Novel Polypyrrole Derivatives to Enhance Conductive Polymer-Tissue Interactions

advertisement

Novel Polypyrrole Derivatives to Enhance Conductive Polymer-Tissue

Interactions

By Paul M. George

BSE, Biomedical Engineering, Tulane University

MSE, Biomedical Engineering, Johns Hopkins University

SUBMITTED TO THE HARVARD-MIT DIVISION OF HEALTH SCIENCES AND

TECHNOLOGY IN PARTIAL FULFILLMENT OF THE REQUIREMENTS FOR THE

DEGREE OF

DOCTOR OF PHILOSOPHY IN MEDICAL AND ELECTRICAL ENGINEERING

AT THE

1~ lr

A t'ar'

·

T

!MAiACUl

l-l

Ttl'-

f'T

I

~

'T'

J'qTr

a*~"rmor-

~,T f'~T

'I 1, 1N~i1 UlllUPl,

W. ILtiINULUklY

T~'Frt'lrdN

lT~WrTfCr'T

MASSACSTTS INSituTE

OF TECHNOLOGY

JULY 2005

0CT

9 2005

LIBRARIES

( 2005 Paul M. George. All rights reserved.

The author hereby grants MIT permission to reproduce and to distribute publicly paper

and electronic copies of this thesis document in whole or in part.

Signature of Author:

J

Harvard-MIT Division of Health Sciences and Technology

,, y , 2005

Certified by:

Robert Langer, Sc.D.

Institute Professor

Harvard Division of Health Sciences and Technology

Thesis Supervisor

Accepted by

Mart a L.

ray, Ph.D.

Edward Hood Taplin Professor of Medical and Electrical Engineering

Co-Director, Harvard-MIT Division of Health Sciences and Technology

ARCHIVES

Abstract

Developing materials that interact effectively with surrounding tissue is a major

obstacle in sensor and drug delivery research. The body's natural immune response

prevents foreign objects from easily integrating with an organism. Without an intimate

link between a biomedical device and the proximate environment, reliable measurements

or delivery of molecules is not possible. Many of the current materials used for

biomedical applications are centered on inert substances and polymers that degrade in the

body but have limited functional capabilities. This thesis work addresses the need to

develop materials that are capable of interacting in biological environments.

Polypyrrole (PPy) is a conducting polymer that is a promising biomaterial for

drug delivery and sensing applications. Because PPy is a polymer that can be made in

degradable forms and because it can be stimulated electrically, it is an interactive

platform for biomedical applications. By accomplishing the following research

objectives, this thesis work could help develop an effective polymeric paradigm for tissue

interactions:

1) Develop a new method to effectively micro-pattern electrodeposited polymers and

metals for in vivo devices

2) Determine the optimal synthesis conditions of the conductive polymer, PPy, for

sensor and implant applications

3) Fabricate PPy tubes to be used as nerve guides to promote nerve regeneration

4) Modify PPy for neurotrophic factor drug delivery devices and antibody-based

sensing applications

Through the use of standard microfabrication techniques, the patterning template

upon which PPy is electrodeposited can be controlled precisely. By utilizing the growth

mechanism of PPy on these templates, three-dimensional polymer objects can be created.

Being able to micropattern the PPy and release the polymer generates the ability to create

implants and devices that are completely erodible in the body.

To develop the optimum conditions for sensor and drug delivery applications, PPy

implants were fabricated and implanted into rat cortical tissue. Compared to similar

Teflon implants, the electrically conductive PPy had preferable characteristics for

material integration in the cortex. Additionally, PPy tubes have been designed and

promoted peripheral nerve growth after tissue injury. By controlling the shape and

morphology of PPy, the polymer implants formed an interactive bridge with their

biological environment.

By incorporating bioactive molecules into the PPy matrix, materials for externally

controlled drug release and sensing devices can be designed. Drug delivery was

demonstrated through the integration of nerve growth factor (NGF), a neurotrophic

factor, into the PPy followed by triggered pulsatile release. Such neurotrophic factors

can be used to promote neural growth in peripheral and central nervous system injury.

Because PPy is easily modifiable through the use of dopants and control of its shape, PPy

provides a flexible platform for novel polymeric-tissue interactions.

2

Acknowledgments

Any body of research truly involves a team effort, and I have been blessed by the

numerous people who have made this work possible. I would like to sincerely thank my

advisor, Robert Langer, for providing guidance and mentorship throughout my doctoral

work. His insights into how research can make an impact in the lives of others and his

integrity as a researcher and a person have shaped my graduate studies and experiences.

David LaVan is another mentor that has helped to direct my research, and his friendship

and advice have been invaluable in my development as a researcher. I would also like to

thank the other members of my thesis committee, Dr. Joel Voldman and Dr. Alan

Grodzinsky, for their insight and assistance during my thesis work. I have also had the

privilege of working with Mriganka Sur whose collaborations have brought the cerebral

aspect into much of my research. The work with his lab has been some of the most

enjoyable of my doctoral work. Jason Burdick is another friend and mentor who has

contributed to my growth as a researcher and helped to direct my research to this point.

Without the interactions and guidance of all of these friends and colleagues, my graduate

work would not have been possible, and the knowledge that I have gained would have

been limited.

Equally important to me has been the support of my family and friends. My wife,

Sierra, has kept me grounded to what is truly important in life. Her belief in me, her love,

and her laughter have inspired me throughout my research and life. I have also been

blessed with parents, a mother-in-law, and an uncle-in-law who have provided the love

and encouragement to fulfill my dreams for which I am very grateful. My wonderful

friends have also kept me balanced and lighthearted throughout my graduate experience.

Many members of the Health Sciences and Technology community have also helped

along the way. Catherine Modica and Patty Cunningham have both been so supportive

and caring as I navigated through my graduate studies.

I am indebted to numerous other lab members have contributed along the way.

Dan Kohane, Steve Chen, and Yadong Wang have provided valuable insight, and I have

also worked with many great undergraduate researchers, Ellen Liang, Moira Kessler,

Anita Hegde, Phillip Alexander, and others, whose assistance has been tremendous.

Gwen Donahue has also provided important microfabrication expertise throughout my

work for which I am extremely thankful.

I would also like to thank the Whitaker Foundation, the Dupont-MIT Alliance,

and the NIH for their funding and support. Without them and other funding agencies,

research and the search for knowledge would not progress.

My graduate experience has been a wonderful one. I truly have been blessed to

have worked with so many caring, giving, and intelligent people.

3

Table of Contents

Abstract .......................................

...............................................................2

Acknowledgments ........................................

..............................................

3

Table of Contents ..............

1.

2.

4

Introduction...........................

..

.

...........................................................

6

1.1.

Biopolymers .........................................

1.2.

Conductive polymers .................................................................................. 8

1.3.

Polypyrrole................................................................................................ 15

1.4.

PPy applications........................................................................................ 25

1.5.

Specific aim s .........................................

31

1.6.

References .................................................................................................

32

Patterning ......

.............................

6

.

......... 45

2.1.

PPy growth................................................................................................

45

2.2.

Single-step 3-D electrodeposition.............................................................

46

2.3.

LIGA .........................................

47

2.4.

Micropatterning......................................................................................... 48

2.5.

3-D structures............................................................................................ 50

2.6.

M orphology ...............................................................................................

53

2.7.

References ..........

57

................................................................

3. Biocompatibility......................

4.

59

3.1.

Polypyrrole/Tissue interaction .................................................................. 59

3.2.

Experimental overview............................................................................. 60

3.3.

Electrodeposition ......................................................................................61

3.4.

In vitro study techniques ........................................................................... 63

3.5.

In vivo study techniques ............................................................................ 65

3.6.

In vitro study results.................................................................................. 68

3.7.

In vivo study results .........................................

73

3.8.

Conclusion ................................................................................................

77

3.9.

References ...........

79

.........

................... .......................................

PPy tubes ...........................................................................................

4

83

4.1.

Peripheral nerve regeneration ................................................................... 83

4.2.

PPy tubes................................................................................................... 88

4.3.

Formation of PPy tubes............................................................................. 89

4.4.

Sciatic nerve study .................................................................................... 93

4.5.

Future work....................................

100

4.6.

References ........................................

102

5. Drug delivery................................................................................... 109

6.

7.

