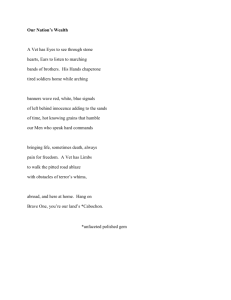

AN CHARLES HUGHEY EVANS

advertisement