Spatial distribution of composition and misfit dislocations on the surface of alloys

advertisement

Semicond. Sci. Technol. 11 (1996) 717–721. Printed in the UK

Spatial distribution of composition

and misfit dislocations on the surface

of alloys

N V Fomin and D V Shantsev

Ioffe Physico-Technical Institute, 26 Polytekhnicheskaya St., St Petersburg 194021,

Russia

Received 25 January 1996, accepted for publication 26 February 1996

Abstract. The Frenkel–Kontorova theory of phase transitions into an

incommensurate phase with the formation of a superlattice of misfit dislocations on

a surface is extended to the case of alloys for which the lattice mismatch depends

on the local composition. A model is considered that takes into account the

possibility of atomic diffusion between the surface and the bulk. Peculiarities of the

conditions at the surface are accounted for by introducing a chemical potential for

one type of the atoms of the alloy which leads to a difference in composition

between the bulk and the surface layer. We calculated the average mismatch

between the surface and the bulk lattices and the critical value of chemical

potential at which the phase transition into an incommensurate phase with misfit

dislocations occurs. A phase diagram of the system in coordinates of temperature

and chemical potential is presented for the alloy Inx Ga1−x As.

1. Introduction

In previous works [1, 2] we discussed the specificity of

the appearance of misfit dislocations and incommensurate

structures in the surface layer or adsorbed film of alloys.

It is well known that the origin of misfit dislocations

is a mismatch of the crystal lattice parameters of the

adsorbed film (or surface layer) and the bulk. A classic

model describing transitions between incommensurate and

commensurate phases is the Frenkel–Kontorova model [3],

which considers a linear chain of adatoms connected to

one another by elastic springs of length a and placed in

a cosinusoidal potential with period a0 induced by the

substrate. For the case of weak interaction between adatoms

and the substrate this problem was solved by Frank and van

der Merwe [4]. The energy of the chain can then be written

as

Z 2

1

2πu(x)

V 0

FFK =

u (x) − δ

+

dx

V0 1 − cos

a0

a0

2

(1)

where u(x) represents the displacements of adatoms with

respect to their positions in the commensurate phase, i.e.

minima of the cosine potential (for the continual approach

to be valid u(x) must be a slowly varying function of

the coordinate x along the chain, i.e. u0 = ∂u/∂x 1),

V and V0 are parameters characterizing the interaction

of adatoms with the substrate and with one another, and

δ = (a − a0 )/a 1 is the misfit characterizing the lattice

c 1996 IOP Publishing Ltd

0268-1242/96/050717+05$19.50 mismatch. When the misfit exceeds its critical value

δFK =

4

√

π α

α=

V

V0

(2)

the model gives the solution in the form of a lattice of

solutions—misfit dislocations—with the period depending

on the misfit.

In alloys the lattice parameter a depends on the

composition c (we will restrict our consideration to binary

or pseudobinary alloys Ac B1−c or Ac B1−c C), and therefore

a change of the local lattice parameter a(c) is made

possible by a change of local composition [5]. This spatial

redistribution of composition proceeds owing to atomic

diffusion in the crystal lattice. In reference [1] this effect

was taken into account in terms of a continual Frenkel–

Kontorova model considering the misfit δ as a function of

the coordinate. Then the energy functional can be written

in the form

Z 2

2π u(x) α 0

V0

u (x) − δ(x)

+

1 − cos

F =

a0

a0

2

β

δ(x) − δ̄ dx

(3)

+

2

where the overbar designates averaging over the coordinate,

and the parameter

β=

fch00 (c)a03

η2 V0

(4)

where η = (1/a)(∂a/∂c), is proportional to the second

derivative of the specific chemical energy of the alloy

717

N V Fomin and D V Shantsev

fch with respect to composition c. In expression (3)

the term containing β accounts for the increase in the

alloy energy caused by a spatially nonuniform distribution

of composition (we consider only the case of positive

β, which corresponds to an alloy stable against spinodal

decomposition). Furthermore the composition modulation

in the vicinity of dislocations lowers the elastic energy by

reducing the local mismatch. The competition of these two

mechanisms leads to a value of critical misfit which is less

than that given by equation (1):

s

s

β

β

4

δc =

= δFK

< δFK .

