A CMOCS-Comnatihle

C omnct T)Dignlav

....

"

.............

by

MAssACHUSS

OF TECh'Nt )OGY

Andrew R. Chen

OCT 21

Bachelor of Science in Electrical Science and Engineering

Massachusetts Institute ot 'lechnology, June 1990

~

,

. .

~

.

..

r

ran

,r

t

T~

r

AN~

2005

LIBRARIES

/-1

Master of Engineering in Electrical Engineering and Computer Science

Massachusetts Institute of Technology, June 1997

Submitted to the Department of Electrical Engineering and Computer Science in Partial

Fulfillment of the Requirements for the Degree of

Doctor of Philosophy

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

June, 2005

MASSACHUSETTS INST1ITUTE

OF TECHNOLOGY

© 2005 Massachusetts Institute of Technology

OCTLIBRARIES2005

All Rights Reserved

LIBRARIES

Signature of Author ...................

, ..... Y.

Department of Electrical Engineering and Computer Science

April 27, 2005

Certified

by..............

..............

.. ... , .....................

Hae-Seung Lee

Professor of Electrical Engineering

/

Certified by ..............................

Accepted

Acceptedby.(y,-~C.i'

by ...........

..

.. ....

[ /if

ThesisSupervisor

.........

..............

~~/ ~

Akintunde I. Akinwande

Professor of Electrical Engineering

Thesis Supervisor

.L

....................

-:

..--.

Arthur C. Smith

Chairman, Committee on Graduate Students

Department of Electrical Engineering and Computer Science

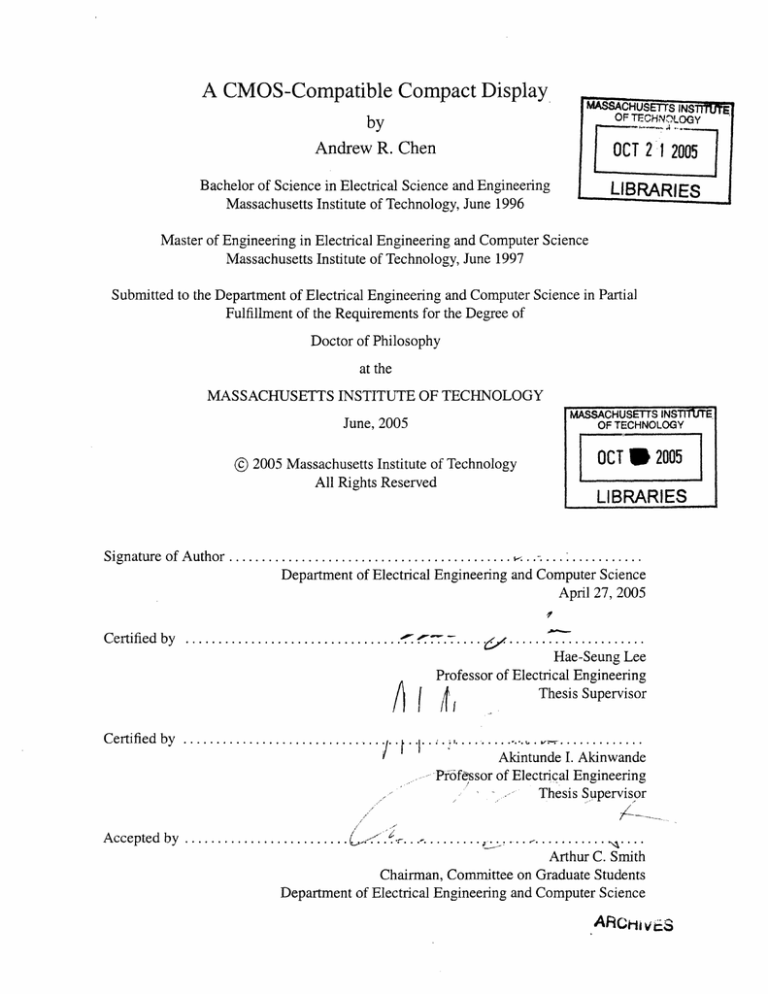

A CMOS-Compatible Compact Display

by

Andrew R. Chen

Submitted to the Department of Electrical Engineering and Computer Science

on April 27, 2005, in partial fulfillment of the requirements for the degree of

Doctor of Philosophy in Electrical Engineering and Computer Science

Abstract

Portable information devices demand displays with high resolution and high image

quality that are increasingly compact and energy-efficient. Microdisplays consisting of a

silicon CMOS backplane integrated with light generating or modifying devices, are being

developed for direct-view and projection applications.

A microdisplay architecture using silicon light emitters and image intensification suitable for a micro-projector application is developed. A standard low-voltage CMOS IC

incorporating display drivers and an array of avalanche diodes produces a faint optical

image, and an image intensifier efficiently amplifies the image to useful brightness. This

architecture has high efficiency and the potential to achieve adequate luminance for pro-

jection applications. A proof-of-concept system with 16x32 arrays is implemented and

evaluated.

A high-performance silicon backplane for the above system is designed, implemented,

and evaluated. The backplane is a standard CMOS die including a 360x200 pixel array

with silicon light emitters, and 10b precision current-mode driver circuits. The driver cir-

cuits can support a number of emissive display technologies including silicon light emitters

and organic light emitting diode (OLED). They employ a self-calibration technique based

on the current copier circuit to minimize variation and fixed-pattern noise while reducing

circuit area by a factor of five to seven compared to a conventional solution. A circuit

technique to improve the retention time of dynamic analog memories is also presented.

This technique allows a dynamic analog memory to retain 10b precision for 500ms at room

temperature.

Thesis Supervisor: Hae-Seung Lee

Title: Professor of Electrical Engineering

Thesis Supervisor: Akintunde I. (Tayo) Akinwande

Title: Professor of Electrical Engineering

4

Acknowledgements

FIRST

I would like to thank my co-advisors Harry Lee and Tayo Akinwande for their

support and thoughtful guidance throughout my doctoral program. They have helped

me with matters large and small, from technical answers to publishing and professional

planning. Their straightforward style and pursuit of quality results are a source of inspiration for many students. I would also like to thank Tom Knight for reading my thesis and

providing insights into the design of microdisplays.

It has been a privilege to be part of the Lee-Sodini lab, and I am thankful to my friends

and labmates for the discussions, help, and fun times we have shared. Iliana Fujimori

showed great patience and teaching skills not only as a co-teaching assistant, but also by

introducing me to imagers, and sharing test chips with me for making initial measurements.

I've learned a lot from Todd Sepke, Anh Pham, and Albert Jerng with whom I've shared

a cubicle for the last two years. Mark Spaeth provided a much wisdom in printed circuit

board design, and arcade games. Pablo Acosta, Ayman Shabra, Mark Peng, Don Hitko,

and Dan McMahill all had answers to my persistent questions as I started my research.

I am thankful to Duane Boning for introducing me to the intricacies of process variation

in semiconductor manufacturing.

and system design.

This basic knowledge is valuable at all levels of circuit

Thanks to Professor Vladimir Bulovic and Yakov Tischler for help in making optical

measurements, and for advice relating to organic LED technology. John Kmyssis and

Annie Wang provided help with electro-optical measurements and data analysis.

