TWO-STAGE PRODUCTION PLANNING IN A DYNAMIC ENVIRONMENT

advertisement

TWO-STAGE PRODUCTION PLANNING IN A DYNAMIC ENVIRONMENT

Stephen C. Graves, Harlan C. Meal

Sriram Dasu, Yuping Qui

August 1985

1698-85

2

INTRODUCTION AND OVERVIEW

In this document we report on research to develop and study

mathematical

models for production smoothing in a dynamic production

environment.

This effort was part of a larger study whose goal

to investigate

the production planning practices for an electronic

equipment manufacturing firm, and

mechanisms

was

for improvement.

in particular to explore

To motivate

research, we need to indicate

possible

the presentation of our

the nature of this production

environment.

The production process can be viewed as a multi-stage system.

In

its most aggregate form there are two

fabrication and equipment assembly.

uncertainty and variability over

time.

Nevertheless,

stages:

component

Customer demand has significant

the cumulative manufacturing

lead

customers demand a high level of service.

manufacturing process

is not totally reliable;

in particular.

is significant yield uncertainty in component fabrication.

The

there

Finally,

production capacity for both component fabrication and assembly

(including final test)

is very capital

intensive.

As a consequence,

it is expensive and/or difficult to adjust the production level.

As a consequence of these characteristics,

make-to-stock system that would

and

reliable delivery times

hierarchical

one to set

one to

lots of

_VI__

·

planning system

to

smooth production and provide

customers.

schedule the daily lot starts

...

1_----_1_111___-

).

Our

study then

short

We considered a

(Hax and Meal,

the aggregate production level

item k

one must consider a

1975) with two

levels:

(e.g 400 lots/month)

(e.g. one

focused on

lot of item j,

the design of

and

two

such

a

3

make-to-stock system.

Key questions in

items should

should

the design of a make-to-stock system are what

be stocked,

at what point(s)

stock be accumulated,

provide

and what

satisfactory service and

smoothing.

in the

production process

stock level

is

needed to

permit adequate production

Our research addresses these questions.

To answer these

questions, we must specify the rules or algorithms that will set the

aggregate output rate and determine

develop mathematical models,

termed production smoothing models,

set the aggregate

output rate.

smoothing models,

see Silver 1967.)

"disaggregating" the

individual

items.

the daily production starts.

(For a review of

into production starts

for

for

these models determines the

level(s) necessary for a desired service

level.

to

-

We then give a mechanism

aggregate output

The analysis of

production

We

stock

In addition, from

these models one can quantify the tradeoff between the smoothness of

aggregate production and the stock level.

In the next

section we describe the production smoothing models

and give their analysis.

production system.

treat

We first present a model for

We then give

two extensions

a two-stage production system.

evaluate

their performance,

computational

to this model

the

to

models and

we report in section 3 on a

study based on data gathered from the electronic

equipment manufacturer.

a wide range of parameter

generate

To compare

a one-stage

insight

In particular,

we simulate

the models

over

settings to assess their accuracy and to

into their

behavior.

4

DEVELOPMENT AND ANALYSIS OF PRODUCTION SMOOTHING MODELS

We develop here a set of production smoothing models that can

be

used to

look at the

tradeoffs between

inventory requirements.

at an aggregate

processing

We assume that production smoothing is done

level for families

requirements.

production smoothing and

of

products that have similar

For now, we will make

the following

simplifications:

we ignore

lot-sizing considerations;

we assume no uncertainty

in the build

time for the

products;

we assume no constraint on

production capacity;

other

be introduced as needed.

The models

simplifications will

should

considerations

permit focus on the production

in the

light of forecast

variability, and yield uncertainty.

examine

the

smoothing/inventory

uncertainty, demand

We will use a simulation to

consequences of the simplifying assumptions.

We model the production activity in a very gross way.

not concerned with detailed scheduling issues,

planning issues.

decomposed

inventory

Figure

stage:

We assume that the production

into a series

all

Then we

assume a known and

production started

stage at time t+1,

for

system can be

in finished goods

fixed lead

(see

time for each

at a stage at time t finishes

being the lead

concerned both with setting

stage,

but rather with the

of stages where we may maintain an

between successive stages and

1).

We are

time of the stage.

the aggregate production

and with deciding how to disaggregate it

level

that

We are

for each

into a production

5

level

much

Furthermore, we want to understand how

for individual items.

is needed as

inventory

We desire

to keep the

aggregate production

possible at each stage,

levels as

is

smooth as

the safety stocks as

and to keep

needed.

low as

providing satisfactory customer service.

while

possible,

it

safety stock, and where

developed a production smoothing model to

illuminate

We have

these

tradeoffs.

We then consider production

We use the production

stage.

we first describe

that drives the production smoothing

forecast process

the aggregate

models.

smoothing models,

the production

To present

smoothing for

one production

smoothing model for one stage as the

building block for developing two distinct models for smoothing two

production stages.

Forecast Process

input

A key

of

aggregate demand.

the process

define

so

for

this

it is

forecast

revised

is the

forecast

is by month

To model

monthly.

we define Ft(s) as

t of aggregate demand in month s (s>t).

the

for

forecast

Then, we

St(s) by

= Ftl(S) + St(s)

Ft(s)

that

that

forecast revision,

of

made at month

We assume

12 months, and that

the next

up to

(1)

to the production smoothing process

St(s)

time s.

denotes the change at

We assume

that

following characteristics:

E [St(

)] = O ,

St(s)

time t in the

aggregate forecast

is a random variable with

the

6

Var

and

t(s)

and

2

=

[(s)]

t(s)

(s-t)

,

independent for all t #

are

t'

We denote the aggregate demand in month t as Ft(t):

'forecast'

of demand

in t made at time t.

From

(1),

the

we can express

the aggregate demand as

k

(2)

Ft(t)

= Ft-k(t)

+

6

E

t-k+i(t)

i=1

where Ftk(t)

ago.

is the initial forecast for demand

in t made k months

The k-month forecast error is given by

k

Ft(t)

- Ft-k(t)

=

&t-k+i(t)

E

i=l

k

and has zero mean and variance equal

to

E

2

a (k-i)

i=1

Thus,

the forecast not only is

unbiased, but also

k-1

= E

o2 (j).

j=o

improves over

time.

We assume that the demand process, D(t)

with E

and

[D(t)]

Ft(t)

From

= D, and Var

[D(t)]

=

= Ft(t),

D for all t.

is stationary

(We will use D(t)

interchangeably to denote aggregate demand in month t.)

(2) we now can compute

the variance of

Ftk(t):

k-1

Var

[Ft-k(t)]

=

-D

E

a2(j)

j=o

Thus,

the variance of the initial forecast depends upon the forecast

horizon length k.

The

longer is the forecast horizon,

is the forecast variance;

there

more

presumably,

for a

the smaller

longer forecast horizon,

is less information available on aggregate demand and there

likelihood to use D as the forecast.

is

7

Smoo'thing for One Stage

Production

We now develop a production smoothing model for one production

stage.

