FOREST PRODUCTS LABORATORY

advertisement

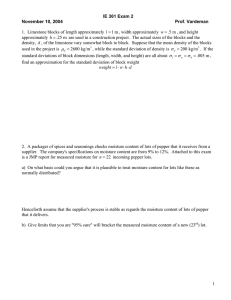

''AGR ..CULTURE ROC'v , J U. S. Department of Agriculture,EForest Servic e FOREST PRODUCTS LABORATORY In cooperation with the University of Wisconsi n MADISON, WISCONSIN HOUSE FRAMING LUMBE R SHOULD BE KILN DRIED By L . V . TEESDALE Senior Engineer SCHOOL OF FORESTR Y OREGON STATE COLLEG E CORVALLIS, OREGO N Published i n SOUTHERN LUMBERMA N July, 1933 By l. . 1- N. Vas '= SD E7 Senior $hgideew 41 should In the average six room hewer a + y -foslla in • ng . be enough to coder the diffewence bets the uae of -initial lumber or the use of part#a 13r seasoned finning* tit*. lea coOducte d cost hae rece it] y hest es=tdtt .ed am the result of experirn by the Forest ProduOtS LaboraEt .z o a moder e priced ho 4 ly les'i than the cost of cet-rectLng , a *ec•trs o shrin*age . s eaboaOd joists a ad otbew -s t members. are used . tft s It has been gene`l practice to coder that air seam ;e material was satisfactory ft)r strOrtural purposes . Alse 'tl ,t thoroughly air seasoned material *4s not avai .labie; pawei-rally sesmWNgN material could be used i.nas nch ai 'e im .derable seasoning would tom . place during the building opeation,.- In the dwelling studied b y Forest Products Laboratory, the joist were A4. ikol.1VO4 hey ae fir bad been in the local 1usib .e' yai at Madison, . during 400 winter, they were only partially seasoned,- tiJA average tent being in eXce Lse -of 25 percent when delivered . Dulles the bui:l ing operation-an aplOORWble ant of drying took place ; however, only -that dryt vgich 0601 rod, 1 efore the plastering ration proved ti. Sit •,tiefici - in minir n. ?1aote.r cracks i e sulk and plates in the houm. OiecS kiln dried ponderos a pine and bed an gage moisture content at t 10 percent when deliverel . 1°ke oring was air dries fah g7eragin g *out 1 g 'pram' fire content when ! When all studs and h fla tore iti'g isel walls ready were • 1 in the top of laseme ;Losabee OM* la& Wag floor, qftf *mows a'b iTrg !fig aim* o exte: and y, and AlINOm ! *Ate , .and b o r were d .' arranto measurement') 4awgjbfb Imo made tween e cap of the, e a ar _~ se devoping washer on the floe.* F gf"xvf °~ ally ance between ' _~. 3geolel hrinamr j► vtqaw betwee* . att llama ! OMNI* ecord of moisother commend,* 06a'4m xu,: contac t pi**, tam two* *No us tre and, brie the 41ois- HO elect, t ime ture vs ote" -' v 1 4. M 1009 The bearing partition was sv ipoed . on a steel girder whic h iilPturn was supped by steel &c .Umns . the studs in both first and bnd floor start on top of a 2 by 4 inch partition plate . With thi s arster$ of construction all joist, plateD, caps, and rough floor act a s supports in the Vertical height of the wall . It is the :age of these mbaas that constitutes practically all of that fob *Mt the pipes were measured from time to time. T%e total •cram in dimension as determine& from each pipe has been plotted on Figure . 1 . The curve AA on both Figures 1 and 2 represents the average moist e content o f the joist, plate, sixbfloor, and cap in . the first i'lo icr• A''+ ;), the curve BB the siim4lar * is in the second floor unit, 00o joist and rough floor of the= rti :ie unit.. The net change of ea0h Vie& determined from the Aktfference in dimensional change bwtween the various pipes is plotted en 1 , 3r 2. For examples Art esents the shrinkag e developing to tie fist floor joist, rough floO,rs partition plate, an d cap as plotted on Figure 2. B represents the sage -members on the second '- ' fi or, =oil the attic j let and floor . The curve C on Fi gRpe 2 was obtained by datemiring the actual shrinkage as shown on Figure 1 aid calculating the p'-r e ,te shrinkage- based on the same amount of woo d across the ac• s used in A and B . With the various curve s 4PO Wit* xI arable in teXUt of a c it of wood, the cli:ffererree it misture content e in imerr iim.ctically all of the e '-f'f sPn'# ; Plaster cracks in the house appeared first in a eiw .we'' • •en. the second floor and later some minor cracks developed in tile bearin g wall and around the fireplace on the first floor . A . f ,ir Iawoportion of the shrinkage had taken piaae before cracks d Ee le d as may be noted one Figures rand 2 . This may be explained by the fait that under ordinar y -use con itions some shrinkage in the structural frame wean take plac e without :producing plaster cracks, or in other words there i•s a certain amount of "take up" or slack between the free ad the meter. Test s have shown that the gro nd , studs ., doer and wind O* .jambs: ck up moisture from fresh plt,s}t•er, and expand slightly, Subs quent rimer redry.ggh very ing they shrink an from the plaster and leave a speae e m, small that will permit some movement of the plaster fheet b