I am grateful for the support of family and

encouraged me and helped me to grow. She has

hours. Thanks to my friends for sharing these

scattered around the country, we are still close.

years, and I will always love them.

friends. My fiancee Lucy has consistently

also put up with my graduate student work

years together. Although many of us are

My parents have cared for me for all these

Integrated circuit fabrication was provided by National Semiconductor. Peter Holloway,

Matt Courcy, Mike Guidry, Sangamesh Buddhiraju, and the physical design staff all contributed valuable advice and assistance.

This research was funded by the MARCO Focus Center for Circuit & System Solutions

(C2S2, www.c2s2.org), under contract 2003-CT-888.

6

Biography

ANDREW

R. Chen received the Bachelor of Science and Master of Engineering degrees

in electrical engineering from the Massachusetts Institute of Technology, Cambridge,

in 1996 and 1997, respectively.

From 1997 to 1999 he was a design engineer at Intel

Corporation, Santa Clara CA, designing circuits for Intel Architecture 32b and 64b microprocessors. He is currently a Ph.D. candidate at the Massachusetts Institute of Technology

studying analog and mixed-signal integrated circuit design.

His research interests include analog and mixed-signal integrated circuit design, imaging systems, and electronic display systems.

8

Contents

1

Introduction to Displays

1.1 Overview.

1.2 Electronic Display Applications and Technologies

1.3 Brightness and Efficiency .............

. . .

1.4 Microdisplays ..............

.

1.5 Micro-projector .............

.

2

3

Background

2.1 Silicon Light Emission ..........

2.1.1 Previous Work and Applications .

2.1.2 Avalanche Breakdown ......

2.2 Device Measurements ...........

2.2.1 0.8 /tm Technology ........

2.2.2 0.35/im Technology .......

2.2.3 0.18tm Technology.

2.2.4 Measurement Summary .....

2.3 Image Intensification ...........

2.4 Circuit Design for Displays ........

2.4.1 MOS Transistors .........

2.4.2 DAC Fundamentals ........

2.4.3 Calibration Techniques ......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

17

. . 17

. . 18

. . 20

. . 22

. . 23

25

... . 25

. . . . 25

.

.

.

.

26

28

28

30

..................

..................

..................

..................

..................

33

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

...

...

...

...

31

....

Micro-projector Design

3.1

3.4

3.3.6

3.3.7

Results

37

37

40

41

45

Design Overview .............

3.1.1 Background: Two-stage displays .

3.2 Micro-projector Efficacy .........

3.3 Test Chip Implementation .........

3.3.1 IC overview ............

3.3.2 Pixel ...............

3.3.3

3.3.4

3.3.5

...

...

...

.

.

.

.

.

.

Pixel Arrays .............

.

Top-level IC Design and Packaging

.

System Design

..

. . . . . . .

.

Image Intensifier and Optics .....

.

Proof-of-Concept System Performance

.

. . . . . . .

. . . . . . . . . . . . . . . . .

9

.

·

.

.

.

.

.

.

.

.

.

. .

...

...

...

...

...

...

...

...

...

. .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

45

46

47

50

51

51

52

53

54

55

56

. 57

...

CONTENTS

10

3.4.1

3.4.2

3.4.3

3.4.4

4

Single Pixel ..............................

Arrays.

................................

Power Measurements .........................

Discussic)n ...................

...........

Backplane IC Design

4.1 Pixel Array.

4.2 Row Drivers ...........

4.3

Column Drivers and Calibration

4.3.1 Overview........

5

6

4.4

4.3.2 Area Comparison ....

4.3.3 Current Copier .....

Biasing .............

4.5

4.6

RefDAC .............

ArrayDAC ............

4.7

Design for Testability ......

4.8

Top-level IC ...........

4.9

System Board and Optics . . . .

Measured results

5.1 Electrical Measurements

5.1.1

RefDAC Linearity

5.1.2

ArrayDAC ....

5.2

5.1.3 Column Variation .

Optical Measurements

..

5.3

5.4

Power Measurements . . .

Sample Images ......

Summary

Topics for Future Investigation

A Precision Oscilloscope Measurements

58

59

60

63

.

.

.

.

.

.

.

.

.

.

.

.

.................

.................

.................

.................

.................

.................

.................

.................

.................

.................

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

63

67

68

68

69

70

75

79

83

86

88

89

95

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . .

. . .

95

95

......

101

......

......

......

......

103

105

108

108

Discussion

6.1

6.2

57

111

. . . . . . . . . . . . . . . . . .

.. 111

............ ........ 112

115

List of Figures

.

1.1 Applications of electronic displays .............

1.2

Flat-panel

1.3

Micro-projector

. . . . . . . . . . . . . . .

display technologies

I-V characteristic

......

20

. . . . . . . . . ....

concept (Fraunhofer-Gesellschaft)

breakdown

19

24

2.1

Avalanche

2.2

Cross-section of twin-well CMOS process

2.3

Diode I-V characteristic,

2.4

2.5

2.6

PMOS test device ...............................

I-V curve for p+/nwell junction in 0.35/um CMOS technology .......

I-V curve for n+/psub junction in 0.35tim CMOS technology . . . . . ...

2.7

Light emission

2.8

I-V curves for two p+/nwell junctions in 0.18um CMOS technology . . . .

0 . 8 /m

. . . . . . . . . . . . . . .....

process

27

..................

.

from six parallel test devices

27

.................

.

29

29

30

30

. . . . . . . . . . . . .....

31

32

2.9 Spectraof light emissionfromjunctionson CMOSdie . . . . . . . . . . . 32

.

2.10 Light output vs. current for junction in 0.18,um CMOS process .....

2.11

. .

.

. .

Intensifier gain vs. number of MCPs . . . . . . . . . . . . . . .

Intensifier resolution vs. number of MCPs . . . . . . . . . . . . . .....

.

Simple image intensifier

. . . . . . . . . . . . . . .

application

.......................

2.12 Microchannel plate (Proxitronic)

2.13

2.14

32

2.16 Gate current for an NMOS device .

34

.

2.15 GaAs Photocathode Sensitivity (Hamamatsu)

34

35

35

...............

36

.....................

38

2.17 Sample and Hold Circuit models. Left: ideal, Right: realistic

........

39

2.18

Current mirror measurements

. . . . . . . . . . . . . . . .

.

......

40

3.1

CMOS IC and image intensifier

. . . . . . . . . . . . . .

.

. .

3.2

Two-stage display architecture for projection application (JVC) .......

46

3.3

Circuit schematic of a single pixel

52

3.4

Block diagram

3.5

IC photomicrograph

3.6

3.7

..

Proof-of-concept system board

Proof-of-concept system with intensifier

3.8

Pixel I-V characteristic, VHI sweep

3.9

Test image of IC under microscope

of pixel array

.

..

.....................

. . . . . . . . . . . . . . .

53

. ......

54

..............................

.

54

56

......................

..................

58

......................

.

45

. . . . . . . . . . . . .

.

58

3.10 32-level grayscale gradient. Bottom two rows are at full intensity ......

59

3.11 Output window of intensifier (20mm) with sample image . . . . . . . ...

60

11

LIST OFFIGURES

12

4.1

4.2

4.3

Overview of CMOS backplane .....

.

.

.

Pixel schematic .............

.

4.4 OLED material layers ..........

.

4.5 OLED pixel schematic .........

.

4.6 Row driver circuit . . . . . . . .. . .

.

4.7 Rnw drive.rtiming

.

4.8 Two-stage calibration technique ........

. . .

.

4.9 Column driver calibration overview ..

4.10 Simple MOS current source ...........

.

4.11 Simple current copier ..............

.

