both Kjell Bakke Ernest Quinn R-9 McCoy submit are Roper Fleet Stanton direct the by typewritten should personnel Coordinators R-4 Owsley Editor reviewed timely technically FSM 7113. The Washington Office preferred. Office should be submitted to the Washington black or glossy should be original drawings The publication. to be The Coordinator to whom field Information an material engineers from several vary items are or news All material only. and all double-spaced typed and white photos. questions articles to should current Service-wide information the that interest informative and of submitted may However pages. will edit for grammar Each to see material short Office for publication Washington format Colley editing Service Forest publishing USDA dates etc. Washington D. C. Depart-ment Agricul-ture 20250. newsletter is published monthly of Agriculture--Forest Service This assumes other than no its use the reader. of Such use or does endorsement of may which retirees interpretation names corporation not constitute an recommendation others distribution its to employees of the U. Department of The only. or use of this S. information by employees. trade firm The for the responsibility own for and be or suitable. approval of is for the official any information evaluation product or service and convenience conclusion to the exclusion of FIELD NOTES DIP DESIGN Civil - Designs Engineer By H. D. Completion of November 1971 the in article this article answer will was sparked by the question Field Notes. It the questions 4 Region Investigations Comments Authors Ryser Hafterson Standards and Technical posed and is raised by Royal M. hoped that publication will catalyze of this of design note-book needed for rational dip information Field measurements limited be conveniently can forms of the type size number of copies shown from acquisition design. and recorded Figure in 7. on field processed Interested readers may obtain a the author. INTRODUCTION Draining water from the surface of unpaved accumulates sufficient designers of mountain arrogant that This paper A theoretical and to provide more rational roads. discouraging. section Often when a dip design technique traffic a dip is destroys watershed is the riding surface a familiar problem doing a good hydraulic job treatment a basis is presented for making design technique It is hoped and share of opinion is which simultaneously satisfies or to becomes it driving over so it. these conflicting requirements. the design on arbitrarily measurements the adjacent it bounces the vehicle hard enough to rap the head of anyone it presents hydraulic and to damage energy roads before is selected a thorough understanding to develop the field measurements and has yielded that this article will encourage their which are badly needed to be used. So far the technique constants to the somewhat I results readers to findings through the forum needed due of the problem has been used if by this basing which are not too make of FIELD subjective nature the needed NOTES. A wide cross of the measurements. out-sloping The problem on unpaved do because roads is to remove water from the road surface. on muddy roads creates traffic the road surface has been used on the rutting tendency of the road when wet has resulted in disfavor such structures as Dips in the road profile dont characteristics Dips very long. the wet road necessarily mud when ruts reduced by the These provide by being too abrupt driveability of success degrees on Outsloping road users soils who have depending primarily which become slippery slipped off the road. Various open top culverts do an excellent job when conditions and high maintenance siltation with varying among first are are right but but unfortunately good hydraulic common. an obvious coincide solution good with and are often too shallow constructed mud formed by ridges ridges in the bottom of the sacrifice water for divert as traffic Effectiveness dip. out of the rut squeezing of the dip act to effectively from the road easily but water divert Most dip designs driveability. formed which cut through the top are mud costs to difficult is which the water follows. Insloping or ruts surface. This as wheels is pass uses further through. free-board the ruts. A 3-inch-deep 6-inch-deep Gravel dip. requires expensive as The rut with 3-inch-high ridges surfacing through is periods. Recalling new that in the bottom enough to cause the head criteria bumping that are needed if water from leaving failure of a the answer to rutting failure by caused typical but often reduction of of the dip. so that the rutting action sediment storage space to sufficient is dikes to prevent may be to build the dip with enough freeboard through and so that there obvious the dip is maintenance and does not prevent sediment accumulates solution as lateral occurs even last between on some of the shallow cant cut maintenance