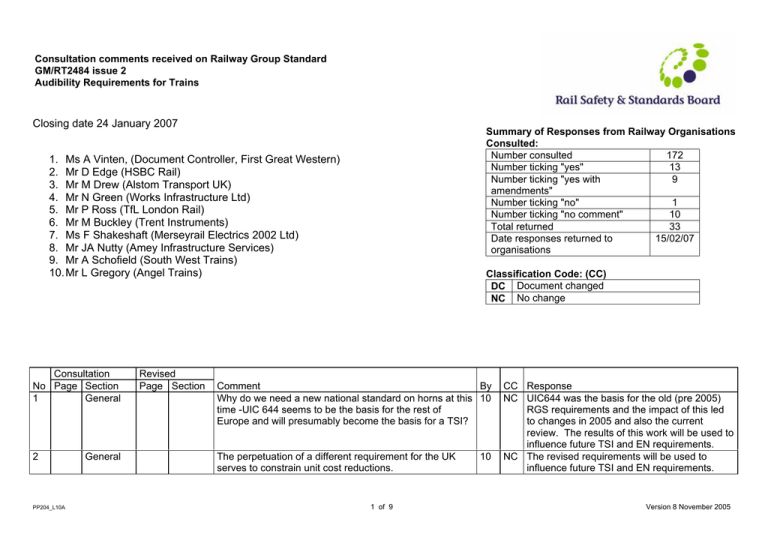

Consultation comments received on Railway Group Standard GM/RT2484 issue 2

advertisement

Consultation comments received on Railway Group Standard GM/RT2484 issue 2 Audibility Requirements for Trains Closing date 24 January 2007 Summary of Responses from Railway Organisations Consulted: Number consulted 172 Number ticking "yes" 13 Number ticking "yes with 9 amendments" Number ticking "no" 1 Number ticking "no comment" 10 Total returned 33 Date responses returned to 15/02/07 organisations 1. Ms A Vinten, (Document Controller, First Great Western) 2. Mr D Edge (HSBC Rail) 3. Mr M Drew (Alstom Transport UK) 4. Mr N Green (Works Infrastructure Ltd) 5. Mr P Ross (TfL London Rail) 6. Mr M Buckley (Trent Instruments) 7. Ms F Shakeshaft (Merseyrail Electrics 2002 Ltd) 8. Mr JA Nutty (Amey Infrastructure Services) 9. Mr A Schofield (South West Trains) 10. Mr L Gregory (Angel Trains) Consultation No Page Section 1 General 2 PP204_L10A General Revised Page Section Classification Code: (CC) DC Document changed NC No change Comment By Why do we need a new national standard on horns at this 10 time -UIC 644 seems to be the basis for the rest of Europe and will presumably become the basis for a TSI? The perpetuation of a different requirement for the UK serves to constrain unit cost reductions. 1 of 9 10 CC Response NC UIC644 was the basis for the old (pre 2005) RGS requirements and the impact of this led to changes in 2005 and also the current review. The results of this work will be used to influence future TSI and EN requirements. NC The revised requirements will be used to influence future TSI and EN requirements. Version 8 November 2005 Consultation No Page Section 3 General Revised Page Section 4 General 8 5 General 6 General 3.2.1.2 Comment By Does the issue of this revision affect the interface with the 10 published TSI on noise? The RGS will be mandatory for any "all work that affects 10 warning horns on vehicles, whether new or modified" this is very poorly drafted, and could be interpreted as routine maintenance to restore designed performance. It should be made clear the level of modification that would trigger compliance. 10 What is the cost benefit forcing compliance across the whole of Great Britain? We understand the changes are intended to reduce nuisance from noise in response to particular sensitive areas on the network. This should therefore be a route specific decision and not impose cost across the board where it may have no benefit. Is the purpose of this revision (to control nuisance noise) within the remit of the RSSB and if so on what basis? G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 2 of 10 10 CC Response NC Train warning horns are outside the scope of the Noise TSI, they are addressed in the respective sub-system TSIs DC Text amended to clarify that it applies only to new vehicles and when warning horn equipment is modified. NC There is no compulsion about the proposals, and the opportunity to consider changes on a route specific basis (as you propose) is therefore protected. The revised requirements are not anticipated to have a material impact on the cost of procuring train warning horns and therefore will not impact on the overall costs for new trains. NC Yes. RSSB’s remit, and that for Railway Group Standards, relates to compliance with the Health and Safety at Work Act 1974. This requires that businesses take account of the impact of their operations on the health and safety of the public. We have established through survey that the impact on the public includes a significant number of cases where the health of neighbours is affected. Horns had previously been considered to be an environmental issue, but when we have evidence of a causal link between operations and the health of the neighbours, it brings it directly into scope. Consultation No Page Section 7 General Revised Page Section Comment By 10 If TOCs apply for a non-compliance prior to 2nd June 2007, what will be the method by which the RSSB plan to control i.e. TNC or derogation and will there be time limitations and what will be required to obtain? CC Response NC A non compliance, pending standards change, has been put in place to permit the early use of this revised standard if Operators wish to use it. NC The requirements apply to new warning horns and