Response Surface Methods Applied to ...

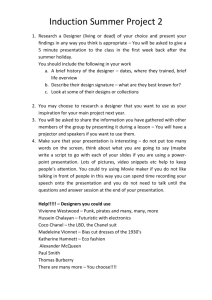

advertisement