Matrix rheology effects on reaction rim growth II: coupled

advertisement

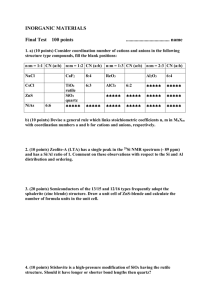

J. metamorphic Geol., 2009, 27, 83–91 doi:10.1111/j.1525-1314.2008.00805.x Matrix rheology effects on reaction rim growth II: coupled diffusion and creep model D. W. SCHMID,1 R. ABART,2 Y. Y. PODLADCHIKOV1 AND R. MILKE2 1 Physics of Geological Processes, University Oslo, Pb 1048 Blindern, 0316 Oslo, Norway (schmid@fys.uio.no) 2 Institute of Geological Sciences, Free University Berlin, Malteserstrasse 74-100, 12249 Berlin, Germany ABSTRACT Chemical reactions and phase changes generally involve volume changes. In confined settings this will cause a mechanical deformation of the matrix that surrounds the reaction sites where the volume change takes place. Consequently, mineral reactions and the mechanical response of the rock matrix are coupled. A companion paper in this issue illustrates this coupling with experiments where quartz and olivine react to form enstatite reaction rims under ambient conditions of 1 GPa and 1000 C. It has been demonstrated that for identical run conditions, the thickness of the reaction rims depends on whether quartz grains are embedded in an olivine matrix or olivine grains are included in a quartz matrix. The experimental conditions, the nature of the results, and the large volume change of the reaction ()6%) leave only viscous creep as a viable matrix response to the reaction progress. A model is developed for this reaction, which combines diffusion of chemical components through the growing rim and viscous creep of the matrix. The resulting rate law for reaction rim growth in spherical geometry shows that the progress rate is proportional to the reaction overstepping and controlled by the slower of the two competing processes; either diffusion pffiffi or creep. If diffusion is rate limiting the usual linear proportionality between rim growth and t results. However, if viscous creep is rate limiting, then the reaction rates are reduced and may become effectively creep controlled. With respect to the experiments in the companion paper it is inferred that the effective viscosity of the two matrix materials, i.e. polycrystalline quartz and olivine, differ by approximately one order of magnitude with the quartz being the stronger one. The absolute values of the inferred viscosities correspond well to published flow laws. The rheological properties of natural rocks are well within the parameter range for which significant mechanical control on reaction rim growth is expected. This implies that for the interpretation of natural reaction rims and corona structures both diffusion and mechanical control need to be considered. In addition the mechanical effect also needs to be considered when interdiffusion coefficients are retrieved from rim growth experiments. This should also be considered for geospeedometry analyses. Furthermore, the control on reaction rate because of slow creep of the matrix is expected to be even more important, compared to the experiments, under colder crustal conditions and may contribute substantially to the frequent observation of only partially completed reactions. We suggest that this phenomenon is referred to as Ômechanical closureÕ, which may be an important mechanism in the kinetic displacement of the boundaries between the stability fields of phase assemblages. Key words: diffusion; mechanical effects; reaction; rheology; rim growth. INTRODUCTION Much growth and dissolution of minerals takes place under conditions of macroscopically non-hydrostatic stress. It has long been recognized that mineral reactions and non-hydrostatic stress may interfere. Grain scale stress heterogeneity and anisotropy may be internally produced through volume changes associated with phase transformation and mineral reactions (Fletcher & Merino, 2001; Lenze et al., 2005). Reaction-induced stress is expected to produce initially elastic and later ductile deformation (Rubie & Thompson, 1985). Reaction-induced stress acts against 2008 Blackwell Publishing Ltd the reaction by which it is generated, and it may slow down and eventually quench the respective reaction (Hacker & Peacock, 1995; Paterson, 1995; Mosenfelder & Bohlen, 1997). A number of models have been developed that analyse the mechanical effects of a matrix (elastic or elasto-plastic) on an inclusion that undergoes a phase transformation (e.g. Lee et al., 1980; Morris, 1992, 2002; Fischer et al., 1994; Zhang, 1998; Barron, 2003; Guiraud & Powell, 2006). Yet, the interplay between net transfer mineral reactions, i.e. reactions that involve chemical transport, and reaction-induced stress is poorly understood. Transport-controlled mineral 83 84 D. W. SCHMID ET AL. reactions typically produce spatially organized microstructures such as reaction rims or corona structures (Joesten, 1977), which form between two mutually incompatible phases or mineral assemblages (e.g. Ashworth et al., 1998; Markl et al., 1998; Abart et al., 2001; Milke et al., 2001). Rim growth experiments in simple systems such as MgO-SiO2 (Brady & McCallister, 1983; Fisler et al., 1997; Yund, 1997; Milke et al., 2001), CaCO3 – SiO2 (Milke & Heinrich, 2002), or MgO – Al2O3 (Watson & Price, 2002) were used to extract effective component diffusivity from measured rim growth rates. So far, all experimental rim growth studies rely on