would be part of any compliance assessment. There is no requirement within the standard to test existing horns, though operators may choose to do so as part of their routine maintenance or in response to any public complaints. NC No it is not. All duty holders have a responsibility to comply with their SMS, but unless a change of horn is triggered, there are no obligations to bring existing horns down to the new levels, though operators may choose to do so as part of their response to any public complaints. NC This information confirms the view that train horn noise levels reduce over a number of years and that the sound levels typically measured from trains with a long service history was less than when newly introduced. This therefore confirms the step change that has been identified with new ‘compliant’ trains. The revised specification is set at a level that has been demonstrated to be acceptable to all. 8 General How recent will horn testing measurements need to be to 10 validate the RGS? An external party could make a fortune testing horn levels… 9 General The implications it will have on the TOCs is that if a unit is 10 reported with an excessively loud horn then the TOC will need to demonstrate that the horn is RGS compliant before entering back into service. Please confirm if this is the correct understanding? 10 General What I thought may be useful , initially, would be to dispel 6 the theory that the new Airchime horns are louder than the original SSD type ( as used on all new builds from the 1960`s through to the mid 1990`s) The original SSD data sheets detailed DB levels of 110 & 112 db @ 30 metres. This equates to 141db @ 1 metre / 127db @ 5 metres. This is identical to a standard Airchime KS horn. This is hardly surprising as the SSD horns were made under license from Airchime & share identical internals (which generate the sound) . All of the readings assume 7 bar air pressure. The data sheet for CS horn shows 132db @ 1 metre. G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 3 of 10 Consultation No Page Section 11 General 12 General Revised Page Section Comment By 6 The output of the horns is a direct result of a correlation of air pressure & flow. We can effect the air flow by orifice restriction, but there may need to be regulation of the input pressure as well. I am including a typical testing record ( which we get with every horn) - this shows a speaking db level of 131@ 1 metre @ 1 bar - this illustrates the db reduction that can be achieved by reducing pressure - the balance is by restriction. To assist in relating our 1 metre readings to db levels @ distance - a Nomograph (supplied separately) has been used. This is extremely easy to use, and can be used either for 1 metre out, or from distance back to 1 metre. eg; to calculate the 30 metre reading from the SSD horn take a line from the right scale starting at 110db - pass through the 30metre division line on the centre scale until you reach the left scale. Then, from this point pass back through the centre scale @ the 5 metre division line & read the db level on the right scale. Another item that may be of interest is a polar plot of the KS horns (supplied separately) shows that there is an approx loss of 6db sound level @ 90 & 270 degrees (to the side) than directly in front of the horn. G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 4 of 10 6 CC Response NC This is helpful to indicate that the revised specification is technically achievable by currently available suppliers of warning horns. NC These plots indicate the change in sound pressure levels to the side of the sound source compared to the forward facing values. This information, coupled with the revised mandatory requirements indicated that the revised values will provide acceptable warning horn volumes. Consultation No Page Section 13 General Revised Page Section Comment By On recent trials utilizing modified CS horns, we achieved 6 db ranges form 95 @ stationary, & from 101 @ 10MPH to 111 @ 100MPH - this was with variable outputs relative to the speed of the vehicle. I feel it necessary to stress that this success was achieved because of the correlation between the reduced flow & controlled / regulated input. The Airchime EPRE controller, which gave us the variable control, was extremely effective in controlling the air pressure