5.1.

Mechanisms of drug delivery..................................................................

109

5.2.

Experimental overview ........................................

109

5.3.

Electrodeposition

111

5.4.

Stability studies ....................................................................................... 111

5.5.

Drug release studies ................................................................................ 112

5.6.

PC-12 cell studies ........................................

113

5.7.

Dopant stability.........................................

114

5.8.

Biotin/NGF attachment ........................................

115

5.9.

Molecule release ........................................

117

5.10.

PC-12 neurite outgrowth ........................................

118

5.11.

PPy drug delivery.................................................................................... 119

5.12.

Hydrogel drug delivery........................................

120

5.13.

tPA ........................................

120

5.14.

tPA release studies ........................................

120

5.15.

References ........................................

125

....................................................................................

Future directions.............................................................................

130

6.1.

PPy modification.....................................................................................

130

6.2.

RF applications of PPy...................................

130

6.3.

PPy neural scaffold ................................................................................. 133

6.4.

References ........................................

Appendix..........................................................................................

Biographical Information ........................................

5

135

136

141

1. Introduction

1.1.

Biopolymers

The versatility of polymers and their ability to interact with tissue have made them a

key fixture in the development of biomedical sensors and drug delivery devices

18-24

Another advantage of polymer-based biomaterials is the ease of control over degradation

properties, surface properties, and the mechanical properties of the materials

25.

With

greater control of biomaterial properties, more effective drug delivery and tissue

interactions are possible

26.

Many polymers have been designed to allow for controllable degradation 25.

Depending on the application, the requirements of the polymer can vary greatly. Some

applications require a long lasting polymer and others require a degradable form. The

development of various degradable polymers has allowed for the release of bioactive

molecules that directly effect the surrounding environment. Polyesters such as poly(dllactic a cid) (PLA) and poly(glycolic acid) (PGA) w ere found to degrade in b iological

environments into naturally occurring products

poly(DL-lactic-co-glycolic acid) (PLGA)

28

27.

Other biomedical polymers such as

and rosin-based materials

29

have been

designed to undergo bulk degradation and have good biocompatible properties. Over the

past 20 years, biodegradable polymers such as the ones mentioned above have been

characterized in biological environments 30

Biodegradation of polymers may occur through various means. Many degradable

polymers are broken down through hydrolysis of components of the backbone (scission)

30.

This can occur either enzymatically or randomly without requiring enzymes.

6

Hydrophobic

material

polymers degrade at the surface because water cannot reach inside the

as opposed

degradation.

to hydrophilic

polymers

which can swell resulting

Polymers with strongly bonded backbone

hyrdolyzable groups require long time frames to degrade.

biodegradable

polymers are polylactides

glycolide and polyhydroxybutyrates

30.

in bulk

(ie C-C bonds) with no

Two of the main families of

including copolymers

of polylactides

These degrade though scission and degradation at

the surface.

_a

aa

aa

Hydrogels are another material

that has been developed to carry and

release drugs

21,31.

Hydrogels allow for

greater control of polymer formation

and degradation.

Some systems have

been developed for in situ crosslinking

controlled by ultraviolet (UV) light

32.

IIg

JljJ\

g

Others have been designed to release in

response to pH or electrical signals

The

incorporation

33.

of cells such as

.............................

osteoblasts into these gels has also been

developed

for

tissue

engineering

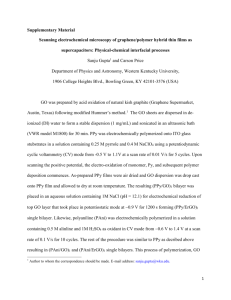

Figure 1.1. Images of biodegradable

polymers at various degradation time

points. PGS at A) 0 days B) 7 days

C) 14 days D) 21 days E) 28 days F)

35 days. PLGA at G) 0 days H) 7

days I) 14 days J)21 days. The PGS

material maintains its shape and

properties more effectively than

PLGA as it degrades. From 6.

..

34

app IIcatlOns .

Materials

have

also

been

designed to match the environment into

which they are placed.

with

Ideally they

7

would

keep these

properties

throughout their

degradation

(See

Figure

1.1).

Polyl(glycerol sebacate) (PGS) has been shown to maintain its geometry and lose

mechanical stability much more slowly than PLGA as it degrades 6,35.

Polymers for biomedical applications have evolved from mostly inert substances

such as teflon to more interactive degradable polymers such as hydrogels and PGS.

Currently, materials are being developed that can dynamically interact with their

environment. Finding polymers that are able to reduce the foreign-body reactions of the

body's immune system and promote positive polymer-tissue interfaces is important for

effective device applications

36.

MEMS devices can have pulsatile release patterns once

in the body 37, and polymeric systems can also be developed for externally modulated

delivery 38.

Conductive polymers are one material being considered that can be

interactively controlled once in the body. Also, because of their ability to deliver charge,

conductive polymers are ideal for more effective interaction with neural cells.

1.2.

Conductive polymers

1.2.1. Conductivepolymer classes

Two general types of conductive polymers exist.

One group is a composite

material that uses a polymer to hold together conductive filler such as metal flakes or

carbon black.

The second group consists of a set of polymers whose backbone

intrinsically propagates charge, making the polymer itself conductive (See Figure 1.2) 39.

One problem with conductive polymers made with a conductive filler is that the need to

use a large percentage of filler creates poor mechanical properties

8

40.

The ability to

control conductivity, the majority of the charge carriers, and to have a completely

polymeric system makes the intrinsically conductive polymers more appealing for

biomedical applications.

Conductive polymers such as polpyrrole (PPy), polyacetylene, polythiophene, and

polyaniline have experienced much development over the past twenty years. These and

other conductive polymers such as polythiopene have been used in a variety of

applications ranging from sensors to capacitors to light-emitting diodes and batteries

41-46.

Additionally, the ability to alter properties of the polymer by incorporating dopants into

the polymer matrix creates more applications for these materials

47,48.

ppy and other

conducting polymers can also be cycled from the neutral or insulating state to the

conductive or oxidative

Semiconducting and Metallic Polymers

through

state

the

applicationof charge.

The

/

cis-polyacetylene

trans-polyacetylene

poly(p-phenylene)

poly(1,6-heptadiyne)

conductive

polymers include a group

of

conjugated

hydrocarbon and aromatic

heterocyclic

polymers

N

including

poly(p-

N

H

H

poly(propriolic

anhydride)

polypyrrole

phenylene),

phenylene

poly(pvinylene),

poly(p-phenylene

sulfide),

PPy,

s

s

polythiophene

and

poly(quinoline)

Figure 1.2. Chemical structures of various conducting

polymers. From 12.

9

polythiopene. Polyphenylenevinylene (PPV) has a structure between polyacetylene and

polyphenylene. It has garnered interest because it can be developed in oriented forms 4 9.

PPy and polyaniline are two of the most common because of their high

conductivity, ease of modification, and stability

48,50-54.

Polyaniline is not only a very

stable conductive polymer, but it can also be modifiend through dopants and by altering

the pH of the medium in which it is deposited

55,56.

Both PPy and polyaniline can be

polymerized through electrodeposition which allows greater flexibility in the fabrication

of these materials.

1.2.2. Conjugatedpolymers

1.2.2.1. Electron classification

- antibondn

Binding

Electrons are classified into one of four

categories in materials.

essential for conductivity.

The

rgy

'rT-antbonding//

electrons are

Core electrons are

/(non-/b/ond/ing

/////

tightly bound to the nucleus and remain on the

elements nucleus with few exceptions.

a

electrons are found between two bonded nuclei

,

din

and are responsible for keeping the structure

Figure 1.3. Binding energy levels of

together.

s, n, and n electron states for organic

molecules From

Fro 33

molecules.

n electrons

are thought of with

heteroatoms (ie. O, N, S, P, etc) and have an

affect on the reactivity of a bond. nt electrons are involved in binding but form weaker

and less-localized bonds than the internuclear bonds of a electrons. The xrelectrons are

10

thought to be moving in the field created by

the nuclei and the other electrons,

E

and they

require the least amount of energy to jump to

the next energy state (See Figure 1.3).

lnsulalor

The

Semiconductor

double bond between the C units gives rise to

the conjugated bond. The

1t

the

atom

one

electron

per

conduction possible.