dips makes it dips are to be further deepened. DESIGN RELATIONSHIPS Head bumping results from by the large Speed plays an important part dip. and some accelerations cautiously unacceptably through the by a design speed so it in determining designers apparently dips. expect Other geometric the elements seems that consistency imposed on the vehicle accelerations vertical the magnitude driver to slow of the vertical down and proceed of the road are coordinated in part would be fostered if dips also conformed to these criteria. The basis for design from the relationship of speed standpoint to vertical of traffic driveability This relationship acceleration. is developed from the can be approximated from the dynamics of centrifugal acceleration z R a 2 1 where centrifugal v tangential velocity R If acceleration a up to tipped is along the upper an. lower accelerations therefore with approximated relationship sufficient developed In K Solving expresses the curvature L length A algebraic difference of vertical 1 equations and of for K spite vertical arcs and the radius can be curves are circular Ref 4. curve in 2 parabolic arc in units of feet a per % 3 A in ft grades in % 2 R Solving circular 100K K where -e. is R where rather than become of this the radius of curvature by assuming that the accuracy accelerations centrifugal segments of thv curves are parabolas the curve. throughout changes plane then the a vertical In highway design the vertical The f.p.s.2 f.p.s. radius in ft the circle vertical in in and expressing speed V ý2 l a in 00K miles/hr yields 4 depen-dent K Equation 4 shows upon speed acceleration Design is V not that K also V-2 46.5a measures the and the acceptable precisely defined will be discussed a. The later in curve being acceptable vertical the section entitled Criteria. As mentioned earlier hydraulic effectiveness control acceleration vertical and of a vertical driveability of rutting. This depth or freeboard demands depth for sediment storage and for is important dimensions. 3 defined in the Figure 1 along with other Q G GA - GD - Freeboard - Distance L - Length of if - from center of dip vertical approach grades are not Length of approach this paper distances relationships imperative that the with which he is convenient is will and lengths sag will be different equal - Dip 1. Dimensions. be expressed in and grades feet using absolute values Ig the calculations to the crest designer relate bottom to hydraulic grade developed are PRC curves crest Figure The and sag Adverse dip grade Lo percents. dip the crest not necessary F Throughout within changes grades symmetry between Approach but T often Original road grade I will be expressed of the grades so or the sag curve it as is situation dealing. multi-plied The F freeboard the top can be found by noting of the crest. Then the point Then the difference PRC of reverse curvature by the distance for equal Ks on Lo between the that the grade crest is in KA and grade 0 at the bottom of the sag and the low point grade between at of the sag and PRC and F Ref 4. and sag curves F From L at elevation between equal to the average them 0 the freeboard is GD Lo 100 the high and low points on the vertical Lo K GD 4 curves 5 then K FGD2 100 or 6 100F GD K relation-ships 6 from equation Notice characteristics driveability that the adverse - GD dip grade F and freeboard of both hydraulic a function is L curvature vertical and Other respectively. are LAK IGDI 7 K IGAI 8 TLIGDIIGI 2 IGAI IGI - DESIGN CRITERIA drive-ability The preceding have developed paragraphs the necessary design relationships basedon param-eters at various the dip vertical vertical in and on hydraulic speeds curves can now and freeboard acceleration effectiveness be obtained However requirements. and grinding out a family of design values constraints imposed by vehicle for erosion control. Also for diverting through knowledge it before allowable speed plugging maximum mentioned earlier an acceptable as values for Design these would be helpful to investigate the and by the underclearance water. of vehicle vertical dip spacing allowable acceleration is not Hand-book yet defined. Vehicle Underclearance 2 Ref jounce. the limits front and rear overhangs and for various at maximum sharpness vehicle dynamic conditions Both composite long vehicle have been compiled to illustrate cars. They are therefore with the possible exception center the worst considered equivalent K The minimum crest vertical K The in is Traffic likely by allowable Engineering and are full given which using Forest roads cars. given by Baerwald are converted K values are shown in 5 to entitled Table to be. about 0.9 since the. full jounce condition extremely improbable. of to appear on future vehicle passenger clearances the technique outlined in the section minimum for dip design appears curve the for the typical the dimensions 2 by Figure