the assumption of isothermal-isobaric conditions. However, such a scenario is not compatible with the notion that minerals are mechanically strong, i.e. can sustain differential stress. As a consequence, in a mineral aggregate, the local volume change will act against the confinement; related to this is the Ôforce of crystallizationÕ concept that goes back a century or more (Taber, 1916; see also Vernon, 2004). Carmichael (1987), Wheeler (1987), and Fletcher & Merino (2001) argued for the existence of reaction-induced variations in local stress in the context of reaction rim growth. The potential effects of reaction-induced non-hydrostatic stress on rim growth rates have, however, not been addressed in a systematic manner. Milke et al. (2009) performed rim growth experiments in the system MgO-FeO-SiO2. They used olivine and quartz starting materials to grow orthopyroxene reaction rims at quartz-olivine interfaces. To test the potential effect of matrix rheology on rim growth rate, they used different matrix-inclusion arrangements. In one set of experiments, about 10 vol.% of olivine grains with an average grain size of 150 lm were immersed in a matrix of fine grained quartz (grain size 20 lm), and in the other set, about 10 vol.% of quartz grains with an average grain size of 150 lm were immersed in a matrix of fine grained olivine (grain size 20 lm). The samples were loaded into the capsules without drying so that the total water content was about 0.1 wt%. To ensure similar run conditions for both matrix-inclusion arrangements, both mixtures were placed into a single capsule. FTIR analyses of the run products showed that within 80 h run duration olivine equilibrated with an aqueous fluid throughout the capsule. In contrast, quartz largely retained its original low water content. Despite similar run conditions, the width of the orthopyroxene rims are significantly different between the two compartments of the assembly: orthopyroxene rims have an average thickness of 10.3 lm in the compartment with quartz inclusion in the olivine matrix and they are on average 6.1 lm thick in the compartment where olivine inclusions are immersed in the quartz matrix. The experimental setup rules out difference in the effective component diffusivity between the two experimental configurations as an explanation for the difference in reaction rim thickness. The volume change of the reaction is too large to be accommodated by purely elastic response of the matrix. Furthermore, the two matrix materials creep under the given conditions and strain rates (see detailed discussion below and Milke et al., 2009). Hence the bulk of the volume change will be accommodated by creep and we therefore develop a coupled reaction-deformation model where the chemical mass transport associated with the rim growth reaction is combined with the viscous creep response of the matrix material. The importance of viscous creep has, in the context of phase change experiments, previously been pointed out by a number of authors (Liu et al., 1998; Morris, 1992; Morris, 2002; Mosenfelder et al., 2000; Rubie & Thompson, 1985). MODEL DERIVATION Our model deals with an isolated (dilute assumption), perfectly spherical inclusion of reactant mineral A in a matrix that consists of the reactant mineral B. The product mineral C is assumed to form a continuous rim between A and B. It is assumed furthermore that the interfaces between the reactant and product phases are perfectly mobile so that the chemical potentials of the mobile components are continuous functions of the radial distance across the interfaces. The setting of rim growth associated with a reaction of the type A + B = C is illustrated schematically in Fig. 1. B C A rB rA rC φ r θ Fig. 1. Cross-sectional sketch of the analysed three-dimensional spherical system. The inclusion A and the matrix B represent forsterite or quartz depending on the configuration; C represents the enstatite rim that is produced by the reaction. rA and rC are the radial distances of the inner and outer limit of the reaction rim. rB is the hypothetical inner interface of matrix B if there was no mechanical adjustment to the volume change caused by the reactions. The observed mechanical response is indicated by the arrows. B is assumed to extend to infinity where a constant pressure boundary condition is applied; the temperature is constant throughout the entire domain. 2008 Blackwell Publishing Ltd COUPLED DIFFUSION AND CREEP MODEL 85 Mass and volume balance At the run conditions of 1000 C and 1 GPa, olivine and quartz cannot coexist stably and an orthopyroxene rim grows from the original quartz-olivine interface into both directions, replacing quartz on one side and olivine on the other. The bulk reaction may be written as: olivine ((Mg, Fe)2 SiO4 Þ þ quartzðSiO2 Þ ¼ orthopyroxeneððMg, FeÞ2 Si2 O6 Þ ð1Þ For the purpose of this derivation the complexities that may arise from the partitioning of Fe–Mg between olivine and orthopyroxene are neglected, and both are considered as stoichiometric phases in the MgO–SiO2 model system (i.e. En = enstatite (Mg2Si2O6), Fo = forsterite (Mg2SiO4), and Qtz = quartz (SiO2)). In this case, rim growth requires transfer of SiO2 and ⁄ or MgO components between the two reaction interfaces where orthopyroxene replaces quartz and olivine, respectively, see Fig. 2. Note that molar quantities