Technician Staffing Levels for Modern Public Transit Fleets TCRP Project E-10 Summary

advertisement

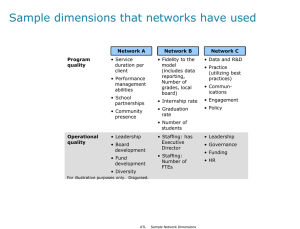

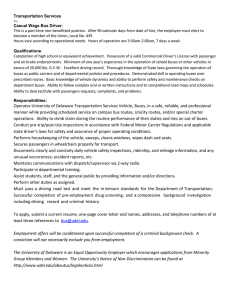

Technician Staffing Levels for Modern Public Transit Fleets TCRP Project E-10 Summary TCRP E-10 Project Scope Analysis of NTD Data, and surveys of 68 Survey of existing data and outreach to transit agencies to identify main factors driving technician staffing levels Develop Interactive Staffing Tool to evaluate local needs and model fleet or maintenance practice changes Develop Guidebook explaining application of findings and how to use Staffing Tool Analysis of NTD Data Reviewed NTD submissions from 321 agencies Correlations identified in several areas: – Between agency size and staffing ratios – Between spare ratio and staffing ratios – Duty cycle and miles based staffing ratios – Data was widely distributed; many outliers might be mistakes in the submission of data or misunderstanding of NTD definitions – Could not really compare “apples to apples” Detailed Staffing Questionnaires 68 Participating Agencies – Diversity of Size – Diversity of Geography Most agencies found it very difficult to provide confident data for the breadth of information sought A main goal – identifying the right fleet with the right staff – e.g. adjusting for outsourced fleets or maintenance staff maintaining non-transit vehicles Geographic Distribution of Participants Region Round 1 Round 2 Total California 10 2 12 Northwest 3 2 5 Midwest 3 8 11 Southeast 1 8 9 Southwest 1 1 2 Mid-Atlantic 5 2 7 New England 2 2 4 Canada 2 16 18 Size Distribution of Participants Agency Size Round 1: Round 2: Total: >1000 Buses 4 2 6 500-999 Buses 3 4 7 250-499 Buses 6 6 12 100-249 Buses 7 10 17 50-99 Buses 5 12 17 <50 Buses 2 7 9 Existing Staffing Levels # of Agencies Agency Size Maintenance Technician Hours per 10k Vehicle Miles Standard Average Deviation 6 >1000 Vehicles Maintained 159 44 7 500-999 Vehicles Maintained 114 54 12 250-499 Vehicle Maintained 97 29 17 100-249 Vehicles Maintained 108 33 17 50-99 Vehicles Maintained 84 39 9 <50 Vehicles Maintained 63 29 Summary of Correlations Strong correlation between variable and staffing level: – Fleet Size (for core maintenance as well as overall) – Fleet Composition (articulated buses / cut-aways) – Level of Outsourcing Summary of Correlations – Fleet Size Technician Hours Per 10k Vehicle Miles, sorted by fleet size 1500 250.0 200.0 1100 Fleet Size (Blue Line) R² = 0.2393 900 150.0 700 100.0 500 300 50.0 100 -100 0.0 Transit Agencies Sorted Largest Fleet to Smallest Fleet Core Maintenance Supplemental Staff (Mech Helpers / Trainees) Heavy Repair VAMS Total Staffing Level Linear (Total Staffing Level) Maintenance Hrs per 10k Miles (Purple Line) 1300 Summary of Correlations – Outsourcing Effect Heavy Maintenance Hours by Fleet Size 200.0 180.0 160.0 Annual hours per vehicle 140.0 120.0 R² = 0.7344 106.9 100.0 80.0 67.2 62.9 60.0 45.5 40.0 20.0 18.5 9.7 0.0 >1000 Buses Maintained 500-999 Buses Maintained 250-499 Buses Maintained 100-249 Buses Maintained 50-99 Buses Maintained (n=6) (n=7) (n=12) (n=17) (n=17) Min Max Mean Linear (Mean) <50 Buses Maintained (n=9) Summary of Correlations – Core Maintenance Core Maintenance by Fleet Size 700.0 600.0 Annual hours per vehicle 500.0 400.0 R² = 0.9035 395.2 341.1 329.5 300.0 288.5 217.5 200.0 227.4 100.0 0.0 >1000 Buses Maintained (n=6) 500-999 Buses Maintained 250-499 Buses Maintained 100-249 Buses Maintained (n=7) (n=12) (n=17) Min Max Mean Linear (Mean) 50-99 Buses Maintained <50 Buses Maintained (n=9) (n=17) Summary of Correlations – Fleet Size Maintenance Technician Hours per 10k Vehicle Miles 180 160 25.8 140 6.0 120 Hours 6.3 16.8 5.6 80 60 16.8 26.7 100 6.7 0.6 3.4 127.0 3.2 82.0 40 80.2 0.0 90.0 74.1 59.7 20 0 >1000 Buses Maintained (n=6) 500-999 Buses Maintained (n=7) 250-499 Buses Maintained (n=12) Core Maintenance Supplemental Staff 100-249 Buses Maintained (n=17) 50-99 Buses Maintained (n=17) Heavy Repair and Overhaul <50 Buses Maintained (n=9) Summary of Correlations – Bus Type Annual maintenance hours per vehicle maintained, sorted by % of fleet articulated vehicles 100.0% 700.0 90.0% 600.0 R² = 0.1075 70.0% 500.0 60.0% 400.0 50.0% 300.0 40.0% 30.0% 200.0 20.0% 100.0 10.0% 0.0% 0.0 Hours per Vehicle % Articulated % CutAways Linear (Hours per Vehicle) Annual Maintenance Hours Per Vehicle % Articulated (Red); Cut-Away (Green) 80.0% Summary of Absent Correlations Small or no correlation between variable and staffing level – Spare ratio (small correlation, but not as big as NTD data) – Duty Cycle (Fleet mph) (small correlation, not as big as NTD data) – Fleet age (very small) – % of time on scheduled maintenance – % of fleet using alternative fuels Most correlations identified were not as strong as found in NTD Data, but data set much more reliable Limitations of Data Breakdown of hours by type of maintenance seems unreliable Definition of “Scheduled” and “Unscheduled” maintenance varied Definitions of “Productive time” varied – some based on contract, others actual timesheets Interactive Staffing Tool The Bus Maintenance Staffing Calculator has three related purposes: Compare actual current maintenance staffing levels with agencies in your peer group Planning tool to determine necessary staffing levels for your particular maintenance operation based on existing factors To model possible changes to maintenance policy to determine the impact it will have on your maintenance staffing levels. Interactive Staffing Tool - Fleet Composition Interactive Staffing Tool – Existing Staff Interactive Staffing Tool – Existing Staff Interactive Staffing Tool – PMI Interactive Staffing Tool – Other Core Maintenance Interactive Staffing Tool – Unscheduled Maintenance and Repairs Interactive Staffing Tool – Heavy Repair and Overhaul Staffing Sufficiency Dashboard Staffing Comparison Dashboard (1 of 2) Staffing Comparison Dashboard (2 of 2)