resulting in front dive rear jounce possible dimensions conservative as Field Measurements. as of camper trailers pulled limiting design values shown tabulated such and composite short vehicle dimensions In order to obtain radii are of curvature. Minimum 1. on a TABLE 1. - Maximum Vehicle Vertical Sharpness Dynamic K Condition Longest Front Sag as Limited by Underclearance. Vehicle Curve of Curvature Normal .2 Front .Div .4 .2 .3 .4 Rear Jounce Full Rear Joce Normal - Front Dive .4 Rear Jounck .8 .6 .1 .2 Full Jounce Shortest Front Normal Front Dive .1 .2 Rear Jounce Full Jounce Rear .3 .2 .8 .6 .4 .7 .7 Normal Front Dive Rear Jounce Full Jounce Crest Normal Longest Front Dive Rear Jounce Full Jounce 1.85 .1 .1 .1 .2 Normal Shortest Front Dive Rear Jounce Full Jounce oW QW ý.Q .4. FRONT WHEELBASE 2. Vehicle REAR . OVERHANG OVERHANG Figure .......4.. Underclearance 6 Limits Curve Sharpness. Erosion impor-tant Control be spaced a variety of Ref considerations closer intervals at soil 6. These parameters Their criteria as lead to the generalization that dips must be deep and must road grades and road grades types influencing criteria the Northern Region in have been developed for by Packer and Christensen from a study of 720 sites indicate that the most developed criteria Spacing increase. road surface erosion for cross drain spacing is soil are type to limit 83 percent Ref 5. and road grade. Packer of erosion to depths rills less than spac-ings 1 inch. In addition to the for the road position the slope. in Figure A plot 3. soil type and road grade they include on the slope the exposure direction of their spacing requirements Since the plot ignores their for various modifying factors modifying factors to account of the slopes soil all types and the steepness of and road grades is shown of which call for closer cate-gories the plot gives their account for the adverse Therefore the maximum allowable dip grade curves are plotted are defined in Table shown in spacing. Figure by adding L 4. to their The Their plotted data has been modified to data represents erosion the distance The distance. soil 2T. type 2. 200 150 NI ----/00 i-T --------- 50 4 Figure rT1TI4 8 APPROACH GRADE 3. - 4A lo-cated - Dip Spacing For V20 as Defined by m.p.h. Road Grade and F1.0 Soil Type. a5fp.s.2 and road on upper third of north facing 80 percent 7 slope. GA G Figure TABLE 2. - Erosion Group o U oo - Dip Spacing. Potential of Soil Groups Description Ref Hard sediments shale II Basalt III Granite sandstone gneiss schist soft quartzite Andesite V Loess 8 soft slate limestone rhyolite conglomerate shale IV 6. of Parent Material I a A 4. limestone glacial silt Superimposed on the plot are from driveability were not in and are derived built merely steepening of tangency dashed The their coincide T line spacing L. is showing road grades lines considerations. These lines show at common shown by GA. The grade 4 shows the dimensions 2T S L and limit spacing required when reached shown on is needed for the the dips if more closely by be spaced is limit indicate grades achieved that the dips can fact approach the sustained of reverse curvature. This a point Figure from the G which the points the graph the as derivation. 9 since _LGDG G 8 LKGDGA 7 T GA 2 - and then K S Substituting in values for 20 m.p.h. For instance a sustained and connected 10 - foot freeboard and vertical of 6 percent grade by a 10.5 percent research to verify an acceptable vertical rill 1.0 GD G GA G of acceleration 5 f.p.s.2 the values plotted. gives feet GD GA acceleration depth is subject erosion type in soil grade. This standard brings out to question. Ideally the tolerable impairment watershed damage and maintenance above criteria are. The door the 125 maximum allowable basic assumption of a 1-inch erosion traffic may be the best there The at of additional the importance and to determine safety of operation. consistent with requires dips to be spaced III criteria should Practically costs. be related to however the open.... is mini-mized out-sloping Design water of the Hydraulic Bottom of the dip requires additional study. In order to remove from the road the hydraulic road at 90 degrees then and hand if creation of a soft a dip crossing when at a longer skew grades are low. the comfort of passenger bottom or outsloping must slope to one insloping is spot and the ensuing will acquire From chuckhole some grade truck considerably dips used to date. The is is to be avoided. automatically but may to be On also the other require but tends to twist the frame of occupants trucks so that they favor square dips. This twisting the typically abrupt the dip crosses the standpoint skewing a dip greatly increases a driveability car and pickup side. If required if sedimentation dips designed effect by the longer and the twisting problem may not be as 9 has been troublesome on criteria severe. in this paper will be Acceleration Vertical is AASHO mentioned by briefly given as the upper limit for a comfortable through ride Policy Ref 1. a sag vertical A value curve. of f.p.s.2 1 However is for trade-off both sag and crest curves other value is therefore to the vertical seldom acceleration value of acceleration is be as such criteria attained. Since minimizing as the length the length designing allowable The example design The problem 6 percent on shown in Figure illustrated and is sacrificed National through the practical at 20 m.p.h. with a --- - 40 5. A effectiveness. for trial basis Forests. Results are a workable value. 