1t

electron serves as

that

Conducting

substance

makes

Polymers which contain

electrons are known as conjugated polymers.

Figure 1.4. Energy gap

representation of an insulator,

a semiconductor and a metal.

From 2

logo (S/em)

1.2.2.2. Band theory

PPy

PAN

(CH),

PT

Others

A

(a)

In

band

theory,

an

insulator

(b)

has

(e)

3

completely

filled

and

completely

empty

energy bands with a large gap between

its

2

(d)

1

0

.1

(el

.2

(I)

(~

(g)

(hI

(m)

(nl

(i)

(q)

(0)

(P)

(r)

(s)

{JI (1<1

.3

.1,

energy bands.

A conductive

material has a

.5

.6

(I)

(w)

.]

number

energy

of free electrons

band

(See

in an incomplete

Figure

1.4).

At

.8

.9

.10

(ul

(v)

(x)

(y) (z)

.11

.12

.13

temperatures

higher than 0 K, electrons can

-14

-15

jump into the higher energy bands creating the

possibility of conduction.

Depending on the

size of the electron gap, the material can be an

insulator

or a semiconductor.

In materials

with electron gaps of approximately

leY

or

11

Figure 1.5. The conductivity of various

conducting polymers at 24 °C. (a-e) forms

of [CH(b)]x, (f-k) forms of PAN, (I,m) PPy

doped with PF6, (n) Ppy (TSO), (o,p)

forms ofPT, (q) PPY (H2S04), (r) PPP

(AsFs), (s) 84Kr-implanted

Poly(phenylenebenzobisoazole),

(t-z)

undoped versions of the respective

polymers. From 2.

below, the number of electrons that are excited at room temperature becomes more

significant, and they are thought of as semiconductors. In general the conductivities of

semiconductors can range from 103 to 10-9 S/cm. Metals generally have conductivities

along the lines of 106 S/cm, and insulators are at the other end of the spectrum with

magnitudes around 10-22S/cm. Most semiconductors are inorganic, crystalline solids, but

conjugated polymers also display semiconductor properties without the inorganic,

crystalline structure.

Doping with an anion or cation can be used to increase the

conductivity of these polymers (See Figure 1.5)

2.

Doping for inorganic and crystalline

solids is slightly different than doping in conductive polymers.

For inorganic

semiconductors, the dopant is at the level of parts per million whereas with conducting

polymers, the dopant can form up to 50% of the polymer weight.

1.2.2.3. Band theory for conductive polymers

Rigid band models like those used in semiconductor physics are not completely

accurate for conductive polymer physics. At first it appears that the conductive polymers

have similar properties as inorganic crystalline semiconductors, but the movement of

electrons varies between these two types of materials. In conductive polymers, oxidizing

or reducing the material does not create free electrons or holes at the conduction bands.

This is because structural deformation occurs along the polymer backbone, where the

transfer of charge occurs, creating areas more likely to transmit charge.

Conductive polymers all have It-conjugatedsystems with alternating single and

double bonds along the polymer backbone. They are unusual because they can conduct

without having partially empty or filled bands.

12

For conductive polymers, when an

electron is excited from the valence band, a polaron is created. Unlike traditional band

theory, the hole that the electron leaves is not completely empty.

Instead, partial

delocalization takes place and results in a structural deformity from several of the

surround monomer units to balance the energy level created by the electron, thus

polarizing the nearby material which transforms into a new equilibrium condition; hence

the term polaron. In PPy, bipolarons form and the change effects approximately four

monomer units 57.

In the doping process, defects are generated that form radical cations or anions

which are also polarons.

A polaron consists of two defects:

a charged defect

accompanied by a neutral defect, also known as an ion and a radical.

Within this

framework, two types of conductive polymers exist: those with a degenerate ground state

(ie. trans-polyacetylene) and those with a non-degenerate ground state (ie. PPy). For the

polymers with degenerate

ground states, the initial

charge forms a polaron,

and a subsequent charge

b)

will

create

polaron.

polarons,

another

The

N

two

however,

H

c)

H

N

H

N

H

H

H

N

N

H

H

Deformatio

Coordinate

degenerate to form two

charge solitons. For nondegenerate

polymers,

Figure 1.6. A schematic of a) a polaron and b) a bipolaron on

a PPy chain. c) The bottom schematic represents the

deformation of the polymer lattice created from the charge

defects. From

16,17

however, solitons are not

13

formed with two charges, but pairs of defects are created called bipolarons. With the

degenerate polymers the energy level for the distorted state is equivalent to that of the

original structure. For the non-degenerate materials the energy level of the distorted state

is not equivalent which causes the bipolaron to form with two charges to maintain

balance

7.

For non-degenerate systems (PPy, polythiophene, etc.) at low doping levels,

charges are stored as polarons and bipolarons. The polaron is the radical cation or anion

accompanied by the lattice distortion resulting from the charge (See Figure 1.6). PPy is a

highly disordered polymer with as many as one defect for every 3 rings 17. These charge

defects create an electrically conductive partially filled band. Bipolarons are formed

when two polarons form on the same polymer chain. Another method of transport occurs

when the polarons and bipolarons hop to nearby chains to carry the electric current.

When PPy is oxidized and becomes more conductive, it is a polycation with many of

these delocalized positive charges on its backbone which are countered by dopant anions.

The function

of

polarons and bipolarons

can also be considered

with band gap analysis

(See Figure 1.7). When a

polaron is formed it forms

two

energy

states

from

the

center of the gap.

An

equidistant

+9

-

-

®

e

___

1////////////////1///IIiA

///

F/77///////7/I///

b e

a

Figure 1.7. Energy levels of a) soliton (neutral, positively,

negatively charged states); b) polaron (neutral, positively,

negatively charged states); c) bipolaron (postively and

negatively charged states). From 7.

14

electron or hole polaron can be formed with the electron polaron having the lower energy

state occupied by two electrons with opposite spins. In bipolaron formation, both energy

states are occupied by two electrons with opposite spin; or if it is a hole formation, both

energy states are empty. In the case of a soliton, only one energy state is formed in the

center of the gap 7.

To maintain conductivity valence electrons must move to conduction band

through the gain of energy. The product of the carrier mobility (), the charge (q), and

the concentrations of carrier (n) is the conductivity (a).

o=

*q * n

For conductive transport the polarons and bipolarons must be able to overcome the

energy barrier and hop from chain to chain.

This interchain hopping is the second

component of charge transport in conductive polymers.

1.3.

Polypyrrole

1.3.1. Background

Finding a conductive substrate with positive tissue interactions is an essential step

for advancing polymeric sensor and drug delivery designs.

Pyrrole is a 5-member

heterocyclic compound (See Figure 1.8). It can be found in heme and chlorophyll and is

produced by either of two production methods: 1) reacting furan with ammonia or 2)

dehydrogenation of pyrrolidine 58. PPy was first synthesized in 1916 where it prepared

by the oxidation of pyrrole to a powder known as "pyrrole black". In 1968 it was first

15

Figure 1.8. PPy with counter ions (A-) to balance charge. From .

electrochemically deposited 59. PPy (structure seen in Figure 1.8) is an electrodeposited

polymer that can be doped with various agents to alter its physical, chemical and

electrical properties

18,60-65.

Additionally, the properties of PPy can be controlled by

plating under various conditions

66-68.

One of the main advantages of PPy is its stability.

Its conductivity decreases only 20% a year in an unprotected environment. It can also

withstand temperatures of 100-200°C depending on dopant and is stable in acids 16

The ability to control PPy's surface properties such as wettability and charge

density creates the potential for modifying tissue interactions with the polymer 69. The

power to alter the properties of PPy through its dopants also adds versatility not seen in

other conductive polymers and makes it appealing for biomedical applications.

Additionally, PPy can be used to electrically depolarize neurons which has been shown to

modify signal transduction pathways and maintain signaling activity over time 70

providing another method to interact with surrounding neural tissue. PPy has been

studied extensively for biomedical purposes, and the ability to form an erodible form

makes PPy an attractive possibility for sensor and drug delivery applications

71,72.

The

erodible forms that have been developed further increase the scope of biomedical

applications including polymeric devices and neural scaffolds

applications, an erodible or stable form may be desirable.

16

72,73.

