Document 11427983

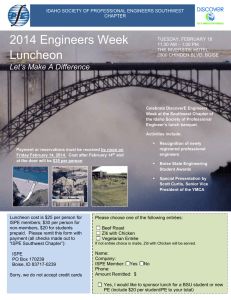

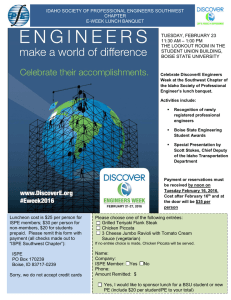

advertisement