Engineering Work Breakdown and Assignment for Global ... Development 17 2'13 LERARPS

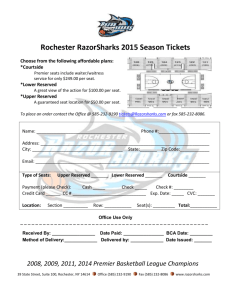

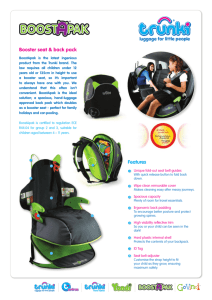

advertisement