Depending on the

1.3.2. Conductivity

One property of PPy that can be modified by altering the dopant anion is

conductivity. Conductivity of PPy can range from those of insulators with almost no

conductivity (10-5 Q-Icm-I) to 100 n-Icm-I

17.

Doping ions help to decrease the band gap

between the energy levels (See Figure 1.9). PPy is conductive because of the ability for

electrons to hop along the polymer chains and across interchains due to the x-conjugating

bonds. By using smaller counter anions with coplanarity with the polymer chains, the

conductivity can be increased

47.

Dopants such as hydrogen peroxide, polyethylene

oxide, dodecylbenzenesulfonate, and salts containing transition metal ions have all been

used

64,65,68,74.

Studies have found that longer deposition times, lower plating potentials

and temperatures, and higher concentrations of monomer and electrolyte are favorable for

conductivity and stability

75.

Other modifications such as increasing the roughness of the

plating surface has also been shown to increase conductivity

The addition of water

U U

Figure 1.9. Band structure

representation of Ppy and how it is

modified with doping: a) no dopant, b)

intermediate doping level - bipolarons

are non-interacting at this point, c) 33%

dopant per monomer, d) 100 % dopant

per monomer. The material has

changed from an insulator with a band

gap of 4.0 eV to a semiconductor with

full doping at l.4e V. From II.

a)

17

47.

+

~

+

~

•

b)

c)

d)

into the electrodeposition solution also produces a more conductive polymer possibly

because water serves as a better proton scavenger than PPy in the solution 76.

Two of the most common dopants that are co-deposited with PPy are polystyrenesulfonate (PSS) or sodium dodecylbenzenesulfonate (NaDBS)

62.

PSS/PPy and

NaDBS/PPy polymers have been used in many applications ranging from actuators to

neural electrode coatings to neural substrates

63,73,77-79.

PPy's

attractive choice for sensor and drug delivery applications.

properties make it an

The ability to dope the

polymer with various molecules and stimulate it electrically creates novel methods for

drug delivery. The conductivity of PPy also creates the opportunity to sense specific

molecules by monitoring changes in the properties of PPy directly or remotely using

radio frequency (RF) technology.

By further exploring the ability to manipulate and

monitor the properties of PPy, more advanced interactions with its surrounding

environment can be achieved.

1.3.3. Deposition techniques

One advantage of conductive polymers is the myriad of methods to produce them.

PPy can be deposited through electrodeposition, chemical bulk polymerization, or vapour

phase polymerization. One method for chemical deposition is to use an organic solvent

such as m-cresol and deposit the polymer film of PPy doped with dodeclybenzene

sulfonic acid

80.

The coating is achieved through the spreading of the conductive

polymer solution onto the surface while the solvent phase evaporates to leave a

conductive coat. This has enabled PPy to be spin coated onto glass substrates with

controlled thickness

81.

Additionally, a dip coating technique has been developed where

18

a polymer containing electron acceptor/initiators

(ie. FeC13 , CuCI2) is placed on the

substrate prior to the vapor deposition. The dip-coated substrates were then placed in the

presence of a dry saturated vapour of the monomer pyrrole for varying periods of time,

and PPy deposits onto the substrate as a film 82. Other methods such as UV-photoinduced PPy formation and plasma polymerized formation have also been performed to

form PPy films 83,84

Electropolymerization of the polymer from a solution through a redox reaction is

another method for polymer production. For aniline and pyrrole chemical polymerization

can occur with the use of an oxidant such as Fe3 + ions or ammonium sulfate 85. Both

chemical

synthesis

and

electrodeposition

have

advantages

and

disadvantages.

Electrodeposition requires a conductive surface, but through the use microfabrication, the

shape of the polymer can be intricately controlled.

Additionally, electrochemical

polymerization allows for more accurate control of polymer thickness and morphology as

well as producing a more pure polymer 8.

For the electrodeposition technique, the pyrrole monomer is mixed in an aqueous

solution, and a potential is applied between the working and reference electrode. The

polymer can be applied with a potentiostatic technique (voltage held constant), a

galvanostatic technique (current is held constant), or potentiodynamic method(voltage is

cycled)

86.

The polymer forms on the anode as an oxidation-reduction reaction occurs.

The anodic oxidation results in a flux of charge and/or neutral species as the polymer

forms 87. Plated PPy remains on the electrode surface while subsequent deposition

continues which shows that the PPy is conductive enough to participate in further

monomer oxidation.

In electrodeposition, doping involves a redox reaction as the

19

polymer forms.

For conjugated polymers, polymers are oxidized or reduced at lower

potentials than the monomers 44.

During the electrodeposition it is important that the working electrode does not

oxidize as the polymer is forming onto it 59. Various groups have discovered methods to

more common metals (Fe, Al, Zn) and not disturb the electrodeposition 59,88. This has

permitted the deposition of PPy onto metals other than the typically inert electrode

materials such as Au and Pt. Techniques such as pulse profile electrochemical deposition

have also been developed to reduce the concentration gradient at the electrode surface

and to prevent diffusional mass transport hindrances to the electrode surface 89.

All of the techniques (vapour deposition, chemical deposition and electrochemical

polymerization) allow for the creation of thin PPy films; however, through the use of

electrodeposition, thick films can also be created. Film thickness is proportional to the

charge used to plate the polymer. It has been shown that the growth of PPy is under

electron-transfer control and self-quenching protonation of the monomer may occur 76.

Traditional electrodeposited PPy is insoluble and infusible because of strong inter- and

intra- molecular interactions and crosslinkings 45. All of these methods yield a stable PPy

film on the desired substrate.

1.3.4. Formation mechanism of electrodeposited PPy

The structure of PPy is a chain of mainly 2,5 coupled aromatic units. PPy is

classified as an aromatic polymer because electrons can cycle around the alternatively

double and single-bonded, ringed carbon structure.

PPy's polymerization proceeds

through an anodic oxidation. The exact mechanism of PPy formation is still debated, but

the basic paradigm is described here. The formation of the polymer begins with an

20

oxidation step creating a cation radical. The cation radical then joins other cation radicals

through a coupling reaction with two stages. The coupling occurs at the most reactive

sites of the cation radicals, the carbon atoms (See Figure 1.10). The first stage of the

coupling is the joining of pyrrole monomers to form dimer intermediates, and the second

steady state coupling reaction is the linking of the pyrrole monomer with oligomeric and

polymeric pyrrole species

8,90.

The monomers are linked by eliminating the two

hydrogens and linking the carbons from which the hydrogen was removed.

For every

three to four polymer rings there is an anion molecule to counter the positive charge

created by the polymer chain units. In summary, the formation of PPy occurs through an

initial oxidation step, followed by a coupling step and then the elimination of H+ ions

(deprotonation), and the cycle is repeated as the polymer forms. The pyrrole monomer

donates an electron to the anode, and the following series of chemical and electron

transfer

reactions

creates

the

polymer

at

the

anode

surface.

During

the

electropolymerization of PPy, the pyrrole dimer has a lower oxidation potential than that

of the monomer, and because of this, monomer units of pyrrole are coupled through

oxidation to the polymer chain. Additionally, as the polymer chain forms, approximately

every three monomer units creates a negative charge which is balanced by the

incorporation of anion dopants into the PPy.

Alternate electrochemical polymerization processes have been offered as well.