are used throughout this paper unless stated otherwise. The bulk reaction may be split into two half reactions (Abart et al., 2004). At the enstatite ⁄ forsterite interface: 1 1 þ c En þ ð1 cÞMgO ð2Þ 1Fo þ cSiO2 ¼ 2 2 and at the enstatite ⁄ quartz interface as 1 1 c En þ cSiO2 ð1 cÞMgO þ 1Qtz ¼ 2 2 ð3Þ The coefficient c expresses the relative fluxes of SiO2 and MgO in molar units. For feasible mass balance scenarios 0 £ c £ 1. Using the thermodynamic data of Holland & Powell (1998), a negative volume change of )6% is calculated for the reaction at the conditions of the rim growth experiments. Microstructural and textural evidence suggests that, irrespective of the matrix-inclusion arrangement, rim growth occurs at close to constant volume replacement at the enstatiteforsterite interface (Abart et al., 2004; Milke et al., 2009) and the volume change is largely accommodated by creep at the enstatite-quartz reaction front. In terms of mass balance this implies that c 0.39. Reaction affinity and the driving force for component diffusion The orthopyroxene reaction rims typically have sharp interfaces with the reactant minerals indicating attainment of local equilibrium during transportcontrolled rim growth (Thompson, 1959; Korzhinskii, 1970). In particular, it is assumed that thermodynamic equilibrium is maintained across the enstatite-quartz and across the enstatite-forsterite reaction fronts. This implies that at given pressure and temperature conditions the chemical potentials of the mobile components, lMgO and lSiO2, are fixed at the enstatite ⁄ forsterite interface through: lSiO2 ¼ Df GFo þ Df GEn 1 lMgO ¼ Df GFo Df GEn 2 ð4Þ and at the enstatite ⁄ quartz interface through lSiO2 ¼ Df GQtz ð5Þ 1 lMgO ¼ Df GEn Df GQtz 2 DfGi denotes the Gibbs free energy of formation from the elements of phase i. Note that DfGi = DfGi(P,T), where P is pressure and T is temperature. The difference in chemical potentials of the respective components between the enstatite ⁄ quartz and the enstatite ⁄ forsterite interfaces is as follows: DlSiO2 ¼ þDf GQtz þ Df GFo Df GEn ¼ Dr G DlMgO ¼ Df GQtz Df GFo þ Df GEn ¼ þDr G ð6Þ where DrG is the Gibbs free energy of the reaction as written in Eqn (1). Diffusion of SiO2 and MgO is driven by gradients in the respective chemical potentials. For the given spherical geometry only gradients in r must be considered and we can express the flux of component i through @li ð7Þ @r where Li is the phenomenological coefficient of diffusion. Assuming that no sources or sinks exist within the enstatite rim (div(J) = 0) results in a chemical potential gradient within the enstatite rim, rA £ r £ rC, that has the following form Ji ¼ Li Fig. 2. Radial section illustrating the component fluxes and hypothetical chemical potentials through the rim. Note that irrespective of the actual configuration the fluxes coming out of A are defined positive as indicated by the arrows. 2008 Blackwell Publishing Ltd 86 D. W. SCHMID ET AL. @li rA rC D r G ¼ @r rA rC r2 ð8Þ Note that both rA and rC change during rim growth. The sign of the right hand side term follows the convention of Fig. 2. It is negative for cases of i = SiO2 and A = Qtz and for i = MgO and A = Fo; it is positive for i = SiO2 and A = Fo and for i = MgO and A = Qtz. The boundary conditions are that the chemical potentials at the interfaces must correspond to the values given in Eqs (4) and (5). The volume of the reactive inclusion A that is consumed per time is through mass balance related to component fluxes by: dVA ðtÞ ¼ ðJSiO2 JMgO ÞSA VA dt ð9Þ VA and VA designate the total and the molar volume of 2 is the the reactive inclusion, respectively. SA = 4p rA surface area of the inclusion A. Since outward fluxes are defined positive the sign of the right hand side term is negative for the olivine in quartz arrangement and positive otherwise. Combining Eqs (7), (8) and (9) we obtain: @lMgO @lSiO2 dVA ðtÞ ¼ LSiO2 þLMgO SA VA dt @r @r ð10Þ rA rC Dr G V ¼L S ; A A rA rC r2 where L = LSiO2 + LMgO is the combined phenomenological coefficient of diffusion, which accounts for the combined diffusive fluxes of SiO2 and MgO. Rate law for reaction rim growth in spherical geometry It is convenient to define reaction progress, n(t), as the fraction of the reactive inclusion that has been consumed at time t: nðtÞ ¼ 1 VA ðtÞ V0 ð11Þ where V0 = VA(t = 0) is the initial volume of the reactive inclusion. Correspondingly r0 = rA(t = 0) is the initial radius of A. From this the following volume and radius relations are obtained: VA ðtÞ ¼ V0 ð1 nðtÞÞ VB VB ðtÞ ¼ V0 nðtÞ VA 1 rA ðtÞ ¼ r0 ð1 nðtÞÞ3 ð12Þ 1 VB 3 rB ðtÞ ¼ r0 1 þ nðtÞ ð13Þ VA 3 VC VC VC ðtÞ ¼ V0 nðtÞ rc ðtÞ ¼ r0 1þnðtÞ 1 VA VA 1 ð14Þ Note that VB(t) designates the volume of matrix phase B consumed. rB is a hypothetical radius that corresponds to the inner interface of the matrix if there would be no mechanical adjustment of the matrix to the volume change. Note that in general there will be a difference between the volumes of the reactant phases consumed and the resulting product, i.e. rC „ rB, as symbolized in Fig. 1. Expression (12) and (14) can be combined with (10) and evaluated at r=rA to obtain a rate law for diffusion controlled reaction rim growth in spherical geometry: dnðtÞ 3LVA ¼ XFðnÞ ð15Þ dt r20 where FðnÞ ¼ 1 1 3 ð1 nðtÞÞ3 1 þ nðtÞ VVAC nðtÞ 1 3 ð1 nðtÞÞ 1 þ nðtÞ VVC A nðtÞ 1 ð16Þ 