5 f.p.s.2 Figure operation. was selected on a Manti-LaSal 5 will illustrate 39ýA this inversely related to gain hydraulic aspects of the foregoing requires the design of a dip with 1.5 ft road which can be driven is of the dip requires that the allowable of 5 f.p.s.2 the Uinta far but indicate that this so theory. acceleration vertical dips into timber roads very sketchy of the drainage dip high as possible consistent with safe vehicle required wherein comfort but not safety is A maximum govern and headlight sight distance - Example 10 Design. vertical freeboard for a acceleration of It is desired to build station is selected undisturbed angle dip with the hydraulic a right because it is bottom at station 473. and the water will therefore section a daylight This flow onto ground. K V2 10 F_ GD ýK K GD Lo PT The approach grade 473 PRS will be 1001.5 1.72 1.72 9.35 selected arbitrarily 4 9.35% 6 use 8 percent as 5 16.1 ft 489.1 16.1 /% 1.72 ft 460525 46.5a 489 thereby making the grade change A GD GA AK L If the erosion percent selected distance approach grade from Figure GA- G of is 2115 also 8.0 2 230 29.8 use 30 9.35 30 feet 17.35% 8.00 17.35 1.72 TL GDG 2 9.35 is 6.0 - satisfactory satisfactory. 8 115 ft 6.0 The approach 7 ft then grade the arbitrarily GA could also selected 3 if the soil type were known. PC489-30459 PI Elevations can be calculated as follows 474 but are normally scaled from the Station Elevations 15PI 473 PRC -6% 16 489 -9.35% 474 PC 459 3916.7 I I 8% 15 11 3915.74 i I 3914.34 3915.54 8 have been profile. Elevations of several points on the curve reference. In practice sufficient accuracy 1 K TABLE are calculated A _ L by from the scaling profile. 3 17.35 _ 0.578%/ft 30 - Example 3. Table 3 below for future in normally obtained is Curve Vertical Calculations. Chord Gradient Station Elevation 1-8.0% 459 PC 3915.54 1 1/2.578102.89%I -5.11%10 469 I .5781 479 5.78% .5781 489 PT -0.51 3915.03 3915.10 16.44%10 5.78% 2.89% 1/2.57810 0.07 10.67%10 0.64 3915.74 I 19.36% of the These are the calculations for the sag portion the crest portions much curve. vertical symmetrical usual though not mandatory about the PRC. miles per hour Fifteen simpler. The V2 K Similar calculations are dip. The is 152 46.5a 46.5 practice is 5 tabulated make to data given in Table minimum the - __ tabulated speed made the for two 4 makes the design since 4 0.97 Instruc-tions if the maximum acceptable 0.9 was shown for use earlier vertical When minimum to be the of the table are as is assumed to be allowable due to vehicle acceleration drainage PRC G and exit GA is 2 percent grades are different enter the table using the desired GD to connect the otherwise for each curve a distance at VPIs point. Locate the Note that the tabulated entrance A value of K underclearance. follows G. Establish the middle of the dip If f.p.s.2 dips on a uniform grade enter the table with the uniform grade designing desired 5 using GD from the greater than G. GA or if approach independently is grade laid and can be found by interpolation 12 Lo downgrade and L. Lay out the taper T. not GA 2 percent greater than and use the adverse out curves. Length L for each approach is grade different grade GA. TABLE Speed 4. - Dip 5 Values for a f. p. S. 2 Freeboard Grade G Design GA 15 0.5 1.0 LIT GD7.2 Lo 7 L GD Lo 1.5 T L 10.2 GD Lo 10 T 12.4 12 2 4 11 25 14 42 16 58 4 6 13 36 16 55 18 73 6 8 15 48 18 71 20 91 8 10 17 63 20 89 22 111 10 12 19 80 22 108 24 133 12 14 20 98 23 130 26 156 14 16 22 119 25 153 28 182 GD5.4 20 Lo 9 GD Lo GD9.3 7.6 13 Lo 2 4 16 30 20 48 4 6 20 46 23 6 8 23 66 8 10 26 10 12 12 14 25 16 23 65 68 26 88 27 92 30 114 89 30 118 33 144 30 115 34 149 37 178 33 145 37 182 40 214 GD4.3 GD6.1 Lo Lo 12 GD7.5 16 Lo 55 20 2 4 22 35 27 4 73 6 28 58 32 82 36 104 6 8 33 85 38 115 42 140 31 8 10 38 118 43 153 47 182 10 12 44 157 49 196 52 229 12 14 49 201 54 244 58 281 30 GD3.6 GD5.1 GD6.2 Lo Lo Lo 14 20 24 2 4 29 41 35 62 40 81 4 6 37 70 43 97 47 121 6 8 45 108 51 140 55 168 8 10 53 153 58 191 63 223 10 12 60 205 66 249 71 286 13 quan-tities. The are equally suited for hand or computer procedures Automatic computer earthwork balanced Dip Location is before locations When dipping a dip undisturbed is or alinement is be factors. of steep grades