One states that the polymerization is begun with the loss of two electrons and a proton

from the pyrrole molecule, and the intermediate is dimerized by a neutral pyrrole

molecule resulting in the loss of a second proton (See Figure 1.1la) 91. Another possible

mechanism is that a cation radical reacts with a neutral molecule to form a cation dimer,

21

1a -

[7

+ e-

+

~~~2_ f11 +2H

H

H

H

H

NH+

--g

+

2H+

+e~H

H n+l

'~n

Figure 1.10. Most widely accepted proposed mechanisms of PPy

electrodeposition. From 2

b)

a)

'

(2a)

H

N

N

~N

NN

H

;I

H

N

H

H

H;

H

H

i

H

N

X

NI

I

+

i

1N+

H

N

\

H

I

I

I'1n~~~~~~~~

N

(2b)

e

H\

H

N

7

H

H

H

N+-N

H

N

H

H

H

Figure 1.11. Alternative proposed methods for PPy electrochemical polymerization. a)

Polymerization begins with the loss of 2 electrons and a proton. The intermediate is

then dimerized by a neutral pyrrole and loses a 2 nd proton. b) The cation radical reacts

directly with a neutral molecule. From 8.

22

and the cation dimer loses a second electron and two protons when forming the neutral

dimer (See Figure 1.1 b) 92. The fact that the first model (See Figure 1.10) corresponds

with the drop of pH observed during polymerization and is in agreement with the number

of electrons used in the reaction make it the most widely accepted paradigm 93.

1.3.5. PPy modification

Ease of modification through dopants has made PPy a popular material to

fabricate. Apart from the dopants used, electrodeposition conditions and alteration of the

chemical structure have resulted in various forms of PPy. The wide range of properties

that can be controlled by altering aspects of PPy formation make the polymer an ideal

material for many applications. Below are several fabrication factors that can affect the

characteristics of PPy.

The solvent in which the PPy is electrodeposited is important for chemical

properties.

Conductivity and mechanical properties can be altered by using various

solvents and altering the amount of water in the plating solution. Conductivity can also

be changed just by modifying the percentage of water. Although the mechanism is not

understood since the chemical compositions are identical, it is believed to correspond

with changes in the polymer unit chain length 93. The presence of water vapour during

electropdeposition decreases the conductivity of PPy by decreasing hopping of electrons

across the polymer 94

Film formation is also proportional to activity of hydrogen ions, anions and the

monomer concentration. It has been found that agitation of the solution can decreases the

23

plating rate because hydrogen ions on the surface might have a catalytic effect. One

group suggests that the anion forms an intermediate species with the pyrrole 9.

Another method for PPy modification is to functionalize the pyrrole monomer by

substituting a desired group in place of the hydrogen molecule. The addition of the new

group can have a great influence on the properties of the polymer. For example, if the

PPy is formed with N substitutions, the conductivity normally drops 5 to 6 orders of

magnitude. This is believed to be due to the fact that the substituition blocks PPy rings

from residing within the same plane 2

1.3.6. Charge transport

Conjugated polymers such as PPy have various oxidation levels that can be

manipulated through the removal of electrons (oxidation) or the addition of electrons

(reduction) by the application of a voltage.

For approximately every three pyrrole

monomers, a positive charge forms and a counter anion is incorporated into the polymer

to bring about charge neutrality. For large dopants such as NaDBS, when the pyrrole is

reduced (a negative voltage applied between the polymer and reference electrode in a

solution) cations from the solution flow into the polymer to neutralize the charge, and the

polymer expands. If the dopants are smaller anions, when the polymer is reduced the

negatively charged dopants will flow out of the polymer into the solution to equilibrate

charge. The ability to change the volume of the PPy has been used to create actuators 96.

It has been proposed that electrons move through PPy by two methods. The first

method involves movement of current across mobile charge carrying regions, polarons

and bipolarons.

Dopants ionize the polymer chain and create a polaron.

24

As dopant

concentration increases more polarons are formed and eventually bipolarons form.

Electrons can then move across a single chain by movement of these charge carrier

regions.

The second method occurs when bipolarons or polarons from two separate

polymer chains reside in the same plane. Electrons, then, travel from polymer chain to

polymer chain by interchain hopping, producing spinless conductivity 97. These two

methods, 1) transfer of polarons and bipolarons throughout a single polymer chain and 2)

hopping of electrons from chain to chain, account for transport of charge in PPy

17.

The

dominant method of charge transfer depends on the type and the concentration of the

dopant in the film

98.

The conjugated backbone of alternating double and single bonds

allows the charged species to move along the backbone, resulting in an electrically

conductive polymer.

1.4.

PPy applications

1.4.1. Technology applications

Several kinds of metallic/PPy (such as Cu-PPy) blends have been made for

possible technological applications 99. By forming stable PPy blends, conductive

polymers can be more widely used in areas ranging from digital displays to integrated

circuits.

Batteries have been one area of development of PPy.

The polymeric battery

operates by the oxidation and reduction of the PPy backbone. For a PPy/lithium battery,

the battery is charged by applying a positive voltage on the PPy with respect to the

lithum, and the PPy is oxidized. Anions are loaded into the PPy from the electrolyte and

at the same time lithium ions from the electrolyte are electrodeposited on the lithium

25

component. When the battery is used, the electrons flow from the lithium, and the ions

flow back to the electrolyte. These lithium ions pass through the load and go into the PPy

which reduces the oxidized PPy. The cycle can be repeated numerous times 00.

1.4.2. Biomedical applications

Over the past 20 years, biomedical applications of PPy have been more closely

studied. Because of its electrical properties, several studies have looked at its interactions

with neural cells

73,101.

The electrical properties of the polymer have allowed for use as

electrode modification for better tissue interactions

61.

PPy has been used as a sensor

through the immobilization of biomolecules on the polymer surface

102.

Additionally, the

pyrrole monomer, itself, has also been modified to allow for more stable sensing

applications

103

1.4.2.1. Biocompatibility

Biocompatibility studies of various conductive polymers have been performed.

Subcutaneous studies of polyethylene and polyaniline films in Sprague Dawley rats have

shown no provoked inflammatory responses

104.

The tissue reaction to PPy-coated

polyester fabrics has been looked at through subcutaneous implantation in SpragueDawley rats. No large inflammatory response was observed 105. PPy composite materials

have also been studied for biocompatibility. Alkaline and acid phosphatase secretion,

staining of macrophage, and histology of the tissue were the common methods for

examining the tissue response to PPy.

Subcutaneous implantation of PPy/poly(DL-

lactide and PPy/poly(DL-lactide-co-glycolide)

26

resulted in no more inflammatory

response than PLGA alone, which is one of the most widely used biodegradable polymers

in biomedical research 101. The biocompatibility studies have not examined stand-alone

PPy in neural tissue which is one area that needs to be addressed before neural

applications can be developed.