particularly at the lower pressure band ( which is what is required to achieve your stated numbers) Hence, I am extremely comfortable stating that we can achieve a db band of 101 - 106, with our CS horn & regulated input. G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 5 of 10 CC Response NC This is helpful to indicate that the revised specification is technically achievable by currently available suppliers of warning horns. Consultation No Page Section 14 General Revised Page Section Comment By 6 From experience, we have noted that with the reduced orifice, the horns can be prone to freezing. This is usually as a result of internal condensation, with droplets freezing at the inlet due to Wind Chill factors. This also explains why some operators register freezing horns in traffic, that, when the vehicles are returned to sheds, the horns work perfectly. We have heard of intermittent failures in the past, and this is probably the reason For this reason, we strongly recommend that all modified horns are upgraded to our heated version. The heaters are controlled by a thermostat, which ensures the heaters commence working as soon as the temperature drops to a pre-set figure (e.g.: 4 deg.C) The heaters ensure the horns are kept warm & dry. It is highly unlikely we would warrant against freezing instances/failures if the operator decides against heated versions. CC Response NC This information is helpful and will be passed forward to those procuring train warning horns to the proposed new standard. The sound output from the CS horns is particularly pleasing, and I am sure will negate any future complaints from the public. 15 2 3.2 16 6 2.1.4.3 3.2 Impact Assessment for Changes to Railway Group Standards – “The requirements will only apply to new warning horns, or when warning horns are modified”. So therefore, current or ‘old’ design horns could be fitted to new trains? Please clarify. 10 DC The text relating to compliance has been amended to clarify when requirements are implemented. Should the final word be “rolling stock” or “vehicle” rather then “train”? 2 NC The term train has been used to be consistent with the opening text of this section. G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 6 of 10 Consultation No Page Section 17 6 2.1.4.3 Revised Page Section 18 2.1.4.4 6 2.1.4.4 19 6 2.1.4.4 6 2.1.4.4 20 6 2.1.5.1 6 2.1.5.1 Comment This clause has not been marked as a change, but has changed. Previous clause (3.1.4.4 in GM/RT 2484 Issue 01) stated that it was appropriate to allow use of a two tone horn as well as an 'automatically varying' one, though preferring an automatic one. The clause does not state a preference for an automatic varying horn but does suggest that this is an appropriate method. If a two volume horn is not stated as being specifically allowed then it could be interpreted as being precluded. The standard could be interpreted as now requiring a 3 level volume horn for trains that travel faster than 160km/h. While it is appreciated that the requirement to fit an additional warning device is not mandatory, there is a concern that by not specifying appropriate tones and levels this could lead to a variety of specifications being used by different manufacturers and operators. This presents problems to manufacturers who would like to offer the same solution for each rolling stock order. If TOC requirements diverge then there may also be additional costs when stock is moved to other routes or stabled at another operator's depot. This is a new clause but has not been marked as a change. Generally this clause is welcome since it specifically states a lower level device is allowable within depot and shunting sidings, which is in line with London Rail’s proposals for Class 378 EMUs. However, it would have been useful if some indication of acceptable volume levels and tone had been given. By 5 CC Response NC 2.1.4.3 and 2.1.4.4 are technically similar to the existing text of the current standard (section 3.1.4.4) and have been separated to clarify the requirements. 3 DC Additional information has been provided to support this clause. 5 Insert “reasonably” between “so far as is” and “practicable” otherwise too onerous. 