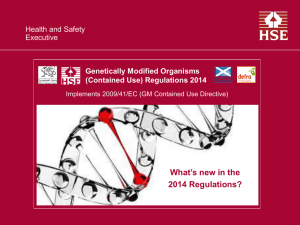

Biological agents Advisory Committee on Dangerous Pathogens Health and Safety

advertisement