One advantage of PPy is that biodegradable forms have been developed. In one

form of erodible PPY, functional groups were added as a side chain

72.

There has also

been a pyrrole modified with a thiophene for stability with three pyrrole units joined by

ester linkages and a aliphatic linker 06. The formation of biodegradable PPy is desirable

to avoid chronic inflammation and so that a device will not remain in the body after the

desired application is performed.

1.4.2.2. Electrical interactions

PPy has been studied as a possible substrate for cultured cells.

Through

stimulation, it has been shown that PPy can modify the DNA synthesis of adherent cells

69.

This allows for more control over the shape and function of cells.

Another

characteristic that can be modified to enhance tissue interactions is the dopants used

during PPy formation.

By using biomolecules as dopants (laminin nonapeptide,

CDPGYIGSR, and fibronectin fragments, SLPF), better in vitro adhesion to the

electrodes was obtained 5. The ability to control the surface and composition of the PPy

surface could help prevent encapsulation - the formation of a non-conductive organic

layer.

The effect of dopants to promote or deter cell growth is one area that could

provide more insight for biomedical applications of PPy.

27

PPy has been utilized as a coating to obtain better tissue interactions.

its biocompatibility

Because of

and surface texture, it has been coated onto microfabricated

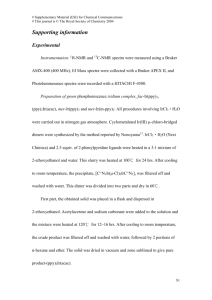

probes to enhance the recording signal (See Figure 1.12)

5,79.

neural

The increased surface area

that the polymer provided helped to decrease the impedance of the electrode and facilitate

neural recording.

Polystyrene sulfate (PSS) has been a common dopant because of its

good biocompatibility

and physical properties of the film

neural microelectrodes

and neural tissue is important to obtain long term recording from

73.

The interface between

neurons.

Figure 1.12. PPy coated on recording sites of microelectrode arrays to enhance

tissue interactions. Various thicknesses have been used to try to find optimal

recording impedance. Thickness corresponds to total charge delivered. From 5.

Electrical stimulation is a method of interacting with cells.

electrical

controlled.

69,73,110

stimulus, cell migration

101,

maturation

108,

By application of an

and DNA synthesis

109

can be

Work has also been done to utilize PPy to modify cells and their behavior

through the application of an electrical stimulus.

shown to enhance neutire outgrowth

Stimulation of the PPy has also

with possible nerve regeneration

28

applications

13.

The ability to dynamically interact with the surrounding environment is a major

advantage when using conductive polymers.

1.4.2.3. Nerve guides

Nerve guides made from synthetic materials have been used to help promoted

nerve growth after nerve injury. Current surgical techniques for nerve repair include

using a sacrificial replacement nervee to repair the damaged nerve. Because of PPy's

electrical conductivity as well as the ability to manipulate its characteristics with various

dopants, it has great promise for enhancing restoration of lost nerve function.

Groundwork for the use of PPy in the repair of nerve injuries began with the study of

neurite outgrowth enhancement of PC-12 with PPy stimulation 73. Because the polymer

itself is conductive, electrical stimulation can occur at a localized site instead of a more

1A

E

M

rue

e·...

.e

1B

1C

e

..... .....

'..,...

.

E = Electrode, M = Membrane, S = Solution, e = electron,

Charged. cation

E = Electrode, M = Membrane, S - Solution, e = electron, G: Charged cationic

polymeric site, 0: Neutral polymeric site,

: Counter-anion (anionic drug), I: Reagent

analyte or chemical trigger, 0o : Product analyte

Figure 1.13. An example of a PPy membrane that can be used for A) chemical

sensing B) electrochemical release of a drug and C) chemical release of a molecule

activated by a reactive analyte. From 4.

29

generalized area.

A silicone tube lined with a PPy membrane has been developed as a nerve guide

'101,1. However, development of a totally degradable polymeric conducting tube would

prove more useful for nerve guidance because of the greater flexibility to modify the PPy

tube and, potentially, the eventual degradation of the entire scaffold.

1.4.2.4. Drug delivery

The ability to force dopant molecules out of the polymer allows for possible drug

delivery applications with PPy 67. Dopamine has been delivered by utilizing this property

of PPy

112;

properties.

however, to date, drug delivery applications have been limited by dopant

Additionally, membranes consisting of PPy have been developed for the

release of adenosine triphospate (ATP) (See Figure 1.13) 4.

The molecules being

delivered still have the size limitations because they have to be incorporated into the

polymer. A method that does not rely on dopant characteristics for drug incorporation

will provide a more general platform for molecule delivery from PPy substrates.

Additionally, the electrical properties of the polymer allow for external interaction to

control drug release.

30

1.5.

Specific aims

Many developing in vivo technologies depend upon the ability of a device to

effectively interact with the surrounding environment. Controlling these polymer-tissue

interactions is an essential component of sensing and drug delivery technologies.

Developing a biomaterial that can be modified to facilitate integration into its proximate

settings opens the door for more effective biomedical devices.

One such material, PPy, is a conductive polymer with unique charge carrying

characteristics that make it an ideal material for biological applications. Previous studies

have examined PPy and its interactions with surrounding tissue.

It has been used to

enhance neuronal interactions with electrodes as well as to stimulate neuronal growth.

The following thesis work addresses the following areas of research:

1) Development of a new method to effectively micro-pattern electrodeposited

polymers and metals for in vivo devices

2) Determining the optimal synthesis conditions of the conductive polymer, PPy, for

sensor and implant applications

3) Fabrication of PPy tubes to be used as nerve guides to promote nerve regeneration

4) Modification of PPy for neurotrophic factor drug delivery devices

31

1.6.

References

1.

Smela, E., http://www.wam.umd.edu/-smela/index.htm (2005).

2.

Riande, E. & Diaz-Calleja, R. Electrical Properties of Polymers (Marcel Dekker,

Inc., New York, 2004).

3.

Feast, W. J. in Handbook of Conducting Polymers (ed. Skotheim, T. A.) 1-44

(Marcel Dekker, Inc., New York, 1986).

4.

Pernaut, J. M. & Reynolds, J. R. Use of conducting electroactive polymers for

drug delivery and sensing of bioactive molecules. a redox chemistry approach.

Journal ofPhysical Chemistry B 104, 4080-4090 (2000).

5.

Cui, X., Lee, V. A., Raphael, Y., Wiler, J. A., Hetke, J. E., Anderson, D. J. &

Martin, D. C. Surface modification of neural recording electrodes with conducting

polymer/biomolecule blends. (2001).

6.

Wang, Y., Kim, Y. M. & Langer, R. In vivo degradation characteristics of

poly(glycerolsebacate).Journal of BiomedicalMaterialResearch66A, 192-197

(2003).

7.

Rehwald, W. & Kiess, H. G. in Conjugated Conducting Polymers (ed. Kiess, H.

G.) 135-173 (Springer-Verlag, New York, 1992).

8.

Sadki, S., Schottland, P., Brodie, N. & Sabouraud, G. The mechanism of pyrrole

electropolymerization. Chemcial Society Reviews 29, 283-293 (2000).

9.

Bredas, J.-L. in Handbook of Conducting Polymers (ed. Skotheim, T. A.) 860-913

(Marcel Dekker, Inc., New York, 1986).

32

10.

Bott, D. C. in Handbook of Conducting Polymers (ed. Skotheim, T. A.) 11921232 (Marcel Dekker, Inc, New York, 1986).

11.

Street, G. B. in Handbook of Conductive Polymers (ed. Skotheim, T. A.) 265-292

