Document 11212089

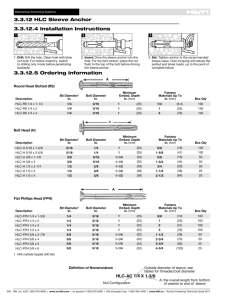

advertisement