Papers Presented at the IEEE 14th... on Fusion Engineering by the Alcator

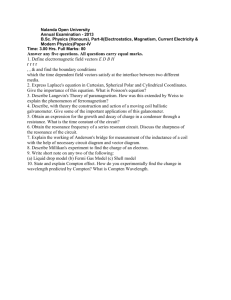

advertisement