RSSB INS & RST Delivery Unit TITLE: BALLAST PROJECTION

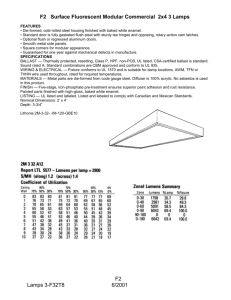

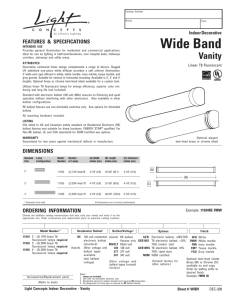

advertisement

RSSB INS & RST Delivery Unit TITLE: BALLAST PROJECTION 1. Reason for this note This topic concerns a relatively recently encountered phenomenon, in which track ballast becomes airborne underneath a high speed train running in normal weather conditions, strikes the under surface of the train leading to damage, sometimes of a catastrophic nature. It is different in nature from well-documented incidents in winter, when large masses of snow or ice, accumulated around bogies, in under-train cavities and couplings etc, fall onto the track ejecting ballast stones and which then hit the train. It is also distinct from British Rail’s problems with HSTs 25 years ago, which were investigated in great detail at BR Research. Amongst the issues causing the problem was ballast being catapulted up from the sleeper ends and ricocheting off the sides of two passing trains. Pieces of broken windows then caused a cascading effect down the length of the trains. Airflow effects were however felt to be a secondary contribution to this. 2. Background The phenomenon of ballast projection had always been linked to railway operation in winter conditions. The mechanism can be simply stated as: Snow and ice is accumulated on the train; Eventually, due to vibration or to melting, an ice accumulation falls down; It hits the ballast; Ballast stones are projected outwards and also towards the train; Stones hitting the train might: (i) cause damage to the train underbody and (ii) gather increased momentum from impact with the train; These stones may then hit the ballast again setting up a chain reaction. Railway operators have encountered this phenomenon for decades. Due to this, SNCF impose speed reductions on high speed trains if there is snowfall or the track is covered by snow. In Germany, DB lowered the ballast level in between the rails “some centimetres” below the sleepers. This measure ensures that falling ice will generally hit the sleepers instead of ballast, and the sleepers will contain any displaced ballast better. In general, these measures work satisfactorily and ballast projection due to winter conditions is no longer considered a significant problem for high speed railway operation. g:\ins & rst\stakeholders\mirror groups\aerodynamics\admin\aero gb wg ballast projection paper.doc 1 of 5 Issue 2 : 27 July 2012 RSSB INS & RST Delivery Unit In contrast to this, it was totally unanticipated when ballast projection events occurred in 2003, leading to train damage under non-winter conditions without ice and snow. During ICE 3 homologation tests in Belgium and France, a total of three ballast projection incidents were recorded at train speeds of up to 300 km/h. There had been no similar incidents before with ICE 3 in Germany, or with TGV in Belgium and France, even at much higher train speeds. It was surmised that the phenomenon was a system interaction problem. The mechanism was thought to consist of the following sequence of events: Ballast stones start to move due to a combination of aerodynamic and track dynamic effects; The stones are accelerated by the induced airflow under the train; Rolling stones hit obstacles and are projected upwards; Stones hit the train and gain a large increase of momentum from impact with the train; Stones hit the ballast and project more stones upwards and, thus, instigate a chain reaction. Shortly after the ICE 3 problems, another incident occurred during 300 km/h test runs of the ETR 500 on a new section of the new high speed line between Rome and Naples. Since there had been no problems with ETR 500 reported up to that point on other Italian high speed lines, there was a suggestion that the design of the new line contributed to the phenomenon. The reported incidents caused damage to the trains involved, costing several hundreds of thousands of Euros each. The ICE 3 train underbody had to be modified to enable operations in Belgium at significant cost. 3. Research into ballast projection There has been a significant amount of research into ballast projection since the reported incidents, firstly in the DeuFraKo Aerodynamics in Open Air Project and more recently in the EU funded AeroTRAIN Project, in both of which RSSB has been involved, (although not directly in the studies of ballast projection). This research has concentrated on trying to understand the aerodynamic and mechanical forces acting on ballast stones during the passage of a high speed train; the way in which