We assume that the production stage

produces it

a finished goods

stock, i.e.,

smoothing model

production

aggregate

to

family and

We use a

inventory.

set an aggregate production

to

starts per month)

produces one

rate

for the family for each month.

To set

the actual

production starts we must disaggregate the aggregate

production

plan according to

the net requirements

(e.g.

for individual

items.

production, we must maintain an

To smooth

the aggregate production rate,

aggregate demand rate,

over short

inventory stock since

being a smoothed average of

will deviate from the aggregate demand rate

time intervals.

production,

In

inventory

To determine the aggregate

the production

requirements we need to analyze the behavior of

smoothing model.

particular, we expect that the more we smooth

the greater will be the stock requirements.

customer service

is

the

But since

determined by the stocks for individual

we also need to understand how the aggregate plan is to

items,

be

disaggregated.

The production

(3)

P(t+l)

= n+

where t denotes

P(t+i)

[Ft(t+l,t+t+n)

the

current

-

is given by

P(t+l,t+t-1)

-

I(t)

+ SS]

time period, and

= the planned aggregate production

to

x

smoothing model

be completed by time t + i;

= the lead time for

production;

started at time t+i-I

9

rule in

its control

terms of

show that it

is both an

In this respect,

al

(1984).

it

is simple and does permit analysis of

In particular,

assumptions

Second,

we will

there

more general

is evidence that

be the

production capacity.

1974).

to express

all variables in

For instance,

in

common

to express planned

However, the actual inventory is likely

translate, using yield factors,

Thus, we need

this actual inventory into the

equivalent wafer starts for the items and

Similarly,

then aggregate over all

for the assembly of electronic

equipment, we might express

planned production

assembly hours;

fabrication facility, the units might be

machine

(4)

where

D(t)

I(t)

=

P(t)

is

for a parts

hours required

To analyze

·9

(3)

for the manufacture of

to be known in terms of chips for individual items.

family.

Third, while

the units need be aggregate measures of

production in wafer starts.

the

for

form.

integrated circuits it might be natural

in

form are optimal

form, we nevertheless can find the

parameter choice for this

In particular,

rule.

cost functions but also

1971,

et

its

implications fro this

(Schneeweiss

optimal

We need to be careful

items

consider.

suitable

linear rules of this

only quadratic

cost functions

the rule may not

units.

see that under

we obtain the disaggregation

or near optimal for not

optimal

interesting and reasonable rule to

it is very-similar to the study by Cruickshanks

First,

behavior.

and will try to

parameters, n and SS,

on the bottleneck

(3) we use the

I(t-1)

is the

+ P(t)

-

----_--1__

terms of

required

facility.

inventory balance

equation,

D(t)

actual family production

the family demand at

in

time t.

completed at time t and

We assume that

8

Ft(t+l,t+t+n)

P

= Ft(t+l)

+

...

(t+l,t+1-1) = P (t+l)

+

... + P

I(t)

+ Ft(t++n

)

;

(t+-1) ;

inventory on-hand at start of

= aggregate

time period t;

SS

= target safety stock level;

n

= window length.

Thus,

in period t we set P(t+l),

completed

periods

later.

the planned production to be

We assume that the

uncertainty in the

production yield

deterministic,

but that

so

production completed at time t+i will deviate

that actual

there is

lead time is

from

the term within the brackets represents the

P(t+t).

In

(3),

forecast

over the time

interval t+l,

... t+.+n minus the cumulative

by time t+X-1 and minus an

production planned for completion

inventory adjustment (the difference between the actual and target

inventory).

We term the quantity within the brackets to be the net

requirements over

set

the time

P(t+t) to be the

window t+t,

to the

interval t+t,

average of

length of the time window.

a decision variable that

on all

items

We note that

In this

respect

it

The value of n will

set to

time

decision variable equal

determine the

The safety stock target, SS,

this production

is

Thus, we

provide acceptable

is also

customer

in the family.

similar to

developed by Holt et al.

differs

is

... t+l+n.

the net requirements over this

... t+t+n where n is an integer

level of production smoothing.

service

t+1+1,

smoothing model

the

minimizing some cost function.

rule.

linear-decision-rule model

(1955,1956).

from that of Holt et al.

is a linear

However,

in that it

Rather,

our decision rule

is not a consequence of

we just pose this decision

10

(5)

= P(t) -

P(t)

where

(t)

(t)

We assume that c(t)

P(t+l)

-

and identically distributed over

(3) to consider the difference

Now we use

(6)

is independent

mean and has variance ap

has zero

time,

the yield uncertainty.

is a random variable that reflects

P(t+1-1)

= n+1

-

t(t+l,t+l+n-1)

We use

(4),

P(t+1-1)

+ I(t-1)}

I(t)

... +

t(t+t+n-1).

and the substitution Ft(t) = D(t) to simplify

(5)

P(t+l)

+

= 6t(t+l)

-

P(t+1-1):

t(t+l,t+l+n-1)

-

Ft-l(t)

+ P(t)

where

+

{Ft(t+l+n)

P(t+l) -

- P(t+1-1)

= n+1

{Ft(t+l+n) +

-

P(t+t-l)

(6)

to

t(t,t+±+n-1)

+

(t)}

from which we obtain

P(t+.) =

(7)

i

+

Thus,

to

we see

F

+

t(t+l+n)

+

--- (P(t+1-1)}

n+l

that the production smoothing model

which is a simple smoothing equation.

(7),

for time period t+t is a weighted average of

for the

t+t+n,

previous

modified

interval

time period t+1-1,

__ ___

is equivalent

Planned

production

the planned production

initial

forecast for

(t,t+l+n-1) and by the realized yield deviation for the

completed in t.

weights

that

so

1/(n+l)

significance of

The window length n determines

is the

(7)

is

1

the

smoothing parameter.

not

simple smoothing equation, but also

_

and the

(3)

by the change in the cumulative forecast over the

production

The

c(t,t+)+n-1)

(t)}

1_---_·^_-_·1111__11I-

only

its

interpretation as a

its usefulness for

11

long-term behavior of

characterizing the

model.

(7),

From

(8)

we can show that

E[P(t+t)]

this production smoothing

in steady-state

= D

and

(9)

= (D

Var[P(t+l)]

2

2

+ ap)

/ (2n

+ 1)

We defer the details of this derivation to the appendix.

also use

[P(t+l)

(7)

to characterize

- P(t+-1)], as well

demand process

is not

the

(8)

and

'step',

as study other cases

stationary

trend component or a seasonal

From

production

(e.g.,

in which the

the demand process has a

component).

(9) we see that the window length n does not

affect the expected aggregate production rate, but does

variability of

We can

aggregate production

the

rate.

control the

As we increase

n,

the

production variance decreases and the aggregate production becomes

smoother.

Thus,

the choice of n dictates the degree of production

smoothing given by

Aggregate

(3).

Inventory Behavior

In addition to

the aggregate production

level,

we also want

understand the behavior of the aggregate inventory level.

necessary tQ see the

service for

effect of

individual items.

planned aggregate

to be

forecast

through t+X:

we focus on

To do this,

at time

t+1.

inventory at time t,

completed over t+l,

is

the production smoothing on customer

inventory level

defined as the current

This

to

... t+X,

minus the

I(t+l):

At time t,

the

I(t+l)

is

plus planned production

cumulative

demand

12

(10)

I(t+l)

By using

(3)

(11)

From

(12)

= I(t)

+ P(t+l,t+l)

to substitute for

- Ft(t+l,t+l).