4.12 Reduced transconductance current copier . . .

.

4.13 Improved current copier ..

.

. . . . . .. . . .

4.14 Passgate leakage scenarios: (a) conventional, (b) voltage

Array floorplan

a.e,'.,

4.15

4.16

4.17

4.18

.a·'v ~ s

.A

.............

e,

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Conventional (left) and improved (right) passgate

RefDAC reference current generator and switch

Bleeder bias voltage generator.

VBIAS circuit ................

4.19 Testability control circuit ..........

4.20 Testability scan chain ............

4.21 RefDAC block diagram ...........

4.22 RefDAC current copier circuit .. . . . . .

4.23 RefDAC row driver .............

4.24 RefDAC column driver ...........

4.25 RefDAC cell pattern .............

4.26 RefDAC copier cell settling time simulation

4.27 Retention time improvement circuit . . .

4.28 ArrayDAC copier schematic ........

4.29 ArrayDAC block diagram ..........

4.30 ArrayDAC registers .............

.

4.31 ArrayDAC data load control.

4.32

4.33

4.34

4.35

4.36

4.37

4.38

4.39

4.40

ArrayDAC calibration control .......

ArrayDAC calibration control, improved . .

5.1

Synchronization circuit ........................

5.2

5.3

RefDAC bit currents, first attempt ..................

RefDAC bit currents, second attempt .................

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

control

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

64

64

65

66

66

67

67

68

69

70

71

72

73

74

...

...

...

...

...

...

...

...

...

...

...

...

...

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

76

77

78

78

78

79

80

80

80

81

82

82

83

84

85

85

85

86

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

...

:s ..............

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

74

Micrograph showing Si-LED pixels, OLED pixel s, and ArrayDACs . . . . 87

Column transimpedance amplifier .....

Die micrograph ...............

High-level program flowchart ........

Clock oscillator ...............

Timing diagram - simple program .....

Timing diagram - optimized ........

4.41 Assembled system board ..........

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

88

89

92

93

93

94

94

95

96

97

...

...

...

...

...

...

...

LIST OFFIGURES

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

5.14

5.15

5.16

5.17

5.18

13

RefDAC INL, second attempt ..........

RefDAC bit currents, final ...........

RefDAC INL, final ...............

RefDAC retention test ..............

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . .

RefDAC retention test, zoomed in . . . . . . .

Transimpedance

amplifier circuit . . . . . . . .

...............

100

ArrayDAC INL .................

ArrayDAC retention test ............

ArrayDAC output current distribution .....

ArrayDAC outputs before and after calibration .

Sample image for pixel luminance analysis . .

Pixel luminance variation by column ......

Column luminance ...............

...............

102

...............

...............

104

105

...............

...............

98

98

99

100

101

.........

......104

103

...............

......... ...... 106

......... ...... 107

Silicon backplane IC emitting light, showing a se,ries of ramps .......

Proof-of-concept system with calibrated backplai ne .............

109

109

5.19 Proof-of-concept system with calibrated backplane and alternative optics . .110

6.1

RefDAC, ArrayDAC, and pixel arrangement.

6.2

Alternative

RefDAC, ArrayDAC,

and pixel arrangement

.116

.116

.117

time . . . . . . . . . . . . . . . . . . . . . . . . . . .117

.118

step response . . . . . . . . . . . . . . . . . . .

A.1 Step responses of four oscilloscope probes.

A.2 Probe settling behavior ...........................

A.3 Four oscilloscope channels, same input ...................

A.4

A.5

Longer observation

Newer oscilloscope

.112

. . . . . . . . . .113

...

...

14

LIST OF FIGURES

List of Tables

1.1

Typical illumination

levels

1.2

1.3

Projector illuminance by application .

Efficiency of light sources .......

Intensifier Performance with two MCPs

3.2 0.18/um CMOS technology ......

3.3 Microcontroller interface definition . . .

3.1

4.1

4.2

4.3

4.4

4.5

PreRef switch truth table ........

ArrayDAC current mirror biasing .

IC power supplies ............

Input pins ................

Output pins

. 20

. . . . . . .

. . . . . . . . . . . . . . .

15

. . . . .

. 21

. 22

...................

...................

...................

...................

...................

...................

...................

...................

49

50

55

76

84

90

91

92

16

LIST OF TABLES

Chapter 1

Introduction to Displays

1.1

Overview

This thesis presents work in electronic display design and integrated circuit design. Electronic systems are becoming increasingly ubiquitous, and displays for a wide spectrum of

applications are being developed. An area of special interest is that of personal portable

electronics, where all system components must be designed for high levels of integration,

compact size, and high energy efficiency. The design of a "micro-projector" for portable

electronic systems is presented. The micro-projector produces an image with adequate

luminance for projection with high efficiency for battery-powered systems.

We propose a micro-projector based on a combination of silicon light emission and

image intensification. A standard low-voltage CMOS IC incorporating display drivers and

an array of avalanche diodes produces a faint optical image. The image is coupled into an

image intensifier that amplifies the image to useful luminance levels. This architecture has

high efficiency and the potential to produce adequate luminance for projection applications.

The advantages of this architecture are compatibility with mainstream CMOS processes,

high efficiency,and potential for projection. Junction diodes which are available in all standard CMOS processes are used to emit light. Process modifications which are often used

in imagers [26] and microdisplay ICs are not necessary. These junctions can be integrated

with high-performance circuits such as calibrated display drivers. The integrated display

can also be integrated with other circuit blocks to achieve a high level of system integration

on a single IC.

The image intensifier is a vacuum device capable of high gain. It uses the mechanism

of cathodoluminescence

to efficiently generate light, and can produce adequate luminance

for projection applications by using the same principles as projection CRT tubes.

A high-performance silicon backplane for the above system is designed and evaluated.

17

CHAPTER 1. INTRODUCTION TO DISPLAYS

18

The backplane is an IC produced in a standard CMOS technology. It includes a 360x200

pixel array with silicon light emitters and 10b precision current-mode driver circuits. The

driver circuits can support a number of emissive display technologies including silicon light

emitters and organic light emitting diode (OLED). They employ a self-calibration technique

to minimize variation and fixed-pattern noise while reducing circuit area by a factor of five

to seven compared to a conventional solution. A circuit technique to improve the retention

time of dynamic analog memories is also presented.

The organization of this document is as follows. The remainder of this chapter is an

overview of electronic display technologies and applications. Chapter 2 provides background on silicon light emission, operation of the image intensifier, and circuit design

concepts relating to display drivers. Chapter 3 presents the design, implementation,

and

results of a proof-of-concept display system using two-stage image generation. Chapter 4

presents the design of a high-performance CMOS backplane for the previously described

microdisplay architecture. Chapter 5 describes characterization and measurements of the

system with calibrated backplane. Finally, chapter 6 summarizes and suggests topics for

future investigation.

1.2 Electronic Display Applications and Technologies

An electronic display is a device that converts time-sequential electrical signals into spatially and temporally configured light signals (images) useful to the viewer [1]. Electronic

displays are used in a broad variety of applications, some of which are shown in Figure 1.1.

The variety of applications results in a large number of technologies currently in use

[2, 3]. The cathode-ray tube (CRT) has been a workhorse for many years. Newer displays

are based on flat-panel technologies which have the advantages of smaller form factor,

lighter weight, and the ability to achieve larger sizes than CRTs.

Flat panel display technologies can be divided into categories as shown in Figure 1.2.