3 W is a generalized reaction affinity. For a stress free transformation, it is equal to the reference reaction affinity X ¼ X0 ¼ Dr G ð17Þ However, if mechanical effects are considered W will have to be augmented with the relevant terms and will become a function of reaction progress. Viscous adjustment of the matrix The problem of a growing or shrinking sphere in an infinite matrix is a frequent one. In its mechanical form it is related to the Lamé problem (Lamé, 1852) the analysis of which was extended to include elastoplasticity, phase transitions, and mineral reactions (e.g. Hill, 1950; Lee et al., 1980; Morris, 1992, 2002; Fischer et al., 1994; Mosenfelder et al., 2000; Fletcher & Merino, 2001). The mechanical equilibrium expression in the considered spherical geometry is greatly simplified, since for symmetry reasons the tangential displacements and shear stresses are all zero and the radial velocity v only depends on the radial distance r. In the absence of body forces we can write: drr 2ðrr rh Þ ¼ 0; þ r dr ð18Þ where rr and rh are the radial and the tangential stress components, respectively. Because of the symmetry, only one tangential stress component is required, i.e. r/ ¼ rh ð19Þ These symmetry arguments also hold for strains and strain rates. 2008 Blackwell Publishing Ltd COUPLED DIFFUSION AND CREEP MODEL 87 Note that in the following mechanical analysis the rim is treated as part of the inclusion, and therefore does not explicitly account for the mechanical properties of the rim. The volume mismatch introduced by the rim growth is assumed to occur at the outer enstatite rim interface and must be compensated by the mechanical response of the matrix. This essentially reduces the mechanical problem to a single domain since only the response of the matrix material to boundary conditions must be investigated. Note that this represents a simplification with respect to the experiments of (Milke et al., 2009) since they observed that the actual volume change is introduced at the inner enstatite interface in the case of quartz inclusions immersed in a forsterite matrix. However, the mechanical effect of the rim is likely to be negligible as the bulk volume compensation must occur by creep of the surrounding matrix. For large reaction progress the volume change will exceed what can be accommodated elastically. Under the given conditions this will cause viscous creep of the matrix. In this case the strain rates are related to the radial velocity by e_r ¼ dv ; dr e_h ¼ v r v The coupling between rim growth by diffusion and viscous creep of the matrix is accounted for by the fact that the Gibbs free energy at the inclusion-matrix interface is a function of the normal stress acting on the interface (Kamb, 1961). This can be expressed in terms of reaction affinity as ð26Þ X ¼ X0 ðrr ðr ¼ rC Þ þ p1 ÞDr V where Dr V ¼ VC VA VB is the molar volume change of reaction. Note that it is assumed that the normal stress across the product rim is constant and therefore the change in flux is essentially due to the different molar volumes. The reaction affinity (26) combined with Eq. (15) yields the following rate law for rim growth in a viscous matrix: dn ¼ dt X0 r20 4gr0 MðnÞDr V rC 3LVA FðnÞ X0 ¼ r20 4gMðnÞDr V NðnÞ 3LVA FðnÞ p¼ rr þ 2rh 3 ð22Þ The boundary conditions are that at the inclusion ⁄ matrix interface the matrix must creep with a velocity that compensates the volume change induced by the reaction, v(rC)=vreact, and that far away the stress state is equal the ambient pressure (p¥), rr(¥) = )p¥. Solving the system of ordinary differential equations, Eqs (18), (21) and (22), under the given boundary conditions we obtain v¼ vreact r2C r2 4r2C ð23Þ r3 2r2 rh ¼ p1 þ vreact g 3C r The expression for the velocity that results from the volume change of the reaction is rr ¼ p1 vreact g 2008 Blackwell Publishing Ltd ð27Þ with 1 3 VC NðnÞ ¼ 1 þ nðtÞ 1 VA p is the pressure defined by ð24Þ 2 3 VC VC 1 VC MðnÞ ¼ 1 1 þ nðtÞ 1 1 3 VA VA VB ð25Þ ð20Þ ð21Þ drc dn VB VC df ¼ ¼ r0 MðnÞ dt dn dt VB with Assuming a viscous only response we can write the constitutive equations for a linear, incompressible viscous material with viscosity g as: dv rr þ p ¼ e_r ¼ dr 2g v rh þ p e_h ¼ ¼ r 2g react ð28Þ Note that W0, F(n), M(n), and DrV are all negative quantities for the studied system and therefore Eq. (27) is positive. DISCUSSION The rate law for coupled reaction and creep, Eq. (27), can be represented in a simplified form as dn dt Dr G r20 diffusivity ð29Þ þ viscosityDr V The rate of progress is directly proportional to DrG, which only takes into account the far-field conditions and therefore expresses the degree of reaction overstepping in terms of ambient conditions (pressure and temperature). The rate of progress is modified by the relative efficiency of the diffusion (effective component diffusivity) and the viscous response of the matrix, 88 D. W. SCHMID ET AL. Table 1. Thermodynamic data and molar volumes from Holland & Powell (1998) calculated for the experimental conditions of 1000 C and 1 GPa. V [cm3 mol)1) Quartz SiO2 23.38 Forsterite Mg2SiO4 44.87 Duration [h] 1 9 )7873 3.85e-16 7e-5 where the former is accounted for by the first term in the denominator and the latter by the second term. The ÔslowerÕ term will be the rate limiting one. If there is no volume change involved, the reaction is entirely