moving ballast stones interact and become airborne and the probability of ballast impacting on trains. Methods applied included: 1/7th model scale test measurements of the airflow in the region between a generic bogie-intercar gap and the track; wind tunnel tests of full scale sleeper-ballast configurations; tests involving catapulting ballast stones into a box of ballast with the resulting motion of the stones being captured by high speed camera; g:\ins & rst\stakeholders\mirror groups\aerodynamics\admin\aero gb wg ballast projection paper.doc 2 of 5 Issue 2 : 27 July 2012 RSSB INS & RST Delivery Unit complementary computational fluid dynamic simulations; full scale measurements of the airflows and pressures generated on the ballast by passing high speed trains; development of theoretical models of ballast movements; development of a ballast projection risk model. The research has confirmed that the problem is a complex, stochastic phenomenon. Within the AeroTRAIN Project, draft proposals have been made, based on the research undertaken, for a measurement technique for the assessment of vehicles in relation to the risk of ballast projection. This methodology is likely to be incorporated in CEN railway aerodynamics standard EN14067. 4. Summary of research findings The research has determined that the basic sequence of events leading to ballast projection is as was originally envisaged. The critical influence of the design of the train underbody, as it affects the pressure field generated by the train on the ballast and the airflow induced by the train on the ballast surface, has been determined. In addition, the influence of ballast height relative to sleeper tops is also better understood. Despite the ballast projection phenomenon being a complex combination of high speed train design, track design and probability, there are some rather simple outcomes of the research that can be stated. 1. Ballast projection is associated with train speeds over 250 km/h. 2. The underbody design of the train is a significant parameter. Two aerodynamic effects that are important are the pressures generated by the train on the ballast and the induced airspeed under the train. The existence of cavities, such as occur near the bogies (particularly for trains with distributed traction1), generalised underbody roughness with low clearances between the train and the track ballast all exacerbate the problem. Smoothing the train underbody profile permits lower clearances to the ballast level and reduces the likelihood of ballast projection, as well as beneficially reducing aerodynamic drag 3. High ballast levels, with ballast above sleeper levels, also contribute to the problem as these, too, reduce clearances between the ballast and the moving train, increasing air speeds under trains and make ballast stones more vulnerable to aerodynamic effects. NB Le Pen and Powrie [1] have undertaken research into the lateral sliding resistance of railway track and have investigated the relative contributions of base, crib and shoulder ballast. Their work suggests that friction between the sleeper/crib ballast interface is the mechanism that contributes between 37% 1 It is not known why this is so or what is the mechanism involved, only that such trains have featured in the reported incidents. g:\ins & rst\stakeholders\mirror groups\aerodynamics\admin\aero gb wg ballast projection paper.doc 3 of 5 Issue 2 : 27 July 2012 RSSB INS & RST Delivery Unit and 50% of the total lateral sliding resistance, in combination with contributions from the crib and shoulder sleeper ballast interfaces. The inference is that increasing the ballast in the crib, above the sleeper tops, would not increase the lateral sliding resistance to any great extent. In addition, increasing the ballast shoulder height is much less effective at increasing lateral sliding resistance than increasing the shoulder width. This suggests that there are no good reasons for increasing the ballast height either alongside the track or between the rails. g:\ins & rst\stakeholders\mirror groups\aerodynamics\admin\aero gb wg ballast projection paper.doc 4 of 5 Issue 2 : 27 July 2012 RSSB INS & RST Delivery Unit 5. 1. References Le Pen, L.M. & Powrie, W. Contribution of base, crib and shoulder ballast to the lateral sliding resistance of railway track: a geotechnical perspective. Proc. IMechE,, pp 113-128, Part F Journal of Rail and Rapid Transit (2011) Terry Johnson Aerodynamics Engineer g:\ins & rst\stakeholders\mirror groups\aerodynamics\admin\aero gb wg ballast projection paper.doc 5 of 5 Issue 2 : 27 July 2012