and at locations where top with horizontal should earthwork preferably The purpose of the dip is to divert do an unacceptable amount of damage. Therefore can it are at the minimum. Correlation as Therefore the profile in the since earthwork an important design function. the road surface such the dips are introduced be made by hand using unit mass should adjustments effective before of earthwork not be used however disturb the necessary relationships of the dip. will essentially computations adjustment programs should the fill from water the most height is needed to avoid hazardous situations the middle of a sharp curve. to be constructed material in since traffic an existing road the will crest soon displace the loose fill be should curve built from material. FIELD MEASUREMENTS As previously mentioned maximum safe of the this value and also Allowable various adapts the technique will be influenced range it is skew and driver as above. technique for estimating inspection. Future type of vehicle experience. important to develop for disseminating a limit loaded weight issues Because of the subjective nature of these FIELD obtained which suspension a wide a composite viewpoint representing experience at for safe operation. value requires a highly subjective judgment acceleration of the factors mentioned an excellent forum develops upon knowledge predicated be determined by driving through a dip can by a variety of factors such of the measurements is which seems to be the upper the speed road alinement dip stiffness section to construction accelerations and recording Determining this acceptable to dip design acceleration. This maximum vertical speeds rational approach this vertical by NOTES engineers should provide Service-wide. para-graphs. The equivalent Once radius K the vehicle is determined by speed profiling and dip curvature calculated. 14 K the dip as outlined are known in the following the acceleration is easily The derivation following once means of calculating the leads to a simple the elevations of three equally spaced points on y px2 the curve vertical acceleration and the vehicle speed have con-stant been determined. form In general of the equation parabola a expresses the sharpness of curvature of change of grade rate vertical is spaced at x K thus determined if the vertical sharpness of curvature distance h as is at shown the point Y in Figure Yi px2 6. V2 4a 46.5 curve sharpness K and velocity 6. - Ya Sharpness of Curvature. the general parabola qx YL r is evaluated Y -h YR Y ph2 Yo Yi Combining these equations 2p Ref 4. This are known. found by measuring the elevations of three points equally Figure origin Y is Y Taking the Meyer derivative K L I The The second Al determined from Equation 4 acceleration r. is a Acceleration qx of change of grade or rate 2p The is h ph2 at all - qh - 2Yi YR 15 r r qh gives YL three points 2ph2 r Finally solve for 2p and multiply by 100 to express 2p in units of percent 2p This can be used equation lh0 YL - YR 2Yi form by plugging in this in per foot. 11 K the elevations or rod readings of the three points. To and that 20 m.p.h. constructed it several assume that the dip previously designed the procedure illustrate times. the following The next step rod readings is is judged to be the to profile 3.16 2.65 the dip. maximum safe in Table 3 speed Three points spaced is by driving through 10 feet apart have 2.72. Then 10 1 K 100 3.16-22.652.72 0.58 1 la and I a The K V2 0.58 46.5 202 mathematical agreement implies a precision which conditions since the constructed 4a 5.0 46.5 will not be obtainable dips will not be perfect parabolas as in this under field contrived example. Several refinements rod readings are plotted with an exaggerated shown in Figure an accurate Averaging will field irregularities 7. profile two Equally and then spaced scale or three sets as give better accuracy suspension are shown in the following from actual measurements. example taken The needed to cope with and do not measurements equally spaced shown because significantly will vertical and smoothed are not necessary yield improved accuracy. the overall 16 - the by eye object is rod readings from the smoothed minor undulations affect scale are absorbed vehicle The smoothing by motion. to as obtain curve. process the wheels and It is important to note that the value determined by experienced the vehicle suspension to downward accelerations the necessity technique this is not the true by the occupants of the vehicle due to the damping acceleration are experienced of treating the skew and of the dip effects Implicit in the foregoing sequentially. in by provided that both upward to the fact and sag portions separately crest vertical and description the measurements is and Never-theless factor critical the experience Perhaps calculations. of change of acceleration the rate is of the technique Substantial modification paper will hopefully provide this measurement gained through rather than will indicate that the the acceleration presented here would undoubtedly a rational basis itself. result. for further investigations of dip design. DIPICALCULATION SHEET ROAD -DIP O O LOCATION 3 o-ACCEPT . DY. ý -44/1 ýýCr1P 77 I-..._ O _ 1 O I VEHICLE f QS j PATE BLE ROAD SPFD._-UP DOWN ._17b$ýi C ND/TIONI4__ALINMENT tt1 y RAM D_ ROAD GRADE____I ROAD X iM4x N 11L dp Fr- IC1y MdH BOTTOM 1 1. 