diffusion controlled. Interestingly only the diffusion term in the denominator shows size (radius) dependence. This size dependency implies that small reactive inclusions will tend to be creep controlled while larger ones will rather be diffusion controlled. Using the values given in Table 1, a time integration of the ordinary differential Eq. (27) was performed to obtain the evolution of the rim thickness with respect to time, Figure 3. From the analysis of the quartz in forsterite case the phenomenological coefficient of diffusion is estimated to be L = 3.85e-16 [mol2 s)1 m)1 J)1], which corresponds to an effective combined component diffusivity of D = 1.6e-16 [m2 s)1].1 Note that this effective component diffusivity was determined from the rim growth rate that was observed for the quartz in olivine arrangement under the assumption that matrix creep effects are negligible, i.e. Dr V ¼ 0. The obtained value is in agreement with the findings of Abart et al. (in press), who derived effective component diffusivities for the same rim growth experiments using a different approach that is based on the thermodynamic extremum principle. Based on the obtained phenomenological coefficient of diffusion we estimate the viscosity of the olivine matrix to be approximately 1e14 [Pas] or less. For such a case the rim thickness pffiffi shows the expected linear growth with respect to t. However, if the matrix viscosity is higher, then the rim growth is substantially reduced. The 1e17 [Pas] curve shows an example which is primarily creep controlled throughout the experiment. Yet, the 1e15 [Pas] curve shows both diffusion and viscous rate controlling effects. Initially the matrix viscosity is rate determining, but as time and rim growth progress diffusion becomes the limiting factor 1 The phenomenological coefficient of diffusion is related to the effective component diffusivity, Di, through Li ¼ ðXi =VÞðDi =RTÞ, where Xi is the mole fraction, V the molar volume of the material within which the diffusion takes place, R the gas constant, and T the temperature. Individual component diffusivities cannot be determined. However, an effective be obtained from combined component diffusivity, D, can en L ¼ ð1=Ven RTÞ Xen SiO2 DSiO2 þ XMgO DMgO , which yields D ¼ 2LVen RT: Rim thickness [μm] 8 DrG [J mol)1] L [mol2 s)1 m)1 J)1] r0[m] 6 12 18 24 36 48 80 Qtz in Ol log10(η [Pas]) 14 (O/Q) 14 15 16 17 10 Enstatite Mg2Si2O6 83.85 3 7 6 Ol in Qtz 5 4 3 2 1 0 0 50 100 150 200 250 300 350 400 450 500 sqrt (Duration [s]) Fig. 3. Time required for the growth of an enstatite rim of certain thickness for different effective matrix viscosities. Rim growth becomes substantially decelerated for matrix viscosities in excess of 1e15 [Pas]. Open circles indicate the rim thickness obtained for the two different matrix-inclusion arrangements in a single experiment. Note that with the exception of the 14 (O ⁄ Q) line this plot is produced for the quartz in olivine setting. 14 (O ⁄ Q) corresponds to an olivine in quartz experiment with a matrix viscosity of 1e14 [Pas]. The difference between the two configurations is marginal. The maximum duration given here is equal to the 80 h of the experiments of Milke et al., 2009. as can be seen from the pffiffilinear relation that develops between growth and t for longer run durations. Hence, creep control is especially important for the initial stages of rim growth when the diffusion distances are short and diffusion is therefore more efficient than during the later stages of rim growth when the reaction rim becomes thicker. The data from the olivine in quartz experiment plots between the 1e15 [Pas] and the 1e16 [Pas] lines, therefore putting the difference between quartz and olivine rheologies at one to two orders of magnitude under the given conditions. Hence, the relative viscosities of the quartz and the olivine matrix materials can be determined from this type of experiment. If the effective component diffusivities are known one can use them as rheometers. Note that the present formulation assumes a Newtonian (linear) viscous creep behaviour of the matrix. A power-law rheology would be more appropriate and hence the usage of these experiments as rheometers more intricate as pointed out by Morris (2002). In any case, it is important to realize that the rim thickness may contain information regarding the efficiency of diffusion as well as viscous creep. The point that the matrix viscosity effect is more pronounced in the early stages of rim growth is also 2008 Blackwell Publishing Ltd COUPLED DIFFUSION AND CREEP MODEL 89 10–6 log10 (Growth Velocity [mm/yr] (log10(Strain Rate [s–1])) 10–8 10 log10 (L [mol2 s–1 m–1 J–1]) Reaction rate dξ/dt [s–1] 10–7 –9 10–10 10–11 10–13 10 10 10 12 10 14 10 16 18 10 10 20 22 10 Viscosity (η [Pas]) 4 (–2) –13 3 (–3) –14 2 (–4) –15 1 (–5) –16 0 (–6) –17 –1 (–7) –18 –2 (–8) –19 –3 (–9) –20 –4 (–10) –21 10 11 Creep Controlled 12 n tio si an Tr 10–12 –12 Quartz –11 0.1 0.5 0.9 Olivine ξ Diffusion Controlled 13 14 15 16 log10(η [Pas]) 17 18 19 20 Fig. 4. Reaction rate as a function of effective matrix viscosity for various stages of reaction progress n; horizontal segments of the curves represent diffusion controlled regime, segments with negative slope indicate creep controlled regime. Note that the transition from diffusion control to creep control shifts to higher