(Marcel Dekker, Inc., New York, 1986).

12.

Pfluger, P., Weiser, G., Scott, J. C. & Street, G. B. in Handbook of Conducting

Polymers (ed. Skotheim, T. A.) 1369-1381 (Marcel Dekker, Inc, New York,

1986).

13.

Kemp, N. T., Flanagan, G. U., Kaiser, A. B., Trodahl, H. J., Patridge, A. C. &

Buckley, R. G. Temperature-dependent conductivity polymers exposed to gases.

Synthetic Metals 101, 434-435 (1999).

14.

Anderson, J. M. Biodegradation and biocompatibility of PLA and PLGA

microspheres. Advanced Drug Delivery Reviews 28, 5-24 (1997).

15.

Kabanov, A. V., Batrakova, E. V. & Alakhov, V. Y. Pluronic block copolymers

as novel polymer therapeutics for drug and gene delivery. Journal of Controlled

Release 82, 189-212 (2002).

16.

Kim, S. W., Bae, Y. H. & Okano, T. Hydrogels: swelling, drug loading, and

release. Pharmaceutical Research 9, 283-290 (1992).

17.

Langer, R. New methods of drug delivery. Science 249, 1527-1533 (1990).

18.

Scheller, F. W., Wollenberger, U., Warsinke, A. & Lisdat, F. Research and

development in biosensors. Current Opinion in Biotechnology 12, 35-40 (2001).

19.

Sieminski, A. L. & Gooch, K. J. Biomaterial-microvasculature interactions.

Biomaterials 21, 2233-2241 (2000).

33

20.

Peppas, N. A. & Langer, R. New challenges in biomaterials. Science 263, 17151720 (1994).

21.

Adhikari, B. & Majumdar, S. Polymers in sensor applications. Progress in

Polymer Science 29, 699-766 (2004).

22.

Holland, S. J., Tighe, B. J. & Gould, P. L. Polymers for biodegradable medical

devices. 1. The potential of polyesters as controlled macromolecular release

systems. Journal of Controlled Release 4, 155-180 (1986).

23.

Schakenraad, J. M., Nieuwenhuis,

P., Molenaar, I., Helder, J., Dijkstra, P. J. &

Feijen, J. In vivo and In vitro degradation of glycine/DL-lactic acid copolymers.

Journal of BiomedicalMaterial Research23, 1271-1288(1989).

24.

Fulzele, S. V., Satturwar, P. M. & Dorle, A. K. Study of the biodegradation and in

vivo biocompatibility oof novel biomaterials. European Journal of

Pharmaceutical Sciences 20, 53-61 (2003).

25.

Hasirci, V., Lewandrowski, K., Gresser, J. D., Wise, D. L. & Trantolo, D. J.

Versatility of biodegradable biopolymers: degradability and an in vivo

application. Journal of Biotechnology 86, 135-150 (2001).

26.

Sawhney, A. S., Pathak, C. P. & Hubbell, J. A. Bioerodible hydrogels based on

photopolymerized (poly)ethylene glycol)-co-poly(alpha-hydroxy acid) diacrylate

macromers. Macromolecules 26, 581-587 (1993).

27.

Burdick, J. A., Frankel, D., Dernell, W. S. & Anseth, K. S. An initial investigation

of photocurable three-dimensional lactic acid based scaffolds in a critical-sized

cranial defect. Biomaterials 24, 1613-1620 (2003).

34

28.

Murdan, S. Electro-responsive drug delivery from hydrogels. Journal of

Controlled Release 92, 1-17 (2003).

29.

Burdick, J. A. & Anseth, K. S. Photoencapsulation of osteoblasts in injectable

RGD-modified PEG hyrdogels for bone tissue engineering. Biomaterials 23,

4315-4323 (2002).

30.

Wang, Y., Ameer, G. A., Sheppard, B. J. & Langer, R. A tough biodegradable

elastomer. Nature Biotechnology 20, 602-605 (2002).

31.

Lee, J.-W. & Gardella Jr., J. A. Surface perspectives in the biomedical

applications of poly(alpha-hydroxy acid)s and their associated copolymers. Anals

of Bioanalytical Chemistry 373, 526-537 (2002).

32.

Grayson, A. C. R., Shawgo, R. S., Li, Y. & Cima, M. J. Electronic MEMS for

triggered delivery. Advanced Drug Delivery Reviews 56, 173-184 (2004).

33.

Sershen, S. & West, J. Implantable, polymeric systems for modulated drug

delivery. Advanced Drug Delivery Reviews 54, 1225-1235 (2002).

34.

Wnek, G. E. in Handbook of Conducting Polymers (ed. Skotheim, T. A.) 205-212

(Marcel Dekker, Inc., New York, 1986).

35.

Kaynak, A. DC conduction in electrochemically synthesized polypyrrole films.

Turkish Journal of Chemistry 22, 81-85 (1998).

36.

Chen, Y., Imrie, C. T. & Ryder, K. S. Pyrrole- and polypyrrole-based liquid

crystals. Journal of Material Chemistry 11, 990-995 (2001).

37.

Dunsch, L., Rapta, P., Neudeck, A., Bartl, A., Peters, R.-M., Reinecker, D. &

Apfelstedt, I. Microstructured conducting polymers. Synthetic Metals 85, 14011402 (1997).

35

38.

Donat-Bouillud,

A., Mazerolle, L., Gagnon, P., Goldenberg, L., Petty, M. C. &

Leclerc, M. Synthesis, characterization, and processing of new electroactive and

photoactive polyesters derived from oligothiophenes. Chemistry Materials 9,

2815-2821 (1997).

39.

Heinze, J. Electrochemistry of conducting polymers. Synthetic Metals 41-43,

2805-2823 (1991).

40.

Lee, J. Y., Kim, D. Y. & Kim, C. Y. Synthesis of soluble polypyrrole of the doped

state in organic solvents. Synthetic Metals 74, 103-106 (1995).

41.

Yamamoto, H., Oshimia, M., Fukuda, M., Isa, I. & Yoshino, K. Characteristics of

aluminum solid electrolyte capacitors using a conducting polymer. Journal of

Power Sources 60, 173-177 (1996).

42.

Liu, Y.-C. & Chung, K.-C. Characteristics of conductivity-improved polypyrrole

films via different procedures. Synthetic Metals 139, 277-281 (2003).

43.

Kumar, D. & Sharma, R. C. Advances in conductive polymers. European

Polymer Journal 34, 1053-1060 (1998).

44.

Fink, J. Electronic structure of conducting polymers: investigations of oriented

samples by electron energy-loss spectroscopy. Synthetic Metals 21, 87-94 (1987).

45.

MacDiarmid, A. G. Polyaniline and polypyrrole: where are we headed? Synthetic

Metals 84, 27-34 (1997).

46.

Sung, J.-H., Kim, S.-J. & Lee, K.-H. Fabrication of microcapacitors using

conducting polymer electrodes. Journal of Power Sources (2003).

36

47.

Kang, E. T., Neoh, K. G. & Tan, K. L. Polyaniline: a polymer with many

interesting intrinsic redox states. Progress in Polymer Science 23, 277-324

(1998).

48.

Colin, C. & Petit, M. Electrochemical preparation and properties of films of

polypyrrole/kappa-carrageenancomposites.Journal of the Electrochemical

Society 149, E394-E401 (2002).

49.

Bhattacharya, A. & De, A. Conducting composites of polypyrrole and

polyaniline: a review. Progress in Solid State Chemistry 24, 141-18 1 (1996).

50.

Sariciftci, N. S. & Kuzmany, H. Optical spectroscopy and resonance Raman

scattering of polyaniline during electrochemical oxidation and reduction.

Synthetic Metals 21, 157-162 (1987).

51.

Kuzmany, H. & Sariciftci, N. S. In situ spectro-electrochemical studies of

polyaniline. Synthetic Metals 18, 353-358 (1987).

52.

Akar, A., Bicak, N., Hizal, G., Kizilcan, N., Okay, O., Ozkul, H., Onen, A., Sarac,

A. S., Serhatli, I. E., Senkal, F., Tunca, U., Uyanik, N. & Yagci, Y. (Istanbul

Technical University, 2001).

53.

Higashio, Y. & Shoji, T. Heterocyclic compounds such as pyrrole, pyridines,

pyrrolidine, piperidine, indole, imidazol and pyrazines. Applied Catalysis A:

General 260, 251-259 (2004).

54.

Akundy, G. S. & Iroh, J. O. Polypyrrole coating on aluminum - synthesis and

characterization. Polymer 42, 9665-9669 (2001).

37

55.

Warren, L. F. & Anderson, D. P. Voltammetric evaluation of quality and order in

electrodeposited polypyrrole films. Journal of the electrochemical scoiety 134,

C503-C503 (1987).

56.

Cui, X., Wiler, J., Dzaman, M., Altschuler, R. A. & Martin, D. C. In vivo of

polypyrrole/peptide coated neural probes. Biomaterials 24, 777-787 (2002).

57.

Masuda, H. & Asano, D. K. Preparation and properties of polypyrrole. Synthetic

Metals 135-136, 43-44 (2003).

58.

Maw, S., Smela, E., Yoshide, K., Sommer-Larsen, P. & Stein, R. B. The effects of

varying deposition current density on bending behavior in PPy(DBS)-actuating

bending beams. Sensors and Actuators A 89, 175-184 (2001).

59.

Kudoh, Y., Akami, K. & Matsuya, Y. Properties of chemically prepared

polypyrrole with an aqueous solution containing Fe2(SO4)3, a sulfonic surfactant

and a phenol derivative. Synthetic Metals 95, 191-196 (1998).

60.

Kudoh, Y. Properties of polypyrrole prepared by chemical polymerization using

