Effects of Axial Turbine Tip Shroud Cavity Flow on

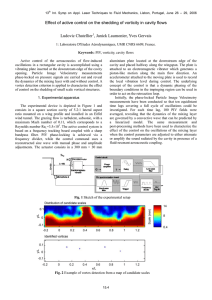

advertisement