High-resolution Micromachined Interferometric Accelerometer C.

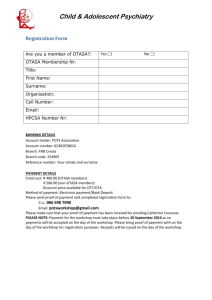

advertisement