2 DC 2.1.4.3 and 2.1.4.4 are technically similar to the existing text of the current standard (section 3.1.4.4). It has been separated into two sections to clarify the requirements. The scope of Railway Group Standards can only mandate requirements on the controlled infrastructure. Additional information has been provided to support this clause. DC Text amended G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 7 of 10 Consultation No Page Section 21 6 2.2.1.1 Revised Page Section 22 8 3.2 8 3.2.1.2 23 8 3.2.1.1 8 3.2.1.2 Comment If the purpose of the horn is to alert persons on or about the track, it is suggested that sound pressure levels are measured 5m in front of the train at the height of an average person – not at the same height of the horn. It is assumed that “in line with the centre of the vehicle” means the vertical centre line of the vehicle. It is suggested that this is clarified in the text. Whilst the briefing note and impact assessment both highlight that this standard is not retrospective, I don’t believe the text in section 3.2 makes this clear "Scope" states the requirements apply to all new equipment. By 4 CC Response NC The measuring method chosen is to ensure that the audibility requirements of the warning horn at 400 metres is achieved. Figure 1 details the measurement position. 9 DC Text amended to clarify compliance requirements. 1 DC Agreed – text amended to clarify requirements. 7 DC Text amended to clarify compliance requirements. Although the number of horns changed is generally low, it is on an individual basis. However according to the interpretation of "new" equipment this could require the additional cost of replacing the second working horn of each pair when one is found damaged or defective. The initial assessment states there will be no material costs to the industry, so FGW presume that like for like replacement will be permitted. Having horns with different loudness when there is no campaign change in progress is likely to lead to low volume horns being reported as defective. Suggest clause is therefore reworded as "new build or modified systems, excluding like for like replacement of existing horns" or this definition is included on page 9. 24 8 3.2.1.2 8 3.2.1.2 Clarification required on meaning of “all work”, eg does this include normal maintenance activity? G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 8 of 10 Consultation No Page Section 24 3.2.1.1 Revised Page Section 8 3.2.1.2 26 8 3.2.1.1 3.2.1.2 Comment Clarification of the test “The Requirements of this document apply to all new equipment used for train horns” to make explicit that there is no requirement to modify existing designs when undertaking any direct replacement (maintenance / failure replacement). What is the precise definition of "new"? Does this mean "equipment used for warning horns" which is first designed, or ordered, or manufactured, or delivered or brought into use after 2nd June 2007? By 3 CC Response DC Text amended to clarify compliance requirements. 5 DC Text amended to clarify compliance requirements. DC Text amended to clarify compliance requirements. DC Text amended to clarify compliance requirements. It has been a practice in the past to be explicit and link implementation dates to e.g. VAB ‘design certificates’, equipment 'first brought into use' to give TOCs and manufacturers reasonable time to implement mandatory changes without delaying delivery programmes for trains ordered but not yet delivered. 27 3.2.1.2 8 3.2.1.2 Similar comment 3 28 3.2.1.2 8 3.2.1.2 What is the precise definition of "work that affects warning horns….whether new or modified"? Would, e.g. scheduled maintenance or direct replacement of a defective piece of equipment anywhere in the horn system mean the requirements of GM/RT 2484 Issue 02 would need to be complied with on that train from that point in time? 5 29 9 30 31 Definitions 9 Definitions 9 Definitions Definitio Typos – LA and LC should have subscripts (viz. ns questionnaire) "Possession-only rail vehicle" is defined but not used in the standard. “Possession – only rail vehicles” appears in Definitions but does not appear to be referred to in the standard. G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 9 of 10 2 DC Text amended 3 DC Agreed – definition deleted. 8 DC Agreed – definition deleted. G:\INS & RST\Standards projects\Lead SC - Rolling Stock\05-125 GMRT2484 issue 2 Train Horns\Consultation\Responses to consultation\2484 comments - industry final.doc 10 of 10