2 SKEW a -fu ooy a 4PS FALLS LL-- L C OI --Q _LO.ý OJI 0. W I. O ý j hC V__ I I O QI Figure For Construction Equation 11 yýv ti t DESCRIPTION _QP n. ýý FUNCTION c RFMARKý. %ý O ýý O $ r 51ýeýD I HYvaA O U -/ SLOPE _ HYDRAULIC 7N _9109ý S WIDTH IIi ROAD SOIL F 9 Inspection 7. it -Field Measurement is merely necessary to against the value used in the design. 17 and Calculation. profile the dip and checkK from oIý REFERENCES 1 AASHO. A of State Highway 2. Baerwald John E. Editor. Haupt Harold U.S.D.A. 4. Meyer D.C. Officials Washington Engineers Washington 3. of Rural Highways. American Association Policy for Geometric Design A Method F. Intermountain Carl F. Route Engineering Traffic D.C. 1965. Handbook. of Traffic Institute 1965. for Controlling and Range Forest Experiment International 3rd Ed. Surveying. Sediment from Logging Roads. Ogden Utah Station 1959. Co. Scranton Pa. Textbook 1962. 5. Packer Paul E. Criteria for Designing Sediment. 6. Packer Lester Drainage 8. Logging Roads. Ogden Utah Station Pence Science Vol. 13 and Locating No. 1 Paul E. and George F. Christensen. Secondary 7. Forest Salvadori M. Dip. Jr. Field U.S.D.A. Inc. 1967. Guides for Controlling Intermountain Sediment from and Range Forest Experiment 1964. A Method Notes Vol. Mario G. and Melvin Prentice-Hall Logging Roads to Control March Englewood L. for Determining the Construction 3 No. Baron. 3. Forest Service Numerical Methods Cliffs N.J. 18 U.S.D.A. 1961. in Grade in 1971. Engineering. a Road NEW ENGINEERING ORIENTATION PROGRAM By The new in Forest Richard Service Orientation The new January 1973. comprehension. These orientation slide-tape Office Program for Engineers was sent to the Regional program programs are will in living indicate the students color short from and interesting to both new and regular Forest informative the earlier engineering program replaces orientation level 11-15 by a of minutes. Service employees. system developed Offices accompanied presentation a slide-tape is mini-exam.The Mini-Exam booklet self-evaluation G. Deleissegues Engineer Washington Civil This 1969. in super-visors. The 1969 programmedlearning system had many strong points such as It was accepted by management and well-received by both trainees It was It provided effective in reducing and attrition effective as an operating and and live program. and denoted It trainees with large engineering specific developed a professional and showed the trainee Forest as interest of orientation are utilized and background by the Forest and knowledge material Service. of available a representative of the engineering context some deficiencies SS were The It later as Some of noted. failure career alternatives profession on the use of too and for the trainees. much programmedinstruction up-to-date audiovisual above material which could not be used with their techniques. the program has been reanalyzed the shortcomings the need to revise and to include material due to its volume. tool. to the deficiencies noted of communicating were at home the first-line supervisor. The lacked 1969 programmed-learning subsystem these deficiencies material was not well-designed changed to strengthen employee the to complete SS-l and SS-2 did not involve a reference pinpointed in The It Due his role amounts which Service teams. In the same series skills supervisors. and to give new Past feedback engineering from the first part of the system an interface and communication his supervisor. 19 between field the at the two and the format employees the evaluations home people feeling of the program or office involved portion - the new The revised version of old SS-1 -2 and SS-5. These are available through -3 now is Regional I SS-1 through Revised 1 ý Phase called and of SS-1 through consists Offices for your immediate use. eliminating the programmedlearning which was by not applicable in this situation and 1 by SS-5 are characterized brief easy and informal style which a using is enhanced en-The by the use of a colorful character Old Old Timer All Forest in - personnel well worth they reviewing. employee we to take the time to see you organization program. You may are sure to learn something they it. concept current want to present didnt know this about of the following consists TT 10 7000 Supervisors TT 11 7000 Part TT 12 7000 Part II TT 13 7000 Part III - TT 14 7000 Part IV - TT 15 7000 Part V Impact TT 16 7000 Self-Evaluation TT 17 7000 Orientation Booklet list I Guide The - The - Greatest Great Men Tradition our Mountains the Action Is - and a glossary of often-used Orientation Booklet. Good to Match Where Sufficient Mini-Exam new includes an introduction abbreviations Self-Evaluation quantities Offices for distribution to - words TT 16 trainee will need only booklets Regional you the orientation is are a seasoned Service. The new system The orientation Service employees will benefit from the history program to all Forest the Forest if courage programs and challenges described O.T. Timer. The new Even called employees. 