groundline were all well below 20%,

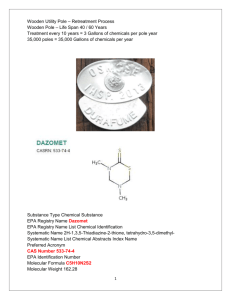

advertisement