viscosity with reaction progress. Fig. 5. Contour plot of log10(growth velocity [mm yr)1]) in g (viscosity) and L (phenomenological coefficient of diffusion) space; isocontours are also labelled for log strain rate (in brackets). Olivine and quartz flow laws are plotted for the calculated strain rates and the experimental temperature of 1000 C. illustrated in Fig. 4 where for a given phenomenological coefficient of diffusion the progress rate is plotted v. viscosity. The three curves represent different stages of progress for the quartz in olivine configuration. For small viscosities the rate is independent of viscosity and entirely determined by the efficiency of diffusion. Once the viscosity reaches a certain transition value the progress rate drastically drops with further increase in matrix viscosity. The transition from diffusion controlled to creep controlled growth occurs at higher viscosities the more progressed the rim growth is. While Fig. 4 illustrates how the viscosity of the matrix restricts the growth of the rim it must be kept in mind that a total reaction stop will not be achieved in this idealized model since linear viscous materials always creep when a differential stress is applied. Therefore the question arises how the growth behaves with respect to time in the creep controlled regime. This end member case can be analysed by setting L fi ¥ in Eq. (27). The result is that the reaction rim grows exponentially in time. This was already derived by Morris (1992) for a similar case where he developed a model that combines the solid-state transformation of a spherical inclusion with the mechanical response of the surrounding matrix. Morris (1992) results show that in the limit of infinitely fast phase change kinetics, the inclusion growth is mechanically restricted and exponential growth of the sphere radius with time is observed. The dependence of the reaction rate on diffusion efficiency and viscosity and the competition between the two mechanisms is best illustrated with a map plot. Figure 5 contours the growth velocity of the outer interface (@rC =@t) for n = 0.01 and the values in Table 1 for the quartz in olivine configuration. The domains of the two rate controlling factors are separated by a relatively sharp transition zone as indicated by the dashed ÔTransitionÕ line. In the diffusion controlled domain the reaction velocity is independent of viscosity changes; in the creep controlled domain the reaction velocity does not depend on the efficiency of diffusion. The isocontour values are given for velocity as well as rate of deformation that is caused by the reaction progress (in brackets). These strain rates together with the temperature of the experiment can be used to evaluate flow laws for the two matrix materials. We use the laws from Hirth & Kohlstedt (2003) for wet olivine and Paterson & Luan (1990, synthetic quartz from silicic acid powder origin) for quartz. These flow laws restrict the region of applicability of the map in Fig. 5. For the estimated phenomenological coefficient of diffusion of L = 3.85e-16 [mol2 s)1 m)1 J)1] and n = 0.01 a strain rate of approximately 1e-6 [s)1] results, which corresponds, for the given temperature, to an effective viscosity of 1e14-1e15 [Pas] for the two matrix materials. This range of effective viscosities corresponds very well with the results that were obtained (Fig. 3) without the knowledge of any actual flow law. For the experimental conditions, the two flow laws lie in the transition region from diffusion to creep control and hence small changes in the viscosity can have significant effects on the rate of rim growth. As already pointed out the actual flow laws are non-linear and vary with strain rate, i.e. the effective viscosity 2008 Blackwell Publishing Ltd 90 D. W. SCHMID ET AL. decreases with increasing effective strain rate. Since the strain rate induced by the reaction decreases with reaction progress we expect that the effective viscosities are initially lower and towards the end of the experiment higher than predicted by the plot in Fig. 3 that assumes a constant viscosity value. While the two flow laws largely support our findings they contradict our experiments in terms of which of the two matrix materials is the stronger, i.e. more viscous one. The experiments show slower rim growth for olivine grains in quartz matrix but the flow laws predict the opposite. This may be due to the inaccurate knowledge of how strong the synthetic quartz is (see discussion in Luan & Paterson, 1992). Reactions that involve relatively large volume changes require matrix adjustments that cannot be accounted for by elastic material response and therefore require creep flow. The experimental conditions of 1 GPa and 1000 C correspond to relatively deep levels of the lithosphere. Regions that are colder and closer to the EarthÕs surface will be characterized by higher viscosities and therefore the closure due to viscous creep will be even more important. CONCLUSIONS Motivated by the experiments of (Milke et al., 2009) we have developed a model for the growth of an enstatite reaction rim at olivine-quartz interfaces that accounts for the systematic differences in observed rim thickness depending on whether olivine grains are embedded in a quartz matrix or vice versa. The reaction is characterized by a bulk volume change of )6%, too much to be compensated by an elastic matrix response. Rock deformation experiments that are run under the experimental conditions of 1000 C and resulting strain rates of 1e-6 [s)1] show that both quartz and olivine creep viscously (Paterson & Luan, 1990; Hirth & Kohlstedt, 2003). Therefore, our model couples diffusion (transport of species through the growing enstatite rim) with the creep response of the matrix. The resulting growth law shows the following characteristics. 