Displays that generate light in response to electrical signals are called emissive displays,

and ones that modulate light are called light valve displays. Examples of mechanisms

used in emissive displays are electron-hole recombination in semiconductors, ultraviolet

radiation exciting a phosphor, or an electron beam exciting a phosphor. Light valves are

examples of a broader class of devices known as spatial light modulators (SLM). These

create spatial modulation on a plane wave of light by various means, for example by reflection or change in polarization. SLMs require an external source of light which may be a

lamp or ambient illumination. The most widely used SLM is the liquid-crystal display. It

is versatile and inexpensive, but transmission is typically low and the operation at extreme

1.2. ELECTRONICDISPLAY APPLICATIONSAND TECHNOLOGIES

19

Pixels

10M

IM

lOOK

10K

1K

0.3"

lin

3in

10in

30in

l00in diagonal

Figure 1.1: Applications of electronic displays

temperatures is difficult.

Emissive displays potentially have higher efficiency than SLMs because they generate light only when and were it is needed.

In contrast, SLM's require a light source to

constantly produce the maximum display luminance, and dissipate unwanted light as heat.

Emissive and transmissive displays work well under moderate illumination, but have difficulty producing very high luminance for applications in sunlight. Reflective SLMs work

well under high illuminance but have reduced energy efficiency under low and moderate

illumination levels where they require an external light source.

Projection systems have the advantage of producing a larger image than than the sys-

tem form factor. Two applications of projectors are digital cinema and portable information

systems. Digital cinema is an application where very large video-rate images are desirable.

Flat-panel displays are available in sizes up to 40 inches, but a projector is lighter, poten-

tially cheaper, and easier to scale to larger sizes. Portable electronic information systems

that are becoming smaller and handling increasing quantities of still and video images.

In this application the goal is to produce page-sized images for personal viewing while

keeping a pocket-sized form factor.

The focus of this work is a micro-projector intended personal information systems.

These are compact electronic systems that will include communication, computing, multimedia manipulation, and data storage. They have been described in literature with various

CHAPTER 1. INTRODUCTION TO DISPLAYS

20

Flat panel displays

Emissive

semiconductor: OLED

UV+phosphor: Plasma

electron beam + phosphor:

Cathodoluminescence

Modulator

polarization: Liquid crystal

reflection: micromirror

transmission: electrowetting

Figure 1.2: Flat-panel display technologies

Conditions

Direct sunlight

Open shade

Overcast day

Twilight

Full moon

Indoors, exacting visual tasks

Indoors, fine assembly work

Indoors, office

Indoors, home

Illuminance, lux

100,000

10,000

1,000

1 to 10

0.1

15,000

1,000

500

100-200

Table 1.1: Typical illumination levels

terms, such as "information bank system" [4]. The constraints of these systems are compact size, high energy efficiency to maximize battery life, high resolution, high bit depth,

and video speed.

1.3 Brightness and Efficiency

This section describes typical illumination levels of various environments, and the required

luminance or illuminance levels for displays. Typical levels of illumination are listed in

Table 1.1. The ratio of illumination varies over a 1000:1 ratio from full sunlight to in-

doors at night. This results in a variety of displays optimized for different ambient lighting

conditions.

The luminance of an emissive display for indoor use such as a television or computer

1.3. BRIGHTNESS AND EFFICIENCY

Application

Movie theater

21

Illuminance (lux) Comments

full control of ambient light

50-80

Office

120-150

Ballroom (dimmed)

Training room (dimmed)

Training room (full light)

150-200

200

400

high background illumination

Table 1.2: Projector illuminance by application

monitor is 25-100 footlamberts. Emissive microdisplays used in head-mounted display systems (HMDs) require much higher luminances because optical transmission (throughput)

is around 15%. Typical luminance is 1000fL at the display output, which appears as 150fL

to the eye.

The required luminance of a projector depends on a number of factors. The contrast ra-

tio determines the ratio between maximum projector illuminance and ambient illuminance.

The output of the projector is spread over the image area, leading to a tradeoff between

illuminance and image size. The properties of the surface where the image is projected

also affect illuminance. An ordinary white surface has a gain of unity. Projection screens

with non-uniform reflection patterns can increase gain in a preferred direction, at the cost

of limited viewing angle and contrast. The illuminance of a projector is:

luminance(lumens)

2

ae(m

area(m2)

* gain = illuminance(lux)

(1.1)

where the luminous output of the projector is in lumens, the area of the projected image is

in square meters, the gain is unitless, and illuminance is in lux. Required illuminance by

application is shown in Table 1.2.

A variety of light-emitting technologies are used today. Table 1.3 compares some com-

monly used ones. Metal halide bulbs are attractive for projectors because of their high

efficiency, high luminous output, and near point-source emission. Organic and inorganic

LEDs are making rapid progress in efficiency, brightness, and the variety of output spectra

available. Phosphor-based light emitters include fluorescent lamps and cathodoluminescent

devices. In these devices, a phosphor converts energy from ultraviolet light or an electron

flux into visible light. Fluorescent lamps are efficient, but because of their large sizes they

can only be used as backlights for modulator-based displays which have low efficiency due

to transmission losses. The cathode ray tube is an example of a cathodoluminescent dis-

play. These can produce extremely high luminance levels, as illustrated by liquid-cooled

tubes used in projection televisions.

CHAPTER 1. INTRODUCTION TO DISPLAYS

22

Efficiency (lumens/watt) Notes

Technology

Metal halide (HID)

50-100

10-400W

T8 Fluorescent

Compact fluorescent

80

30-60

4-foot, 32W

Cathodoluminescence

OLED

48

10-30+

[5]

White inorganic LED

32+

Halogen

12-20

10-100W

Incandescent

6-17

7-100W

Table 1.3: Efficiency of light sources

1.4

Microdisplays

Microdisplays produce high-resolution images typically less than one inch on a side. They

are commonly used in both the smallest and the largest display applications. Typical nearto-eye devices are head-mounted displays [6] and video camera viewfinders. In these devices, optics provide magnification for comfortable viewing. Projection applications include high-definition televisions and computer projectors. In these systems, the microdisplay modulates very high luminance levels from an external light source. Microdisplay

technologies are also being applied to novel applications such as three-dimensional

dis-

plays [7], switching of optical communication signals [8], high-end photo printers [9], and

optical tweezers [10].

An emerging opportunity for microdisplays is the micro-projector. The micro-projector

is part of a pocket-sized personal information device. It projects a high-resolution image

approximately the size of a piece of paper (8in = 20cm) for personal viewing. Its main

advantage is the ability to produce images of reasonable size with a very small form factor.

The micro-projector must produce high luminance, high resolution images while being

compact and highly energy efficient. Emissive microdisplays can be designed to have these

characteristics.

Presently the leading technologies for microdisplays are liquid crystal on silicon (LCOS)

[11], micromirrors, and organic LED. These technologies can be constructed on top of a

silicon integrated circuit with additional processing. Using a silicon backplane provides

access to high-performance circuits at the pixel or array level, and alleviates the problem

of large numbers of interconnect wires between the pixel array and driver circuits.

Liquid crystal displays use an organic material to modify the polarization of light. Pixels are modelled as capacitive elements and driven with AC voltage waveforms. A variety

of circuit techniques for driver circuits have been investigated [12, 13]. Color is usually

1.5. MICRO-PROJECTOR

23

achieved by using patterned color filters and sub-pixels for red, green, and blue, at each

pixel location.

