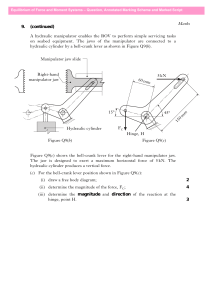

Design and Prototype Fabrication of a Manipulator for

advertisement