1. The progress rate is proportional to the reaction overstepping. 2. The progress rate is controlled by the slower one of the two processes, either diffusion or creep. The transition zone between the two regimes is quite narrow. 3. Only the diffusion term is sensitive to the initial size of the reactive inclusion. For small sizes diffusion is efficient and reaction rate is likely to be creep controlled, depending on the actual values of the kinetic parameters (viscosity and efficiency of diffusion). For large sizes the inverse is true. 4. With progressive rim growth the diffusion distance grows and diffusion tends to become more important as a rate controlling mechanism. 5. If rim growth occurs without any volume change then the progress rate is not affected by viscous creep of the matrix and the usual linear proportionality between rim thickness and the square root of time results. This progress rate represents the upper limit; reactions with volume change and non-negligible matrix creep response will yield progress rates that fall below this maximum. 6. The importance of the viscous creep is directly proportional to the volume change of the reaction. 7. In the creep controlled regime the rim growth is exponential in time (cf. Morris, 1992). In terms of the experiments of Milke et al., 2009 our model explains the difference in rim thickness with a difference between the two effective matrix viscosities of about one order of magnitude. The actual values, 1e14-1e15 [Pas], correspond well with the range of published flow laws for quartz and olivine under the given conditions. Our experiments show that the synthetic quartz was mechanically stronger (more viscous) than the San Carlos olivine. The results of our analysis imply that natural coronas and reaction rims may contain information on both component diffusion as well as viscous creep of the matrix. Analogous to thermal closure (Dodson, 1973) reactions can be closed mechanically. As compared to our experiments, mechanical closure will be even more prevalent throughout crustal conditions where the effective viscosities are larger. ACKNOWLEDGEMENTS We thank three anonymous reviewers and K. Schulmann for their constructive reviews. This work was supported by a Center of Excellence grant from the Norwegian Research Council to PGP and through DFG project AB 314/2-1 (FOR 741). REFERENCES Abart, R., Schmud, R. & Harlov, D., 2001. Metasomatic coronas around hornblendite xenoliths in granulite facies marble, Ivrea zone, N Italy, I: constraints on component mobility. Contributions to Mineralogy and Petrology, 141, 473–493. Abart, R., Kunze, K., Milke, R., Sperb, R. & Heinrich, W., 2004. Silicon and oxygen self diffusion in enstatite polycrystals: the Milke et al. (2001) rim growth experiments revisited. Contributions to Mineralogy and Petrology, 147, 633–646. Abart, R., Petrishcheva, E., Fischer, F. D. & Svoboda, J., 2009. Thermodynamic model for diffusion controlled reaction rim growth in a binary system: application to the forsteriteenstatite-quartz system. American Journal of Science, v. 309, doi: 10.2475/02.2009.02. Ashworth, J. R., Sheplev, V. S., Bryxina, N. A., Kolobov, V. Y. & Reverdatto, V. V., 1998. Diffusion-controlled corona reaction and overstepping of equilibrium in a garnet granulite, Yenisey Ridge, Siberia. Journal of Metamorphic Geology, 16, 231–246. Barron, L. M., 2003. A simple model for the pressure preservation index of inclusions in diamond. American Mineralogist, 88, 1615–1619. Brady, J. B. & McCallister, R. H., 1983. Diffusion data for clinopyroxenes from homogenization and self-diffusion data. American Mineralogist, 68, 95–105. 2008 Blackwell Publishing Ltd COUPLED DIFFUSION AND CREEP MODEL 91 Carmichael, D. M., 1987. Induced stress and secondary mass transfer: thermodynamic basis for the tendency towards constant-volume constraint in diffusion metasomatism. In: Chemical Transport in Metasomatic Processes (ed. Helgeson, H. C.), pp. 239–264. Reidel, Dordrecht. Dodson, M. H., 1973. Closure temperature in cooling geochronological and petrological systems. Contributions to Mineralogy and Petrology, 40, 259–274. Fischer, F. D., Berveiller, M., Tanaka, K. & Oberaigner, E. R., 1994. Continuum mechanical aspects of phase-transformations in solids. Archive of Applied Mechanics, 64, 54–85. Fisler, D. K., Mackwell, S. J. & Petsch, S., 1997. Grain boundary diffusion in enstatite. Physics and Chemistry of Minerals, 24, 264–273. Fletcher, R. C. & Merino, E., 2001. Mineral growth in rocks: Kinetic-rheological models of replacement, vein formation, and syntectonic crystallization. Geochimica et Cosmochimica Acta, 65, 3733–3748. Guiraud, M. & Powell, R., 2006. P-V-T relationships and mineral equilibria in inclusions in minerals. Earth and Planetary Science Letters, 244, 683–694. Hacker, B. R. & Peacock, S. M., 1995. Creation, preservation, and exhumation of ultrahigh pressure