Micromirrors are an array of mirrors on top of a silicon chip that are controlled electrically. At each pixel location, a mirror reflects light to either the output or a heat sink [14].

Color output is achieved in frame-sequential mode using a rotating color filter wheel.

Organic LED is an emissive technology that promises high image quality and reasonable manufacturing cost. OLED microdisplays with silicon backplanes have been demon-

strated [15, 16]. They promise excellent image quality and potential power savings because

of their emissive nature. OLED performance has been steadily improving, and packaging

and sealing [17] have also improved in recent years. Color can be produced either by filter-

ing of a white image (similar to the case of liquid crystal), or by stacking layers of different

light-emitting materials to produce different colors.

1.5

Micro-projector

A micro-projector would allow a pocket-sized electronic system to display high information content images and video at a reasonable size for comfortable viewing. Because a

projector produces images larger than its own form factor, the system can be pocket-sized

while producing page-sized images. The cost of computation has decreased to a point

where the display, user interface, and battery are primary bottlenecks in portable system

design. A compact display capable of presenting high resolution images and video enables

new uses for portable electronic systems. Figure 1.3 is an illustration of this concept [18].

This contrasts with the flat-panel display approach where the system must be larger than

the image size, or the display must be designed to fold or roll-up when not in use.

Compact projector systems have been demonstrated and are described in the literature.

Keuper [19] describes a projector consisting of a white LED light source, liquid-crystal

modulator, and lens. Projectors using lasers, either a raster-scanned single beam or multiple

beams in parallel, have also been demonstrated [20, 21, 22]. For near-to-eye applications,

a laser beam can be modulated and swept onto the retina to produce an image [23, 24, 25].

Laser-based projectors do not require refractive optics for focusing, which may permit

them to be more compact than ones using lenses. They also have good energy efficiency.

The disadvantages of these systems are (1) they require precision mechanical systems to

position the laser beam, (2) they must address the problem of image flicker because they

operate at low duty cycles, and (3) safety concerns if the beam is pointed at the eye, or if

higher power is used to produce high luminance images.

24

CHAPTER 1. INTRODUCTION TO DISPLAYS

Figure 1.3: Micro-projectorconcept (Fraunhofer-Gesellschaft)

Chapter 2

Background

This chapter presents previous work and preliminary studies on components of our microprojector design: silicon light emitters, image intensifiers, and calibrated driver circuits.

An introduction to light emission from silicon is presented along with measurements of

light emitters in standard CMOS processes. The image intensifier and its basic concepts

are introduced.

Display driver circuits are digital-to-analog converters (DACs). An overview of DACs

is presented along with circuit and device considerations that influence their design. A

major concern in data converter design is the management of variation that arises from the

manufacturing process. A circuit called the current copier can produce precise currents

while occupying less area than a conventional solution. The current copier is introduced

here, and its implementation is discussed in depth in Chapter 4.

2.1

Silicon Light Emission

2.1.1

Previous Work and Applications

The emission of light from silicon p-n junctions was first reported in 1955 [27, 28]. Since

then, it has been used for a variety of purposes. Silicon light emitters were used in a data

storage system to produce dots on photographic film [29]. Light emission from the channels

of MOSFET transistors has been used for debugging and fault analysis of microprocessors

[30]. The idea of using integrating light emitters and detectors on the same chip dates back

to at least 1965 [31], and the application of on-chip optical interconnect is receiving atten-

tion as metal wires have become a bottleneck in the design of high performance integrated

circuits [32].

Silicon is an indirect bandgap material, therefore when electrons and holes recombine

25

CHAPTER 2. BACKGROUND

26

the probability of a photon being emitted is small. This is in contrast to the III-V materials

used commercially in LEDs that are efficient photon sources.

In forward bias, p-n junctions emit photons with energy equal to the bandgap energy. In

silicon this is 1.12eV, corresponding to photons with a wavelength of 1100nm. In avalanche

breakdown, hot electrons can cause photons with higher energies to be emitted. Lightemitting devices in standard CMOS technologies have been studied [33, 34], and the best

reported quantum efficiency is 5 *

10

- 7

phot/elec [35].

Efficiently generating light from a silicon substrate is an area of research interest [36,

37]. Efficiency can be improved by various dopants or altering the shape or material properties of silicon devices [38, 39]. These advances may eventually be integrated into mainstream manufacturing processes. Another solution is the integration of efficient optoelectronic devices on a standard silicon substrate [40]. Novel device and circuit designs for

light emitters are being explored, for example a structure to lower the breakdown voltage

of silicon light emitters [41].

2.1.2

Avalanche Breakdown

This section explores the properties of silicon junctions in avalanche breakdown used as

light emitters. Light emission from avalanche breakdown produces photons with larger

energies than the bandgap energy. Emission can be in the visible or near-infrared regions

of the spectrum.

When a junction diode is biased with a large negative voltage, the electric field across

the junction is very large. When a conduction band electron enters the field, or is created

by thermal processes, collisions with valence electrons can move them into the conduction

band. A cascading or multiplying effect occurs, and the current grows dramatically over

a small voltage range. The I-V characteristic of a silicon p+/nwell junction in avalanche

breakdown has the shape shown in Figure 2.1. Current through the junction grows until limited by external components such as series resistance or a current source circuit. Operating

a junction diode in reverse breakdown is nondestructive if the current through the junction

is limited. Spinelli and Lacaita [43] provide a more detailed description of avalanche diode

physics.

This abrupt characteristic allows the use of low-voltage control circuits. A large DC

bias is needed to make the junction enter avalanche breakdown, but once avalanche breakdown occurs the change in voltage required to modulate the current is very small. Consider

a junction with the characteristic in Figure 2.1. The cathode is connected to a +12 volt supply, and the anode to a "leakage "current sink of lnA in parallel with an adjustable current

2.1. SILICON LIGHT EMISSION

nited

le-3

le-4

avalanche

le-5

breakdown

~le-6

•

le-7

le-8

le-9

leakage

le-10

-11

-10

volts

-9

-8

Figure 2.1: Avalanche breakdown I-V characteristic

NMOS

PMOS

~

~

~///////////l/~n///~//1.

~/////////N/////r/////N///

a~dri

~

'/////I//NN//N///~////,

~~

Figure 2.2: Cross-section of twin-well CMOS process

sink. The voltage at the cathode will be 12-10.5=1.5V for currents up to 100PA, producing

a 105 dynamic range which is more than adequate for display applications.

In a twin-well CMOS process, as shown in Figure 2.2, the p+/nwell junction is the best

suited for integration. It is electrically isolated from other devices on chip. When the nwell is connected to a high voltage and the p+ region connected to a low voltage, avalanche

breakdown occurs. No substrate currents are created by this structure, and the n-well voltage can be safely controlled by MOS devices. The p+/nwell junction breakdown voltage

is designed to be much higher than the nominal power supply voltage, to ensure proper

operation of CMOS circuits. This reduces the energy efficiency of light emitting junctions,

which should be designed for avalanche breakdown at the smallest possible voltage.

The p+/nwell junction is available in all standard CMOS processes, and low-voltage

CHAPTER 2. BACKGROUND

28

devices can be used to drive them. This eliminates the need for more costly high-voltage

processes. In addition, other circuit functions that require high-performance devices such

as processors or memory can be integrated together with light emitters.

