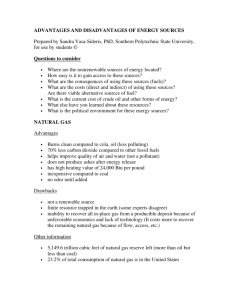

DISCUSSION PAPER Regulating Greenhouse Gases

advertisement