metamorphic rocks. In: Ultrahigh Pressure Metamorphism (eds Coleman, R. C. & Wang, X.), pp. 159–181. Cambridge University Press, Cambridge. Hill, R., 1950. The Mathematical Theory of Plasticity. Clarendon Press, Oxford. Hirth, G. & Kohlstedt, D. L., 2003. Rheology of the upper mantle and the mantle wedge: a view from the experimentalists. In: Inside the Subduction Factory (ed. Eiler, J.) Geophysical Monograph, pp. 83–105, American Geophysical Union, Washington. Holland, T. J. B. & Powell, R., 1998. An internally consistent thermodynamic data set for phases of petrological interest. Journal of Metamorphic Geology, 16, 309–343. Joesten, R., 1977. Evolution of mineral assemblage zoning in diffusion metasomatism. Geochimica et Cosmochimica Acta, 41, 649–670. Kamb, W. B., 1961. Thermodynamictheory of nonhydrostatically stressed solids. Journal of Geophysical Research, 66, 259–271. Korzhinskii, D. S., 1970. Theory of Metasomatic Zoning. Clarendon Press, Oxford. Lamé, G., 1852. Leçons sur la The´orie Mathe´matique de LÕÉlasticite´ des Corps Solides. Bachelier, Paris. Lee, J. K., Earmme, Y. Y., Aaronson, H. I. & Russell, K. C., 1980. Plastic relaxation of the transformation strain-energy of a misfitting spherical precipitate – ideal plastic behavior. Metallurgical Transactions A-Physical Metallurgy and Materials Science, 11, 1837–1847. Lenze, A., Stockhert, B. & Wirth, R., 2005. Grain scale deformation in ultra-high-pressure metamorphic rocks - an indicator of rapid phase transformation. Earth and Planetary Science Letters, 229, 217–230. Liu, M., Kerschhofer, L., Mosenfelder, J. L. & Rubie, D. C., 1998. The effect of strain energy on growth rates during the olivine-spinel transformation and implications for olivine metastability in subducting slabs. Journal of Geophysical Research-Solid Earth, 103(B10), 23897–23909. Luan, F. C. & Paterson, M. S., 1992. Preparation and deformation of synthetic aggregates of quartz. Journal of Geophysical Research-Solid Earth, 97(B1), 301–320. Markl, G., Foster, C. T. & Bucher, K., 1998. Diffusioncontrolled olivine corona textures in granitic rocks from Lofoten, Norway: calculation of Onsager diffusion coeffi- 2008 Blackwell Publishing Ltd cients, thermodynamic modelling and petrological implications. Journal of Metamorphic Geology, 16, 607–623. Milke, R. & Heinrich, W., 2002. Diffusion-controlled growth of wollastonite rims between quartz and calcite: comparison between nature and experiment. Journal of Metamorphic Geology, 20, 467–480. Milke, R., Abart, R., Kunze, K., Koch-Muller, M., Schmid, D. W. & Ulmer, P., 2009. Matrix rheology effects on reaction rim growth I: evidence from orthopyroxene rim growth experiments. Journal of Metamorphic Geology, 27, 71– 82. Milke, R., Wiedenbeck, M. & Heinrich, W., 2001. Grain boundary diffusion of Si, Mg, and 0 in enstatite reaction rims: a SIMS study using isotopically doped reactants. Contributions to Mineralogy and Petrology, 142, 15–26. Morris, S., 1992. Stress Relief during Solid-State Transformations in Minerals. Proceedings: Mathematical and Physical Sciences, 436, 203–216. Morris, S. J. S., 2002. Coupling of interface kinetics and transformation-induced strain during pressure-induced solid-solid phase changes. Journal of the Mechanics and Physics of Solids, 50, 1363–1395. Mosenfelder, J. L. & Bohlen, S. R., 1997. Kinetics of the coesite to quartz transformation. Earth and Planetary Science Letters, 153, 133–147. Mosenfelder, J. L., Connolly, J. A. D., Rubie, D. C. & Liu, M., 2000. Strength of (Mg,Fe)(2)SiO4 wadsleyite determined by relaxation of transformation stress. Physics of the Earth and Planetary Interiors, 120, 63–78. Paterson, M. S., 1995. A theory for granular flow accomodated by material transfer via an intergranular fluid. Tectonophysics, 245, 135–151. Paterson, M. S. & Luan, F. C., 1990. Quazite rheology under geological conditions. In: Deformation Mechanisms, Rheology and Tectonics (eds Knipe, R. J. & Rutter, E. H.) Geological Society Special Publication, pp. 299–307. Geological Society, London. Rubie, D. C. & Thompson, A. B., 1985. Kinetics of metamorphic reactions at elevated temperatures and pressures: an appraisal on experimental data. In: Metamorphic Reactions Kinetics, Textures, and Deformation (eds Rubie, D. C. & Thompson, A. B.), pp. 27–79. Springer, New York. Taber, S., 1916. The growth of crystals under external pressure. American Journal of Science, 41, 532–556. Thompson, J. B., 1959. Local equilibrium in metasomatic processes. In: Researches in Geochemistry (ed Abelson, P. H.), pp. 427–457. Wiley, New York. Vernon, R. H., 2004. A Practical Guide to Rock Microstructure. Cambridge University Press, Cambridge. Watson, E. B. & Price, J. D., 2002. Kinetics of the reaction MgO+Al2O3 fi MgAl2O4 and Al–Mg interdiffusion in spinel at 1200 to 2000 degrees C and 1.0 to 4.0 GPa. Geochimica Et Cosmochimica Acta, 66, 2123–2138. Wheeler, J., 1987. The significance of grain-scale stresses in the kinetics of metamorphism. Contributions to Mineralogy and Petrology, 97, 397–404. Yund, R. A., 1997. Rates of grain boundary diffusion through enstatite and forsterite reaction rims. Contributions to Mineralogy and Petrology, 126, 224–236. Zhang, Y. X., 1998. Mechanical and phase equilibria in inclusion-host systems. Earth and Planetary Science Letters, 157, 209–222. Received 8 May 2008; revision accepted 24 November 2008.