GAO HOMELAND SECURITY Voluntary Initiatives

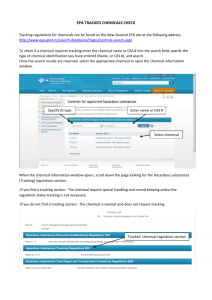

advertisement