Wet Labs

advertisement

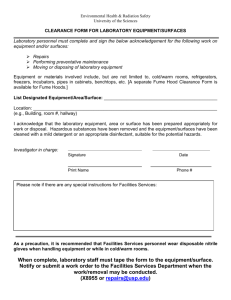

Green Building Design, Construction & Operations Standards Environmental Impacts by Space Type (Wet Labs) Wet Labs fume hoods and close the sash when they are not in use. Areas of impact Energy & Atmosphere Indoor Air Quality Materials & Resources Water Conservation Innovation in Design For Fume Hood Safety Guidelines: http://www.sfu.ca/ehs/research/chemsafety/expo surecontrol/fume_hood_safety.html Energy and Atmosphere Intent Science buildings consume a lot of energy compared to other campus buildings. Spaces need air-conditioning and lab equipment such as fume hoods exhaust a significant amount of heat energy. Air-conditioning (HVAC) While research labs must have air conditioning for temperature control in the space, undergraduate and teaching labs do not need to be cooled, and mechanical systems can be limited to providing heat and ventilation only. Energy modeling of the whole building can allow equipment to be optimized. Fume Hoods To ensure safe containment of chemicals in use, fume hoods are required to maintain high fume hood face velocity and high air volume. This results in significant heat loss. With high performance fume hoods, the design and the number of fume hoods, the type of fume hoods and the heat recovery systems all have significant impact on long term energy use of science labs. The type of lab may also guide the choice of fume hood: Teaching Labs (undergrad labs) – These labs are typically not continuously in use by students so using constant air volume fume hoods in these labs will allow the sash to be shut off completely to maximize energy savings. Users should always turn off constant air volume (Tip: Identify the fume hoods that must always be shut off completely by a different paint colour to differentiate them from VAV fume hoods or use the fume hood sticker sign). Research Labs – In these labs, fume hoods typically must stay on for environmental safety reasons. Variable air volume (VAV) low flow fume hoods are a good choice for this type of labs as users can pull down the sash to an almost closed position (or “off”) allowing safe operation while going to an energy saving mode (the exhaust fan is throttled back). Heat recovery - Provide one heating coil by adding a heat exchanger. The run-around loop is very common because of its versatility. Enhanced Best Practices Commissioning Commissioning should meet ASHRAE 90.1 2007 (or higher) standards & comply with Enhanced Commissioning LEED requirements. Commissioning process activities must be completed for the following energy-related system. • HVAC & Refrigeration system and associated controls • Lighting & Thermal DDC systems • Domestic Hot water systems • Renewable energy system (if applicable) Zero use of CFC / HCFC in refrigerants Chlorofluorocarbons (CFCs) are not permitted in HVAC & R systems. Replace or upgrade existing systems to alternative refrigerants. Where they exist, monitor existing units to minimize CFC leaks. 1 * LEED Canada for New Construction and Major Renovations 2009 * BUILD SMART – Greater Vancouver’s Source for Sustainable Building Solutions Green Building Design, Construction & Operations Standards Environmental Impacts by Space Type (Wet Labs) See Appendix - “Low-emitting Material source by division” Optimize Energy Performance with - Energy modeling - Energy efficient glazing - External Louvers and sun shades - Energy recovery system - Variable speed exhaust systems - Occupancy sensors - Temperature control system - High-performance fume hoods - Renewable Energy Resilient surfaces are an integral part of the Wet Laboratory space type design. Use epoxy paint for lab walls and monolithic, seamless, chemical-resistant vinyl sheet flooring with integral coved base and Mylar finish. Lighting and Controls • Use high performance compact fluorescents to optimize energy use. SFU standard fixtures are - Fluorescent PL 25x2 (Ledalite PureFX) in TBar ceilings - Fluorescent PL 28x2 (Ledalite-Pique) in open ceilings Dust Control Research experiments and lab equipment are sensitive to changes in temperature and humidity, but they are equally sensitive to dust and other foreign particulates. • Consider if a task or ambient lighting design is needed for the space function. Office lighting levels can be lower than ambient lab lighting. • Provide light control systems such as occupancy sensors or daylight sensors • Zone lighting controls parallel to exterior walls to allow sensors to be operated efficiently • All control systems should be connected to the DDC system Indoor Air Quality Intent Providing good Indoor Air Quality (IAQ) contributes to the comfort and well-being of the users in the building and has been linked to improvements in health and increase in general productivity. Day light & View For laboratories, natural indirect light will protect the equipment or specific research environment. Materials & Resources Intent Reduce waste, reduce the use of materials and resources and encourage the use of products with high recycled content. Storage of recyclables Designate an area for recyclable collection and storage