Production and Organizational Learning:

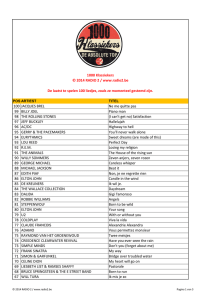

advertisement