Unsteady Disturbance Structures Han G. Park

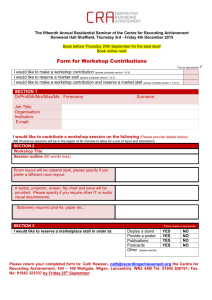

advertisement