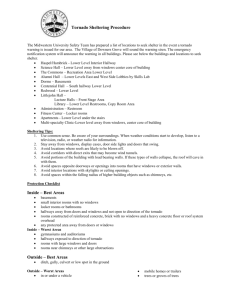

Taking Shelter from the Storm Includes Construction Plans

advertisement