In unmodified CMOS processes, avalanche breakdown occurs first around the perimeter

of the junction area. This is due to a combination of surface states and the high electric

fields at the edges of the junction area. For a microdisplay using front-emission from a

silicon IC, lateral breakdown is desirable over vertical breakdown because it occurs closer

to the surface and allows more photons to escape. Lightly doped guard rings can be used

to modify the doping profile of avalanche diodes if bottom-surface breakdown is preferred,

for example for back-emission from a thin substrate [44].

Avalanche diodes are more commonly used as in sensitive imaging devices for photon

counting and operation at low light levels, and many articles have been published on their

design in that context [42]. An important design consideration is to avoid covering light-

emitting junctions with silicide. Most CMOS processes include a mask to selectively block

deposition of silicide, and it should be utilized for light-emitting junction areas. Silicides

are deposited over diffusion regions to reduce their sheet resistance. They are nearly opaque

to light and reduce optical transmission by 80-90% [45].

2.2

Device Measurements

A preliminary study was performed to characterize the light-emitting properties and reverse-

breakdown characteristics of p-n junctions manufactured in commercial CMOS processes.

Limited information and data on the use of these junctions as light emitters is available,

therefore we characterized devices manufactured in commercial 0.8um , 0.35um , and

0. 18pm CMOS processes. In all three processes, the p+/nwell junction showed avalanche

breakdown behavior when a large reverse bias was applied.

2.2.1

0.8pum Technology

A test device in the Hewlett Packard 0.8[tm (CMOS26G) process is measured. The process

has n-wells, one poly layer, and three metal layers. Nominal operating voltage is 5V. The

test device is the junction between the a source/drain diffusion of a PMOS transistor and

its n-well.

Junction area is 50 x 1.5um , and the device is covered with silicide. The

electrical characteristics of this device in reverse bias are shown in Figure 2.3. Reverse

leakage current rises gradually between 0 and -18V. At -18V, avalanche breakdown occurs

and current increases by over six orders of magnitude over a very small voltage range until

2.2. DEVICE MEASUREMENTS

Id vs Vd N76VAF

-20

-15

-10

-5

0

Diodevoltage (V)

Figure 2.3: Diode I-V characteristic,0.8upm process

Figure 2.4: PMOS test device

it is limited by series resistance.

The pictures in Figure 2.4 were created with a CCD camera mounted on a microscope. On the left, the microscope light is on and the four-terminal test device is visible.

The device is connected to four metal pads for use with a probe station. The n-well and

source/drain pads were bonded to package pins for easier testing, and solder from the bonding process is visible on the two pads on the right side. On the right, the microscope light

and room illumination were turned off and a long-exposure image shows light emission

from the p-n junction. Current through the junction is 130PA, and light emission is concentrated at the sides and corners of the p+ diffusion area. Light emission was visible in

a darkened room, in agreement with published reports of broadband emission from silicon

junctions in avalanche breakdown.

CHAPTER 2. BACKGROUND

30

Chipl1 - d2626Rverse

03111102achen

1.OE-02-

- -----------

1.0E-03

1.0E-04

i

1.0E-05

X

1.0E-07

.0E6oE

.

,

1.OE-08

1.OE-091.OE-10

-11

-10

-9

-7

-8

-6

Vd (volts)

Figure 2.5: I-V curve for p+/nwell junction in 0.35p1mCMOS technology

Chip #1 d2726

03/11/02 achen

0.010.0075 0.005

0.0025

o

-

0

-0.0025

-1.5

-0.5

0

0.5

-0.005

-0.0075

-0.01 .....

Vd (volts)

Figure 2.6: I-V curve for n+/psub junction in 0 . 35 p1mCMOS technology

2.2.2

0.35pm Technology

The characteristics of the p+/nwell junction in the TSMC 0.35/um CMOS technology were

measured. The process has n-wells, one poly layer, four metal layers, and silicide block.

Nominal operating voltage is 3.3V. Avalanche breakdown of the p+/nwell junction occurs

at -10.OV as shown in Figure 2.5.

An n+/psub junction in this process was also measured, as shown in Figure 2.6. Reverse

breakdown occurs due to tunnelling instead of avalanche breakdown, and the I-V characteristic is much less abrupt. Compared to avalanche breakdown, a much larger voltage swing

is needed to produce the same change in current. This makes control with low-voltage

devices difficult or impossible. The mechanism of zener tunnelling is not expected to emit

photons, therefore this junction is not useful for light emission purposes.

2.2. DEVICE MEASUREMENTS

Figure 2.7: Light emissionfrom six paralleltest devices

2.2.3

0.18pm Technology

Devices in the TSMC 0.18prm CMOS technology were measured. This process has nwells, thin and thick oxide transistors, one poly layer, six metal layers, and silicide block.

Nominal operating voltages are 1.8V for thin oxide devices, and 3.3V for thick oxide devices. The test structure consists of six 12x14[pm junctions connected in parallel, as shown

in Figure 2.7. When this image was taken, ID = 700pLA and VD = -10.OV. Reverse

breakdown current-voltage characteristics are shown in Figure 2.8.

Emission occurs at discrete points mostly around the junction perimeter, and luminance

varies between the junction areas due to random manufacturing variation. This variation is

exacerbated by the parallel connection of pixels which allow unevenly located "hotspots"

to carry most of the total current. To improve uniformity, pixels should be small in size

and driven individually by current sources. This technique allows well-controlled transistor electrical characteristics to control light emission instead of poorly controlled junction

characteristics.

The emission spectrum for a p+/nwell junction on the 0.18p/m CMOS chip is shown

in Figure 2.9. In forward bias, the junction emitted photons at its bandgap energy (1.1eV

= 1100nm). In reverse bias, a broadband emission spanning the visible and near-infrared

wavelengths was observed. This is consistent with published data.

By comparing images of the display with a reference target, we estimated the quantum

efficiency of silicon light emitters to be - 10- 7 photon/electron. This value are comparable

to published results for light emission from silicon devices. The silicide layer was not

blocked, so the efficiency of the p-n junction without silicide should be higher.

32

CHAPTER 2. BACKGROUND

Chip3 -d3331reverseI-V

0824101 achen -100uA a -10.1V

Chip3 -d3334

08124101

achen-100uA @-10.1v

1.OE-03 4 A

. t..............................................................

._

_'

..

1.0E-04

1.0E-05

1.0OE-06

I 1.OE-07

"n4

__

o!

_Seris_|

-

1.OE-08

r

1.0E-09

.u

t

***146-

1.OE-10

I

-- I

1.OE-11

-11

-10.5

-10

Vd (volts)

i

i

1.0E-12j

-11

-9.5

-10.5

-10

-9.5

-9

Vd(volts)

Figure 2.8: I-V curves for two p+/nwell junctions in 0.18pm CMOS technology

Chip #3 d3334

forward20s -08.27.01-achen

Chip #3 d3334

reverse20s -08.27.01

35

600

30.0

10

500

, _

-,

r-4,

- f:'"

-

25

400

- -

20

-Series1

15

300

200

1010

0

100

5

800

850

900

950

1000 1050

04

1100 1150

1200

450

550

wavelength(nm)

i3s

.

.

.

