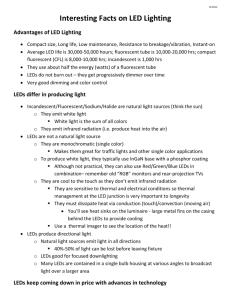

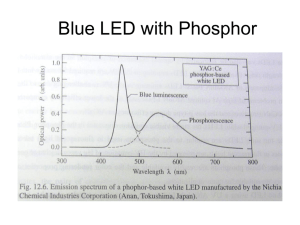

White LED

advertisement