that is appropriately sized and located in a convenient area. Contact SFU Facilities Services for detailed requirements. Construction Waste Management Specify as part of the General Conditions in all project specifications that the contractor must meet specific construction waste management goals (e.g. 75% diversion of demolition to be sorted and recycled). Carbon Dioxide (CO2) Monitoring This is recommended and can be easily installed at a low cost. Recycled Content Choose high post-consumer recycled content materials & increase the use of products that are manufactured within the region. Low-emitting Materials Reduce the quantity of indoor air contaminants that are odorous, potentially irritating and /or harmful to the comfort and well-being of installers and occupants. Reduce the use and depletion of finite raw materials and long-cycle renewable materials. 2 * LEED Canada for New Construction and Major Renovations 2009 * BUILD SMART – Greater Vancouver’s Source for Sustainable Building Solutions Green Building Design, Construction & Operations Standards Environmental Impacts by Space Type (Wet Labs) Go to the Metro Vancouver Green Guide Product to get further material resources. Certified Wood Require lab casework and furnishings to use a minimum 50 % wood-based materials and products (FSC certified wood is required by LEED). Water Conservation Intent Minimize the water consumption in cooling equipment with chilled water, safety showers and eyewashes, as well as general use needs in the labs. • Low –flow faucets [1.0 gpm] with infrared sensors can help to reduce the water usage. Single pass cooling equipment water use can be reduced by - specifying multi-pass, closed loop, or aircooled equipment options (note that some equipment types may not function properly if other than single-pass is specified, be sure to check with equipment manufacturer first) to arrive at the most water- and energy-efficient cooling system - Specify an automatic shut-off valve to the cooling system to eliminate usage when equipment is not running (to be used only on equipment where indoor air quality is not a concern) - Provide alternative uses for single-pass effluent such as use in landscaping, boiler or cooling tower make-up water, toilet flushing, etc. (Reuse should ensure that effluent does not contain any waste stream such grease or chemical agents). Innovation in Design other changes, and permit a variety of uses that contain individually controlled connections to HVAC, utilities and safety devices. Modular design defined spatially by floor-toceiling structural slab with under-floor plenum divider. Begin the commissioning process early during the design process and execute additional activities after systems performance verification is completed. Case Studies of Wet Labs • TASC 1 & 2 • Blusson Hall & Saywell Hall References and Resources • Whole Building Design Guide www.wbdg.org • Canadian Green Building Council http://www.cagbc.org Green Labeling and Certifications: Adhesives – South Coast Air Quality Management District Rule #1168 • Sealants – Bay Area Air Resources Board Reg. 8, Rule 51 • Paints and coatings – Green Seal GS 11 & GC-03 • Carpet – Carpet and Rug Institute (CRI) Green Label Plus Hard surface flooring - Floor Score Wood – Forest Stewardship Council (FSC) Contributions by: Wendy Lee, Sook Suh Last updated: 24 November 2011 • Maximize flexibility so uses can expand easily, and readily accommodate reconfigurations and 3 * LEED Canada for New Construction and Major Renovations 2009 * BUILD SMART – Greater Vancouver’s Source for Sustainable Building Solutions Green Building Design, Construction & Operations Standards Environmental Impacts by Space Type (Wet Labs) Glossary Single-pass equipment Cooling equipment circulates water one time through a piece of equipment to cool it, and then the water is discharged (often to the sewer). This cooling equipment is often specified for such end-uses as: CAT scanners, degreasers, hydraulic equipment, condensers, air compressors, welding machines, vacuum pumps, ice machines, x-ray equipment and air conditioners. 4 * LEED Canada for New Construction and Major Renovations 2009 * BUILD SMART – Greater Vancouver’s Source for Sustainable Building Solutions Your Fume Hood Rating is: 1 Most Critical Remains in Full Mode 24/7. 2 3 Critical Only USER has control. Always place into Standby Mode when not in use. Fume hood is automatically turned Less Critical back to Standby Mode after 8 hours. Always place into Standby Mode when not in use. One fume hood in SSB is responsible for the production of 10 tonnes of CO2 emissions per year from heating energy. That’s equivalent to burning 4,310 liters of gasoline. If your fume hood is rated 2 or 3, you can reduce these emissions by always placing your fume hood back into Standby Mode when NOT in use. For more information on fume hoods at SFU, visit: http://www.sfu.ca/facilitiesmanagement/ … If at any time you wish to change the rating of this fume hood, please email your request to Facilities Management at: http://www.sfu.ca/FacilitiesManagement/contact/contact.html. Allow 24 hours for a response.