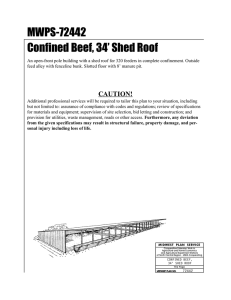

\ the SHED by An

advertisement