(5)

π α(α + β)

α+β

At β → ∞, when a nonuniform distribution of composition

is energetically unfavourable, expression (5) naturally

transforms into (2), while small enough β values provide

instability of the commensurate phase for as small a misfit

δ as desired. Another interesting feature of the Frenkel–

Kontorova model for alloys is the power-law dependence

of the interaction between two misfit dislocations on the

dislocation spacing l:

Fint = 8π 2 V0

a0 α

l β

(6)

with the interaction sign corresponding to repulsion.

Therefore the phase transition can be described here as a

second-order phase transition on the basis of the Ginsburg–

Landau theory with an order parameter of 1/ l, while in

the classic Frenkel–Kontorova model the dependence of

the energy on the order parameter at the critical point

is not analytical. In generalizing the Frenkel–Kontorova

model to the case of a substrate with finite rigidity many

authors took into account the interaction between misfit

dislocations through elastic strain in the substrate (see [6]

and references therein). It should be mentioned that the

elastic interaction of misfit dislocations is proportional to

1/ l 2 at large distances, i.e. it decays more quickly than

would be expected from equation (6).

An important point for the analysis carried out in

reference [1] is the assumption that the average composition

in the chain is constant, which rules out the possibility of

atomic diffusion between the chain and the bulk. In the

present paper we give up this assumption and allow atomic

diffusion along the chain as well as beyond it (surely, if

an atom of type A leaves a site of the crystal lattice, it

is replaced by another atom of type B). As a result, and

as will be shown below, the conclusion of reference [1]

that the critical misfit δ tends to zero when the parameter

β approaches zero remains valid, while the power-law

interaction (6) between dislocations disappears.

2. Generalization of the Frenkel–Kontorova model

to alloys with regard to atomic diffusion between

the chain and the substrate

It is supposed that the atoms of the surface layer of an alloy

are placed in peculiar conditions with respect to the atoms

in the bulk since some bonds of surface atoms are dangling

or their hybridization takes place. Then it can be expected

718

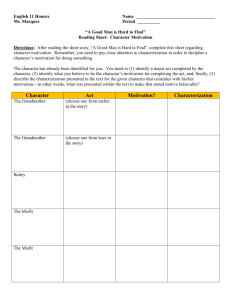

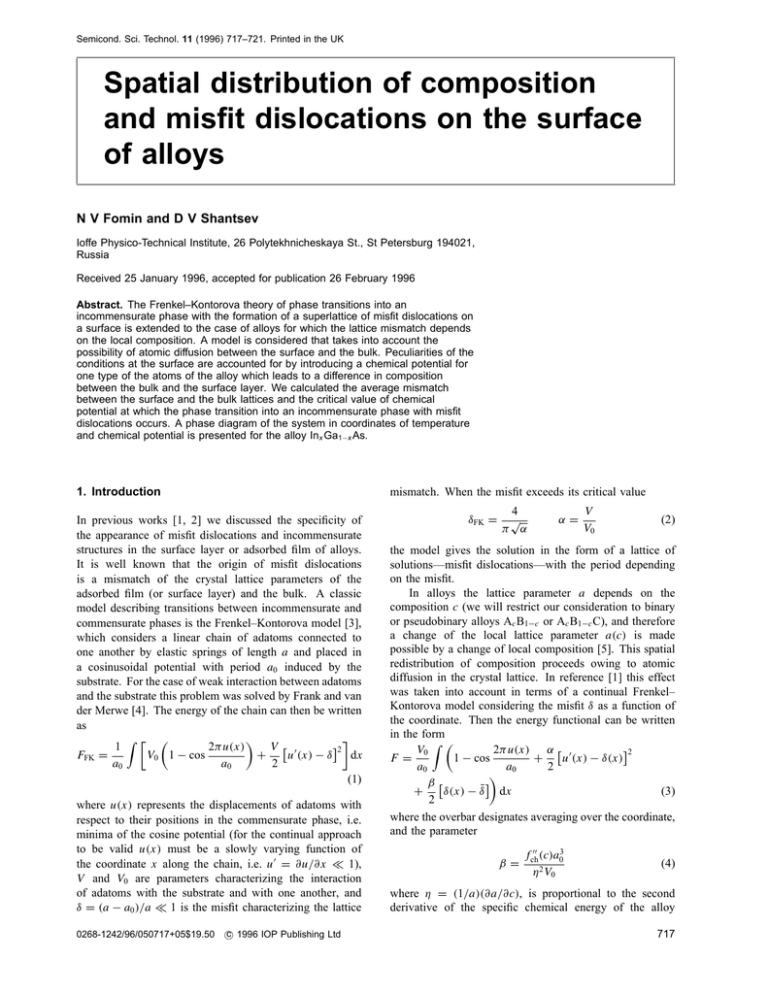

Figure 1. Black and white circles represent atoms of two

types for a binary alloy. Peculiar conditions at the surface

provide a difference in compositions and hence a mismatch

of lattice parameters at the surface and in the bulk.