eC e contact is reestablished. After the take up or slack was absorbed > t%R % mus e under consideration further shrinkage calmed the !racks to e= nd i g propQx.tian to the slaririage . In spite of the amo . o s li ge fob MI6* baiises,ira i s• arid of shrinkage ire terror of ,,r other defects has not been .important on the first 'l,oe'Gt the second floor some unsightly cracks have developed . air because of c isren in the frames of two doors in cross walls, adjustment o the ha teas been rely so that the doors would latch. O. igtaZ •hacks did not appear in the first flo ;a~F IMKAI about 7 percent ~ge in moisture content had taken place i the 'wooden members . this basis these cracks might •n t'Dave appeared at Ll if the original moisture content of the members coeposing the first ~• ii~ii. Mow than 13 pereenta The figure of 13 R1009 -2- percent is obtained by adding the 7 percent to 6 percent, which is th e lowest moisture content found in this unit . Cracks in the second floo r appeared after about 5 .42 percent moisture change had occurred in th e first floor units and )4-1/2 percent in the second floor units . On this basis the first floor joist units should contain less than 11-1/ 2 percent moisture and the second floor less than 12 percent (4-1/2 + 7--1/2) to prevent plaster Cracks on the second floor . In other words , if plaster cracks and other shrinkage effects are to be avoided kil n dried lumber having a moisture content of approximately 12 percent o r less at the time of installation should be used in house framing . With joist of low moisture content is relatively unimportant with the advantage platform type for interior partitions . For structuresthe advantage lies wholly with the of original moisture content . the method of constructio n somewhat in favor of th e bungalows or one-stor y platform type regardles s Throughout the greater part of the United States the minimu m moisture content range of thoroughly air seasoned material is 12 to 1 5 percent, but the average for stock as it comes from the lumber yard i s generally higher . Stock may be considered well air seasoned and stil l contain 15 to 17 percent of moisture . Such material will lose ver y little moisture during the building operation as it is already nearly i n Equilibrium with the atmospheric condition . Best results will be ob tained by having structural material kiln dried to a moisture conten t averaging say g to 10 percent . During the building operation such stock will absorb some moisture from the atmosphere but the average moisture content will remain appreciably lower than air dried stoc k under like conditions of exposure . The surface may become wet fro m rain but such moisture will dry off rapidly during subsequent dr y weather . Kiln dried joist may not always be available in the loca l lumber yard, in which event owners and builders should place order s for kiln dried material with their dealer . • . ■ "I'■ 1. Figure 1 .--Curves showing shrinkage (a) between bash tt girders and attic floor ; (b) between first floor partition cap and attic floor ; (c) b. tween second floor partition cap and atti c floor. The average moisture content of *e wood represented in the : first floor, second floor and attic units is also shown, 7 Shrinkage (inches) Apr O 19 3 Ma . y June _ Dec . Jan . 193 '. Feb . I Max . Apr;_. May June Jul y Aug . Sept. Oct . Nov. Dec . • Jan. 193 Feb , Mar . Apr._ May _ June July Sett . Oct . Nov . Dec . R1009 si" - ~~~- Final coat of pilaster ~ H J 1 H O Vl O 1- Plaster, cracks in evidence . / -7 Plaster racks in ev Idence on is i o• r ~-Mil i I ~!' , ' ME. _ ■_ ' aN -■ gm _ _ rim s ~■ _■ ____. ____ n __m °: : ~- _ 1 4, jois t 2''xg " 2nd floor jois t a ■~, . 1st floo r jois t 2"x10 rr . rearin g partit i on ho ing po si ti on of rod s rams= •iii__ ____►_I__ i. I_ __=_~i 119 10 .1--BIIWM • r 1 Figure 2 .--Curves showing shrinkage (a) between top o f basement girder and top of first floo r partition cap ; (b) between top of firs t floor partition cap and top of second floo r partition cap; (c) between top of secon d floor partition cap and attic floor.. The average moisture content of each unit i s also show. 0 Apr . N 0 June_ t Jul y Aug . H L7l H 0 _,jilplll -- ii Final coat oplaster El j Sept . Oct : ter cracks in evid ence ton 2 , • ? - .ar - - - PI Nov . - -- • N 0 Metal o May I- Moisture content ' (percent ) i,ge (inch) N l.,.l Vl q 0 0 0 ( Plaste l crackss in evidenc on 1st floo •- ----- -- Dec ; 1- Jan , Feb . Mar . 11E= Apr . May Jun e Jul y Au g. 1111 Sept, Oct . Nov . Dec. ~ ' =BEM ' =11I= N Mar . Feb . Apr . May June 1 Auge Sept . Oct t Nov . Dec . 11•1 111111•1=11I _ OMEN ~i -1 MIIII s 1E9=111 M IB M "I Mil 11=11 MiU ■i ■ tit N Jan . Feb.. Mar . r Apr . sm. P1009 ■ r UN 1 N Jan , Jul y _ n~