Document 11212118

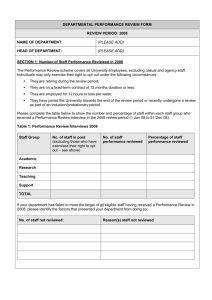

advertisement