(a ) A coherent structure (mismatch is sufficiently small);

(b ) presence of misfit dislocations (mismatch is large).

that it is energetically more favourable for atoms of one

type to be at the surface than for atoms of the other type.

This tendency should lead to a change of alloy composition

at the surface and hence to a mismatch between lattice

parameters at the surface and in the bulk (see figure 1).

If the composition change is small, a linear approximation

can be used for this dependence.

Let us write the total energy of the system. In the

spirit of the Frenkel–Kontorova model we will suppose that

the bulk of the alloy is rigid and has a spatially uniform

composition c. Then the linear term in the chemical free

energy expansion in terms of composition variation

fch (c + 1c) = fch (c) + fch0 (c)1c + 12 fch00 (c)(1c)2

(7)

vanishes when integrated over the whole material and the

integral of the quadratic term over the bulk is far less than

that over the surface. Thus, the total energy of the system

can be written as an integral over just the surface layer:

Z 2

V0

2π u(x) α 0

u (x) − δ(x)

F =

+

1 − cos

a0

a0

2

β

+ [δ(x)]2 − γ δ(x) dx

(8)

2

where δ is the misfit between the lattice constant at the

surface and the average lattice constant. Here we used

Vegard’s rule for the linear dependence of the lattice

parameter on composition δ = η1c. The parameter γ

is related to the effective chemical potential µ (the energy

associated with exchange of an atom of type A and an

atom of type B between the surface and the bulk) by the

following expression:

γ =

µ

ηV0

(9)

where V0 is, as before, the amplitude of the cosinusoidal

potential characterizing the interaction between the chain

of the surface atoms and the bulk.

Varying (8) with respect to δ, we obtain the Euler–

Lagrange equation:

α 0

γ

δ(x) =

u (x) +

.

(10)

α+β

α

Misfit dislocations on the surface of alloys

Substitution of δ, expressed in terms of u by (10), into (8)

allows us to write the energy as

Z V0

2πu(x) α∗ 0 2 α∗ γ 0

F =

u dx

1 − cos

+ (u ) −

a0

a0

2

β

(11)

where

αβ

α∗ =

(12)

α+β

and the energy reference point is chosen so that the energy

of the commensurate phase is zero, F [u(x) ≡ 0] = 0.

Expression (11) differs from the related one in reference

[1] by the absence of the term with (ū0 )2 responsible

for the interaction of dislocations. This is because in

reference [1] the misfit δ̄ was predetermined since the

average composition in the chain was assumed to be

constant. This time, however, the predetermined value is

the chemical potential µ, while δ̄ is defined by the condition

of minimization of the energy and, according to (10), it

increases when a lattice of misfit dislocations with period

l = a0 /ū0 appears:

α a0

γ

δ̄ =

+

.

(13)

α+β l

α

Note that expression (11) coincides with the corresponding

expansion in the Frenkel–Kontorova model with misfit γ /β

and elastic constant α∗ .

Now let us find the function u(x).

Varying

equation (11) with respect to u gives the sine-Gordon

equation:

2πu a0 2

2πu 00

sin

=

α∗

(14)

a0

2π

a0

whose first integral is

− cos

2πu

α∗ 0 2

1

(u ) − 2

=

a0

2

z

(15)

where 1/z 2 is an integration constant which must be

determined from the condition of minimization of the

energy. It is easy to see that z takes on values from 0

to 1. Expressing the function cos u through (15), we can

write the average energy density as a function of z:

V0

γ

1

0 2

¯

f (z) = 3 1 − 2 + α∗ (ū ) − α∗

ū0

(16)

z

β

a0

where the dependence of u0 on z is determined by (15). It

is convenient to express (ū0 )2 and ū0 in terms of elliptic

integrals:

Z 2π p

E(z) =

1 − z 2 cos ϕ dϕ

0

Z

K(z) =

0

2π

dϕ

p

.