P(t+l,t+x-1)

(10),

- nP(t+)

I(t+l) = SS + Ft(t+l+l,t+l+n)

(11),

in

we obtain

.

we see that

E[I(t+.)] = SS

In addition, we can show its variance

(after substantial

algebra)

to be

(13)

Var[I(t+)]

=

n2

2n+

2

(

+

2

n-1

)

2

2

n+l

j=0

This characterization

be

useful

of the planned aggregate

level

for a

While the expectation of planned inventory level

equals the

target safety stock,

length n.

From

inventory level

length n,

inventory level will

the target safety stock SS and of the smoothing

specification of

(linear)

i=0

in determining the customer service

parameter n.

+j

(13)

its variance depends

on the window

we argue that the variance of the planned

essentially increases

since the second term

linearly with the window

in (13)

is dominated by the first

term.

Disaggregation and Customer Service

To determine the proper choice for the target safety stock SS,

we need to know how

individual

· _··

items

_________I___

the aggregate

or equivalently,

inventory is spread over

the

how the aggregate production

level

13

is disaggregated

into

item production.

We must set

starts for each item so that the planned production

family is achieved;

that

the production

level for

is,

E P(k,t+X) = P(t+l)

k

where P(t+l) is given by (3) and P(k,t+l)

is the production

for item k started at time t for completion by time t+1.

implies

that the planned inventory level for

call

I(k,t+l),

it

(14)

E

the

level

This

item k at time t+X,

must satisfy

I(k,t+l) = I(t+I)

k

where

I(t+1)

is given by

(10).

To characterize the service

level for

item k in period t+1 for

a particular disaggregation, we can express its planned inventory as

I(k,t+t)

where

I(k,t)

= I(k,t)

is current

+

- Ft(k,t+i)]

inventory and Ft(k,t+i)

demand forecast for month t+i

will

~ [P(k,t+i)

i=1

.

is

the current

The actual inventory at time t+t

be

I(k,t+t)

= I(k,t)

+

E [P(k,t+i)

- D(k,t+i)]

i=l

where for time t+i,

P(k,t+i)

demand, and where negative

that the

difference

is actual

production and D(k,t+i)

inventory denotes a backorder.

I(k,t+l)

- I(k,t+l), which reflects

uncertainty and cumulative forecast error

of

time periods,

zero

2

mean and a variance ck.

I(k,t+t)

/

k

to

is

the

We assume

yield

for k over the lead time

is a normally-distributed

random variable with

Consequently, we can use zk =

indicate the service

level

for k at time t+t from

14

a particular disaggregation

deviations of

(14).

zk denotes

safety stock protection provided by

Now suppose we set P(kit+1),

the

likelihood of stockout

I(k,t+l) = z

(15)

for all k.

Thus,

I(t+t)

we can use

specified by

/

(12)

standard

I(k,t+l).

I(k,t+2), so that

is the same for all

items k,lor equivalently

E

k

(15)

into

(14),

we find that

rk

and

(13)

to characterize the service

z) for a choice of SS and n.

level

The expected service level

the

greater will be the

month.

depends only on the safety stock target

But the amount of variability in

smoothing parameter n;

(as

We see that z is a random

variable, and thus the service level will vary from month to

SS.

items.

rk

By substituting

z =

or equivalently

in period t+1

we want zk = z for all

Thus,

the number of

the service

level depends

the more that we smooth production,

variability in service

from month

on

the

to month.

We have assumed here that it will always be possible to

disaggregate production

Indeed,

if current

to

satisfy (15).

inventories are

simultaneous satisfaction of

production

(P(k,t+l) < 0)

Obviously,

this

assumption of

(14)

and

(1981)

for items with large current inventories.

is not possible.

However,

that we produce to stock;

'balanced' inventories

ordering policies

we expect that the

be appropriate for the

we will

test this

We note that a similar

is made by Eppen and Schrage

and by Federgruen and Zipkin (1984)

centralized

the

(15) may imply negative

assumption with the simulation exercise.

assumption of

is not guaranteed.

'out-of-balance',

'balanced' inventories will

family of items

This

in their studies on

for multilocation distribution

15

systems.

Two-Stage Models

In this

section we extend the one-stage model

operation with

two

stages,

e.g. fabrication

and assembly.

an operation we may have not only a finished goods

also an intermediate

1).

inventory between the

The intermediate

partially,

inventory permits

the production of

smoothing model

stages.

disaggregates

we will

need to

stages.

The

first approach

without an intermediate

model;

include

it

is to

upstream stage smooths

stages.

Thus,

the intermediate

level for the

smoothing by the

The notation will be very

stage

the previous

but will

the various models.

The

intermediate inventory to permit

They differ

inventory,

upstream stage

for both

stages as one

and then to use

its production.

downstream stage.

the production.

plan.

in terms of how

In the

and on forecasts of

In the

third model,

information

the production

production

is based on the echelon

similar

to that

the

second model,

production smoothing by the upstream stage relies on

about

least

(parts fabrication)

this approach any further,

second and third approach use the

the

at

characterize how each stage

view the two

in the simulation study of

some decoupling of

(see Figure

for production smoothing for two

inventory,

we will not discuss

stages

production rates

the aggregate production

We mention three approaches

stage

(assembly).

needs to set aggregate

In addition,

two

For such

inventory, but

one to decouple,

the upstream

from that for the downstream stage

to a production

inventory.

for the one-stage

16

model.

We

let

1

downstream stage,

we want to

that

find

starts

respectively, and define 1t=

for the

and

completed by t+1 1,

inventory,

at

environment.

these

Then at time t

planned production

denote the planned

in t to

be completed

intermediate

to denote the planned finished-goods

the times

We present

1 +1 2 .

and for the downstream

planned production that starts

I(t+1 2 )

for the upstream and

upstream stage Q(t+t 1 ),

We use J(t+1l) to

inventory,

items

2 denote the lead times

in t to be

stage P(t+12),

by t+t 2.

and

t+1

and t+1 2,

1

models for the

respectively.

simplest two-stage production

We assume that there is a one-to-one mapping between

produced in the upstream stage and items produced by

downstream stage.

receives

That

is,

each

the

item from the upstream stage

further processing at the downstream stage and results

unique end

item.

are defined so

in a

Furthermore, we assume that the production units

that

one unit

of downstream production

starts

requires as

input one unit of

completed upstream production.

Although we

present the models for this setting, we can extend it to

more complex environments, such as when the downstream stage

performs

assembly of sets of

components produced by the upstream

stage.

To extend the one-stage model to a two-stage system requires

the specification and analysis of

a production

each stage.

in a way that permits one

We desire

to do

how the planning at one stage

intermediate

discuss

first

this

impacts

inventory can be used

the downstream stage,

smoothing rule for

the other stage,

and how the

to decouple the stages.

since

to see

We

it will be simpler.

