U.S.-JAPAN TRADE IN CONSTRUCTION by TAKAFUMI CHIBA

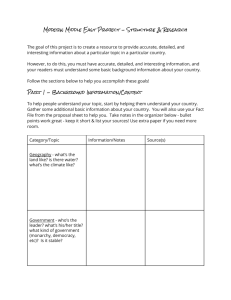

advertisement