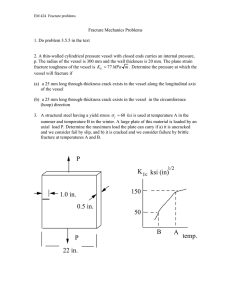

-1- by JAMES (1968)

advertisement