A in the Automotive Industry

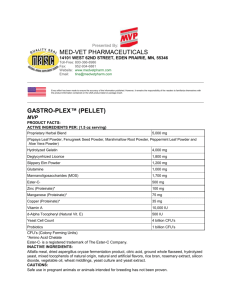

advertisement