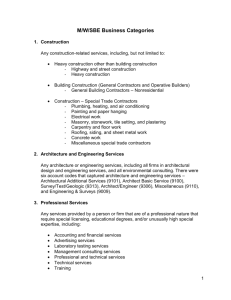

U.S. CONSTRUCTION AS A POTENTIAL ... FOR KOREAN INTERNATIONAL CONSTRUCTION INDUSTRY by

advertisement