1 − z 2 cos ϕ

(17)

The functions u(x), solutions of (15), describe a lattice of

misfit dislocations with period l defined as

√

Z a0

α∗ zK(z)a0

l(z) =

(u0 )−1 du =

.

(18)

√

2 2π

0

Further we have

(ū0 )2 = l −1

Z

a0

0

E(z)a0

u0 du = √

2α∗ π zl(z)

ū0 = a0 / l.

Substituting these expressions into (16), we obtain

√

α∗ E(z) α∗ γ a0

1

V0

¯

.

−

f (z) = 3 1 − 2 +

√

z

β

l

a0

2π z

(19)

(20)

(21)

The value z = 1 corresponds to the commensurate structure

(u(x) ≡ 0). An incommensurate structure emerges if

f (z) has a minimum at z = z0 lying within the interval

[0, 1]. Near the point of phase transition (z = 1) the

dislocation density 1/ l is small and the expression d =

√

V0 (4 α∗ /π − α∗ γ /β) has the meaning of the energy

necessary for one dislocation to be formed. If this energy

is negative, formation of a dislocation is favourable. The

generation of dislocations proceeds until the interaction

(repulsion) between them comes into force. Since K(z)

and hence, according to (18), l(z) diverge logarithmically

at z = 1, the interaction between dislocations decays

exponentially with their spacing which, in turn, implies a

singular dependence l −1 (d ).

The condition of the transition into the incommensurate

phase can be written in the form

γ

4

> √

β

π α∗

(22)

by analogy with the Frenkel–Kontorova model (see

equation (2)).

Now let us turn to more convenient variables. Applying

the regular solution approximation [7], we can write the

specific free energy of a binary alloy as

1

{cµA + (1 − c)µB + c(1 − c)

Wmole

+ RT [(1 − c) ln(1 − c) + c ln c]}

fch (c) =

(23)

where µA and µB are the chemical potentials of atoms of

type A and B, is the interaction parameter, R is the gas

constant, T is temperature and Wmole is the molar volume.

Applying (4) and (23), we obtain the following expression

for β:

β = tα.

(24)

Here t is linear in temperature:

t=

RT − 2c(1 − c)

c(1 − c)NA V η2

(25)

where NA is the Avogadro constant. Substituting (9) and

(24) in (22), we obtain the applicability condition for our

model

p

4η p

µ > µc =

V0 V t (1 + t).

(26)

π

The fulfilment of this condition means that the chemical

potential µ, providing for atoms of one type an excess

concentration at the surface with respect to that in the bulk,

is high enough for the average misfit between surface and

√

bulk lattices to achieve the critical value 4/(π α∗ ). The

719

N V Fomin and D V Shantsev

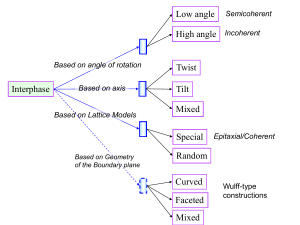

Figure 2. Phase diagram in coordinates of the effective

chemical potential and temperature for the alloy

Inx Ga1−x As. The critical line separating commensurate (C)

and incommensurate (I) phases is given by equation (26);

parameters are taken from [9]; α = 20. The (C) phase

corresponds to a coherent structure at the surface. The (I)

phase corresponds to the presence of misfit dislocations.

The full line indicates the temperature range where our

model is applicable (see (30)). Tc is the critical temperature

of spinodal decomposition.

phase diagram of the system for the alloy Inx Ga1−x As is

presented in figure 2. Since it was assumed that β > 0, our

analysis is valid only for T > Tc where Tc = 2c(1−c)/R

is the critical temperature of spinodal decomposition of the

alloy. According to experimental data (see e.g. [8]), for

III–V compounds Tc is in the range 300–1000 K, which

corresponds to typical temperatures of epitaxial growth.

Theoretically, at T close to Tc , equation (26) gives µc → 0.

It should be noted, however, that in this case we appear to

be beyond the continual approach.

Next, let us find the range of applicability of our model.

For harmonic expansion of the chemical energy to be valid

the following condition must be fulfilled:

δ

|aA − aB |

=η

a

(27)

where aA and aB are the periods of monolattices consisting

of atoms of type A and type B respectively. In addition,

for the continual approach to be applicable it was supposed

that

1

(28)

u0 ≈ √ 1.