650

750

850

wavelength

(nm)

Forward bias

Reverse bias

Figure 2.9: Spectra of light emission from junctions on CMOS die

PMTVoutvs. d - Chip 3 logilog

10102102

achen,Johnkym

10000

1000

0

100

10

10

01

100

-Id(mA)

Figure 2.10: Light output vs. current for junction in 0.18,um CMOS process

950

-Snes1|

2.3. IMAGE INTENSIFICATION

33

The relationship between junction current and luminance was measured in a darkened

room using a photomultiplier tube. A linear dynamic range of over 100:1 was measured, as

shown in Figure 2.10. This measurement was limited by the test apparatus, and the linear

dynamic range of the junction is expected to be larger. The linear relationship between

current and luminance suggests the use of linear current-mode driver circuits for silicon

light emitting junctions.

2.2.4

Measurement Summary

The reverse breakdown characteristics of junctions three commercial CMOS technologies

were observed. Avalanche breakdown with light emission was observed from the p+/nwell

junction in all three technologies, and breakdown voltages ranged between -18 and -10OV.

A

rough measurement of quantum efficiency agrees with published data, and the emission of

a broadband spectrum covering visible and near-infrared also agrees with published data.

The linear relationship between current and luminance suggests the use of current-mode

driver circuits.

2.3

Image Intensification

The image intensifier is a vacuum device that accepts a two-dimensional optical image and

produces an amplified version of its input [46]. It is commonly used in night vision and

scientific applications. In its simplest form it has two parts: photocathode and phosphor

screen, as shown in Figure 2.11. In this example, a lens focuses an image onto the pho-

tocathode. The photocathode is a metallic material which emits electrons in response to

light by the photoelectric effect. A two-dimensional flux of electrons is accelerated toward

the phosphor screen by a large electric field. Electrons strike the phosphor screen, causing

photons to be emitted in the same two-dimensional pattern. These typically have gains up

to 100 photon/photon. Dark emission from the photocathode is typically very low, resulting in a large dynamic range. Power consumed is proportional to light output, an important

trait for portable systems where energy is limited.

The device is very efficient because light is produced by cathodoluminescence, using

electrons to excite phosphor. A type P-22 phosphor produces 40 lumens/watt with electrons accelerated with 6kV [5, 47]. In addition, phosphor screens are capable of handling

large amounts of power and producing high luminance levels as shown by their application

to projection tubes.

Adding one or more microchannel plates (MCP) increases the gain of the image in-

CHAPTER 2. BACKGROUND

34

Objective lens

Eyepiece

Scene

Eye

Image

Image

Figure 2.11: Simple image intensifier application

to the

Screen

Figure 2.12: Microchannel plate (Proxitronic)

tensifier. An MCP is a plate of glass with many microscopic holes running through it. A

large DC voltage is applied across the plate, creating an electric field through the channels.

An electron striking one end of a channel causes secondary electrons to be released, as

shown in Figure 2.12. An avalanche effect occurs, and gain of a single MCP can be as

high as 5000 electron/electron.

104

The overall gain of an image intensifier with one MCP is

105 . With two MCPs, gain of 106 is achieved. Gain of intensifiers with varying

numbers of MCPs is shown in Figure 2.13. While gain increases with more MCPs, spatial

resolution decreases because the gaps between MCPs allow electrons to cross-over into

adjacent channels. Resolution versus number of MCPs is shown in Figure 2.14.

A DC bias current called the "strip current" flows through the MCP. Typical MCP

resistances range from 2 * 106 to 1082Q. For best linearity, the strip current needs to be

larger than the current of the electron flux being amplified. This additional current reduces

the energy efficiency of the intensifier.

Intensifier gain and dynamic range can be improved by using a semiconductor material

as the photocathode instead of a metal. Quantum efficiency improves by a factor of four

over a broad range of wavelengths, resulting in higher gain. The sensitivity of a galliumarsenide based photocathode is shown in Figure 2.15. This cathode has peak efficiency

between 650nm and 850nm, and is well matched to the avalanche mode silicon light emitter

with spectrum shown in Figure 2.9. Matching photocathode sensitivity to the light source

2.3. IMAGE INTENSIFICATION

35

IntensifierGain vs # of MCPs

1.UtI-+Ud

1.OE+07

= 1.OE+06

0

:1 1.OE+05

0

r- 1.OE+04

-

9 1.OE+03

1.OE+02

1.OE+01

0

1

2

3

MCPs

Figure 2.13: Intensifiergain vs. numberof MCPs

Resolutionvs # of MCPs

E 20

E

E

i 15

5

10

o

5

0

0

1

2

3

MCPs

Figure 2.14: Intensifier resolution vs. number of MCPs

CHAPTER 2. BACKGROUND

36

103

102

H-

-z

-0UJ

Z

I U

On LL

i--LL

Z LU

101

z

100

0T1

-

RADIANT SENSITIVITY

- - -'

10-1f

300

ANTIMFFFIINCY.

I

F . " I..' .. 'I----'-- ' I I

400

500

600

700

800

I

900

1000

WAVELENGTH (nm)

Figure 2.15: GaAs Photocathode Sensitivity (Hamamatsu)

also improves rejection of spurious input signals and reduces background noise.

In the future, the image intensifier could be replaced by smaller or more efficient structures. MEMS micromachining might help to miniaturize the intensifier itself [48], and

aid in integrating the intensifier with a silicon integrated circuit. The large glass vacuum

envelope could be replaced with a smaller vacuum package.

An up-converter might replace the intensifier if the efficiency of silicon light emitters

were increased, or if efficient infrared emitters were integrated onto an IC. The up-converter

converts photons at one wavelength to shorter wavelength, for example an infrared image

can be converted to a visible one. A pixelless up-converter for mid-infrared imaging is

described by Luo et al. [49]. It could eventually compete with image intensifiers, with the

advantages of being smaller and requiring lower operating voltages.

2.4. CIRCUIT DESIGN FOR DISPLAYS

2.4

37

Circuit Design for Displays

The driver circuits for an electronic display are typically digital to analog converters which

convert stored digital data into into analog waveforms used to produce an image. Management of leakage currents and device variation are key issues in data converter design.

Introductions to these topics are presented, followed by a survey of digital to analog converter topologies and techniques, with emphasis on circuits for display applications. The

current copier is a circuit that uses a self-calibration technique to reduce sensitivity to device variation. Its basic concept is presented, along with potential advantages in the design

of display driver circuits.

2.4.1

MOS Transistors

Leakage Currents

Circuit techniques to reduce leakage currents have been proposed, for example a 12b accurate analog storage cell [54]. Our design, as described in Chapter 4, uses circuit techniques

to minimize the effects of overlap capacitance and leakage currents on the current copier

circuit.

In the analog context, the main effect of leakage currents is to reduce circuit precision.

An important property of CMOS circuits is their capability to store charge on floating

nodes. The sample-and-hold

circuit shown in Figure 2.17 is a widely used example of a

charge-based circuit. An important figure of merit is how long it can retain a value within

a specified level of precision. Non-ideal effects in the sample and hold circuit include off-

current through the switch, junction leakage through parasitic source/drain diffusions, and

charge injection due to overlap capacitance (CGD) of the switch device.

Gate and subthreshold leakage are serious problems for charge-based circuits such as

the sample-and-hold.

In charge-based circuits, the retention time is how long a circuit can

preserve a stored value within a specified level of precision. Long retention times allow the

circuits to function longer between calibration cycles, and reduce the amount of resources

spent on periodic calibration.

A transistor is often used as a MOS capacitor because gate oxide has the highest ca-

pacitance per area (fF/,um2 ) of structures available in common CMOS processes. Charge

leakage through the gate limits the time period that a sampled value can be retained, and

changing device area does not remedy the problem because both capacitance and leakage

current are proportional to area. Poly-poly or metal-metal capacitors are available in some

processes, although their capacitance per unit area is much lower than the MOS capacitor.