aqueous solution containing Fe2(SO4)3 and anionic surfactant. Synthetic Metals

79, 17-22 (1996).

61.

Sabouraud, G., Sadki, S. & Brodie, N. The mechanisms of pyrrole

electropolymerization. Chemical Society Reviews 29, 283-293 (2000).

62.

Lyons, M. Transport and kinetics in electroactive polymers. Advances in

Chemical Physics 94, 297-624 (1996).

63.

Chapman, B., Buckley, R. G., Kemp, N. T., Kaiser, A. B., Beaglehole, D. &

Trodahl, H. J. Low-energy conductivity of PF6-doped polypyrrole. Physical

Review B 60, 13479-13483 (1999).

38

64.

Wong, J. Y., Langer, R. & Ingber, D. E. Electrically conducting polymers can

noninvasively control the shape and growth of mammalian cells. Proceedings of

the National Academy of Sciences, USA 91, 3201-3204 (1994).

65.

Nashat, A. & Langer, R. Temporal characteristics of activation, deactivation, and

restimulation of signal transduction following depolarization in the

pheochromocytoma cell line PC- 12. Molecular and Cellular Biology 23, 47884795 (2003).

66.

Zelikin, A., Shastri, V., Lynn, D., Farhadi, J., Martin, I. & Langer, R. in Material

Research Society Symposium Proceedings GG2.7.1-GG2.7.5 (2002).

67.

Zelikin, A. N., Lynn, D., Farhadi, J., Martin, I., Shastri, V. & Langer, R. Erodible

conducting polymers for potential biomedical applications. Angewandte Chemie

41, 141-144 (2002).

68.

Schmidt, C. E., Shastri, V. R., Vacanti, J. P. & Langer, R. Stimulation of neurite

outgrowth using an electrically conducting polymer. Proceedings of the National

Academy ofSciences, USA 94, 8948-8953 (1997).

69.

Liu, Y., Cui, T. & Varahramyan, K. All-polymer capacitor fabricated with inkjet

printing technique. Solid-State Electronics 47, 1543-1548 (2003).

70.

Kassim, A., Basar, Z. B. & Mahmud, H. N. M. E. Effects of preparation

temperature on the conductivity of polypyrrole conducting polymer. Proceedings

of the Indian Acadamyof Sciences (Chemistryand Sciences) 114, 155-162

(2002).

39

71.

Zotti, G., Cattarin, S. & Comisso, N. Electrodeposition of polythiophene,

polypyrrole and polyaniline by the cyclic potential sweep method. Journal of

Electroanalytical Chemistry 235, 259-273 (1987).

72.

Yuqing, M., Jianrong, C. & Xiaohua, W. Using electropolymerized nonconducting polymers to develop enzyme amperometric biosensors. TRENDS in

Biotechnology 22, 227-231 (2004).

73.

Stucky, G. D. Polymers all in a row. Nature 410, 885-886 (2001).

74.

Cui, X., Hetke, J. F., Wiler, J. A., Anderson, D. J. & Martin, D. C.

Electrochemical deposition and characterization of conducting polymer

polypyrrole/PSS on multichannel neural probes. Sensors and Actuators A 93, 8-18

(2001).

75.

Reut, J., Reut, N. & Opik, A. Preparation and characterization of multilayer

systems consisting of the soluble and electrochemically synthesized polypyrrole

films. Synthetic Metals 119, 81-82 (2001).

76.

Freund, M. S., Karp, C. & Lewis, N. S. Growth of thin processale films of

poly(pyrrole) using phosphomolybdate clusters. Inorganica Chimica Acta 240,

447-451 (1995).

77.

Khedkar, S. P. & Radhakrishnan, S. Application of dip-coating process for

depositing conducting polypyrrole films. Thin Solid Films 303, 167-172 (1997).

78.

Fang, Q., Chetwynd, D. G. & Gardner, J. W. Conducting polymer films by UVphoto processing. Sensors and Actuators A 3271, 1-4 (2002).

40

79.

Hosono, K., Matsubara, I., Murayama, N., Shin, W., Izu, N. & Kanzaki, S.

Structure and properties of plasma polymerized and 4-ethylbenzenesulfonic aciddoped polypyrrole films. Thin Solid Films 441, 72-75 (2003).

80.

Malinauskas, A. Chemical deposition of conducting polymers. Polymer 42, 39573972 (2001).

81.

Doblhofer, K. & Rajeshwar, K. in Handbook of Conducting Polymers (eds.

Skotheim, T. A., Elsenbaumer, R. L. & Reynolds, J. R.) 531 (Marcel Dekker,

New York, 1998).

82.

Abrantes, L. M. & Correia, J. P. On the initiation and growth of polymer films

onto electrode surfaces. Electrochimica Acta 44, 1901-1910 (1999).

83.

Hermelin, E., Petitjean, J., Aeiyach, S., Lacroix, J. C. & Lacaze, P. C. One-step

polypyrrole electrodeposition on zinc and other oxidizable metals in aqueous

media. La Revue de Metallurgie-CIT, 1501-1508 (2000).

84.

Schuhmann, W., Kranz, C., Wohlschlager, H. & Strohmeier, J. Pulse technique

for the electrochemical deposition of polymer films on electrode surfaces.

Biosensors and Bioelectronics 12, 1157-1167 (1997).

85.

Diaz, A. F., Kanazawa, K. K. & Gardini, G. P. Electrochemical polymerization of

pyrrole.Journal of the ChemicalSociety-ChemcialCommunications14, 635-636

(1979).

86.

Kim, K.-J., Song, H.-S. & Kim, J.-D. Mechanism of electropolymerization of

pyrrole in acidic aqueous solutions. Bulletin of the Korean Chemical Society 9,

248-251 (1988).

41

87.

Asavapiriyanont, S., Chandler, G. K., Gunawardena, A. & Pletcher, D. Journal of

Electroanalytical Chemistry 177, 229 (1984).

88.

Diaz, A. F. & Bargon, J. in Handbook of Conducting Polymers (ed. Skotheim, T.

A.) 81-116 (Marcel Dekker, Inc., New York, 1986).

89.

Kemp, N. T., Kaiser, A. B., Lui, C. J., Chapman, B., Mercier, O., Carr, A. M.,

Trodahl, H. J., Buckley, R. G., Patridge, A. C., Lee, J. Y., Kim, C. Y., Bartl, A.,

Dunsch, L., Smith, W. T. & Shapiro, J. S. Thermoelectric power and conductivity

of different types of polypyrrole.Journal of PolymerScience: Part B: Polymer

Physics 37, 953-960 (1999).

90.

Yakovleva, N. M., Yakovlev, A. N. & Chupakhina, E. A. Structural analysis of

alumina films produced by two-step electrochemical oxidation. Thin Solid Films

366, 37-42 (2000).

91.

Jager, E. W. H., Smela, E. & Inganas, O. Microfabricating conjugated polymer

actuators. Science 290, 1540-1545 (2000).

92.

Chance, R. R., Bourdreaux, D. S., Bredas, J.-L. & Silbey, R. in Handbook of

Conducting Polymers (ed. Skotheim, T. A.) 825-857 (Marcel Dekker, Inc., New

York, 1986).

93.

Yueqiang, S., Carneiro, K., Ping, W. & Renyuan, Q. in International Winter

School: ElectronicPropertiesof ConjugatedPolymers(eds. Kuzmany,H.,

Mehring, M. & Roth, S.) 2-11 (Springer-Verlag, Kirchberg, Tirol, 1987).

94.

Cioffi, N., Torsi, L., Losito, I., Di Franco, C., De Bari, I., Chiavarone, L.,

Scamarcio, G., Tsakova, V., Sabbatini, L. & Zambonin, P. G. Electrosynthesis

42

and analytical characterisation of polypyrrole thin films with copper

nanoparticles. Journal of Materials Chemistry 11, 1434-1440 (2001).

95.

Reynolds, J. R., Baker, C. K., Jolly, C. A., Poropatic, P. A. & Ruiz, J. P. in

Conductive Polymers and Plastics (ed. Margolis, J. M.) 1-40 (Chapman and Hall,

New York, 1989).

96.

Wang, Z., Roberge, C., Dao, L. H., Wan, Y., Shi, G., Rouabhia, M., Guidoin, R.

& Zhang, Z. In vivo evaluation of a novel electrically conductive

polypyrrole/poly(D,L-lactide) composite and polypyrrole-coated poly(D,L-

lactide-co-glycolide)membranes.Journal of BiomedicalMaterial Research 70A,

28-38 (2004).

97.

Cosnier, S. Biomolecule immobilization on electrode surfaces by entrapment or

attachment to electrochemically polymerized films. A review. Biosensors and

Bioelectronics 14, 443-456 (1999).

98.

Dupont-Filliard, A., Roget, A., Livache, T. & Billon, M. Reversible

oligonucleotide immobilisation based on biotinylated polypyrrole film. Analytica

Chimica Acta 449, 45-50 (2001).

99.

Kamalesh, S., Tan, P., Wang, J., Lee, T., Kang, E.-T. & Wang, C.-H.

Biocompatibility of electroactive polymers in tissues. Journal of Biomedical

Material Research 52, 467-478 (2000).

100.

Jiang, X., Marois, Y., Traore, A., Tessier, D., Dao, L. H., Guidoin, R. & Zhang,

Z. Tissue reaction to polypyrrole-coated polyester fabrics: an in vivo study in rats.

Tissue Engineering 8, 635-647 (2002).

43

101.

Rivers, T. J., Hudson, T. W. & Schmidt, C. E. Synthesis of a novel, biodegradable

electrically conducting polymer for biomedical applications. Advanced Functional

Materials 12, 33-37 (2002).

102.

Sun, S. & Cho, M. Human fibroblast migration in three-dimensional collagen gel