α∗

According to (10) and (20) in the vicinity of the phase

transition, δ is given by

s

β

4

.

(29)

δ≈

π α(α + β)

Replacing strict inequalities by nonstrict ones and dropping

numerical coefficients, we obtain from (24) and (27)–(29)

the range of applicability of our model:

αη2

1

t .

α−1

1 − αη2

720

(30)

It can be seen that at η < α −1 the model is inapplicable

at any temperature. Since the parameter η is always less

than unity (for real compounds far less than unity), the

approach discussed is appropriate only for the case of

weak interaction between surface atoms and the substrate

(α 1). In principle, it is beyond reason to expect such

a large difference in interactions of surface atoms with one

another and with the substrate, though if it is assumed that

not one but n near-surface layers are placed in peculiar

conditions then α for such a system increases n times.

Nevertheless there is reason to believe that in a qualitative

sense our analysis adequately accounts for the enhanced

tendency of alloys to form dislocations owing to the

spatially nonuniform distribution of composition and that

it can also be used for describing the thermodynamically

non-equilibrium process of epitaxial growth. Finally it

should be mentioned that in the case of n near-surface

layers we should replace the quantity µ by nµ, and from

(26) it follows√that the critical value of chemical potential

µc decreases n times.

As an example, we propose a numerical estimation

using parameters for which our model is correct. According

to (9), for Inc Ga1−c As = 2.9 kcal mol−1 , η = 0.069, and

to estimate the quantity V , the elastic energy per atom,

we take the value of a pertinent combination of elastic

moduli which is ≈ 730 kcal mol−1 ; then at c = 1/2,

α = 20 and T = 770 K condition (30) takes the form

0.05 0.08 0.11, which is appropriate for a qualitative

description of the situation.

3. Conclusion

In summary, we have developed a model describing the

surface of an alloy in terms of the atomic diffusion between

the surface and the bulk. It was assumed that conditions for

the composition parameter in the surface layer differ from

those in the bulk, which results in a mismatch of surface and

bulk lattice constants. If this mismatch is large enough there

occurs a phase transition into an incommensurate phase

with the appearance of misfit dislocations. At temperatures

far from the melting point atomic diffusion is suppressed

because for an atom to hop into an interstitial it is necessary

to overcome a potential barrier of the order of the bonding

energy, and that is why the mechanism discussed in this

paper can be responsible for slow degradation of alloys.

However, our chief tendency that the appearance of misfit

dislocations is facilitated in alloys owing to the possibility

of a spatially nonuniform distribution of composition seems

to be appropriate also for the process of epitaxial growth

when the analysis in terms of equilibrium thermodynamics

used here is inapplicable. Allowing atomic diffusion into

the bulk leads to the disappearance of strong interaction

between dislocations, which takes place in the chain with a

fixed average composition. As a result, the model predicts

a phase transition similar to that considered by the model

of Frenkel–Kontorova, i.e. with a singular dependence of

the free energy on the order parameter (superlattice period).

The results obtained can be useful from the standpoint of

choosing the optimum conditions for the epitaxial growth

of non-defect structures of alloys.

Misfit dislocations on the surface of alloys

Acknowledgments

The authors are grateful to V A Shchukin and R A Suris for

fruitful discussions and interest in the work. The work was

supported by the Foundation for Fundamental Research of

Russia, grant no 93023199.

References

[1] Fomin N V 1994 Sov. Phys. Solid State 36 754

[2] Fomin N V and Shantsev D V 1995 Fiz. Tverd. Tela at press

[3] Frenkel’ F I and Kontorova A A 1939 J. Phys. (USSR)

1 137

[4] Frank F C and Van der Merwe J H 1949 Proc. R. Soc. 198

206

[5] Khachaturyan A G 1983 Theory of Structural

Transformations in Solids (New York: Wiley)

[6] Fomin N V 1991 Sov. Phys. Solid State 33 111

[7] Ilegems M and Panish M B 1974 J. Phys. Chem. Solids 35

409

[8] Ipatova I P, Malyshkin V G and Shchukin V A 1993

J. Appl. Phys. 74 7198

[9] Glas F 1987 J. Appl. Phys. 62 3201

721