17

Downstream Stage

for the downstream stage is

The production smoothing model

by

2

rule

{(Ft(t+l,t+1 2 +n)

= n+

P(t+t 2 )

(16)

where n is the window length and SS

Thus,

stock

target.

equal

the average of

...

we set the

level at time t for completion by time t+.

planned production

the

Namely,

that given for a one-stage system.

identical to

t+

2

as

(3) we set

in

from the previous section

analyses

given

directly to P(t+1 2 )

The extension of

(3)

+

I(t)

by

(16)

is the finished-goods safetyplanned production

the

of (16).

and

to

demand on

the

intermediate

I(t+t 2 )

the

implied by

is less clear.

is not

time t.

extend (3) we need an appropriate forecast of

,

inventory apply

as

the downstream stage:

inventory at

2

inventory is

As a consequence,

to the upstream stage

by the production by

to

the time window t+1

of the planned

is because the demand on the upstream stage

is set

,

2}

sufficient component

available to permit the execution

2 -1)

P(t+l,t+1

requirements over

the net

We assume that

+n.

2

-

independent,

P(t+1 2 )

(16).

This

but

is the

Consequently,

to

the planned production

for the downstream stage over the smoothing window for the upstream

stage.

We suggest

Upstream Stage:

below two approaches.

Production

The first approach is

an explicit

forecast

of

to

to

Intermediate

Inventory

smooth the upstream production using

the downstream production

over the

smoothing

18

window.

The production smoothing

(17)

Q(t+t

= m+1

1)

{Pt(t+X

-

where

for i=l,

...

t1 +m.

at time t, net of

J(t)

+l,t+X+m)-

Q(t+l,t+t 1 -1)

+ SS 1 }

J(t)

m is the window length,

Pt(t+g+m) and Pt(t+1 2+i)

2

rule is

Pt(t+t 2 +1,t+X+m)

= Pt(t+1 2 +1)

+

...

is a forecast made

at time t of P(t+1 2+i)

denotes

intermediate

the downstream

the actual

+

inventory

production started at time t;

that

is,

(18)

J(t)

and SS1

We note

is

J(t-1)

-

here that P(t+12+i) will

P(t+X2)

Hence,

for the

Pt(t+1 2 +1,t+l+m)

(18) we can rewrite

that is analogous to

_m_

upstream stage

is

-

denotes

interval

the demand forecast

t+1,

...

t+ll+m.

as a simple smoothing equation

+

[Pt(t+12,t+l+m-1)

Pt-l(t+1 2 ,t++m-l)] +

l(t)

+

{Q(t+1-1) )

Q(t)

.

Thus,

planned production for the

a weighted average

the previous period and

requirements

(17)

{Pt(t+l+m)

-

= Q(t)

inventory.

(7):

Q(t+ 1l) = m+l

where el(t)

intermediate

be the demand on the upstream stage

upstream stage over the time

Using

(19)

+ Q(t)

the target safety stock

at time t+i.

for the

=

the

of

the production

initial forecast

level

of cumulative

from

net

in time t+l+m.

To specify Pt(t+1 2 +i),

simple smoothing equation

we note

that

(16)

is

equivalent

to a

19

P(t+1 2 )

(20)

= n+1

{Ft(t+1

+

=

t(t,t+X

+

2 +n-1)

2(t)}

(P(t+12-1))

{

) is the forecast revision as defined before, and

where St(

C2(t)

+

2 +n)

-

P(t)

Now the forecast of

P(t).

P(t+1 2 +1)

made at time t

should be

since

n

(n+1)

+

2 +n+1)

Ft(t+1

i=2,

(22)

Similarly we can use

is zero.

...

forecast P(t+12+i)

to

R1+m:

=

Pt(t+1 +2)

2

=

Pt(t+l+m)

In spite

(21)

P(t+12 )

the expected-yield

the expected forecast revision is zero and

variation

for

1

= (---)

Pt(t+X 2 +t)

(21)

of the

(n;)

(-)

1

that

fact

Ft(t+t 2 +n+2)

Ft(t+l+m+n)

+

+

(

1)

n

( -)

Pt(t+12+1)

+m -

Pt(t+I

l)

the smoothing equations for the upstream

form as those for

a single-stage

[(17)

and

(19)]

have the same

system [(3)

and

(7)],

we have not analyzed fully the random variable

stage

for

planned production Q(t+1 1 ).

upstream production Q(t+l1 )

planned production,

demand.

a way

to

which

itself

We will need

this

smoothing model.

do expect that

to

'decode' this double smoothing in

the

or

any other measure of

it

is

easy to show that E[Q(t+

simulation

to

see

(However,

to use

D.)

the planned

is a smoothed average of customer

the variance of Q(t+t 1 ),

production smoothing.

is because

is a smoothed average of the downstream

We have not been able

find

This

Despite

behavior

this

of this

exactly the

behavior

1]

=

of

lack of an analytic result, we

smoothing model

for the

upstream

20

stage will

system.

closely parallel

that predicted for a single-stage

In particular, due

to the double smoothing, we expect that

the variability of the upstream production will depend upon the sum

of

the window lengths,

m+n.

J(t+

1)

= J(t)

is given

inventory at time t+. 1

The planned intermediate

+ Q(t+l,t+l

1)

-

Pt(t+1

2

by

+l,t+t),

which can be rewritten as

J(t+ll)

= SS 1

+ Pt(t+1+l,t+l+m)

by substituting from

clear that

E[J(t+t 1 )]

(17)

-

mQ(t+t

1)

Again, although it is

for Q(t+l,t+t1 -l).

= SS 1,

we have not been able to

characterize

analytically the variability in the planned intermediate

Nevertheless,

we need the planned intermediate inventory to specify

how the upstream aggregate planned production Q(t+

disaggregated

Q(k,t+t 1 )

for

inventory.

into planned

production for

1

)

individual

is

items,

e.g.

item k.

For this model we disaggregate the upstream production to

to equalize the service

across all

items.

levels

To do this,

from the intermediate

we set Q(k,t+t

1

)

try

inventories

such that

£ Q(k,t+tl) = Q(t+11), and such that the planned intermediate

k

inventory for item k, J(k,t+ll), provides the same level of

protection against

variance of

stockout for all k.

Define aklto be

the

the deviation between the planned intermediate

and the actual

intermediate

inventory at time t+1 1 :

inventory

21

~2

akl1= Var[J(k,t+l1)

= Var[

- J(k,t+l

1

{Q(k,t+i)

E

1 )]

- Q(k,t+i)

i=l

Pt(k,t+1

Then,

for

~2

given &ki

intermediate

where

+ P(k,t+1

+i)

we disaggregate Q(t+l 1 )

inventory for k

J(k,t+tl)

2

= z

2

+i)}]

so that the

planned

is given by

kl'

z is

z = J(t+t 1 )

/

E

kl'

k

Unfortunately, though, we are not able

^2

ak1'

to determine analytically

since we cannot determine the forecast error for downstream

production, Var[Pt(k,t+12+i)

need to

- P(k,t+1 2 +i)].

estimate it empirically or substitute

error for

demand, Var[Ft(k,t+1 2 +i)

error for

downstream production.