20 reading Mini-Exam and TT 17 of these two training booklets The suggested and acronyms. remaining booklets were sent to are kept with the slide-tape programs. the program Additional is The binder copies of all training booklets through Central Supply Washington Previous WO A orientation Central Supply limited supply until subsystems - the new TT is returned to the Regional mission Appropriation 10 through TT 17 are no longer All other subsystems are the five slide-tape the Old Timer the Forest still in the new tell you all through the system texts Office. is them. available SS-l contains the Service and a Program and for use. available Engineering hearing your comments both good and any ideas you have for improving its a subject programs in available programs have replaced training texts for the slide-tape and organization of engineering you have seen we would appreciate After numbers Office. of the old programmedlearning orientation Section. Offices. for this program are available in limited July 1974 from the Division of Engineering Washington history Let it when stay with the program set slides and tapes should and when sent to Forests bad on Orientation the package System including it. about the Forest Service about which we should be well informed. 21 - its interesting informative and REGIONAL OF ENGINEERING NEWS DIVISION 5 Region Wins Award Slide-Tape I The Forest I Planning Services Transportation Project located Berkeley in Engi-neering R-5 and assigned to the Division of .ýýý has received ý F National Ann produced ETr show Film Educational Award Corneille slide Festival for a recently presentation. The is entitled 1973 the The What-if and was developed Analysis for manage-711 Oakexplaining transportation to Forest tools ment and The positions. won presentation Slide-Tape tF staff Trophy in the land in April. 200 film and It Best of the Film Festival which was held Y r analysis Officers in in was one of over slide entries entered internationally. develop-the The Leader of the Transportation plan-slide V. M. Dekalb Planning Project Project Ann Corneille Past President of Project Oakland Board of Education and sponsor of the film strip award and James Halverson of the Lawrence Berkeley Laboratory who produced tape show receive the award. meat the is Berkeley Stanford the Project in the The R-5 What-if developed University in ning and managing cooperation Analysis show is Forest available for use in road systems on Forests. These techniques from network with the University and San Jose State University. field and widespread computerized techniques analysis ranging are being completing the of various National data collection System Planning Transporation analysis to of California Implementation has begun on Service use should occur within a few years. upon request from the Division of Engineering RO. Editors Note 4 6 8 9 and We will month preceding happy be 10 Please to publish news items from submit your news item to reach the next months publication. 22 the all Regions. Whats Washington Office the news in Regions on the first 1 2 3 day of the WASHINGTON OFFICE DIVISION OF ENGINEERING NEWS AND STANDARDS CONSULTATION C. R. Weller shore-line fish-ing North-ern gen-erated Assistant Director Chippewa Chippewa Flowage. Flowage and land. Ninety-two percent National in significance due to the world. States Power tribe owns of near-pristine expanse wild atmosphere and reputation acres within Company owns approximately 25000 acres of the dam with This the first project is Because of the resource values of the project lands as the best muskellunge the project LacCourte the focal point recommended the U. by is for recapture Government the Federal is now by the Forest is before the in Service. 1968 recommended and that the lands be integrated Chequamegon National Forest. In March 1972 recommended recapture and return of Indian lands to the remainder to be a part of the National Indian of a major natural resource into the contiguous Interior also boundary Oreilles Forest. All power Department of Agriculture S. area has undeveloped. from the dam. The project releases Power Commission for relicensing and water The is approximately 1800 acres and 110 acres are National controversy. recapture a 17000-acre There are approximately 27000 downstream Federal its is of the 205 miles of shoreline U. S. Department of the the LacCourte tribe - oppo-nents Conservation environmental groups have alleged that present management values. Petitions to intervene to the relicensing. public involvement Hearings Forest. Several State agencies appears D.C. have filed also threatens the ecological and by both supporters and been involved. On-the-ground to favor recapture. on the relicensing have already started in Washington have been September been held 13. 