38

CHAPTER2. BACKGROUND

Leakagetest

NIIOS Vs--Vb=VdO - Die 0

-n

41,UU-I

Z

8/02/0

achen

. . _...._ ....

I

1.OOE-13

Z011",

i 1.00E-14

i

i

i

i

i

Efa1

1,00E-15

i

i

41

1 OOE-16

0

0.5

1

1.5

2

Vg (volts)

Figure 2.16: Gate current for an NMOS device

Gate leakage of a large 1.8 volt NMOS device was measured with a semiconductor

parameter analyzer at room temperature as shown in Figure 2.16. For this measurement the

source, drain, and bulk are at zero volts.

The resulting data are consistent with published results [50, 51], and the primary mechanism for gate leakage is direct tunnelling through the thin (32A) gate oxide. To assess the

impact of gate leakage, consider a sample-and-hold implemented in this technology with a

voltage tolerance of lmV and a stored voltage around 1.OV.

I

area

Current density at 1.OV is lOfA/,m

2

C AV

area

(2.1)

(2.1)

and capacitance per unit area is 8fF/um2 . The

retention time is 800us. Display applications require retention times that are larger by

orders of magnitude. For example, a display operating at 100 frames per second with one

refresh cycle per frame requires a minimum retention time of 1/100 second, or 10ms.

In a 0.18tim technology, one solution is to use thick-oxide transistors (70A vs. 32A)

at circuit nodes where charge is stored. Thick-oxide transistors are available in most commercial CMOS processes. These devices have thicker gate dielectrics resulting in orders

of magnitude less gate leakage. They also have larger minimum feature sizes and worse

high-frequency performance than thin oxide devices. Capacitance per unit area is lower

than for thin oxide devices, but still higher than other capacitor design options.

As CMOS processes scale to smaller dimensions and power supply voltages are reduced, there is pressure to reduce the threshold voltage. Reducing the threshold voltage

increases on-current due to a larger (VGS - VT) factor. However it also increases subthreshold conduction by a factor of ten for every 90-100mv decrease in VT. This can be

2.4. CIRCUITDESIGN FOR DISPLAYS

39

I

Figure 2.17: Sample and Hold Circuit models. Left: ideal, Right: realistic

seen by setting VGS to zero in the equation for subthreshold conduction:

ID,OFF= Iseq(- V T)/nkT

(2.2)

In digital CMOS circuits, leakage currents cause static current to flow from from power

to ground. It increases power dissipation and causes reduced noise margins due to signal

degradation. In designs with millions of transistors per chip, leakage currents can exceed

the currents used in active operation.

Negative gate drive (V

< 0) and the "stacking

effect" have been used to reduce subthreshold conduction currents [52, 53].

Device Variation

The design of high-performance data converters depends on an understanding of device

variation and how to manage it. Variation is caused by random fluctuations which oc-

cur during the manufacturing process, and affects both material properties (doping levels,

threshold voltage) and geometries (transistor width and length). The most commonly used

variation model for MOSFET threshold voltage and currents is of the form aID k

[55]. Other models have also been proposed, i.e. [56].

Maintaining consistent image qualities across a display is a challenging problem, and

becomes even more difficult as integrated circuit feature sizes decrease. Traditional analog

designs use layout techniques such as symmetry and dummy devices to improve matching.

In a microdisplay, devices must be spread over a wide area and such techniques are not

practical. To measure variation across large length scales, we designed an NMOS current

mirror with 22 legs spanning 2.0 millimeters in the TSMC 0.18pm process. This structure represents a realistic design for a microdisplay where drivers are spaced across a die.

All devices were 2*2ipm in size. In a microdisplay, the currents through individual driver

circuits are small because there are many operating in parallel. The input current was set

CHAPTER 2. BACKGROUND

40

Die 0. ceumrrrt

rlrrr

tLuA

VdmOi, M

1.2DE

1.10-

.

1~SH7

1

a

5

7

pIillen

9

11

Figure 2.18: Current mirror measurements

at 1LA, and the drain voltage of mirror devices was 0.9V. Threshold voltage for NMOS

devices is 380mV from simulation models, and the VGS corresponding to 1,uA is 495mV.

The variation between output currents is aID = 2.5%. When there are 1,000 drivers on a

chip, circuits should be designed at the 4a or 5a certainty level. This represents 3.5b precision, far short of current application demands. Modem commercial display systems have

8b resolution, and 10-12b displays are being developed. To achieve reasonable resolution,

circuit techniques to improve matching between display drivers will be necessary.

2.4.2

DAC Fundamentals

Digital to analog converters (DACs) are used in display systems to convert digital data into

analog waveforms that control light emitters or light modulators. This section is survey of

DAC circuit design techniques with emphasis on converters useful for displays.

An ideal unipolar voltage-mode DAC has an output range from zero volts to (2 N - 1) *

VLSB volts. It accepts a digital data word d(N: 1) and performs the function:

N-1

VOUT = VLSB * i,

d(i) * 2

(2.3)

i=O

The output voltage is discrete, and quantization noise is: VQ,rms= VLSB/xV

natively, this can be expressed as the signal-to-noise

. Alter-

ratio: SNR = 6.02N + 1.76 dB, where

N is the number of bits. Johns and Martin [57] provide a discussion of non-ideal behavior

in DACs.

DACs can be divided into two groups: Nyquist rate DACs that change their outputs

once per cycle, and oversampling DACs that change their outputs multiple times per cy-

2.4. CIRCUIT DESIGNFOR DISPLAYS

41

cle. Nyquist DACs can be implemented using voltage-mode or current-mode techniques.

Voltage-mode DACs produce an analog voltage using techniques such as a resistor lad-

der or switched capacitor circuits. The output voltage typically requires buffering with an

operational amplifier to reduce output impedance. As an example, Bult and Geelen [58]

describe a circuit topology based on the R-2R ladder.

Current-mode DACs are attractive in CMOS technology because MOS transistors are

voltage-controlled current sources (VCCS) with medium transconductances, allowing precise control of current. A current-mode DAC can be simpler to implement than a voltagemode one because currents can be summed by connecting current sources in parallel. A

straightforward example is DAC made by switching 1024 identical current sources, achieving 10b precision at 40MHz in 0.8pum CMOS [59]. Note that a voltage output can be

produced by attaching a transimpedance amplifier to the output of a current-mode DAC.

Segmented DAC architectures use different techniques to generate portions of the output current, for example [60] describes a DAC with a unary decoded architecture for its

MSBs and a binary architecture for its LSBs. The MSBs are optimized for high precision,

while the LSBs use a structure that minimizes circuit area.

Oversampling converters are attractive for moderate speed applications where digital

circuits run much faster than the sampling frequency. For more information, Norwsowthy,

Schrier, and Temes have a book on delta-sigma converters [61]. Display drivers typically

require large numbers of converters that operate in parallel. Low-frequency operation, low

power dissipation, and small circuit area are important, therefore Nyquist rate converters

are preferable.

Dynamic element matching [66, 67] converts errors due to component mismatch to

uniformly distributed white noise. For example in a fully segmented DAC, if all cells

have exactly the same duty cycle then the mismatch is averaged out and much greater

dynamic precision achieved. Two more examples are swapping current sources at half the

time period to build a 14b accurate divide-by-two network [68], and a 14b DAC using