Upstream Stage:

Production to

Hence, we would either

the known forecast

- D(k,t+t 2 +i)],

Echelon

for the

forecast

Inventory

The second approach for smoothing the upstream production

based on the notion of echelon inventory.

a production

stage equals

all

inventory,

that is downstream of the stage.

inventory for the upstream stage

is

The echelon inventory for

including work-in-process,

In a two-stage system, the

is the intermediate

the work-in-process within the downstream stage,

echelon

inventory, plus

plus the finished-

22

goods

inventory.

Each period this echelon inventory is increased by

the amount of production

completed by the upstream stage, and

decreased by the amount of customer demand.

production

level for the

requirements

...

the

We set the planned

upstream stage to be the

echelon

inventory over

the

average of

the net

interval t+l,t+1+1,

t+l+m, where m is the window length:

(23)

Q(t+ 1 )

To explain

+

on

is

(J(t)

-

=

-

l {Ft(t+l,t+t+m)

-

Q(t+l,t+l1-1) -

-

J(t)

stocks), and

is the current

Q(t+l,t+1 1 -1)

+ SS 2

I(t)

-

(I(t)

echelon inventory

The sum of the current echelon

(t+l,t+1 1+1 2 -l)

since

2

should cover

is the

lead time for

Production at the upstream stage that is

started at t will be input into echelon inventory at time.t+

will not be available for

customer demand until

since Ft(t+l,t+l+m) = Ft(t+l,t+1-1)

bracketed term

echelon

in

2)

(exclusive of safety

inventory and the planned input over (t+l,t+1 1 -l)

the downstream stage.

+ P(t+l,t+1

SS 2 )

is the planned input to the echelon

inventory over (t+l,t+1 1 -1).

customer demand over

2)

+ SS 1 }

the bracketed term, note that

SS 1)

P(t+l,t+t

(23) corresponds

inventory over

set planned production

t+1 1+1

+ Ft(t+l,t+l+m),

to

(t+l,t+l+m).

1

. but

= t+R.

2

Now,

we see that the

the net requirements

on the

As we have done previously,

to be the average of

the net

we

requirements on

the appropriate inventory over the chosen smoothing window.

The analysis of

stage

__

is

identical to

system where we replace n by m,

(SS1+SS2 )

_

(23)

and

I(t)

by

((t)

that

for

(3)

for the

P(t+l) by Q(t+t 1 ),

+ P(t+l,t+1

2)

+ J(t)).

one-

SS by

In particular,

23

we can rewrite

(23) as

Q(t+£ 1)

1

= m+l

+

{Ft(t+t+m)

t(t,t+l+m-1)

m

+ el(t)

from which

+

+

2(t)}

(mQ(t+l1 -1))

we can obtain

E[Q(t+l1)

D

]

and

Var[Q(t+l 1 )]

2

p

where

.

Q(t)]

= P(t)

= Var[e2 (t)

as expected,

Thus,

+

-

to the window

echelon

planned

In

parallels

that for

(10)

-

(13).

define the

(24)

fact,

analysis

we use

I(t+

)

+

the planned intermediate

this,

To see

+ P(t+Z1 +l,t+t)

I(t+l 1 )

inventory

echelon

for the planned

this, we write the counterpart

(23) to

P(t +

P(t+l+l,t+)

to

(10)

to

inventory:

+ P(t+ll+l,t+l) + J(t+t 1 )

we find

for the

it is

model,

for this

= I(t)

substitute for

+ J(t+)

Q(t+l,t+

=SS

1

From

is inversely

its variance

while

+ P(t+l,t+z 2 )

+ Q(t+l,t+l

Then,

rate

the planned inventory for the one-stage system.

planned echelon

I(t+l 1 )

-

length for smoothing.

is not immediate

the

= Q(t)

the aggregate upstream production

inventory at time t+R 1 ,

J(t+t 1 ).

(2m+1)

2

and aQ = Var[e l (t)

P(t)]

While the characterization of

inventory J(t+l 1 )

/

)

the demand rate,

equals, on average,

proportional

+

= ( D

that the mean

echelon

1)

in

1-1)

+ SS

2

(24)

+ J(t)

Ft(t+lt.11)

to

obtain

+ Ft(t+tl+l,t+l-m)

m Q(t+ )

1

inventory equals

SS 1

+ SS 2

24

+ 12D, while

its

variance is given by

m2

2m+l

2

2

+

(

+

2

Q)

-

I +j

m

2(m_

12+m-

E

[1

j=om+1

+

To disaggregate Q(t+1 1)

each item k, Q(k,t+l 1 )

E Q(k,t+l

We can do this

Namely,

for item k,

I1D(k),

equals Zkl

l

(i)]

1)

1)

manner to that for the one-stage system.

so that the

planned echelon safety stock

+ P(k,t+

I(k,t+t 1 )

1l+l,t+l )

+ J(k,t+1

1

)

-

where z is given by

E 0

kl equals

v 2

i=O

I(t

P(t+

1) E

1 +l,t+)

and

It1+j

E-

such that

in a similar

defined as

2

[aD

]

we need to find the planned production for

) = Q(t+

we set Q(k,t+

j+l

)

+ J(t+t

D

kl

the variance of

1

[Q(k,t+i)

-

+ [Ft(k,t+i)

Q(k,t+i)]

-

D(k,t+i)]

i=l

In words,

echelon

time

kl

is the

variance of

inventory for time t+t

t+t1

for item k.

planned echelon

Thus,

1

the deviation between the planned

and the actual

safety stocks

for all

yield uncertainty and forecast

for

items,

safety stock

(i.e.

the

where we have

the cumulative upstream

error over the

this disaggregation

planned echelon

inventory for

this disaggregation equalizes

normalized by the standard deviation of

rationale

echelon

scheme

either

is

lead

time t 1.

to try to

in the

The

spread the

intermediate or

25

finished-goods

intend for

level

inventory),

each item's

items.

By

'evenly!, we

echelon safety stock to provide the same

and from yield uncertainty in

lead time

As

before, the measure of

+SS 2 )

the upstream stage over

its

1.

disaggregation,

1

the

of protection against uncertainty both from the forecast

errors

(SS

'evenly' over

lerel

z, is a random variable.

akl,

a

/

the

while

its variance

is

of

protection from the

Its mean is given

by

directly proportional to

(25).

to term the first

It will be convenient

(produce to

intermediate inventory) approach as the decoupled model and to term

the

second

the first

(produce to echelon

case,

the

intermediate

The upstream stage produces

downstream

stages

forecast.

But the stages

produce

to the

are

the

inventory based on

stage draws

stages.

a forecast

of

its raw materials

demand

namely the

same forecast,

'nested'

In

both the upstream and

stage

in that the upstream

inventory which contains

produces to the echelon

stage and its

to this

In the second case,

inventory.

the nested model.

inventory decouples

the downstream

downstream usage, while

from this

inventory) as

the downstream

inventory.