23 in Sawyer County Wisconsin they TECHNOLOGICAL IMPROVEMENTS Heyward Taylor T. Assistant Director Name Products Evaluation of Trade evaluation of highway trade name Engineers by memorandum dated categories were evaluated. Used Highway in Construction products 24 1973. An or Maintenance. has been distributed to 1000 all Materials Regional different products in 23 depart-ments. Subcommittee The along with in was made available AASHO the or rejection which the products 1. 2. to the a brief Materials. 7. 8. Bituminous materials 12. Testing various concrete 13. materials trade Structural categories systems components 14. Structural concrete admixtures 15. Bituminous membranes paints rejuvenators and preservatives and materials 16. Concrete finishing Reflective crack control 17. Soil stabilizers products 18. Traffic marking materials Concrete patching 19. Mulch materials 20. Miscellaneous 21. Rust passivators 22. Joint fillers seals and and roadside Culverts and drainage name in materials and cement Deicing by name with respect and construction Portland and erosion controls. materials 23. Adhesives chemicals Materials Engineers be consulted The listed equipment cement structures Regional status of the evaluation. explanation structures 10. is and use Skid control Barriers 9. product 11. Waterproofing 6. Each membership and its Aggregates curing 5. State highway various a description AASHO are were evaluated Portland 4. by Service through Forest and additives 3. was compiled by the supplied name and address and Nearly of products Subcommittee on the manufacturers to acceptance 80-page list on Materials from information list participation The August products are in the best position with respect for further information to their in this area. 24 use to decide in on a forest the usefulness environment. of the They should OPERATIONS func-tions Harold Strickland L. Assistant Director The Washington Management. Engineering of Engineering and the Deputy the Director The Sections on matters principal functions dealing with Forest The Programs. section Aiken are handling working Management Systems. with Congress and Pollution Trails Messrs. Frank Mrs. Aileene titles Forest mail and liaison Congressional Roads and Development Frost Management Engineers and Mrs. Chiefs Office for National Section and Management for Engineering Operations staffed with four people is Management Office Engineering to the Assistant Director support as staff Abatement Hammond and Dale O. McVay Management Assistant appropri-ation Phyllis coordinate NFS all material concerning and other Service. and/or The sources for this information are adjustments projections of needs for information made cycle takes you until Federal two how provided things change to you survey Act for and legislation for in the at FY in Act and 1974 now review. The impacts possible in the FY are which available final Chiefs Program and Work pressures reports which direct the for $140 million each provide 2 Number 6 June levels. before and Congress of funds for preparing sales its supporting specifying purchase design. of these actions 1974 time new time are will set drinking water standards monitoring and regulation of our water systems and Copies of these actions that supporting its program affects this go out from Washington see Field Notes Vol. 1974-1976 reports which prohibit the use Pending you of the Forest services the field submit. Projections years from the time requests authorization Appropriations location and in in on data from your reports and from multilevel historical Aid Highway Act of 1973 and year for roads and trails The and/or materials for hearings activities the reports are interest specific use of authorizations 1970 on backup engineering receive an allocation As examples and of The on based prepare sent in by you. The complete budget develop. affecting legislation personnel budget requests for the above programs participate the and prepare and coordinate budget analyses bills Engineering secretary. and can be secured will allotments Planning their by your Operations be analyzed and reflected FY and provide for state use. to you 1975 tentative allotments section as fully and FY for your as 1976 Advice. 25 GPO 870-667

![[#FWDIP-74] PVSS invalid Bits (including range) are not all reflected](http://s3.studylib.net/store/data/007282728_1-8b675e5d894a5a262868061bfab38865-300x300.png)