COMPUTATIONAL STUDY

To examine

the proposed production smoothing models.

conducted a computational study based

items produced

computational

on data gathered on the set of

in one manufacturing facility.

study

is

threefold:

we

The purpose

of

the

to understand how much inventory

26

is needed

in a make-to-stock system and where that inventory should

be positioned;

to compare the effectiveness of the different

production smoothing models for a two-stage system;

determine,

via a comparison to a simulation,

approximate analyses of these

the test data,

and finally

Test

the

computational

the accuracy of the

smoothing models.

then the simulation

and to.

We first describe

program that we have developed,

results.

Scenario

To test

the production smoothing models we abstracted a test

scenario based on data gathered

the results given here,

from a manufacturing operation.

we have disguised this data to protect the

identity of the manufacturing firm.

are representative of

In Table

the results

I we give

family, we consider only

system.

We exclude all

200 units

these

per month,

However,

the reported results

obtained using the actual data.

the mean demand rate

its standard deviation for the

this

For

family of

(units

items.

Of

25 as candidates for

per month)

the

38

and

items

in

the make-to-stock

items that have a start rate of less than

since

it would

be

too risky

to plan to

stock

low-demand items.

We assume that there are two production stages and that each

item requires processing from both stages.

first stage

stage

(

2

is three months

=1).

·1_

find it

1 =3)

and is one month for the second

The first stage processes each

exactly 500 units.

We will

(

The lead time for the

The second stage can process

convenient to express

__1___1__·_1_11_1_____-___-·----

item in a lot of

the

lots of any

simulation results

size.

in

27

terms

of

the lots

For the

per month

for

the upstream stage

sample of

25

items,

28.5 lots per

month

For the test scenario

and

revision step

(

81

lots

= 811).

we assume that the forecast process

that for eac h item k,

the

variance of

is

the forecast

is given by

a2(o)

=

2(1)

2

.1

QD

2

a2(2)

.13

D

a2(3)

.2

oD

cr2(4)

=

2(5)

=

.23 aD

acr2 ( j )

Thus,

the mean monthly demand is

(500 units/lot) and the standard deviation of aggregate

demand aD is

unbiased,

(500 units/lot).

0

for j

> 5.

any forecast for 6 or more months

monthly demand,

and is not revised

ahead

equals the mean

until there

is 5 or less months

to go.

We assume that

in each stage.

data

there is no uncertainty in

There are two reasons

from which to estimate

for this.

the parameters of

Second, we had observed in an earlier

the production yield

First,

we had no

the yield uncertainty.

study of a comparable

production operation that the uncertainty in the forecast errors

dominated

that

in

the yield realization.

including only the uncertainty in

capture

given

this

the primary

behavior of

Hence, we hope

our study.

by

the forecast errors we will

the smoothing models.

information on yield uncertainty, we could

into

that

Nevertheless,

easily incorporate

28

We can

for

find ok

item k over a given lead time 1,

the variance

of

2

ak

, the variance of

D

for

of the

item k

2

2

a (0) + ( 2 (0) +

2

cumulative forecast

from the above

forecast revision

(Table

the

specification of

steps and from the knowledge

1).

For instance,

(1))

+

2

error

if

t=3 then

2

2

a ()

r(2))=

.63a

D

For later reference, we note that the sum over the 25 make-to-stock

items of the standard

E ak' is

25 lots

when

deviations of

t=1 month,

the cumulative

63 lots when

forecast errors,

=3 months,

and 86

k

lots when

=4 months.

Simulation Program

We have written in PL-1 a program to simulate the production

planning process

for a two-stage production system.

is a discrete-time simulation where the time unit

Each month

the

simulation generates

The simulation

is one month.

customer demand and a demand

forecast for the next twelve months for each item.

inventories

for the items

are increased by completed downstream

production and are depleted by the demand amount.

created when insufficient

inventories exist.

disaggregation to determine

The intermediate

the production

inventories

for the

starts by the downstream stage.

(3)]

and

its

items are increased by

by usage from the

Note that the

intermediate

inventory cannot have backorders;

insufficient

inventory exists,

___1__11__^____11_l_l_-__--

[e.g.

starts for the downstream

completed upstream production and are depleted

production

Backorders are

The simulation then

applies a specified production smoothing model

stage.

The end

rather,

if

then the downstream production

starts

29

the simulation then applies a

Finally,

need to be reduced.

specified production smoothing model

(17)] and

[e.g.

disaggregation to determine-the production starts

stage.

the

Note

simulation.

of the

for the upstream

then repeated each month for the run length

process is

This

its

that,

in

effect, the simulation acts as

if

events, customer demand, production starts, and completed

production,

occur at

the start

(or end)

For our tests the simulation is

of

every month.

run for

1000 months where

the

first 40 months are for initialization and various statistics are

collected over the remaining 960 months.

forecast time series

common demand and

comparability of

Thus,

simulation runs

in order

for different

to

increase the

smoothing models.

in performance between two simulation runs

any differences

will be

the smoothing models and not due to any differences

due to

To generate

in the realization of the demand or forecast process.

forecast time series,

the demand and

obtains

Ft(s)

as a lognormal

with variance

In the

relies on a

The simulation

2

[see

(s-t)

previous

random variable with mean Ftl(s) and

(1)].

section we develop the disaggregation procedure

with no restrictions on the sign of

this procedure may

the forecast revision process

suggest the impossible,

namely negative

The

production for an item with an excessively high inventory.

simulation does not permit negative production.

disaggregation results

the

in this outcome

production starts for that

disaggregation procedure is

Similarly,

Indeed,

the production outcome.

Rather,

for a particular

item are set

repeated for the

to zero and

remaining

the disaggregation procedure assumes

if the

item, then

the

items.

that

sufficient

30

raw material

is available to make the desired production starts.

For the upstream stage,

However,

the simulation retains this assumption.

for the downstream stage,

more production of a particular

item than is available in its

intermediate

inventory

intermediate

inventory).

item exceeds

the available raw material, we set

to

the raw material

procedure

for the

(i.e.

the simulation will not start

Rather,

level and

if the desired production for

then repeat

remaining items

aggregate production

impose a lot

the upstream stage.

its production

Thus,

the planned

for the excluded

size of

500 units

500 units.

is to compute

units to start, divide by 500 to

the nearest

integer.

item).

for all

To accomplish

this we have to modify the disaggregation procedure to

The modification

equal

for each item the monthly

production starts must be a multiple of

restriction.

an

the disaggregation

(after we reduce

by the amount preset

For the simulation we

items for

we do not permit backordering on the

reflect this

the desired number of

convert to lots, and

then round to

We assume no such restriction for the

downstream stage, although we could

impose a fixed

lot size,

if

appropriate.

The simulation also has the capability to limit the aggregate

production for each stage.

not be capable

case,

production starts equal

production smoothing model

to the

and the capacity

computational work

but assume

the upstream stage might

of starting more than 90 lots per month.

we would modify the

from the model

For instance,

minimum of

limit,

to

In

set

the desired start

say 90 lots.

this

rate

However.

in the

that we report, we do not use this capability,

that there are no

limits

to

the production at each stage.

31

The disaggregation of upstream production for the decoupled

(produce to intermediate

forecast

item-level version of

replace

-

(21)

by the amount that would be started

the intermediate inventory.

P(k,

starts

In this

is necessary because

This modification

level;

from their desired

hence,

compare

the

the actual_

of future

Results

section we present

and discuss our

First, we

in two parts.

one-stage model

Second, we

consider the application of a

and study its behavior on the test

them against

work.

computational

scenario.

and

consider the two versions of the two-stage model

each other and versus

the one-stage model for

test scenario.

the one-stage model

To apply

to the test

make-to-stock system with a finished-goods

intermediate

inventory.

scenario, we assume a

inventory but with no

months.

rate,

in the

In effect, we combine the two stages

test scenario into one stage with a production lead time

via

(21)

by the downstream stage.

Computational

We do this

in

t+1t2 ),

if there were no shortages in

production starts may not be an accurate reflection

production

We

intermediate inventory perturb the actual

stockouts in the

production

for item k,

starts

actual production

the

with one modification.

(22),

via an

this forecast

We generate

downstream production.

of

requires an item

inventory) approach

Each month we use

(3)

to set

=

4

the aggregate production start

which is disaggregated based on the finished-good inventories

(14)-(15).

32

We used the simulation to compare the "actual"

found

from the

simulation)

of the one-stage model

behavior from our analysis of

We report our results

window

lengths n=0,1,2, ...

120 and

150

lots

(recall

show the consequences

standard deviations

aggregate

the fill

e.g.

(9),

(13).

We have run the simulation for

6 and for safety stock targets of SS = 80,

ak = 86

that

from production

lots

= 4 months).

for

smoothing, we

To

report the

of aggregate production P(t) and of the actual

inventory position

rate,

(as

with the predicted

the one-stage model,

in Table 2.

behavior

I(t).

As a measure of service we

report

which equals the fraction of demand that is satisfied

by inventory without any delay.

From

the simulation

two decision parameters,

results in

this table we can see how the

the window length and the safety stock

target, affect the reported performance measures.

Namely,

the

window length essentially determines the measures of production

smoothing

[the standard deviations of P(t)

and

safety stock target determines the fill rate.

I(t)],

This is

with the analysis of the production smoothing model.

the analytic results

of

the actual

(9),

(13)

while the

consistent

Furthermore.

are reasonably accurate predictions

(simulated) values. 1

approximations made by the analysis

This

indicates that the

(i.e.

ignoring lot-sizing. and

assuming that inventories remain balanced so that the proposed

disaggregation

this test

is always

feasible)

do not give

significant

errors

scenario.

Finally, from Table 2 we see the implications

stock system for

starts needed

for

this

family of

the sample of

items.

items

of

a make-to-

The average production

in the test scenario is 81

in

33

lots

of

per month.

80

90%

lots

fill

We see that maintaining a finished-goods inventory

(about one month of demand),

improves service to a 95% fill

length

for

rate.

To get to a 98%

investment in another 30 lots.

the

production smoothing mdel

(n=0),

production start rate,

while equal

lots

standard deviation of

nearly 30

to exceed 120 lots

below 50 lots

16% of

16%

lots.

Thus,

of the time,

possible by increasing the window length,

returns.

For instance, a window

using a six-month cumulative

deviation of production

the monthly

on average,

has a

we expect production

and similarly to fall

smoothing is

but with decreasing

length of n=2,

forecast

rate

extent of

Substantial production

the time.

lots

fill

dictates the

With no smoothing

to 81

in a

The choice of window

production smoothing.

starts

will result

Increasing this safety stock by 50% to 120

rate.

requires an

on average,

(6=n+l),

which corresponds

reduces,

the standard

starts by almost 60% over no smoothing.

The

cost from increased production smoothing is a slight degradation

fill

rate,

and an

increased variability in

the actual

to

in

inventory

position.

We

examined the two-stage models to

possible by inserting an intermediate

see what improvement

inventory between the

To examine the smoothing behavior, we first

smoothing models for

lengths.

effectively independent

levels.

approach

(produce to

results

for

stages.

simulated the two

a fixed safety stock but with varying window

As with the one-stage system,

stocking

is

of the

the

safety stock targets

Table 3 gives the results

intermediate

the nested

approach

smoothing behavior

inventory)

is

for reasonable

for the decoupled

while Table 4 gives

(produce-to echelon

inventory).

the

In

34

both cases

Table

the

safety stock

3 shows

= 100

targets are SS

and SS

2

= 120.

that for the decoupled approach the production

smoothing behavior for the downstream stage is as predicted and

independent of the upstream stage.

upstream

is

The production behavior for the

stage, for which we do not have an analytic

reflects the effect of double smoothing:

prediction,

the upstream production

is

set by smoothing the forecast of downstream production, which itself

is a smoothed average

of

the demand forecast.

Consequently, for a

fixed window length for the upstream stage there is

smoothing as the downstream window length grows.

the one-stage system,

In contrast with

the fill rate provided by the safety stocks is.

very dependent on the level

the fill

_

greater

of production smoothing.

In particular,

rate declines dramatically with longer window lengths

smoothing) for the downstream stage.

the item forecasts

This

is due to

(more

the fact that

of downstream production used by the upstream

stage become less accurate with longer window

downstream stage. 2

As a consequence,

frequent stockouts,

which ultimately results

the

lengths for the

intermediate inventory has

in poor customer

service.

In Table 4 we see

the comparable

for the nested approach.

Here,

production smoothing behavior

the analytic predictions of the

production smoothing for both stages are reasonably accurate.

Furthermore,

the level of smoothing for the upstream stage

totally independent of the downstream stage.

virtually independent

And

the fill

is

rate

of the choice of smoothing parameters,

is

as we

saw for the one-stage system.

To explore the impact of the safety stock

levels, we contrast

35

in

Table 5 the fill

rates

safety stock choices.

from the two approaches

Due to the fact

decoupled approach is very

that the fill

sensitive to the

smoothing, we simulated a set of

positioning of

these

stocks

stock target to be set

hope of

= 1).

to provide insight

production

(m=l,

smoothing

n=O).

below 40 lots,

results

We

into the proper

and to allow comparison with the

providing reasonable service

Based on the

smoothing

We did not permit the

(Table 2).

stage model

level of

rate for the

cases with substantial

(m=3, n=2) and another set with limited

chose the safety stock levels

for a series of

one-

downstream safety

since below that we have no

(recall that

in Table 5,

we make

ak = 25

lots when

the following

observations:

a)

(produce to echelon inventory),

For the nested approach

fixed

total

safety stock

insensitive with slight

(SS 1 +SS 2 ),

the fill

for a

rate is relatively

improvement as more safety stock is

placed downstream.

b)

the fill

rate

intermediate inventory)

(produce to

For the coupled approach

is very sensitive to both the amount of smoothing

and the

positioning of

service

again deteriorates with increased smoothing.

fixed

placed

total

the safety stock.

safety stock,

in the intermediate

(SS 2 =40)

As seen in Table 3,

For a

fill rate improves as more stock

inventory as long as a minimal

is kept downstream;

beyond this minimum,

is

level

service will

be degraded.

c)

see that the nested

In comparing the two approaches,

we

approach dominates the decoupled

approach for

substantial

smoothing.

When there

is

the case with

limited smoothing,

36

however, the

decoupled approach

is slightly better,

provided

the appropriate inventory positioning.

In comparing either of-the approaches for the two-stage model

with the one-stage model, we need more inventory with a two-stage

model

than with

a one-stage model fora given

instance, a safety stock of 120

a 95-96% fill rate.

provides a 90%-92%

lots with

the

fill rate for the same

However,

Thus, a two-stage model

total safety stock;

the cost

to hold

finished-goods

stock in

inventory.

can be prefereable to the one-stage model

for

the finished-goods

For

We can achieve this

with the one-stage model with a finished-goods safety stock of

lots for window lengths n=2 and n=3.

For comparable smoothing with

n=2 and with intermediate safety stock of 80

lots and a finished-goods

safety stock of

stage model would be preferable if

inventory is

goods inventory.

80

we would need the nested approach with

smoothing windows m=3,

intermediate

if

low enough

inventory.

a 90% fill rate is desired.

the two-stage model,

the

rate but with limited

the holding cost for the intermediate inventory is

instance, suppose

For

the one-stage model, gives

it typically will cost less

intermediate inventory than in the

relative to

rate.

The nested approach for the two-stage model

decoupled approach can provide a 94% fill

smoothing.

fill

40

lots.

Thus, the

two-

the holding cost for 80 lots of

less than that for 40 lots of

finished-

ll

37

FOOTNOTES

Note that we report the standard deviation of actual inventory,

Since the

rather than that of planned inventory as given by (13).

actual inventory is given by

I(t+Z)

= I(t+1)

2

+

{P(t+i) - P(t+i)}

i=1

+

{(F

i=l

we can express

by (13).

its

variance

(t+i)

- D(t+i))

t

in terms of

the variance

of

I(t+i)

given

2

To disaggregate upstream production for the decoupled approach, we

We obtained this

need an item forecast of downstream production.

By using an

- (22).

forecast via an item-level version of (21)

alternate forecasting method, namely proportioning the aggregate

forecast by the expected demand level, we could avoid the

However, this alternate

degradation in fill rate seen in Table 3.

forecast method resulted in system performance that was strictly

dominated by the nested model (Table 4).

38

APPENDIX

Derivation of _81_and_91

By recursive substitution for P(t)

P(t+t)

=)(n+

i=o n+

({F

t

n+1

6t i(t-i,

in

(7) we obtain

(t-l+.+n)

t-i+I+n-1)

+

+

(t-i)}

where we assume that an infinite time history exists.

we have that

By assumption

i

for all

E[Fti (t-i+t+n) + 6ti(t-i, t-i+t+n-1)

+ E(t-i)] = D

and

VarF ti(t-i+t+n)

t-i

Furthermore,

+

ti

t-i (t-i , t-i+.+n-1)

+ C(t-i)]

=

we have assumed that these bracketed terms are

independent across time.

E[P(t+)

=

nDi

i =0

Thus,

we

obtain

n+1

DVar[P(t+

I

Var[P(t+l)

=

i=0

=(D

(n1)2 (n)2i

n l

n+i

+

P) /

(2n

+1)

(o 2

D +

2

O'p)

2

D

+

2

P

I1

39

References

Cruickshanks, A. B., R. D. Drescher and S. C. Graves, "A Study of

Production Smoothing in a Job Shop Environment," Management Science

30, 3 (March 1984, 168-380.

Eppen, G. and L. Schrage, "Centralized Ordering Policies in a

Multiwarehouse System with Lead Times and Random Demand," in

Schwarz, L. (ed.), Multi-Level Production/Inventory Control Systems:

Theory and Practice, North-Holland Amsterdam, 1981.

Federgruen A. and P. Zipkin, "Approximations of Dynamic,

Multilocation Production and Inventory Problems," Management

Science, 30, 1, (January 1984), 69-84.

Hax, A. C., and H. C. Meal, "Hierarchical Integration of Production

Planning and Scheduling," In Studies in Management Siet

Sciences, Vol.

I_ Logistics, M. A. Geisler (ed.). North Holland-American Elsevier,

New York, 1975.

C. Holt, F. Modigliani, and H. Simon, "A Linear Decision Rule for

Production and Employment Scheduling," Management Science 2, 1-30

(1955).

Iand J. Muth, "Derivation of a Linear Decision Rule

- -----for Production and Employment," Management Science 2, 159-177

(1956).

Schneeweiss, C.A., "Smoothing Production by Inventory Application of the Wiener Filtering Theory," Management

7 (March 1971), 472-483.

An

Science

17,

_____-"Optimal

…

Production Smoothing and Safety Inventory,"

Management Science, 20, 7 (March 1974), 1122-1130.

Silver, E. A., "A Tutorial on Production Smoothing and Work Force

Balancing," Oerations Research, 15, 6 (November-December 1967),

985-1010.

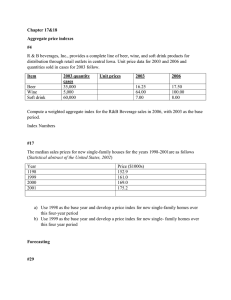

Figure 1: Two-Stage System

--4

I

II

#upstream'

II

I

·

II

'downstream'

customer

demand

TABLE 1: DEMAND FOR TEST SAMPLE.

500 demand units equals one lot.

Starred items(*) are excluded from Make-to-Stock System.

DEMAND

ITEM CODE

MEAN

STD. DEV

*1

2

2

*2

1

1

*3

18

21

*4

8

16

5

651

961

6

214

362

*7

137

298

*8

11

15

9

325

238

10

237

293

11

483

569

*12

2

6

13

1315

1121

14

1953

1685

15

6729

4793

*16

1

3

17

554

722

*18

48

49

*19

20

30

20

1887

1951

TABLE 1 CONTINUED ON NEXT PAGE.

TABLE 1 (continued)

DEMAND

ITEM CODE

MEAN

--

--------

STD. DEV

21

2193

1908

22

587

604

23

615

728

24

833

665

*25

47

151

*26

27

8

1206

11

1603

28

15691

12278

29

1142

2286

30

336

677

*31

81

242

32

246

660

33

749

890

34

817

1199

35

232

636

36

360

822

37

279

634

38

819

1336

Safety Stock

Window

Length

SS= 80

SS = 120

SS = 150

Predicted

Std.

Deviations

n = 0

29.8, 30.1*

.92

29.8, 30.2

.96

29.1, 30.1,

.98

28.5, 30.8

n= 1

17.4, 34.0

.91

17.3, 34.3

.96

17.2, 34.1,

.98

16.4, 34.9

n=2

13.1, 37.5

.90

13.1, 37.9

.96

13.0, 37.6,

.97

12.8, 39.4

n =3

10.8, 40.8

.90

10.8, 41.3

.95

10.8, 41.0,

.97

10.8, 43.6

n =4

9.3,44.0

.89

9.4, 44.4

.95

9.3,44.0,